Leaderboard

Popular Content

Showing content with the highest reputation since 04/13/2024 in all areas

-

11 points

-

10 points

-

7 points

-

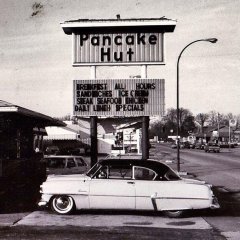

My Great Grandfather, and guessing my Great Grandmother with the '55 Dodge (I'll be inheriting this summer) and what I believe is a '55 DeSoto. The truck was my Great Grandfather's then my Uncle's, and then my Parent's, and soon to be mine. My Dad just told me that he is getting too old to work on too many toys, and he is giving it to me. It is in a little worse shape than here, but pretty much original. I'll post pictures of it's current state, in the correct area, when I get it out of the barn, but from what I recall it definitely will need a gas tank and fuel pump, amongst other things.6 points

-

A legendary attribute of early Rolls-Royce Motorcars was the ability to balance a coin on the radiator whilst the engine was purring quietly. While there is neither a R-R or 5-shilling coin in this video, here is friend Jerry's 1950 Plymouth with a Canadian Loonie riding the fresh air vent, radiator and cylinder head!5 points

-

Passing along some research info. I looked at various bolts to replace the oe cylinder head bolts, all seem to use a smaller hex head. I wanted some with the stock size head 11/16, necked down like the original style. I've found an option for the cylinder head bolts that have 11/16 hex size. Original application was for an olds 350 v8. Dorman part number 675-060, sold in sets of ten per package - about $20 at Summit. Slightly longer than original, but work perfect even with a .070 milled head. Only a minor mod needed for the three bolts that go into the intake ports, grind to shorten them or use a hardened washer. Hope this is useful to others.5 points

-

4 points

-

As I noted earlier in this thread, I generally plan to have the ol' Dodge out in May. Roads are usually clear of salt and the weather is cooperative. For the past several years, the first sojourn has been to take the missus out for the Mothers Day breakfast at the Houlton Lodge of Elks, and this year, after always thinking "gee, that would make a nice picture", I actually finally took a picture. This Lodge building was already 40 years old when our car was new, oldest original Elks Lodge in the State of Maine.3 points

-

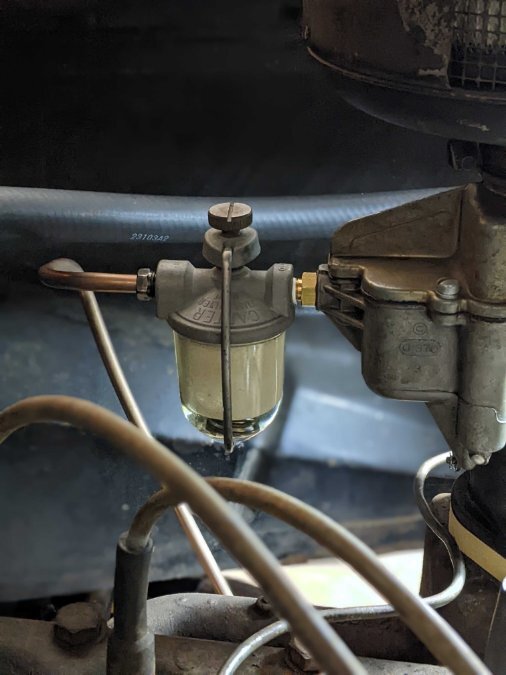

If you have an original pump I’d rebuild it. We’ve all had problems with the pin walking out on the new pumps. Since I’m a machinist I plan on making a new pin for mine. I’ll have a shoulder on one end and I’ll drill the other end for a cotter pin.3 points

-

hopefully any time I see Stick and Mud associated with house building, it will be the last names of the contractors. 👷♂️3 points

-

My love of old cars started with the Model T. I have a 27 Roadster and a few others. The Model T driving experience is not one I’d offer to just anyone however! I sold a 27 tudor to a guy and gave him the whole driving lesson. A week later I got an email describing how he pressed down on the low pedal thinking it was the brake, drove into another car then took his foot off the pedal. I am glad he didn’t send me a photo. My philosophy of old cars is we are stewards of them for the time we have with them. They can certainly out live us if we are careful with them or we can destroy them in a split second. When you consider the history of the world since your 26 was made it is remarkable that it is still here, let alone the human race. When someone goes on about how they want to put their Plymouth body on an S10 chassis, I cringe. That ole Plymouth could live on for decades and still be a nice car. Once someone “modernizes” it, it has taken a big step to the scrap yard. Consider the car magazines of the 1950s. Where are all those “Customized” cars that graced the magazine covers now? Survivor cars got that way because of the stewardship of a chain of owners. In some cases it was just benign neglect that contributed. Cherish your old car and it may out live you!3 points

-

In my mad mind there is only one way to operate an Overdrive, that is as the factory intended. The thing is called Automatic Overdrive for a reason. It works so well without drama when installed properly I just don't understand why anyone would jury rig one, except ignorance of how to wire one properly. I've never stopped looking for easier cheaper cleaner ways to do it right. Throttle switches are way over priced from suppliers who think they have you over a barrel. At $125 I think that is obscene. I found a seller on eBay who had hundreds of military surplus bus door switches that do exactly the same thing as the reproductions and even looks the same for $6.50 ( I bought 10 for gifts to friends ) The reproductions are really floor switches for Ford products anyway. The MoPar switch is smaller and fits on the carburetor. Those can be had from the Studebaker guys for around $35 but you need to make a simple bracket and rig a lever on the carburetor throttle ( or find an Overdrive ready carburetor ). My latest and greatest find is a small switch with a pull cable from a Nash/AMC for $21. I really like this one as it is so clean and simple. Since you connect it to the lever that comes from the foot pedal its action is really smooth and effortless. You can change carburetors and manifolds without re-engineering how you trigger the switch. Then there's the relay, another obscenely priced item at $125. If you have changed to 12 volts one of the little Bosch style cube relays will work nicely for about $2.50. I like my 6 volt cars and found the same thing made in Germany for 6 volt for $18, but I am told the 12 volt version will work with 6 volts if you get the high amp version. The last thing is how to wire it. If you have a shop manual there's a description which also has the color the wires should be in there. Seems to me the only valid reason for not having a shop manual is illiteracy ( trust me I am not joking on this. Literacy is still a major problem especially in auto repair ) I have found that sometimes the Plymouth manual is short on an explanation and photos so I have all the MoPar manuals for the era of my Plymouth. But then I love shop manuals. I am the person your Mom told you about who reads technical manuals for entertainment. lol Anyway that's my two cents. If it works as intended you are not dependent on "Driver technique" and you can let anyone drive your car ( but why would you let anyone drive your car? )3 points

-

3 points

-

3 points

-

I've used Rustoleum and Tractor Supply's implement paint for rust "proofing" on many projects over the years. No paint will kill rust that isn't addressed but it can inhibit surface corrosion on clean surfaces. Two VW Beetle floor pans (inside and out) and running gear received the Rustoleum satin and gloss finishes and both have held up well for over twenty years. I usually use a brush because the paint can be applied thicker and the cost and mess is much less than spray cans. I've also bought quarts, thinned with mineral spirits and shot it with a spray gun when that was the best option.3 points

-

I have an admittedly tight focus on the KT Keller cars, so that's what I research and play with. It's all about having fun after all and those are the ones I like. I am a huge fan of Overdrive transmissions because they don't really change the charm of the cars and actually add to it. When you put one in your car your speedo will be off at all speeds because the speedometer pinion gear was selected for a 4.1 ring and pinion. The good news is you can swap out the pinion from your old three speed to the O.D. and all will be back to normal ( assuming your speedometer doesn't need service ). But what if you changed the rear end ratio or the tire size? I don't advocate changing rear axles because I don't see much to be gained there. You can easily change the differential carrier ( aka 3rd member ) in a Plymouth if you want another ratio. Where I live there's lots of open road with highway speeds of 55 to 70 so optional ratios, tires and O.D. go well with my Plymouth. My P17 Coupe came with 6.40-15 tires ( modern equivalent 195/75/15 ) and a 3.73 final drive ratio so the speedometer pinion would be a 17 tooth gear ( p/n 652-848 ) for an example. Chrysler designed the pinions to use the same 6 tooth gear on the output shaft so you only need to change one gear to correct the speedometer. One thing you find out right away is selecting speedo gears is not an exact science. You can get close and you might hit it right on the button but you more likely will be over or under by 2 or 3 mph. That's why the Highway Patrol has an enforcement tolerance. So let's look at tires first 6.40 15 = 195/75/15 standard tire for a P17 6.70 15 = 205/75/15 standard tire for a P18 7.60 15 = 225/75/15 an optional size tire Final drive ratios 3.90 very common on long wheelbase cars 3.73 standard ratio on many optional on all 3.54 optional Chart of ratios & tires vs speedometer pinions 3.90 6.70 15 17 tooth pinion 3.73 6.40 15 17 tooth pinion 3.73 6.70 15 16 tooth pinion 3.54 6.70 15 16 tooth pinion All 7.60 15 16 tooth pinion So you can see you're not going to get an exact reading but you can get close enough to avoid a ticket. The part number for the 16 tooth pinion is 652-846. I have found that if you have the number for an obscure part the parts house will look to find it in their inventory but they are likely to blow you off if you just say "I need a 16 tooth speedometer gear." Happy hunting!3 points

-

Yup, between 65 and 70. When I had earplugs in, I tended to go faster, haha....3 points

-

I'm going to agree with this, I have a 1951 engine the crank is stamped 10/10 .... the bearings have no markings though.2 points

-

2 points

-

Rebuilding gets ya new rubber on the original style pumps that do not fall apart like the new pumps. https://p15-d24.com/links/2 points

-

Henry Ford was a lot of things but communist wasn’t one of them. He admired Hitler, financed him and supplied him with anti-Semitic propaganda, so you might say he had fascist tendencies. He sued a newspaper for libel and made the mistake of testifying in court. The defendant’s attorneys had a fun time embarrassing him by showing how astonishingly ignorant he was. He could not say when certain events happened in American history such as the year of the revolutionary war. He won the suit because he had been libeled, however the jury awarded him $5. Henry Ford was a tea totaler and he used to break into his son Edsel’s house and pour out all his liquor. Edsel died of an ulcer that became cancerous and Henry knew he was the cause. I visited the Henry Ford museum and in back of his collection of steam engines is this enormous steam powered twin cylinder double acting generator set. It’s easily as big as a house! It took at least two men to operate it. When you look at it and then read the card that describes it you find that this was in the powerhouse of the Highland Park factory and there were 8 of them! If Ford was the master of this beast and 7 of it’s siblings which powered his factory then it’s no wonder he became a little nuts. His wasn’t success it was megalomania. When Ford’s grandson took over things changed quickly. The flathead took 46 cores to produce and the Ford engineers were so proud that “Y-block” OHV V8 ( 1954 ) only required 26 cores. Of course the Chevy V8 only required 9 cores ( 1955 ). So Ford had a lot of ground to make up and it was mostly from Henry’s stubbornness. Ford’s initial success can be directly linked his use of the best machine shop in Detroit, namely the Dodge Brothers. They knew what they were doing. So why am I not surprised that another guy who knew what he was doing, would buy their company when he got the opportunity. I grew up being told that Henry Ford was an American hero. The truth is he was a very flawed human being. But then people in glass houses…..2 points

-

Following up on what I ended up doing with my A/C system as outlined in post 1. Took my old compressor off and dumped the oil. It was clean and looked good. No failure in compressor. The original compressor on my car was a vane type. Prone to shorter life than a radial piston type. I ordered a brand new radial piston compressor off Rock Auto. It was prefilled with PAG oil. The proper amount they claimed. I installed the new compressor and re-installed hoses. I got way down under the dash and replaced 2 cabin fresh air intake filters. I booked an appointment at the A/C shop. Told them that I recently installed a new compressor and last year a new condenser and receiver dryer. I asked them to remove the new compressor and drain it. Install the correct about of oil. Replace o-ring seals. Pressure up system and test for leaks. They found none. They Sucked the system down for a while and refilled it with refrdigerant. Installed a new Compressor drive belt. They told me it blows ice cubes out the dash now. I agree. System works very well. I saved a ton by buying my own new condenser, dryer and compressor,then installing them myself. They had no issue with me doing that myself. Good guys to deal with. I'll be recommending them. Happy to say I'll be cool this coming summer!2 points

-

Really nice truck! I dunno, I think a good soaking with PB Blaster will free her up!2 points

-

Oilite is a sintered bronze material that is self lubricating. Chrysler has used to for 70+ years, I'd pass on the steel one. You can punch in the mopar part number, 53298, into NAPA's website and they sell the bushing for under $5. Autozone wants $25, pass, lol. Dorman Bearing 690-005 works too2 points

-

Here is something you might consider. Having the cable break and not being able to release the hood latch would be a major irritation. I applied the same remedy I put on my TR6 which has hinges on the leading edge of the hood. If that cable breaks you really have a problem! I added a second cable for emergency release and it has a handle in the left front fender well. I can reach up in the fender and release the latch with little effort.2 points

-

2 points

-

Might be the voltage regulator. Simple test, start the car and use the hand throrrle to up idle to 800 or so. Use a jumper wire to ground the field terminal. The field terminal is the smaller diameter generator terminals. The ammeter should peg to full charge. If it does the generator is working, and the fault is in the regulator and or it's wiring. If the regulator cover will come off, remove the cover and clean all these points. Retest. If still no charge, check the regulator wires and connections.2 points

-

I would purchase the spare carb for that price and then have a machine shop pull the old brass rod and then install a new rod and then have a spare throttle body. $20 is cheap for a carb and then youcan play with th eold carb and get some education on how it all works. Just my $20 worth of input. Rich hartung Desoto1939@aol.com2 points

-

A little temperature increase when you stop is normal. At idle there is less coolant circulating and less air flow because the fan is spinning slower. This causes a bit of heat soak and your temp gauge will go up some. It should stabilize and go down again once you have more RPM and air flow.2 points

-

If you get an email saying your password is expiring do not click on the link. It is a phishing attack attempting to get your login information. We do not have a password expiration policy at this site so ignore and delete any such emails. I do recommend setting a unique password for this site, and using a unique passwords for other sites you visit. I also recommend using the two factor authorization option on your account for additional security.2 points

-

Have someone step on the clutch (you need the clutch pedal working) while trying to install. This will release the clutch and allow the disc to move and align to the shaft and should seat the trans.2 points

-

I have improved my valve set when using the cold method. Yet I prefer the hot method. A gauntlet glove on one hand/forearm is helpful to prevent burns. I shut off the hot engine. Make my adjustments. Then run it and test. I like the positive feedback when a running engine pulls the feeler gauge in, just right. Then I know its right and brings a smile. The wheel and inner fender window removal is great. After a good hot valve set, I come out from the car with a black sheen. Looking like I’ve been in an underground coal mine. Good times. I do enjoy a good hot flathead valve set. It’s rewarding and takes me back to 1950. Romanticizing a valve set…What have I become? Lol.2 points

-

I had my bumper off completely and cleaned and painted the brackets and I do not recall the well being in the way to the point I could not do the task. The well does not just slip out of the trunk pan. Welded in place....2 points

-

Could it be exhaust heat riser flapping around? Wire it in open (rotated fully clock wise) and wire it there temporarily. Might also be the flapper shaft leaking. Remember if you decide to remove the manifold assembly, there are 13 fasteners holding it together. When reinstalling, leave the four bolts holding the manifolds together just snugged. They can then get a final tighten when finished tightening the 13 manifold nuts. Another consideration when putting the manifolds on, tighten the fasteners in a spiral pattern starting in the middle and working outward to the ends. Do not over tighten. Snug them then add quarter turn, start and run the engine to operating temp. When it has coold enough to work on, snug and quarter again from the center out. Then check the 4 on the heat riser. These assemblies heat and cool at different rates, they need to be able to move as they do so. Over tightening prevents this and leads to cracking. Remember the magic number is 13 plus 4(heat riser) When I did mine, I took an old Taiwan box end wrench took out a section of the box like a tubing wrench, and ground it thinner to make it easier to get the nuts that are partially obscured behind the exhaust casting. Good luck.2 points

-

As others have said, the Dodge/Chrysler/Plymouth/DeSoto flathead sixes have hardened exhaust valve seats from the factory, and they are very capable of handling modern, unleaded gas without any issue. They came that way starting in 1933 or 1934, and remained that way throughout all years that they were produced, which was well into the 1970's. So you don't need to worry about that.2 points

-

I speculate that pre ww2 bolts were more likely to be cut but with the advancements in the military equipment, i.e. planes, etc, stronger threaded fasteners were needed. Just a thought. dan...2 points

-

The filter is far from the headers. The pipe that it is close to is an intake runner, and when the engine is running those runners stay very cold. That's why I built it like that. Cold air is denser and allows more power to be made. The long runners introduce a ram effect on the intake charge and produce more power. This was a question about installing the windshield and rear window.2 points

-

I like aluminum paint, it dries without any buildup. Check the inside of the tires for any tags, that could eventually rub a pin hole in the tube. I wiped the inside of the tires and the tubes with corn starch with a cloth. It doesn’t need a lot. I paint the bead of tire with rubber lube, so the bead slides easily on the wheel as it sets, you can put the lube on the wheel seat to ensure a soft seating of the bead. The flap doesn’t need any lube. Set the opening of the lock ring opposite the valve stem. I have a special hammer/mallet with a duck bill on the other side. I use the rubber part to tap the lock ring into place as I fill the tire slowly by adjusting the pressure on my regulator. This assumes that your rings are clean and no cracks, they have been painted and the notch in the wheel where they lock is perfectly clean. I’ve trashed wheels and rings that had been beaten with metal hammers. The lock ring ends should be almost touching when done correctly. Any questions, ask, it is a risky job even if you’ve done it before. These are 16” wheels, but the same design as the 20” wheels that I have. Once the bead is set and the lock ring is secured properly, I let the air out and refill with the valve core installed to eliminate any tube wrinkles. After you get it to pressure, you can bend the valve stem for access when the wheels are on the truck. If there is anything you don’t understand, ask. Rick D.2 points

-

Another vote for making your own. It’s like a puzzle to solve. You screw a few up. You learn. You get better. Building and shaping your first ever 3 ft line across the left rear axle housing? Order two 25 ft rolls of 3/16” brake line tube. 😄2 points

-

preformed and then curve and bent to fit a box for shipping, you better off making your own tailor fit set.......2 points

-

Here's a possibility. I wonder if the Dodge rod bolts have threads that are cut, while the Pontiac rod bolts have rolled threads. Rolled threads are formed by dies that displace (smash) the material into the shape of threads, without removing any material. This results in threads that have larger outside diameter than the adjacent shank section of the bolt. On the other hand, cut threads are just that - they are made by cutting material away to achieve the thread shape, so the threaded section diameter will not be any larger than the diameter of the adjacent shank. It's kind of hard to tell from your photo, but it looks like that might be the situation. If so, then accordingly, the Dodge rod might be made with smaller bolt holes to snugly fit its cut-thread bolts, but the Pontiac bolts, with their rolled threads are too large to fit. I have a couple of Dodge 230 flathead rods at home, along with their bolts, and I can tell you that the threads in those bolts have the appearance of being cut, which surprised me, since I have seen other Dodge flatheads that have the appearance of having rolled threads. I have no reason to think that those are not the original bolts, and perhaps they were early rods that used cut-thread bolts. I could take some measurements and photos of those rods and bolts some time in the next few days and we can see if they match the dimensions of your bolts. We can also see how thin my other rods are (the ones that used rolled-thread bolts) in the wall between the bolt holes and the bearing saddles. I remember them being pretty thin. We might find that you have room to ream out the bolt holes in your rods to accommodate the slightly larger Pontiac bolts, or some aftermarket bolts, such as those from ARP. From the strength and durability (fatigue) standpoint, the bolts containing rolled threads are very much preferred. I believe virtually every manufacturer uses those types of rod bolts nowadays and have for many, many decades. I remember seeing early rod bolts from other engine makes that used cut-thread bolts, but I think most everyone moved away from that type of design long ago.2 points

-

with all due respect, items needed to exact this repair is common at any hardware store or big box building supply, TSC etc that one can walk in, get the item, pay and immediately got to work repairing. While mail order from many companies and sites are MOST BENEFICAL when you dealing/needing bulk quantity, I have to state IN MY OPINION this is not the best option for this particular thread. Heck if it boils right down to it, one can find where a person may park a chevy/gm product and find where these have fallen off and free for picking up. Ok so the last part is a joke...maybe real at times, but still intended as a jab/joke.2 points

-

SURVIVOR: saw this Dodge between Lake Graham and Newcastle2 points

-

By turning the ignition on and then off you did the same thing the points do when opening and closing, letting the coil fire a plug, and if a gas mixture is in that cylinder when it fires it'll rock the engine. That's my guess.2 points

-

Just use a torch to get the plug red hot....that oughta bust the rust loose................. 😲 🤣2 points

-

Mark does an excellent job explaining the inner working of the doors. Check it out. 1941 Plymouth Restoration (#13) The other videos in his series are also very well done. You can tell he was an educator.2 points

-

John-T-53, thanks for all the pictures. I’m sure a lot of us would like to make the tailgate and BBQ. Just not practical for most. However, your pictures really let those of us who can’t make it live vicariously through your pictures. The most and best of the bunch! I would love to bring this old girl to the BBQ but it involves border crossing (not a problem with a passport) and a three, four, or possibly five day drive depending on weather and lack of problems. It doesn’t have a tailgate but does have the next best thing…..a big butt trunk.2 points

-

you may be onto something Sniper, I am going to say a rolling wheel gathers no red paint.....2 points

-

I use the in my opinion a lot because most of my unsolicited comments are just that, an opinion and in no manner saying good bad or indifferent....but just as I see it. The fact I will then state the whys and wherefores of my opinion is to say that it is not just a whim or silly notion and give some background, color and size ratio etc...technically I could care less one way or the other what anyone chooses to do as it is not my car no more than if a person likes or dislikes what I do with mine. Big hobby folks, I will admit at one time it would rankle me see what some folks may do...but hard lesson to learn is JUST NOT MY BUSINESS....the red wheels, there is NO WAIVER here......lol2 points

-

Ach, I'll admit I'm the a-hole driver...in many other drivers' eyes. Speed limit, turn signals, obey traffic laws, "usually courteous" (nobody's perfect), etc. But I don't do it out of a sense of virtue, it's more like...spite! I know it annoys the heck out of bad drivers to no end.2 points

.thumb.jpeg.28cb36506a6b17cd30e7d4a22504384d.jpeg)