-

Posts

8,283 -

Joined

-

Last visited

-

Days Won

95

ggdad1951 last won the day on March 30

ggdad1951 had the most liked content!

Reputation

2,425 ExcellentAbout ggdad1951

Profile Information

-

Gender

Not Telling

-

Location

Oak Grove, MN

-

Interests

woodworking, playing hockey, skydiving, landscaping, college hockey (GOPHERS), Vikings, Dodge trucks!

-

My Project Cars

1951 B3D "FEF", 1948-NOW Street rod truck "TODD", 1951 COE "PUMA", 1953 1.5 ton tip bed "ART", 1951 1 ton flat bed "PARTS"

Contact Methods

-

Biography

restored great grand dad's 1951 1 ton (FEF) now onto TODD!

-

Occupation

Engineering Manager/Mechanical Engineer

Converted

-

Location

Eagan MN

-

Interests

wood working, landscaping, skydiving

-

Light socket.

-

Almost as good: as the Edison base we found sheetrocked up in my friend's house.....right next to a squirrel nest in a cieling....and it was LIVE.

-

Do it right and only do it once. I tend to go a bit big on wiring, larger gauge if I can. Follow the codes, even if you aren't getting inspected. As stated above, it SHOULD (in theory) make things safer...altho some of the codes I've seen as of late make me question that. UL is just a for profit company that has convinced everyone they make things safer. I've dealt with them for may years in a previous job, and mostly it was hittting a threshold of money input on a design to get the rating....and some of the things they wanted, well, just lets the stupid people be stupid and not cleanse the gene pool...design for the lowest level of intelligence and then make it even more dumber. In my new shed I put batt on the walls (2x6) and blew in the cieling (what a fun way to spend a day) for R38. Do what you need to do for your area to keep the hot/cold in/out and move on. Just make sure not to block the eaves for the soffit ventilation. I've run across it all over my years building and helping others: use of an extension cord in a wall instead of ROMEX 3 taps in a breaker box off a breaker hot/neutral switched running hot thru a ground unsupported load bearing areas caulk used to seal a drain line hole or joint duct tape on bare wires jbox on a wall with live bare wires hanging out 3 wires tapped onto a screw on outlets breakers "forced" to not trip ungrounded conduit tapping 110 off 220 every screw/nail under the sun to put a wall/sheetrock up the list never ends.....

-

18th Annual Clements Tailgate BBO, in Clements California

ggdad1951 replied to 48Dodger's topic in Mopar Flathead Truck Forum

-

18th Annual Clements Tailgate BBO, in Clements California

ggdad1951 replied to 48Dodger's topic in Mopar Flathead Truck Forum

Damn now I gotta pack my banana hammock -

- 734 replies

-

- 3

-

-

18th Annual Clements Tailgate BBO, in Clements California

ggdad1951 replied to 48Dodger's topic in Mopar Flathead Truck Forum

T shirt, shorts and sandals! Can't wait! -

18th Annual Clements Tailgate BBO, in Clements California

ggdad1951 replied to 48Dodger's topic in Mopar Flathead Truck Forum

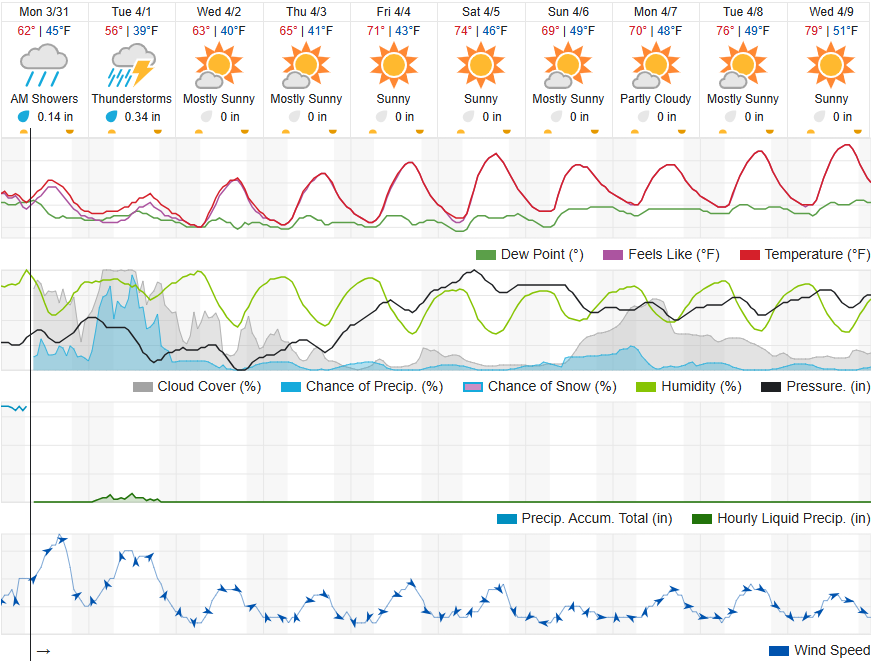

Weather terrorists say mid 70's and sunny after a few days of rain......seems to always be sunny on show day! -

18th Annual Clements Tailgate BBO, in Clements California

ggdad1951 replied to 48Dodger's topic in Mopar Flathead Truck Forum

Gonna be 60 here today....might bust out the sandals! On another note, John might have to build another drain canal this year from in front of the house if the forecast rain shows up early next week! -

18th Annual Clements Tailgate BBO, in Clements California

ggdad1951 replied to 48Dodger's topic in Mopar Flathead Truck Forum

You mean warming UP to 60! Tropical shorts weather for me! -

Pitman Arm Attachment to the Steering Gearbox

ggdad1951 replied to bkahler's topic in Mopar Flathead Truck Forum

IF and IF I rememebr right, center the box and the link goes "down"-ish. -

18th Annual Clements Tailgate BBO, in Clements California

ggdad1951 replied to 48Dodger's topic in Mopar Flathead Truck Forum

I know and I have....I get conflicting results depending on website. Asking the man on the ground.....and this is mostly a joke. -

18th Annual Clements Tailgate BBO, in Clements California

ggdad1951 replied to 48Dodger's topic in Mopar Flathead Truck Forum

About a week and a half out! What's the forecast there slim? -

Tigerwood....30 year ground contact...similar to the ironwood family.

- 734 replies

-

- 734 replies

-

- 2

-