-

Posts

9,294 -

Joined

-

Last visited

-

Days Won

83

Merle Coggins last won the day on January 11

Merle Coggins had the most liked content!

Reputation

1,990 ExcellentAbout Merle Coggins

- Birthday 03/29/1967

Profile Information

-

Gender

Male

-

Location

Menasha, WI

-

My Project Cars

1950 Dodge B-2-C-116

Converted

-

Location

Waukesha, WI

-

Interests

Motorcycling, working on my truck

Contact Methods

-

Occupation

Technical trainer for a Construction Equipment Dealership

Recent Profile Visitors

9,809 profile views

-

It should be pretty easy to make one with a piece of threaded rod. Remove the screw where you'll be putting the stud and take it to the hardware store to match up the threads and purchase a piece of threaded rod with matching thread size along with a few nuts. Cut the length you need and thread it into the pump. Use a nut to tighten it down against the pump body, and a couple more nuts at the top to hold the heat shield. Mine had a wing nut on top, but a regular nut would do the job too.

-

Coolant flow to heater core

Merle Coggins replied to General23cmp's topic in Mopar Flathead Truck Forum

It sounds like you'll be pulling the head soon to address the head gasket issue, so that will be a good time to clean and inspect the coolant passages in the head that seem to be plugged up and blocking flow to the heater port. -

Coolant flow to heater core

Merle Coggins replied to General23cmp's topic in Mopar Flathead Truck Forum

Yes, you should be able to blow air into the cooling system through that hose unless there is a shut-off valve, and it is closed. You should also have coolant flow out of that hose if you hold the end below the coolant level. If it doesn’t you either have a closed shut-off valve or the coolant passages in the head are plugged. The water pump wouldn’t be able to build any useable pressure at cranking RPM. It’s not a positive displacement pump so it needs RPM to create flow. -

One thing to keep in mind when dealing with brakes that pull in one direction upon application... The fault may actually be on the opposite side of the direction it pulls. The general consensus is that the brake is "grabbing" and making the vehicle pull in that direction. But sometimes the brake on the other side is being lazy and not applying as it should. This could be caused by seized components, or by a failing flexible brake line.

-

Click the 'Messages button and select "Go to Inbox" at the very bottom. From there you'll find check boxes next to each message string. As you 'check' them you'll see a popup button to delete the message string. There's even a "Select All" button at the top of the list.

-

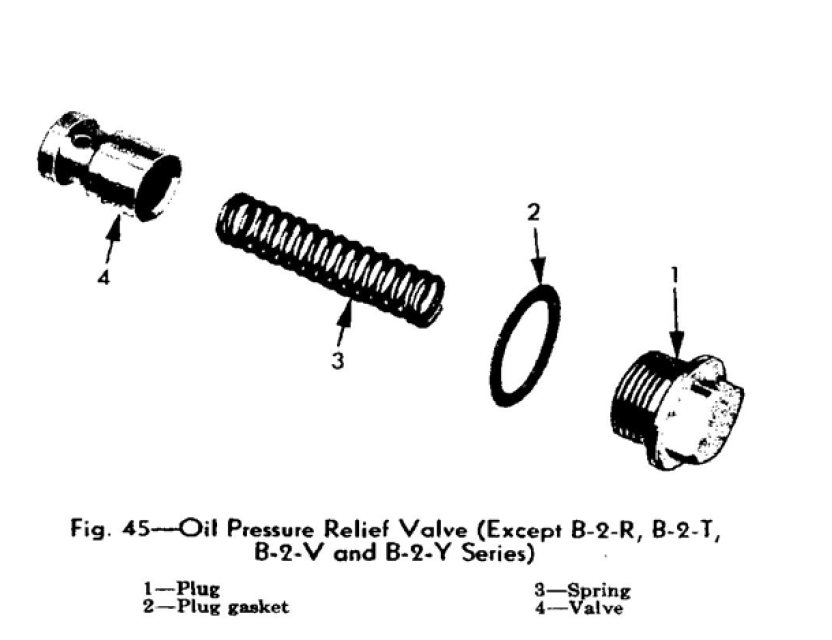

Just below where your oil filter lines connect you'll find a plug. Behind that plug is a spring and plunger for the oil pressure relief. When the valve is closed it also blocks the return flow from the filter to prioritize oil pressure to the engine. When proper pressure is achieved the valve should open to relieve the excess pressure, and at the same time open the return path for the filter so that oil can flow through it.

-

Yes, close enough. Especially since my truck runs just fine with it. LOL… it’s actually nice here today. Low to mid 80’s with a nice breeze.

-

I just performed the test on my truck. I got 4 oz. After 15 pump pulses. It would be a little low based on Ed’s spec., but it’ll hold 4.5 psi on a pressure test. So I’ll use this as a guideline too.

-

Yes, that oil pressure is too high. It's possible that your oil pressure regulator spool is stuck closed. If you want to verify with another gauge look at the left side of your engine, where the current gauge connects, and you'll see a raised ridge that runs the length of the block. This is the main oil galley and it will have 4 ports (1/8" NPT) along the length. One is where your dash gauge connects. Any of the other 3 can be used with a manual gauge to verify the pressure.

-

Thanks guys. This gives me a target to shoot for. As Robert said, this is not stated in the truck shop manual. It only references the pressure. And, in the test procedure it states 3-1/2 - 5-1/2 psi, but if you look in the Specs pages it shows 4-5 psi. (Gotta love inconsistency in service literature 🤔) It’s good that the Plymouth manuals state it. I might do a test on my truck one evening this week for comparison/baseline.

-

Hello. I’ll be helping a friend to diagnose a potential fuel pump issue this coming weekend. I have what I need to check the fuel pressure, and I have that spec (4-5 psi). However, I can’t find a spec for the pump volume. I’m aware of volume tests where you disconnect the line going to the carb and direct the flow into a container, then crank the engine for a certain amount of time and measure the volume. Does anyone know that spec for our trucks?

-

Anytime I’ve experienced backfiring out of the carb after distributor work, I found that the distributor was installed 180 degrees off. Double check #1 TDC on the Compression stroke. Then recheck your plug wire placement. Also, extremely retarded timing could be firing the spark plugs on the intake stroke, causing backfire in the carb. Either way, double check the timing.

-

Your stick may not be holding enough brake pressure to activate the switch. Get a helper to step on the brake pedal while you test it, or rig up your test light so that you can see it while stepping on the brake pedal.

-

If you connect the 2 wires together at the brake light switch will the brake lights come on? Have you done a continuity check of the brake pressure switch with pressure applied?