-

Posts

534 -

Joined

-

Last visited

-

Days Won

2

Everything posted by Veemoney

-

Increasingly Difficult To Find Manual 6V Battery Chargers

Veemoney replied to keithb7's topic in P15-D24 Forum

My old "Die Hard" 6/12v charger gave up and you know that usually happens when you need it. HF is not far but they only had smart charger models and I picked up this one after reading some good reviews on it. It is a "high freq" model with settings for wet, AGM and Gel batteries. It was on sale cheap and got me going. As Young Ed mentioned Facebook marketplace is easy enough to use just click the local button so I can pick-up and see it before I buy. I found an old school not so smart model on Facebook Marketplace for $12 locally, 10amp and no shut-off so It has to be monitored closely during use. I check volts with a fluke meter when charging. -

Forget unloading the groceries just use Uber Eats.

-

Reading about the L-6 engine motorcycle that blew the motor doing 180mph on the salt track brought back an experience I had so I thought I would post it here while killing some time. I had only ridden jap bikes and the z1-900 was my bike at the time a fellow worker approached me to buy his brother's Harley. His brother belonged to a local chapter and was in jail needing Lawyer money. With no Harley experience but the excitement of a new project I purchased the 1974 bike after looking it over and understanding there were issues. Kickstart only it took a while to start but with good title in hand I started the drive home. Rolling down the road and snap I have cop lights behind me so I pull over and dismount but leave the bike running for fear it won't start. The cop just wanted to bring me the kicker lever that fell off and let me know the lights were dim. The old bike frame was raked using steel plates over the neck to flush it out. had an embossed skull on the tank and chrome Girder front end that looked new. I took the bike apart and found a number of things wrong or missing, one being there was no stator in the bike to charge the battery. I rebuilt and upgraded parts and paint and it was a pretty cool ride. No front brake and stock disk in the rear the way many choppers ran back then. Well, a year or so later I'm returning home after dropping a girl off and riding solo next to a friend and his girl. We're doing 65-70mph down the road and I felt something like a bump, but it seemed something was wrong, so I reached down with my left hand and felt a crack at the lower frame tube just below the neck. Didn't want to hit the rear brake so I slowly started reducing throttle thinking about speed wobble. About the time I put my hand back on the bars another bump like move and I was noticeable lower to the ground, a second later another drop down and the skid pan is dragging on the pavement. My friends said the sparks were shooting out as I was dragging on the pan just hoping it didn't dig in and throw me or the front end separate completely. Amazing all the scenarios that go through your head as it moved side to side like a fishtail. Once it slowed to about 10 mph or so I spied a grassy area and took it to the side of the road where it slowed down quickly in the gravel and fortunately allowed me to ride it out without a complete dismount. Only thing holding the front end on at that point was the front tab on the Mustang gas tank. The 2 lower tubes had cracked just under the steel flush plates which I assume was the first drops I felt, when the upper tube let go well the excitement started. All good and not even a scratch to show for it we trucked it home and I started the repair. Looked like some bad welding when they raked it out and then covered it with the plates. Picture below is directly after pulling it off the truck in 2 pieces and starting the repair. Still have the bike too

-

@1500lbs when the engine goes and you only have a small rear brake, I can imagine what he was thinking.

-

Great read, thanks for posting. They managed to get 122 hp out of the smaller 1934 L-head without modifying the exhaust or adding multiple carbs. Gotta love it.

-

I don't see the 2 welds on the window uprights or maybe they are higher up.

- 734 replies

-

Looks nice pulled up close like that.

-

Getting my 46 WD15 repaired and back on the road

Veemoney replied to lostviking's topic in Mopar Flathead Truck Forum

Viking, Pictures speak for themselves, WOW. Glad to see you digging in at it and the new thread for progress. Before you grab the hammers make sure to get some good ear protection. -

1946 WD15 rear end swap...and full replumb of brakes

Veemoney replied to lostviking's topic in Mopar Flathead Truck Forum

Disheartening just reading about it. The upside that no one was physically hurt, and damage was limited to your own truck should let you focus on the repairs. As much as I hate doing body work and frugal as I sometimes can be, I would be content knowing damage was limited to my truck and things I could fix. -

Looking for 39-47 WC-WD bed wood dimensions

Veemoney replied to 47Jim's topic in Mopar Flathead Truck Forum

Good advice Ed. Always better to measure twice before cutting especially understanding there can be a difference in the strips. ? -

Looking for 39-47 WC-WD bed wood dimensions

Veemoney replied to 47Jim's topic in Mopar Flathead Truck Forum

Here is what I have for dimensions on the 6.5ft bed WC. I posted this in the past here as well. Hope it helps. Total 6-red oak planks {boards] 13/16 thick, 78 long and 7 ¾ wide 2 planks [ left and right outside] one saw kerf 1/8 deep x 1/8 wide 1/2 inch from inside edge on upper side .Saw kerf allows the rail to settle and to grip plank. 4 planks saw kerf on top ,2 per plank 1/8 deepx1/8 widex1/2 from edge -

Current Build Card Request Status

Veemoney replied to billrigsby's topic in Mopar Flathead Truck Forum

Back on 8/6/2012 Danielle provided build cards per my request for my 47 WC and 67 Charger. Very nice Woman and glad to see she is still working to support these old Mopars. With both of my build cards she sent additional printed sheets with details about the vehicles. That may be due to the changes I noticed in her letter to you compared to mine. I noticed the stationary in your letter is different than what she provided in my letter which has: Pentastar logo at the top followed by Chrysler in bold text Historical Services/Chrysler Group LLC at the bottom after her signature Here is some info on options including "Deluxe Cab" below and the pricing OPTIONS Trucks: Air cleaner, one quart instead of standard one pint ($3.70). Rear bumper ($6.35). Deluxe cab equipment, includes hair pad seat cushion and back, armrest (left side), dome light, dual vacuum windshield wipers, one sun visor, plastic coated trim ($26.65). Generator: 230 watt, six- to eight-volt/32 amp / hour. High-charging at low engine speed ($8.30). Governor ($5.15). Oil filter, replaceable. -

Here is my water gutter to capture and redirect rainwater that makes its way through the center split on my 47 Dodge 1/2 ton. This was my first stab at something to keep the water from pooling on the cylinder head. Seems to work well enough as it slopes back toward the firewall allowing the water to drain at the rear of the pan. I had intended to add a drain hose to it at some point but that's on my "To Do" list. Nothing fancy, used some residential duct purchased at Home Depot and it has held up well for a few years now.

-

- 3

-

-

-

I use dish soap for the lube.

-

I just got a new spark plug wire kit. How to install it?

Veemoney replied to MarcDeSoto's topic in P15-D24 Forum

Yes, that is basically it. To do a nice job install the plug end and route the wire the way you want them to run and then mark and cut figuring you will loose ~3/8" of length trimming but gain it back with the crimped end. I usually put the boot on before installing and crimping the end and then slide it up. Will work either way. -

Once you install the headlights and bumper that should add some color with the bumpers. Picture shows the red paint in the diamond and stripes of the stainless badge. You could also add some pinstripe around the badge also shown in pic. 1947 Silver Dodge Pickup Truck Custom Hot Rod Garage T-Shirt 47 Muscle Car Tees | eBay

-

I painted a jet boat, car and many motorcycles in the backyard or driveway. Just have to pick your day so weather doesn't work against you understanding you are in Washington. One individual on this site used an inexpensive tarp style carport as his workshop/spray booth and was happy with his results. Check out his booth and work for some ideas on the cheap

-

Not finding the 6 volt electric fuel pump discussion

Veemoney replied to 47Jim's topic in P15-D24 Forum

Here are 3 that I found using the search function. GL -

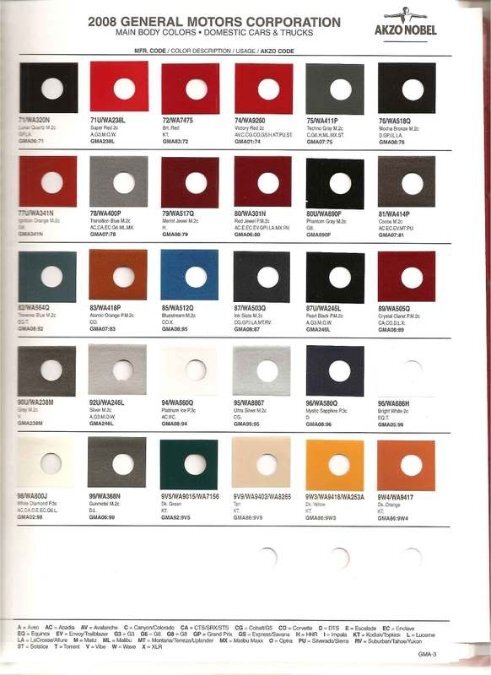

A couple thoughts and keep in mind I don't paint for a living: You have the original paint though thick you may be able to add the recommended thinner/reducer to bring it back to a usable state for filling the scratches. I had some luck with this in the past. Keep in mind it is hard to get an undetectable scratch fill even with the same paint without considerable work. Try it out on a small test spot first. The new paint purchased that is off some you can try tinting it to match. The shop that mixed it could adjust it taking a small sample and adding for example black to darken and compare it to a panel If you brought it to them until they came up with a closer match keeping tabs on what and how much was added. I have cans of old paints and do this myself sometimes for touchups, especially on faded colors. Manually using the books with paint chip colors works well if they have the chips with the holes in the center like the ones shown below. You take the page out of the book and your painted part outside in the sunlight and place the chip page over the part to get the best match comparing your part in the hole to the surrounding paint color in the paint chips till you get the best match. Check it at different angles. If they don't have the holes they never worked well enough for color matching.

-

Knucklehead, Put a good plan together just in case and don't go quietly into the night. I hope to hear some good news soon.

-

I used a sharkbite fitting in a tough spot 2 years ago. Man that is the ticket when you have 1 spot that just won't take. When I filled my system originally, I used a pink RV anti-freeze throughout the whole system so if I decided to not heat the garage I could just close that loop and not have to drain it.

-

A lot of water can escape through a crack that big. Sounds like you had some luck limiting the damage and a fairly quick fix to get back up and running. Successful rebound from a bad event.? When I was a kid we had one of those tub washers with the wringer rollers that would transfer the clothing to 2 rinsing tubs. The back room they were in had no heat so we kept the pipes wrapped. On one occasion we lost a pipe to the freeze. Hot water pipe always will freeze first. The floor was like an ice rink that time with the trapped water. I had to fix it being the oldest boy but everthing was galvanized there so measure and head to the hardware store.

-

My friend had a Raleigh, was a good ride. Bianchi is as you noted fast and great for smooth roads, it came 12 speed from the factory and I have all the stock parts. The Schwinn is still a great all around road bike but back in the day it went off road often. I still ride it or my newest and only other bike below. Specialized 21 speed set up with Gator road tires, fishing rod holders at the rear tire and tackle bag. Probably should look into some fenders

-

res a Schwin Continental I picked up as a teen. If you look at the front neck it is a lot longer than most so I assumed it to be an extra large frame ball buster. I few years back I modified the vertical post tube, dropped the top bar down in the rear and added the pogo spring for the seat to smooth out the ride. The yellow bike is a Bianchi chrome-moly

-

Master cylinder relief port blocked by piston seal?

Veemoney replied to Bryce Mcclintock's topic in P15-D24 Forum

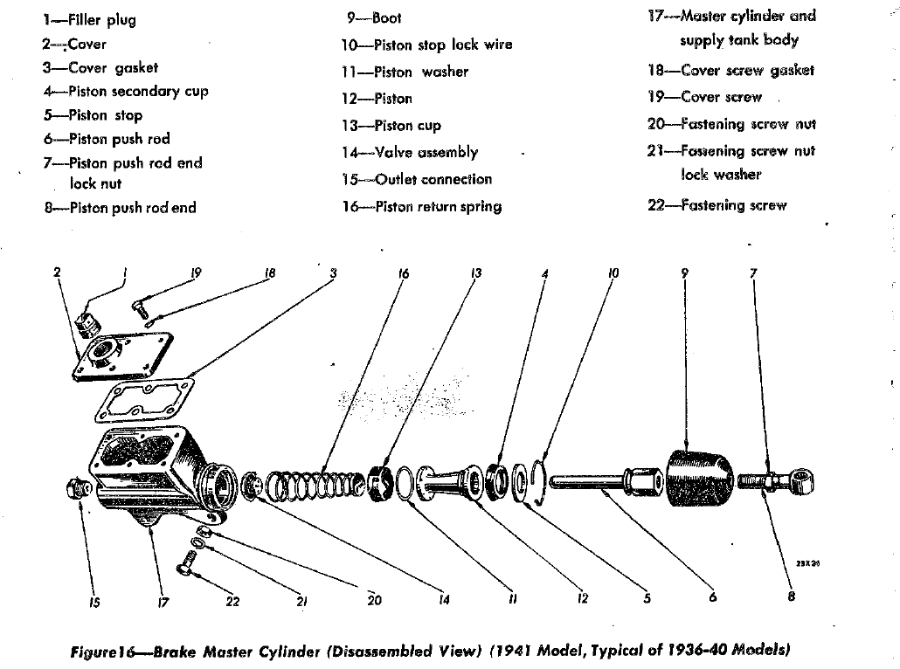

You mentioned you backed off the MC rod to provide clearance. Were you able to pull back the rubber boot on the MC to confirm the piston has traveled all the way back to the snap ring as TodFitch mentioned above. If you check this and it has not traveled back to the snap ring then it could likely be rust in the MC which is common over time with the Dot 4 fluid if it was not changed in a while. Image below is an earlier MC but components should be similiar.

.jpg.44d6ad69526ff35aee4194a5044ac50f.jpg)