-

Posts

534 -

Joined

-

Last visited

-

Days Won

2

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Veemoney

-

You could go look at if a smaller diameter tire and possibly rim would work to give some drop. Those front springs are likely tired, and tires on it now may need replacing anyway. To Snipers point the frame and oil pan will likely limit moving the axle up unless your prepared to notch out some sections to butcher it up. Best to get it cleaned up and running before any major changes if it were me. Keep us posted

-

Welcome to the site. Solid metal and the painted chassis is a great start. The condition of the wood bed makes for easy removal. I just finished doing the wood bed on my 47WC and I started with a sawsall in the middle where you have a hole now.

-

You did good at that price. I recently had a copper drain line start leaking. It was 1.5" copper and was about $90 for a 10' piece. I needed 20' and went with PVC 2 pieces for under $12 instead. Bed frame angle, some are harder than others, some are tough like tool steel to machine and others are soft. You get an idea of what you have by running a file on it or spark test, some can be hardened and folks make knives out of them. That may be what you have. Best practice start with a small drill and not running to fast taking care not to get it hot and work harden it moving up in size from there using a cutting oil or coolant helps reduce friction heat. I do have some small carbide drills but haven't had to use them just the Harbor Freight gold coated which hold up pretty good. I completed a good bit of grinding with carbide burr bits a few months back and still catching metal slivers from it so I don't envy you that

-

Steel like everything else has gone up in cost. I try to keep cost down while not sacrificing quality, call it frugal or cheap but who doesn't enjoy a good deal. If you have time check the following for steel. Search Craigs List and F-book Marketplace for Angle Iron or bed frames. I don't specify size so I can see what is available in my area. Call or visit the local thrift stores to see if they have any bed frames or other items I can repurpose. Last time I checked for a similar size by me a 3-4' stick of angle at say Home Depot or Tractor supply was about 20-25 bucks. 8' at a steel shop about $50 and 20' just around $105. If you weld you can always use the extra steel somewhere.

-

I like it a lot. Can't wait to see once you get it in the truck. Have you confirmed if you need to modify the hood or just run without one?

-

What did you shoot for on compression? I like the modern ring set-up, care to share cost for the upgrade?

-

my memories of Clovis and the drives back and forth from Muleshoe exactly. Along with racer snakes and the large rabbits come to mind whenever that area is mentioned.

- 181 replies

-

- engine running

- engine rebuild

-

(and 1 more)

Tagged with:

-

Getting my 46 WD15 repaired and back on the road

Veemoney replied to lostviking's topic in Mopar Flathead Truck Forum

Nice fix from where you started you got it looking pretty straight. Most expect an old truck to show some character marks if it is a daily driver and are just happy to see it on the road. I'm sure you'll get plenty of thumbs up on it. -

Piece of black PVC capped at the bottom and a clean out in the top, 1.5-3" works fine.

-

As PA suggested wipe it all down and fill the MC again. Get someone to push the pedal while you check for fluid leaks. Not sure when your last R&R of the system was but don't rule out a bad line leaking under pressure when checking the MC underneath the car.

-

Getting my 46 WD15 repaired and back on the road

Veemoney replied to lostviking's topic in Mopar Flathead Truck Forum

Looks blue and shiny to me. The blend worked out well enough. I'm starting some paint patch work on a spot at the backside of the cab along with replacing the bed wood on mine. Hate having the old truck down in the summer. -

If you have the correct 2 wire sender, it will be marked also with 1 and 2 stamped on the top of the sender. Sender is supposed to ground when screwed down to the tank, I recommend running a ground wire from 1 of those screws to ground.

-

Getting my 46 WD15 repaired and back on the road

Veemoney replied to lostviking's topic in Mopar Flathead Truck Forum

Sounds like you have a plan. I'm familiar with metrology equipment and software. My thought was the manual contour gauge depending on the size of the individual slats or needles is directly related to your accuracy in the tight radiuses, that may make it tough to get an accurate curve fit along with its true start and stop for each curve when they go from convex to concave. It may get you close enough, and I'm Interested to see how it goes. GL -

Getting my 46 WD15 repaired and back on the road

Veemoney replied to lostviking's topic in Mopar Flathead Truck Forum

Progress is good. My thoughts are no need to get to bent on perfection if down the road you will redo the paint. Nice enough is good enough for now. Have you considered making a mold of the floorboard contour inside and out That should help with measuring if they will use a scanner, arm. There are some expensive kits but as long as you have no negative draft areas you could use some play-do on a small section of each. Then some light grease or oil to help with release in that section and bondo filler to capture the contour. A 1" section should be enough to allow the 3D measurements. Not sure if that would allow you to get the floorboard mounted earlier and tweak and paint inplace? Just thinking of options. -

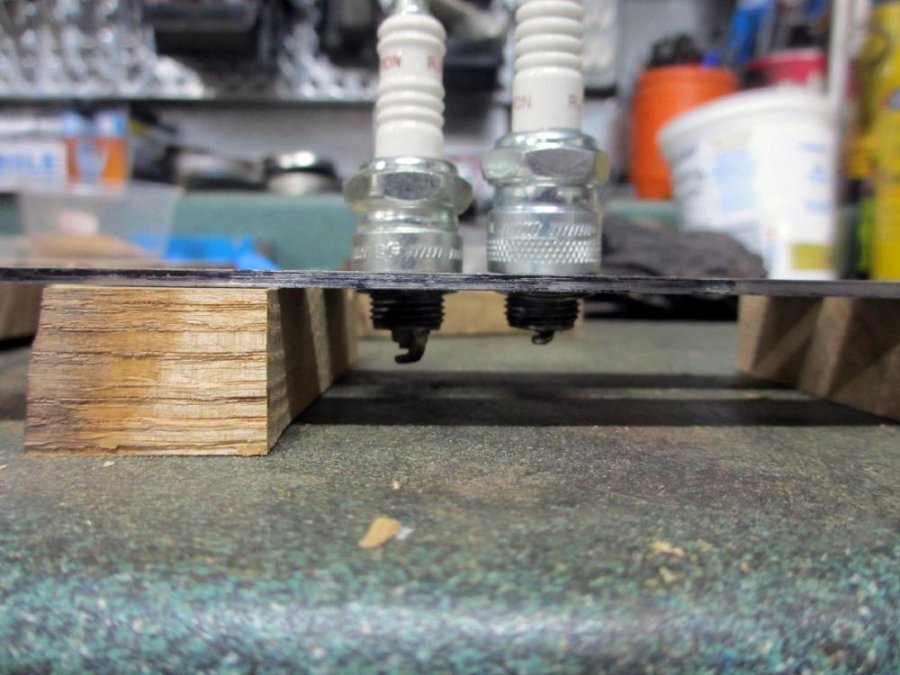

Be careful with the projected tip plugs. I picked up a few boxes of these some time back on the cheap. I use the J12C in a number of cars and motorcycles. In my flathead they were to long and I did not have enough clearance between the valve and plug to run them. Roughly about .090" longer from the shoulder to the tip than the RJ12C. I show the RJ12YC on the left and the RJ12C on the right. Also my head is shaved about .080".

-

Here is how I tested the set-up out of my 47 WC. Below the testing info is the proper hook-up of your gauge according to the Motors Manual. It does not show the gauge needs to be grounded and during my testing I did not ground the gauge but it doesn't hurt anything if you do. It is important that the gauge sits upright as it would in the dash for balance. Also note the gauge does take a bit to warm up before the needle moves so don't expect it to jump when you give it power. Make sure the sending unit flange is level and grounded to the battery. I had a tough time getting a good ground at the flange. Carefully clean the points of the gauge by pulling bond paper through the closed set Gauge does not require ground but should be upright as if it were in the dash so the balance is correct. Set float on gauge up near the position it would be when the tank is full Use jumper wires to connect numbered terminals first Hook up power with jumper wire from 6v battery to Ign SW terminal on gauge. Give it a minute or 2 to warm up and start moving to full if it moves great If not check sender ground and try it at a couple positions mine was touchy Move the float 1/4 inch to see if this gets a reaction Next position the float as if the tank was empty. You can measure the gas tank from the flange to the bottom of the tank to get the position. and see if the gauge responds correctly. You can hook up an ohm meter to terminals 1&2 and check to see as you move the float arm if the resistance changes. it should and if not the resistance windings could be dirty, distorted or not making contact with the float arm which takes the current to ground. I disassembled my sending unit and the windings were full of crud as well as distorted. The arm contact needs to rub lightly on the windings, mine needed to be bent out slightly to make contact. Once cleaned adjusted and assembled it worked.

-

1941 Dodge WC and Horse trading

Veemoney replied to 9 foot box's topic in Mopar Flathead Truck Forum

Seems like a truck with plenty of character and being it is a runner, well worth the trade and effort to get it the way you would like with the parts you have on hand. Looking forward to seeing it's progress if you post it. -

Getting my 46 WD15 repaired and back on the road

Veemoney replied to lostviking's topic in Mopar Flathead Truck Forum

It looks good and straight and you got paint on it, that meets your goal for now. Time to get the fender and floorboard done before it gets to hot to paint. Most painters see area defects in their paint jobs where others don't. Another thing that helps is when it is assembled. The more pieces you put on the less you notice any particular area in many cases. Right now your looking at the repair on the door and lower but once the fender and floorboard is painted and mounted you won't notice it as much with other parts mounted is my guess. -

Westleys Bleche-wite. I used this product a lot and it works well. The whitewalls on motorcycles can get stained and brown over time. Spray this on and let it set for 10 minutes then scrub it off. Stubborn stains I use it with an SOS pad and never any issues just keep whatever your scrubbing with clean or you will rub dirt back into the tire. After cleaning with this I use a tire dressing to finish it off. Back tires on a Harley see lots of oil. They changed Westleys to Black magic brand and it is not as good from what I hear which don't work for crap so make sure you get Westleys if you can find it

-

Just finished dressing and checking the gap on the points in my 47. I heard good and bad on the Pertronix ignition system and have stayed clear of it. I used a number of these type modules on motorcycles with similar results. I found going back to the stock point system eliminated those issues especially on the old kick-start bikes where you pay with sweat equity. Hope it works for you as well as it did for me.

-

Nice turn-out and plenty of good Iron

-

Plenty of info in the link below on fuel gauge/sender problem & testing.

-

Getting my 46 WD15 repaired and back on the road

Veemoney replied to lostviking's topic in Mopar Flathead Truck Forum

Nice to see some color on it. Progressing but I can't tell how well it matches to you get some shine to it. -

Here is a wall hanger from the Midwest. Some say a leaking seal got the best of this guy and he just started cutting. Or maybe just some other craziness., Marketplace - 48 Plymouth Coupe 1/2 Car Unique Advertisement | Facebook

-

I updated the link in the previous post with the picture. should be good.