Leaderboard

Popular Content

Showing content with the highest reputation since 04/12/2024 in all areas

-

6 points

-

My Great Grandfather, and guessing my Great Grandmother with the '55 Dodge (I'll be inheriting this summer) and what I believe is a '55 DeSoto. The truck was my Great Grandfather's then my Uncle's, and then my Parent's, and soon to be mine. My Dad just told me that he is getting too old to work on too many toys, and he is giving it to me. It is in a little worse shape than here, but pretty much original. I'll post pictures of it's current state, in the correct area, when I get it out of the barn, but from what I recall it definitely will need a gas tank and fuel pump, amongst other things.5 points

-

4 points

-

I have an admittedly tight focus on the KT Keller cars, so that's what I research and play with. It's all about having fun after all and those are the ones I like. I am a huge fan of Overdrive transmissions because they don't really change the charm of the cars and actually add to it. When you put one in your car your speedo will be off at all speeds because the speedometer pinion gear was selected for a 4.1 ring and pinion. The good news is you can swap out the pinion from your old three speed to the O.D. and all will be back to normal ( assuming your speedometer doesn't need service ). But what if you changed the rear end ratio or the tire size? I don't advocate changing rear axles because I don't see much to be gained there. You can easily change the differential carrier ( aka 3rd member ) in a Plymouth if you want another ratio. Where I live there's lots of open road with highway speeds of 55 to 70 so optional ratios, tires and O.D. go well with my Plymouth. My P17 Coupe came with 6.40-15 tires ( modern equivalent 195/75/15 ) and a 3.73 final drive ratio so the speedometer pinion would be a 17 tooth gear ( p/n 652-848 ) for an example. Chrysler designed the pinions to use the same 6 tooth gear on the output shaft so you only need to change one gear to correct the speedometer. One thing you find out right away is selecting speedo gears is not an exact science. You can get close and you might hit it right on the button but you more likely will be over or under by 2 or 3 mph. That's why the Highway Patrol has an enforcement tolerance. So let's look at tires first 6.40 15 = 195/75/15 standard tire for a P17 6.70 15 = 205/75/15 standard tire for a P18 7.60 15 = 225/75/15 an optional size tire Final drive ratios 3.90 very common on long wheelbase cars 3.73 standard ratio on many optional on all 3.54 optional Chart of ratios & tires vs speedometer pinions 3.90 6.70 15 17 tooth pinion 3.73 6.40 15 17 tooth pinion 3.73 6.70 15 16 tooth pinion 3.54 6.70 15 16 tooth pinion All 7.60 15 16 tooth pinion So you can see you're not going to get an exact reading but you can get close enough to avoid a ticket. The part number for the 16 tooth pinion is 652-846. I have found that if you have the number for an obscure part the parts house will look to find it in their inventory but they are likely to blow you off if you just say "I need a 16 tooth speedometer gear." Happy hunting!3 points

-

Yup, between 65 and 70. When I had earplugs in, I tended to go faster, haha....3 points

-

with all due respect, items needed to exact this repair is common at any hardware store or big box building supply, TSC etc that one can walk in, get the item, pay and immediately got to work repairing. While mail order from many companies and sites are MOST BENEFICAL when you dealing/needing bulk quantity, I have to state IN MY OPINION this is not the best option for this particular thread. Heck if it boils right down to it, one can find where a person may park a chevy/gm product and find where these have fallen off and free for picking up. Ok so the last part is a joke...maybe real at times, but still intended as a jab/joke.2 points

-

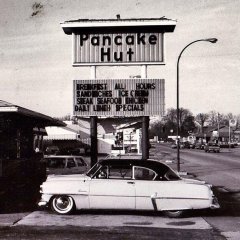

SURVIVOR: saw this Dodge between Lake Graham and Newcastle2 points

-

Likely not a "factory" accesory, more likely a mass produced catalog or dealer option, these aren't listed in the Accesories section of the manuals.2 points

-

Just use a torch to get the plug red hot....that oughta bust the rust loose................. 😲 🤣2 points

-

John-T-53, thanks for all the pictures. I’m sure a lot of us would like to make the tailgate and BBQ. Just not practical for most. However, your pictures really let those of us who can’t make it live vicariously through your pictures. The most and best of the bunch! I would love to bring this old girl to the BBQ but it involves border crossing (not a problem with a passport) and a three, four, or possibly five day drive depending on weather and lack of problems. It doesn’t have a tailgate but does have the next best thing…..a big butt trunk.2 points

-

you may be onto something Sniper, I am going to say a rolling wheel gathers no red paint.....2 points

-

See now a song comes to mind I see a black wheel and I want to paint it red Apologies to The Rolling Stones2 points

-

I use the in my opinion a lot because most of my unsolicited comments are just that, an opinion and in no manner saying good bad or indifferent....but just as I see it. The fact I will then state the whys and wherefores of my opinion is to say that it is not just a whim or silly notion and give some background, color and size ratio etc...technically I could care less one way or the other what anyone chooses to do as it is not my car no more than if a person likes or dislikes what I do with mine. Big hobby folks, I will admit at one time it would rankle me see what some folks may do...but hard lesson to learn is JUST NOT MY BUSINESS....the red wheels, there is NO WAIVER here......lol2 points

-

•pinched tube on intake manifold appears to be the vacuum source for the vacuum windshield wiper motor •intake manifold appears to have a partial PCV setup •spark plug wires appear a little on the long side...universal sets with 90° boots can be sourced2 points

-

I dunno, call me a snob but I's rather spend my tool money on real quality tools. Like Starret or Mitutoyo. Yeah, they cost a bit more but are definitely quality tools.2 points

-

I haven't posted in a while, but there is at least one other thread about this car. I have owned it since December 1989. It is my first car, got it when I was 17. Two years ago I had a fire under the hood. Not big enough to cause a lot of problems, but enough that I decided it was finally time to do a mostly full "restoration." I disassembled everything, stripped most of it, then took it to a good paint shop. Picked it up last December, and now have it mostly put back together. I have driven it around the block, and hoped to drive to my local glass shop to have the windshield and rear window installed professionally. When I talked to him about doing the job, he seemed enthusiastic, and knowledgeable. I dropped off all the parts(windshields, weatherstripping, and stainless) yesterday waiting for a call telling me to bring the car. Went by the shop this morning and he told me he wasn't sure how to do it and afraid to try. I've got the manual and instructions, and have read everything about it, and now have the weatherstrip installed on each of the glasses. Question for anyone who has done this on a 53-54 car. Do I need to put the stainless on before I rope the windshield(or rear window) per the manual? I've built a stand to hold the window vertical, which makes it a bit easier, but it's still quite difficult to get the stainless in place. How hard is it to install the stainless after the windows are in place? Thanks for any info.1 point

-

The engine pictures are current, but it's not done under the hood. Planning on using a fuel block and hard lines. I set that up before I was able to find the right fittings to use on the hard lines. The filter is in a temporary position. As an update, I have been able to put some of the stainless on the strips that are on the glass. Slow going and hard on the hands.1 point

-

Here's a possibility. I wonder if the Dodge rod bolts have threads that are cut, while the Pontiac rod bolts have rolled threads. Rolled threads are formed by dies that displace (smash) the material into the shape of threads, without removing any material. This results in threads that have larger outside diameter than the adjacent shank section of the bolt. On the other hand, cut threads are just that - they are made by cutting material away to achieve the thread shape, so the threaded section diameter will not be any larger than the diameter of the adjacent shank. It's kind of hard to tell from your photo, but it looks like that might be the situation. If so, then accordingly, the Dodge rod might be made with smaller bolt holes to snugly fit its cut-thread bolts, but the Pontiac bolts, with their rolled threads are too large to fit. I have a couple of Dodge 230 flathead rods at home, along with their bolts, and I can tell you that the threads in those bolts have the appearance of being cut, which surprised me, since I have seen other Dodge flatheads that have the appearance of having rolled threads. I have no reason to think that those are not the original bolts, and perhaps they were early rods that used cut-thread bolts. I could take some measurements and photos of those rods and bolts some time in the next few days and we can see if they match the dimensions of your bolts. We can also see how thin my other rods are (the ones that used rolled-thread bolts) in the wall between the bolt holes and the bearing saddles. I remember them being pretty thin. We might find that you have room to ream out the bolt holes in your rods to accommodate the slightly larger Pontiac bolts, or some aftermarket bolts, such as those from ARP. From the strength and durability (fatigue) standpoint, the bolts containing rolled threads are very much preferred. I believe virtually every manufacturer uses those types of rod bolts nowadays and have for many, many decades. I remember seeing early rod bolts from other engine makes that used cut-thread bolts, but I think most everyone moved away from that type of design long ago.1 point

-

The drag links I'm familiar with had one end with cotter pin and slot cut into the end that a wide screwdriver blade or drag link socket fit into for adjusting and the other end would be a tie rod style. If the end that has play is similar to the tie rod style Sniper put up, replacement is your needed. If the other style, I believe some replacement sockets and cup, spring may be available. Post a pic of the bad end if you can.1 point

-

I think I’m a year with the electric 6V boost pump in Chrysler. No complaints. It will push through vapor lock. I have done so with it. I do like it spliced into ignition switch (wire to fuel gage). Then I cannot leave it on when I park the car. I have left the heater blower and AM radio on by accident. They were wired to direct non-switched power sourced. Dead battery the next morning. A sure way to ensure premature death of an otherwise good 6V battery.1 point

-

Ok. Here is the Summit Racing listing of electric fuel pumps (2000+ hits related to fuel pumps): https://www.summitracing.com/search?SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=electric fuel pump Most of the pumps have fewer than ten reviews except the......wait for it.......Carter pumps, the most common which have hundreds of reviews averaging at least 4.5 stars. Here is the search return for just Carter pumps and related stuff: https://www.summitracing.com/search?SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=carter electric fuel pump If you want to look elsewhere you might check into Bosch, AC Delco, Airtex and Walbro but I have no personal experience with them. I've run Carter rotary pumps on two vehicles over the past 15 years with no failures. But the one on the Plymouth might die tomorrow.....1 point

-

Hopefully this post skirts the rules...i have been unsuccessful finding arm rests. My last hope is that someone can send me one for templating and I can ship it back. A friend suggested making them out of wood. But the shape is fairly complex and I'm not a good woodworker. If anyone has any other suggestions, my ears are open. Attached is a pic i found online. Thanks, Andrew1 point

-

1 point

-

for the most part our Home Depot, Lowes, TSC and local hardware stores carry a fairly good selection of hardware....NOW THEY DO NOT have everything....and SAE fine stainless does fall in that DOES NOT HAVE But I do have a company locally that has a better selection and prices and will sell 1 or a thousand with the same courteous service. Cannot say that for a certain main stream specialty store that by the way went tits up in this area due to the poor management and over the top gouging prices. For many folks the TSC by the pound hardware is a pretty good deal when you look at. I was not saying ordering on line was out of the question, sometimes it is the only means to an end on some very special hardware......and I have ordered in my fair share, I do however give the locals a chance to fill the order first so not to have stop/delay a segment of a build/process. Common sense stuff folks, nothing more.1 point

-

Last year redid the wood bed of my truck. Some of the carriage bolts and nuts I was able to reuse by just a quick brush and repainted them (the heads only) with the POR15 Black Glossy Paint. I used it on my bed strips as well and all these parts were steel. I looked online for hardware, E-bay, Ace, Grainger to name a few after taking inventory on what I needed that was not salvageable for hardware. I found the best prices for what I needed at Menards online. Based on prices everywhere I decided to go with hot zinc dipped hardware and added the sizes for carriage bolts, washers and nuts to my online cart. Menards will pull your order and have it waiting for you at the pick-up counter but they charge extra for that, so I printed my online cart list and went down and grabbed them myself.1 point

-

1 point

-

and as such when it is no longer original (as in not broken on assembly) toss these for some fresh hardware preferably stainless steel, BUT if you are a purist, and must stay with the stock stuff break out the molasses and let the big dog eat, weld the breaks, chase the threads and when completed apply for social security......enjoy a few pancakes while soaking your nuts and other hardware1 point

-

well, .008 is within factory specs..just at the upper end..you can ride as is..and monitor this and address should it change...or go the added step to reduce this now while you are working this issue. The problem with many values and ideas expressed here is they do not reflect the values and standards of the engineers and it was well known, Chrysler aligned the company with the best engineers out there. Some folks just like to yell out, close enough and throw in the towel as it may be labor intensive.1 point

-

So in 2005 I bought 4 uniroyal 205 75 r15 radials from Walmart,at 52 bucks with mounting balancing and unlimited road hazard warranty, mounted on new 15 inch aftermarket rims,if memory serves I ran them for 2 years. They were a bit short in diameter compared to the 6.00x16 original size. In 2007 we decided to drive to Charlotte, NC to attend the POC event there. In preparation for the trip I mounted a pair of 225 75r15 on the rear to drop some rpms going down the road. I put the 205 take offs in a black contractors trash bag and stored them under my work bench in the garage. Three years ago, I replaced the fronts with the stored pair. After about 45000 miles the fronts showed equal wear, at about half tread depth, no scalloping and no visible checking or bulging. The reserved set still looked new with 80 % tread and no visible faults. They have about 9000 miles on them since re mounting. The rears now have about 60k on them. They show as good condition with about 1/2 tread left. They came from Pep Boys and are what was then their Cornell house brand, according to the paper work their out the door price was 115 for the pair. Looking back, my father would be proud of my parsemoney in this matter. Others would call me a cheap SOB. Whatever, I think, I will let them ride for the season. Looking on line, both the 205 75 and 225 75 sizes have been relegated to trailer sizes through tegular retail sources, so not good news. I loath the thought of dealing with Cocker...1 point

-

SURVIVOR: saw this Dodge between Lake Graham and Newcastle1 point

-

My point was that O.D. cars had final drive ratios in the neighborhood of 4.10 ( some places say 4.30 ) and the speedometer pinion that went with it. Thus no matter what gear you were in the speedometer would read incorrectly. Which is true even if that line was unnecessary ( my bad ). All transmissions that have speedometer gears measure the driveshaft rotation speed. Some exceptions are for example VW Beatles measure left front wheel speed and SAAB 99/900 which have the gear on the differential. You can buy speedometers that measure GPS signals and the are dead on with no connection to the wheels or driveshaft but they are really pricey. What I was trying to get across was that you can correct your speedometer reading with an easy swap of the speedometer pinion gear. If you want an O.D. transmission ( R10 G1 ) you can change the speedo pinion with the one in your old transmission. However if you swap differential carriers to get the ratio you want, you need to score the speedo pinion from that car. There is an exception here in that the 3.54 ratio is usually in an automatic transmission car and that speedometer pinion is not the same design as the manual transmission. Slight changes in tire size can get you closer as well.1 point

-

Been a few years since I replaced the glass in my '48 P15 front door but I'm pretty sure I recall that piece slips off the stud. Most likely yours is rusted to the stud, may need some solvent and persuasion....maybe some heat?1 point

-

The pilot bushing is an oilite bushing DO NOT USE SANDPAPER on oilite bushings DO NOT REAM an oilite bushing READ https://oilite.com/best-machining-practices1 point

-

Weren't the new motors stamped right after they bolted them to the frame (so that you have the matching numbers on the motor and the frame)?1 point

-

That number doesn't come up in my 51 Mopar parts book so it looks like your 49-50 only is right. I just inherited a bunch of Dads books I'll see if he has a 50 Plymouth parts book1 point

-

"OD" as he's known, about to head out in his '93 Cummins, back to Escalon. There was also a similar or equal year truck that showed up, a dualie (no photo, unfortunately). The two owners connected, and an exchange of parts is planned in the near future. Heading back down the 101 for the return trip.... F the 5.1 point

-

We always get at least one or two orphan makes at this event each year. Jim's brother's silver Kaiser showed up again, and below is Charlie's '55 Nash, with body design by Pininfarina of Torino. I really enjoyed this car. AMC's thrifty 195-6. Note: no intake manifold. The exhaust "manifold" is just a steel pipe with cutouts bolted to the block. "Brendt" strikes a pose. Best of show award Really hope to see this COE on the road next year! The aftermath of Joe's Motorhome debacle on Sunday.... photo credit: @48Dodger1 point

-

1 point

-

1 point

-

For several years I was hounded about getting a dog. Pun intended. Didn't want to do it. Not because I don't like dogs but because I do like dogs. I get too attached. I finally relented and on a Saturday morning and we took off on a two hour ride - one way - to pick up a basset hound puppy. That was eight years ago. Daisy is my buddy now. She hurt her back a few days ago and it was after hours. And the vet we usually use was going to be out of town for the Easter weekend and wouldn't be back until Monday. So I found an alternate local vet and took her in yesterday. OK I'm almost to the point of this post. I expected it to be a thousand dollars when I went back to pick her up. But I'll pay that - I don't skimp on medical stuff when it comes to people or pets. That's just one of the things that has to be done. BUT the bill was only 500 dollars - still not cheep. Now being of the old car mind set that means that I have 500 dollars left over to get some parts for the 47 P15. Not sure I'll get away with that😂 PS: I expected spinal problems in an old dog. But turns out it's only a pulled muscle. Really good news.1 point

-

Almost certain that was a 218 car.. Once you "rod" it go all the way. But for sure get you a service manual for all necessary specs and diagrams1 point

-

The factory front plate mount for our D24 is similar to what Eneto-55 shows. It clamps onto the front of the bumper via one of the bumper bolts. Which just happens to be in the center of the bumper. For consideration, Maine requires two license plates, too, but allows for the use year-of-manufacture plates for antique cars. Maine only issued one license plate in 1948, so it is legal for us to display only the rear 1948 plate. The car does have to be registered as an antique, though. Might that work in Idaho?1 point

-

Ray, where is your original post? This one? Just reply to it with all your updates.1 point

-

Thanks sniper and DJK for digging up info. And here's my two cents about electric pumps. First off, I love 'em! And here's why: When one of my vehicles has been sitting for a long time, I don't have to waste precious battery capacity cranking the motor to get fuel up to and in the carb. I also put a electric switch in the supply line to the pump so that, in Autumn when I'm putting cars to sleep, I can turn off the switch and keep running the motor until it dies. This does a good job of draining the carb, reducing varnish build-up. Yes, I could use a gas additive (and I often do), but with lots of cars and equipment, and full gas tanks in each, that's lots of Stabil! And, in regards to leaving the mechanical pump in the line, I've done that numerous times, but one thing to consider is this: if you do that and the rubber diaphram of the mechanical pump fails, you'll get raw gas going into your crankcase and diluting your oil... and not know it!1 point

-

Second that thought. Never saw a plug blow apart on a flathead till I had three Champion plugs do it over two days. Switched to AC and never had another issue, same with the NGK which I also use in all my small engines, ATVs and motorcycle.1 point

-

Champion spark plugs...ran them for years in everything from V8s to single cylinder lawn and garden equipment...then in the late 90s, they needed to be replaced more often from electrode wear, and by the mid aughts they were blowing apart in the small engines, larger engines were fouling and hard to start in cold weather. Switched to AC Delco on big engines and NGK in small and haven't had a lick of trouble since.1 point

-

I looked at the license plate mount this afternoon, and tried to get the old plate off to be able to get a decent picture. It isn't quite as I remembered. The center (vertical) bracket hooks under the bumper, and the center bumper bolt passes through it, securing it to the bumper. Then there is a horizontal c channel bracket fixed to it (welded?), with long slots, to accommodate various mounting points for the different shapes of license tags used during that era. This is the best I could do, as the tag mounting bolts are rusted fast, and just turn on the back side. (I could have broken the tag off, but didn't want to ruin such a perfect license plate.... )1 point

-

1 point

-

Well, same here, the pup eventually become family and usually cause less trouble or heartaches. My little dog asks for nothing, gives all. I have had a number of dogs over the years and yes, they all been good animals. But this little guy, he is very special. He was 14 last Christmas...I have had pugs since early 80's....they my favorite breed. Here he is doing his Don King impression.1 point

-

I remember doing the exact same thing (finger tightening lug nuts) on my first car. Got out of the driveway and the tail gave a little wiggle, which I thought was odd. made it another 300 yards and the rear gunner side of the car suddenly dropped. I softly applied the breaks while looking over my shoulder twords the trouble area to see my right rear tire bounce passed me, over q guardrail and into a blackberry bush. After an adventure extracting the tire. I could find nothing broken and realized I had not tightened the lug nuts. I ended up buying a new set of lug nuts to replace the ones that fell off. So dont feel like you have a monopoly on dumb mistakes. We all do it!1 point