Leaderboard

Popular Content

Showing content with the highest reputation on 02/03/2022 in all areas

-

Thanks for those helpful scans of tech bulletin s. Heres a little more information on sourcing the fluid drive oil. For starters, i kept wondering what that DTE stands for. Turns out it means dynamo, turbine, engine. After reading your previous posts and that great seminal post (I forget his name this moment) we can sum it up to say we need an oil with a 32 iso and good anti foaming additive. Turbine oils are a good category. So,prompted by not wanting to buy a 220 dollar bucket, i did some deep digging and found a few cheaper alternatives that still satisfy our requirements: Mobile DTE light circulating oil ISO 32. ( currently 155.87 on ebay) DTE 24 is iso weight 32 while DTE 25 has a iso of 46 Shell turbo oil T 32 115.51 Chevron Regal R&O iso 32 98.28 Sunoco Sunnis turbine oils 932 64.31 At petroleumservicecompany.com Phillips 66 turbine oil 32 79.40 yoderoil2 points

-

they are pipe plugs (NPT) I believe 3/8x18 NPT any parts store should have them. FWIW 3/8 pipe is measured ID but has an OD of .675, where as a 5/8x18 NC bolt is .625 OD the smaller one is either 1/8 x 27 NPT .405 od or 1/4 x 18 NPT .54 od NPT Nominal(national) Pipe thread2 points

-

Actually second drive as I had my ‘51 Dodge out last week. However, I had my ‘53 Plymouth Belvedere out today for the first time in 2022. We had snow and cold on Monday but another Chinook (see earlier post) arrived and it was 11C (52F) today. Roads were great. It felt a little cool as it was quite windy but the car has a great heater. The 4-Door ‘53 Belvedere was a Canadian only car as far as I know. This one is a survivor including original paint. It has a few scratches and some gravel rash but is pretty good for 102,000+ miles. It had rings and the valves lapped about 30,000 miles ago and still runs strong and uses very little oil. I’ve owned the car since 1975. If you look above the roof in the second picture you can easily see the Rocky Mountains. Although I live on the prairies of southern Alberta, the mountains are only about 80 miles away as the crow flies.1 point

-

Do those specs really say that the kick down should only be used at speeds under 35MPH?1 point

-

I would be inclined to focus on the location given on the build card. Is it possible that the T&M Garage in Miami, AZ was doing business as Frisco Motors (or vise versa)? If so then there should be some legal record of that either in microfilms of old local newspapers (legal notices) or with the city, county or state (not sure how Arizona deals with "doing business as" paperwork). Microfilms of old newspapers should also have any car dealer ads. So regardless of the entries in the old business directories if a dealer was using Frisco as a name there ought to be an ad in there. Copper mining was a big business in Arizona in that era so I would not be surprised if the Miami-Globe area was more populated and wealthy back then that they are now and could support at least one daily newspaper.1 point

-

If this were a high RPM, high performance, engine it may make a difference. But I wouldn't expect you to gain enough performance differences to warrant the added work, compromising the integrity of the valve guides in the process.1 point

-

Did the Chrysler engineers do this in any of the later blocks? This engine was manufactured and refined over some decades. If the later ones don't have this adaptation then there's your answer. Either detrimental or offers no benefits. Just my thoughts anyway....1 point

-

FWIW; To fill my fluid drive I used a squeeze bottle that has a nozzle on it that I attached some clear rubber hose onto. It was originally intended for use during one of the steps to fill cracks in basement walls (as if that info helps). It only holds a pint of fluid, and only flows so much, so it took a few refills and some time to finish with the fluid drive, but I didn't spill any oil when filling. I use it whenever I need to fill something that has difficult to reach fill holes. Yes, draining made a mess, don't think that can be helped much.1 point

-

I would actually say that pump puts out too much pressure for a single carb, you only need a 2-4lb pump or you definitely need to install a fuel pressure regulator. I ran an electric from day one in my truck, and yes lots of good help above, in regards to a good pre filter and also make sure the pump is as close to the tank as possible, as the like to push, not pull. I did run just a straight key on with a fuse, so it did run constantly in the on position, but I was 12 volt and had a ignition with an accessory setting to run anything I desired without the pump going, but your ideas are a safer way to go.1 point

-

While I do understand many have installed a electric pump in the system just to prime the engine before starting ... seems it would be a handy feature to have available. After prime they shut it off and run off the mechanical pump. I dunno, I bought a mechanical fuel pump from Napa a couple years ago. If truck sits for a few months, it takes a bit of cranking to prime ... but it always does. So far. I wonder if too much fuel pressure is not actually crap from your old tank disintegrating & causing the floats in the carb to stick? Would a new tank, fuel pump, carburetor tear down and clean correct your current problems? The return line you speak of sounds like a good idea. I think Uncle Tony explains it really good here.1 point

-

Maybe it's just me, but I get the feeling that this engine is going to fight you the entire way. Someone taught you patience. Of did you just settle down with age? I'd be tempted to melt that block down by now. Just to get even. Lol.1 point

-

1 point

-

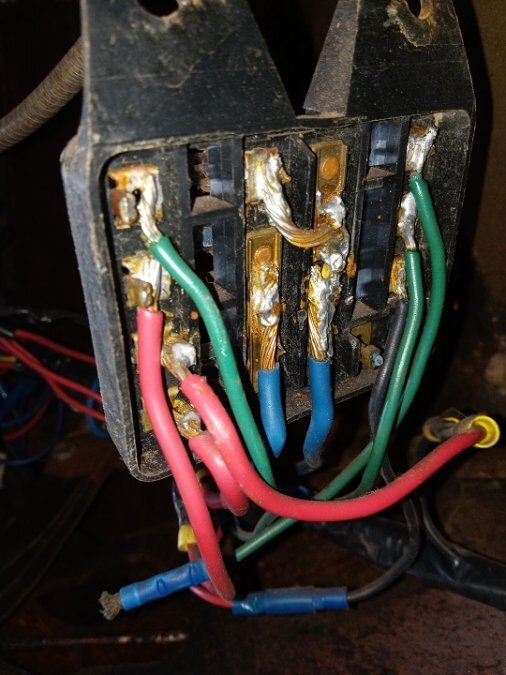

Addressing the comments all Willy Nilly. The car has been entirely rewired with radio shack grade wiring and (Poorly applied) crimp on connectors. Who ever did the soldering was of questionable skill. I replaced the fuse box because the mountain of solder on the back was grounding against the firewall. Much to my dismay, there still appears to be a short in the system. and who knows what connections are valid? The wiring is beyond saving and needs to be replaced. That is the reason behind my having a new wiring harness installed. I have already upgraded to 1/0 gauge battery cables. Starter wires. and had the starter professionally rebuilt. Considering replacing the starter solenoid as the starter drags with anything less than 12 volts applied even with a fully charged battery. so I suspect someone slipped in a 12v solenoid. I plan on going to a 12v electrical fan and LEDs as I have heard bad things about 6v varients. This will remove strain from the engine (The electrical fan alone is worth upto 30 horsepower in parasitic drag. On a 100 hp engine that is near a third of the engines power just turning the fan) and hopefully promote efficiency. Engine speed. I dont have a Tachy-o-meter so I am unsure what the engine RPM was where I tested it. I did bring the RPMs up slightly with the "Throttle" control. I will test again later with higher RPM. I apologise if my comments are unclear of poorly formed. I am a stroke survivor and sometimes find it difficult to put my thoughts into words.1 point

-

The charging system as engineered is there to replace power expent by the battery. If your battery is new and fully charged, and your car starts easily with just a few revolutions, there is no charge being called for, so generator output at idle would be near nothing on a properly regulated system. At full potential the generator can probably put out 7.5 volts give or take above idle. But this would only be needed with a marginally healthy battery and a high demand. Doing the grounding the field test, you should see a full charge via the Amp gauge, but increased rpm is needed.1 point

-

The tappets I put in my 230 were probably new (NOS) at the time, and I think I can put my hands (and micrometer) on them when I get back in town at the end of this week. I'll try to remember to do that. I expect they will be somewhere in the range of 0.6235 - 0.6240, as that's what the manuals all state they should be for new parts. I can tell you by memory that all the unused oversize tappets I've measured (several dozen of them) were right in the range where they were supposed to be for new parts, and I seem to recall that most of them were at or very near the bottom of that range. So your measurements for your tappets (0.6235) sound just right for standard size tappets, although at the very bottom of the range. It sounds like they have very little wear.1 point

-

I replaced the generator on the 47 P15 with a 6 volt positive ground 60 amp alternator about 6 months ago. The new alternator and universal bracket cost about the same as rebuilding the generator. Then I would have had to address the voltage regulator. It was cheaper to go with the alternator. Now I don't have to worry about it. Still have the generator and it works. The wires inside are burnt and the front bearing needs replacing. I don't have the knowledge to remove the front pully without breaking something. You don't have to change the pully on the water pump. Just order the new alternator with the correct wide pully.1 point

-

Ive met a few interesting people, but you exceed all of them. We will have to take a drive with our two cars when I get mine on the road.1 point

-

1 point

-

Great pics. Would be a dream of mine to visit that big country in a post covid world and me in good health. Something to aim for...... Thanks for posting ?1 point

-

RE: Brent It has been noted that when he attends the BBQ (on Brandt Road), his name temporarily changes to "Brendt" in the spirit of congruence.1 point