Leaderboard

Popular Content

Showing content with the highest reputation since 04/06/2024 in all areas

-

11 points

-

10 points

-

7 points

-

My Great Grandfather, and guessing my Great Grandmother with the '55 Dodge (I'll be inheriting this summer) and what I believe is a '55 DeSoto. The truck was my Great Grandfather's then my Uncle's, and then my Parent's, and soon to be mine. My Dad just told me that he is getting too old to work on too many toys, and he is giving it to me. It is in a little worse shape than here, but pretty much original. I'll post pictures of it's current state, in the correct area, when I get it out of the barn, but from what I recall it definitely will need a gas tank and fuel pump, amongst other things.6 points

-

Forum started in 1998 on some open source forum software. Was pretty buggy and required a lot of time to keep it working. Basically as the number of posts grew the index would get corrupted and have to start over. Remember the forum updates when we started anew?? Then went to a commercial product, I think it was vbulletin. I think they got bought and then support got pricey. Started looking for another solution and ended up going with Invision, partially because they had tools to migrate from the previous vendor. Migration was a pain, but got it done. Invision has maintained a fair price structure and is good about bug fixes and security updates. Support has also been good. They are reducing some of their features like the store for physical item sales, which is going away very soon. They don't think they can compete in that market with all the other marketplace solutions available. Same was true of the chat function. FYI additional security with the ISP has been implemented and guest access is again available.5 points

-

5 points

-

5 points

-

4 points

-

Been awhile since I've been in an engine but I would recommend that once you remove the lower cap place some kind of sleeve over the threads of the cap bolts , rubber/vinyl hose, masking tape, etc. this will avoid worries of bolt threads scraping the crank shaft as you push the piston up per Sniper's recommendation. Just a thought.4 points

-

A legendary attribute of early Rolls-Royce Motorcars was the ability to balance a coin on the radiator whilst the engine was purring quietly. While there is neither a R-R or 5-shilling coin in this video, here is friend Jerry's 1950 Plymouth with a Canadian Loonie riding the fresh air vent, radiator and cylinder head!3 points

-

My love of old cars started with the Model T. I have a 27 Roadster and a few others. The Model T driving experience is not one I’d offer to just anyone however! I sold a 27 tudor to a guy and gave him the whole driving lesson. A week later I got an email describing how he pressed down on the low pedal thinking it was the brake, drove into another car then took his foot off the pedal. I am glad he didn’t send me a photo. My philosophy of old cars is we are stewards of them for the time we have with them. They can certainly out live us if we are careful with them or we can destroy them in a split second. When you consider the history of the world since your 26 was made it is remarkable that it is still here, let alone the human race. When someone goes on about how they want to put their Plymouth body on an S10 chassis, I cringe. That ole Plymouth could live on for decades and still be a nice car. Once someone “modernizes” it, it has taken a big step to the scrap yard. Consider the car magazines of the 1950s. Where are all those “Customized” cars that graced the magazine covers now? Survivor cars got that way because of the stewardship of a chain of owners. In some cases it was just benign neglect that contributed. Cherish your old car and it may out live you!3 points

-

3 points

-

I've used Rustoleum and Tractor Supply's implement paint for rust "proofing" on many projects over the years. No paint will kill rust that isn't addressed but it can inhibit surface corrosion on clean surfaces. Two VW Beetle floor pans (inside and out) and running gear received the Rustoleum satin and gloss finishes and both have held up well for over twenty years. I usually use a brush because the paint can be applied thicker and the cost and mess is much less than spray cans. I've also bought quarts, thinned with mineral spirits and shot it with a spray gun when that was the best option.3 points

-

I have an admittedly tight focus on the KT Keller cars, so that's what I research and play with. It's all about having fun after all and those are the ones I like. I am a huge fan of Overdrive transmissions because they don't really change the charm of the cars and actually add to it. When you put one in your car your speedo will be off at all speeds because the speedometer pinion gear was selected for a 4.1 ring and pinion. The good news is you can swap out the pinion from your old three speed to the O.D. and all will be back to normal ( assuming your speedometer doesn't need service ). But what if you changed the rear end ratio or the tire size? I don't advocate changing rear axles because I don't see much to be gained there. You can easily change the differential carrier ( aka 3rd member ) in a Plymouth if you want another ratio. Where I live there's lots of open road with highway speeds of 55 to 70 so optional ratios, tires and O.D. go well with my Plymouth. My P17 Coupe came with 6.40-15 tires ( modern equivalent 195/75/15 ) and a 3.73 final drive ratio so the speedometer pinion would be a 17 tooth gear ( p/n 652-848 ) for an example. Chrysler designed the pinions to use the same 6 tooth gear on the output shaft so you only need to change one gear to correct the speedometer. One thing you find out right away is selecting speedo gears is not an exact science. You can get close and you might hit it right on the button but you more likely will be over or under by 2 or 3 mph. That's why the Highway Patrol has an enforcement tolerance. So let's look at tires first 6.40 15 = 195/75/15 standard tire for a P17 6.70 15 = 205/75/15 standard tire for a P18 7.60 15 = 225/75/15 an optional size tire Final drive ratios 3.90 very common on long wheelbase cars 3.73 standard ratio on many optional on all 3.54 optional Chart of ratios & tires vs speedometer pinions 3.90 6.70 15 17 tooth pinion 3.73 6.40 15 17 tooth pinion 3.73 6.70 15 16 tooth pinion 3.54 6.70 15 16 tooth pinion All 7.60 15 16 tooth pinion So you can see you're not going to get an exact reading but you can get close enough to avoid a ticket. The part number for the 16 tooth pinion is 652-846. I have found that if you have the number for an obscure part the parts house will look to find it in their inventory but they are likely to blow you off if you just say "I need a 16 tooth speedometer gear." Happy hunting!3 points

-

Yup, between 65 and 70. When I had earplugs in, I tended to go faster, haha....3 points

-

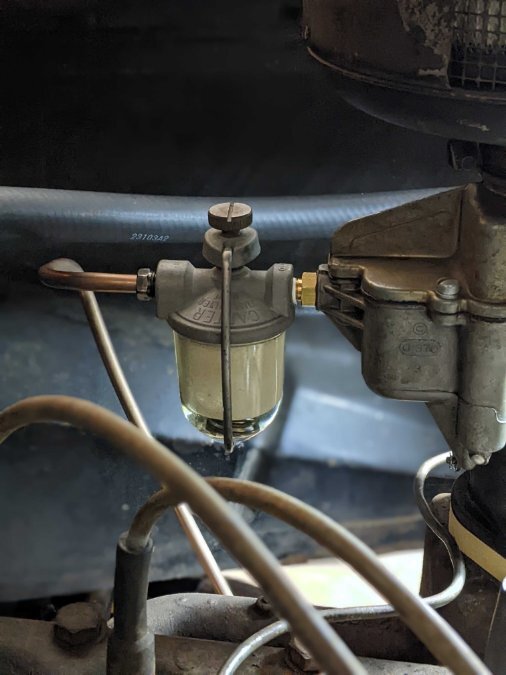

Thanks sniper and DJK for digging up info. And here's my two cents about electric pumps. First off, I love 'em! And here's why: When one of my vehicles has been sitting for a long time, I don't have to waste precious battery capacity cranking the motor to get fuel up to and in the carb. I also put a electric switch in the supply line to the pump so that, in Autumn when I'm putting cars to sleep, I can turn off the switch and keep running the motor until it dies. This does a good job of draining the carb, reducing varnish build-up. Yes, I could use a gas additive (and I often do), but with lots of cars and equipment, and full gas tanks in each, that's lots of Stabil! And, in regards to leaving the mechanical pump in the line, I've done that numerous times, but one thing to consider is this: if you do that and the rubber diaphram of the mechanical pump fails, you'll get raw gas going into your crankcase and diluting your oil... and not know it!3 points

-

Public Service Announcement.Time to spring into warm weather driving mode. Remember to reverse your car's battery cables to change heater to cooler function. Happy Motoring to all.3 points

-

Ok. So. That was probably the most spectacular celestial thing I've ever seen. I still wouldn't go out of my way to see another total eclipse, but I am definitely glad I got to see this one. We were in the 100% zone, the skies were crystal clear, and we had an unobstructed view, so for three minutes and some seconds, all you could see was the sun's corona, and three stars/planets that popped up, seemingly out of nowhere. Like turning on a light switch. Funny light effects for an hour leading up to it during the partial eclipse, then BAM, it's dark, the temp dropped a good ten degrees, the wind stopped, everything got quiet, and you could look at the moon/sun with the naked eye, surrounded by the awesome display of the sun's corona. I guess I was expecting groups of white-robed Druids to pop up chanting pagan rituals, not that that didn't happen, but I didn't see any. I had to go through town earlier in the morning and it was already crowded at 0800, but then we stayed home. Had some friends over later to watch the event, who said it was packed downtown when they went through at about 12. Doesn't look like we got the full quota of madness that was predicted, but still got enough people to challenge our planning and preparations. Traffic on I-95 northbound was not quite bumper to bumper, but it stopped to watch the event for a good 45 minutes. The day isn't over yet, though, and tomorrow is worthy of staying home, too, everyone who trickled in over the past three days will be leaving at once. I got a kick out of this - there was a rumor going around that Taylor Swift flew into the Houlton International Airport on her private jet to witness the total eclipse. A friend was assigned to monitoring inbound air traffic, (his wife and kids were who came to our house to witness the event), all he would say was that a fancy private jet flew in, but he wouldn't confirm/deny her presence, despite our encouragement to propagate that rumor whether true or not. So, if you've never been outside, standing on the ground, to actually see a total eclipse in person, I think you've missed something worth seeing. Won't be another one in North America for something like 20 years.3 points

-

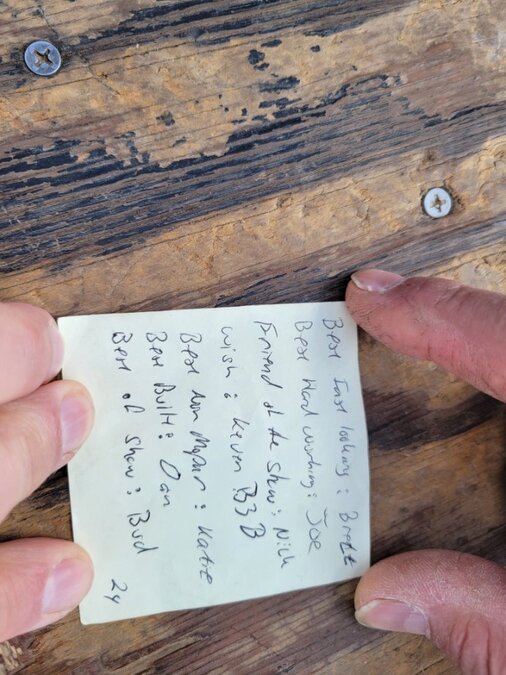

My photo dump. Sadly we missed "Friend of the Show" pic. I'll update pics with the awards tomorrow. Twinsies the grand master Tim! Best Non Mopar: Katy 71 Range Rover Best Hard Working Truck: Joe Light Blue B1/B2 Best Built Truck: Dan Red C series Best Fastest Looking Truck: Brett R/T Challenger (it identifies as a truck) Best of Show: Bud Red modified B3/B4 Not shown: Friend of the Show: Nick 4x4 B1/B2 Wish you were Here: Keven B1B (sorry have the year wrong in the note, I was looking at Brent)3 points

-

A beautiful example of a Special Deluxe! You notice the only reason the coin fell over was the torque of the engine when it was revved up.2 points

-

In my mad mind there is only one way to operate an Overdrive, that is as the factory intended. The thing is called Automatic Overdrive for a reason. It works so well without drama when installed properly I just don't understand why anyone would jury rig one, except ignorance of how to wire one properly. I've never stopped looking for easier cheaper cleaner ways to do it right. Throttle switches are way over priced from suppliers who think they have you over a barrel. At $125 I think that is obscene. I found a seller on eBay who had hundreds of military surplus bus door switches that do exactly the same thing as the reproductions and even looks the same for $6.50 ( I bought 10 for gifts to friends ) The reproductions are really floor switches for Ford products anyway. The MoPar switch is smaller and fits on the carburetor. Those can be had from the Studebaker guys for around $35 but you need to make a simple bracket and rig a lever on the carburetor throttle ( or find an Overdrive ready carburetor ). My latest and greatest find is a small switch with a pull cable from a Nash/AMC for $21. I really like this one as it is so clean and simple. Since you connect it to the lever that comes from the foot pedal its action is really smooth and effortless. You can change carburetors and manifolds without re-engineering how you trigger the switch. Then there's the relay, another obscenely priced item at $125. If you have changed to 12 volts one of the little Bosch style cube relays will work nicely for about $2.50. I like my 6 volt cars and found the same thing made in Germany for 6 volt for $18, but I am told the 12 volt version will work with 6 volts if you get the high amp version. The last thing is how to wire it. If you have a shop manual there's a description which also has the color the wires should be in there. Seems to me the only valid reason for not having a shop manual is illiteracy ( trust me I am not joking on this. Literacy is still a major problem especially in auto repair ) I have found that sometimes the Plymouth manual is short on an explanation and photos so I have all the MoPar manuals for the era of my Plymouth. But then I love shop manuals. I am the person your Mom told you about who reads technical manuals for entertainment. lol Anyway that's my two cents. If it works as intended you are not dependent on "Driver technique" and you can let anyone drive your car ( but why would you let anyone drive your car? )2 points

-

As an added fact, it was a Chrysler engineer that developed the oilite bearing....2 points

-

Oilite is a sintered bronze material that is self lubricating. Chrysler has used to for 70+ years, I'd pass on the steel one. You can punch in the mopar part number, 53298, into NAPA's website and they sell the bushing for under $5. Autozone wants $25, pass, lol. Dorman Bearing 690-005 works too2 points

-

Here is something you might consider. Having the cable break and not being able to release the hood latch would be a major irritation. I applied the same remedy I put on my TR6 which has hinges on the leading edge of the hood. If that cable breaks you really have a problem! I added a second cable for emergency release and it has a handle in the left front fender well. I can reach up in the fender and release the latch with little effort.2 points

-

Might be the voltage regulator. Simple test, start the car and use the hand throrrle to up idle to 800 or so. Use a jumper wire to ground the field terminal. The field terminal is the smaller diameter generator terminals. The ammeter should peg to full charge. If it does the generator is working, and the fault is in the regulator and or it's wiring. If the regulator cover will come off, remove the cover and clean all these points. Retest. If still no charge, check the regulator wires and connections.2 points

-

A little temperature increase when you stop is normal. At idle there is less coolant circulating and less air flow because the fan is spinning slower. This causes a bit of heat soak and your temp gauge will go up some. It should stabilize and go down again once you have more RPM and air flow.2 points

-

2 points

-

I had my bumper off completely and cleaned and painted the brackets and I do not recall the well being in the way to the point I could not do the task. The well does not just slip out of the trunk pan. Welded in place....2 points

-

Could it be exhaust heat riser flapping around? Wire it in open (rotated fully clock wise) and wire it there temporarily. Might also be the flapper shaft leaking. Remember if you decide to remove the manifold assembly, there are 13 fasteners holding it together. When reinstalling, leave the four bolts holding the manifolds together just snugged. They can then get a final tighten when finished tightening the 13 manifold nuts. Another consideration when putting the manifolds on, tighten the fasteners in a spiral pattern starting in the middle and working outward to the ends. Do not over tighten. Snug them then add quarter turn, start and run the engine to operating temp. When it has coold enough to work on, snug and quarter again from the center out. Then check the 4 on the heat riser. These assemblies heat and cool at different rates, they need to be able to move as they do so. Over tightening prevents this and leads to cracking. Remember the magic number is 13 plus 4(heat riser) When I did mine, I took an old Taiwan box end wrench took out a section of the box like a tubing wrench, and ground it thinner to make it easier to get the nuts that are partially obscured behind the exhaust casting. Good luck.2 points

-

As others have said, the Dodge/Chrysler/Plymouth/DeSoto flathead sixes have hardened exhaust valve seats from the factory, and they are very capable of handling modern, unleaded gas without any issue. They came that way starting in 1933 or 1934, and remained that way throughout all years that they were produced, which was well into the 1970's. So you don't need to worry about that.2 points

-

The dimmer switch might have corrosion on the contact points. Press the dimmer switch several times to clean the contacts. Check the fuse for the light switch might be blown. Go to the headlight junction block and use a test lamp to see if you have current flowing to the connection block. If you have power to this section then your lights might be toast. Pull a headlight bulb disconnect the wire connecter then test with a 6 volt battery charger to see if they light up. If they light up then check each connecter at the base of the bulb to see if you have current flowing to the socket. Also could be a grounding issue or maybe the bulbs are bad. Just basic diagnostic procedures. Rich hartung desoto1939@aol.com2 points

-

I like aluminum paint, it dries without any buildup. Check the inside of the tires for any tags, that could eventually rub a pin hole in the tube. I wiped the inside of the tires and the tubes with corn starch with a cloth. It doesn’t need a lot. I paint the bead of tire with rubber lube, so the bead slides easily on the wheel as it sets, you can put the lube on the wheel seat to ensure a soft seating of the bead. The flap doesn’t need any lube. Set the opening of the lock ring opposite the valve stem. I have a special hammer/mallet with a duck bill on the other side. I use the rubber part to tap the lock ring into place as I fill the tire slowly by adjusting the pressure on my regulator. This assumes that your rings are clean and no cracks, they have been painted and the notch in the wheel where they lock is perfectly clean. I’ve trashed wheels and rings that had been beaten with metal hammers. The lock ring ends should be almost touching when done correctly. Any questions, ask, it is a risky job even if you’ve done it before. These are 16” wheels, but the same design as the 20” wheels that I have. Once the bead is set and the lock ring is secured properly, I let the air out and refill with the valve core installed to eliminate any tube wrinkles. After you get it to pressure, you can bend the valve stem for access when the wheels are on the truck. If there is anything you don’t understand, ask. Rick D.2 points

-

Another vote for making your own. It’s like a puzzle to solve. You screw a few up. You learn. You get better. Building and shaping your first ever 3 ft line across the left rear axle housing? Order two 25 ft rolls of 3/16” brake line tube. 😄2 points

-

preformed and then curve and bent to fit a box for shipping, you better off making your own tailor fit set.......2 points

-

Here's a possibility. I wonder if the Dodge rod bolts have threads that are cut, while the Pontiac rod bolts have rolled threads. Rolled threads are formed by dies that displace (smash) the material into the shape of threads, without removing any material. This results in threads that have larger outside diameter than the adjacent shank section of the bolt. On the other hand, cut threads are just that - they are made by cutting material away to achieve the thread shape, so the threaded section diameter will not be any larger than the diameter of the adjacent shank. It's kind of hard to tell from your photo, but it looks like that might be the situation. If so, then accordingly, the Dodge rod might be made with smaller bolt holes to snugly fit its cut-thread bolts, but the Pontiac bolts, with their rolled threads are too large to fit. I have a couple of Dodge 230 flathead rods at home, along with their bolts, and I can tell you that the threads in those bolts have the appearance of being cut, which surprised me, since I have seen other Dodge flatheads that have the appearance of having rolled threads. I have no reason to think that those are not the original bolts, and perhaps they were early rods that used cut-thread bolts. I could take some measurements and photos of those rods and bolts some time in the next few days and we can see if they match the dimensions of your bolts. We can also see how thin my other rods are (the ones that used rolled-thread bolts) in the wall between the bolt holes and the bearing saddles. I remember them being pretty thin. We might find that you have room to ream out the bolt holes in your rods to accommodate the slightly larger Pontiac bolts, or some aftermarket bolts, such as those from ARP. From the strength and durability (fatigue) standpoint, the bolts containing rolled threads are very much preferred. I believe virtually every manufacturer uses those types of rod bolts nowadays and have for many, many decades. I remember seeing early rod bolts from other engine makes that used cut-thread bolts, but I think most everyone moved away from that type of design long ago.2 points

-

By turning the ignition on and then off you did the same thing the points do when opening and closing, letting the coil fire a plug, and if a gas mixture is in that cylinder when it fires it'll rock the engine. That's my guess.2 points

-

Likely not a "factory" accesory, more likely a mass produced catalog or dealer option, these aren't listed in the Accesories section of the manuals.2 points

-

Mark does an excellent job explaining the inner working of the doors. Check it out. 1941 Plymouth Restoration (#13) The other videos in his series are also very well done. You can tell he was an educator.2 points

-

Rmon...........Can I throw a curved ball into the ring...........lol............in 1973 I installed a 318 Poly V8 in my 1940 Oz Dodge.............at the time there were no instructions available nor did I have much in the way of outside help but I could weld and use a tape measure so I had a go.........I was 19 and basically did a few things more than once but I still have the car & its Poly V8.........now you have a 1954 Plymouth.......did you know that in 1957 Chrysler here in Australia introduced what they called a Chrysler Royal..........it was based on the 1953/54 Plymouth body and chassis with 1955/56 front & rear fenders attached.............the interesting thing that you need to be aware of is that the Chrysler Royal for the 6 yrs of its use in Australia from 1957 to 1962 had a 313( essentially the same as the 318) Poly V8 which is basically the same block as the 1966 onwards 318/340 & 360 V8's that mopar used and in fact these later engines are in fact not as wide nor as heavy as the earlier 313/318 poly and also use a much lighter transmission............your best bet would be to get as late an LA series Mopar V8 & trans that you can, also a later rear axle from either a mopar or something else that fits & a disc brake conversion for the front and have at it ..........I've attached 3 pics of the Oz Chrysler Royals showing that 1953/54 Body shell....each in these cars was available with a 313(318) Poly V8 and cast Iron Torqueflite push button trans.......also a couple of pics of my 1940 Dodge 4dr Sedan & the 313/318 Poly V8 thats lived there for 51yrs now........regards from Australia.......Andy Douglas2 points

-

The decline of the Champion Spark Plug and the death of a company. The Champion electrode was made from mainly tungsten powder at a company called Fansteel in North Chicago. They mixed, pressed, sintered, burnished and then brazed it to the copper sparkplug core before shipping them out to Champion for assembly. The company also made many other items like the Lynx golf club casting, High end tungsten darts (Black Widows & Diamond Backs) as well as supporting WW1 & WW2 military needs, they downsized in the late 80s and were dismantled early in the 90s along with VR Wesson a sister company that made carbide cutting tools. Fansteel Inc.docx2 points

-

Second that thought. Never saw a plug blow apart on a flathead till I had three Champion plugs do it over two days. Switched to AC and never had another issue, same with the NGK which I also use in all my small engines, ATVs and motorcycle.2 points

-

Champion spark plugs...ran them for years in everything from V8s to single cylinder lawn and garden equipment...then in the late 90s, they needed to be replaced more often from electrode wear, and by the mid aughts they were blowing apart in the small engines, larger engines were fouling and hard to start in cold weather. Switched to AC Delco on big engines and NGK in small and haven't had a lick of trouble since.2 points

-

I looked at the license plate mount this afternoon, and tried to get the old plate off to be able to get a decent picture. It isn't quite as I remembered. The center (vertical) bracket hooks under the bumper, and the center bumper bolt passes through it, securing it to the bumper. Then there is a horizontal c channel bracket fixed to it (welded?), with long slots, to accommodate various mounting points for the different shapes of license tags used during that era. This is the best I could do, as the tag mounting bolts are rusted fast, and just turn on the back side. (I could have broken the tag off, but didn't want to ruin such a perfect license plate.... )2 points

-

Not sure if it’s been mentioned but make sure you use engine assembly lube on the bearings during assembly. Otherwise it’s metal on metal when starting or even turning over with the starter. Not a good thing!2 points

-

SURVIVOR: spotted this '52 in Jacksboro...it's had some work done but this was the only time I saw it at the old fillin station that I've motored past several times in the last 6 months2 points

-

Since the easiest position to replace the bearings is at the bottom of the stroke, two cylinders will have the best access, the other 4 will have severely compromised access. Replace the bearings in the two at the bottom one at a time, rotate the crank until another two are at the bottom, do those and then rotate again to get the last two. It only takes about 4 inches of fuel line that way.2 points

-

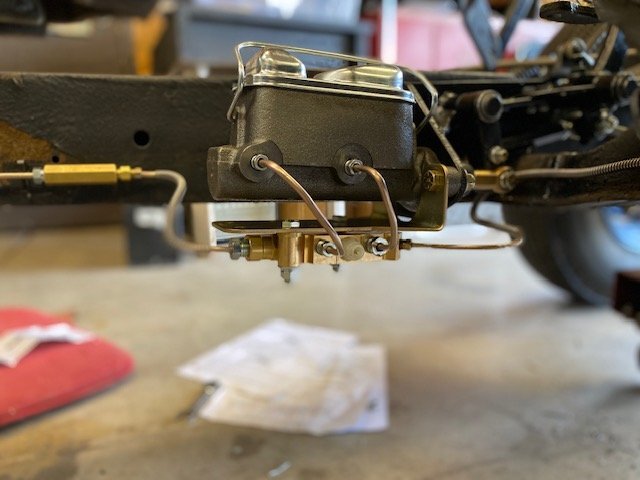

I'm moving right along on my '52 Suburban build. This week I finished upgrading the brakes to a dual master cylinder from ECI Hotrod Brakes and Brackets. It's very well made and I had no trouble fitting it to my existing underfloor brake pedal. The instructions were good, and the only thing I had to buy extra was a bracket off eBay, to hold the combination valve below the master cylinder. I tried to re-use all the original clutch parts that I could, but needed to add a bit of metal to the clutch pull back spring arm as it was wallowed out, and install new clevis pins. My wife donated her old tan purse for the clutch fork seal. I saved some $ by using the P15D24 Forum template and made one myself, as AB and others are all out of stock. Next-steering column fun! ECIChrysler.mov2 points

-

2 points

-

Gentlemen, with all due respect, I would refrain from posting practical jokes in the technical forum. You never know when someone might actually consider this as a sound advice 🙄2 points

-

Facebook didn't exist when I first joined, I think Zuckerberg was only a gleam in his daddy's eye. I've talked to a few folks that know about the Forum but don't seem to want to join because it isn't FB. I ask them what kind of info they get from FB versus what they are looking for, usually don't get a sensible answer. Seems to me they can't grasp how helpful the Forum can be, they lean towards thinking the Forum can't possibly be better than FB just because it existed before FB.2 points

.jpg.b4d2e66dd2d75ec0841a1288a9cbcfb9.jpg)

.thumb.jpeg.28cb36506a6b17cd30e7d4a22504384d.jpeg)

.jpg.2ad4c606e3fa10cf0f255b4a0154bfb9.jpg)