-

Posts

2,558 -

Joined

-

Last visited

-

Days Won

83

Everything posted by Sam Buchanan

-

It is very possible. If you are in a neighborhood you must control the overspray otherwise you might end up paying for paint repair on several vehicles. Not to mention the way you will be accused of jeopardizing the health of the chillrun......yes....you could become an infamous guy in the hood.... ?

-

Where is the electric pump located and is it the only pump you are using? The pump, especially if it is the only pump, needs to be located near the fuel tank so it is pushing fuel. If it is located near the engine so it has to pull fuel, this is more likely to result in vapor lock issues or introduce air into the fuel line (which reduces fuel pressure) if there is a tiny leak at a fitting.

-

Marc, I am assuming you are using the same paint brand/system for the primer and color finish. That is very important as modern paints (they are actually very sophisticated "finishes") are designed to cross-link with each component. I suggest you get the technical docs for the system you are using and follow the procedures detailed.

-

Looks like it's time to weld up the hole in the rod and redrill it. I've made pins out of bolts that have shanks long enough to cut off the threads.

-

I don't have definitive answers, but I can speculate with the best. I suspect that under the right (wrong) conditions the fuel begins to vaporize in the carb soon after a hot engine is shut down. This occurs because cool fuel is no longer flowing into the bowl and temps rapidly ramp up. The vapors have to go somewhere so they exit the carb and begin cooling back into the liquid phase. The liquid fuel then puddles in the intake manifold and we have a scenario where the air/fuel mixture is incorrect until enough air is drawn into the manifold to begin evaporating the the puddle. This causes longer cranking than we see when the puddle isn't there. Winter gas could make this situation worse since it boils at a lower temp (higher vapor pressure). There have been many times with the P15 and other carbed cars that I've noticed fuel odor after a hot shutdown and this is a sure sign of fuel boiling off in the carb (assuming there are no leaks). The reason the car starts better after an hour is probably due to the puddle in the manifold having evaporated. I don't have much to add concerning the lack of fuel in the filter unless it was also hot enough to promote the gas boiling off as vapor. Since it has no place to go except into the carb it just makes the problem worse. It might be that you had a "worse case scenario" where high temps and a very "winterish" blend of gas came together. But I'm just speculating.....

-

You seem to be missing the key element we are all stating about the starting difficulty. You stated it yourself in your original post. "About 15 minutes later I tried to start the old girl" The key here is "15 minutes". Go back and read our posts about fuel percolation to see how this is relevant.

-

That's the technique I find most useful as well if the car has sat for 15 minutes. Holding the throttle open reduces intake vacuum so more fuel isn't drawn into the carb which would make the problem worse. Once the engine has cranked enough to clear the puddle of fuel it starts. I don't think ambient temp has much to do with this. The carb is bolted to a chunk of iron that is in turn bolted to an even bigger chunk of iron that gets pretty hot regardless of air temp.

-

My P15 starts nearly instantly five minutes after a hot shut down. But wait 20 minutes and it struggles a bit. Yes, fuel percolation as the gas boils in the hot carb, overflows the bowl and dumps raw gas down the intake manifold. Now we have a “flooded” carb. Some cranking is needed to clear the puddle in the manifold and regain proper fuel/air mixture. Pumping the gas pedal is the kiss of death… Winter gas really makes this situation worse because the higher vapor pressure makes the gas boil at a lower temp.

-

Trouble removing oil pressure relief valve. 48 DeSoto

Sam Buchanan replied to MarcDeSoto's topic in P15-D24 Forum

50% acetone and 50% ATF should do the trick. -

Trouble removing oil pressure relief valve. 48 DeSoto

Sam Buchanan replied to MarcDeSoto's topic in P15-D24 Forum

Instead of WD-40 try a mixture of acetone and automatic transmission fluid. -

Trouble with oil filter connections 48 DeSoto

Sam Buchanan replied to MarcDeSoto's topic in P15-D24 Forum

Here are the fittings I installed for my bypass filter, some of this might be applicable for the Desoto installation. You can also see the new oil pressure hose. All these fittings were purchased at a local auto parts store, the tubing is pre-flared brake line. -

Trouble with oil filter connections 48 DeSoto

Sam Buchanan replied to MarcDeSoto's topic in P15-D24 Forum

Brake lines work fine for the filter, I bought the rubber oil pressure hose from one of our major vendors, think it was AB. https://www.oldmoparts.com/parts/l_engine/hose-engine-to-oil-gauge/ -

Water pump rebuilder: http://water-pump-rebuilders.com

-

I suspect the actual manufacturer is…….China.

-

Is that the same carb that is sold as an N228 by Mike's Carburetors?

-

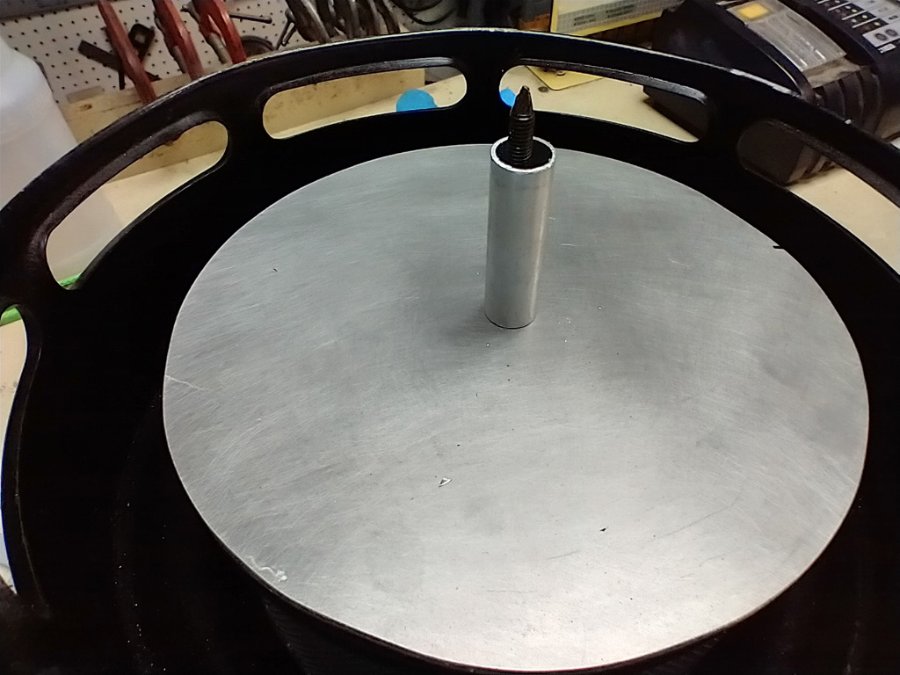

Some photos of my paper filter conversion, very happy with it. Here it is with the paper element, very stock-looking.

-

I use a Carter pump located just forward of the fuel tank as the only pump. The mechanical pump was removed and a blockoff plate installed. This pump has been in service on my P15 for two years and I ran the same type pump on a carbed kit car for ten years. Flawless service in both applications, no return lines. If I wanted a pass-through pump I would install a Facet pump such as the ones I use on aircraft as a boost pump. The Facet pump on my RV-6 aircraft has been in service for 22 years, still clicking. I also used a Facet pump in the Chevy S-10 when the 2.8V6 was replaced with an engine that didn't have a mechanical pump. This is the 6v Carter rotary pump, have only used it as a primary pump, don't know how it would function pass-through.

-

Why would you run a return line? This is a low-pressure pump designed for use with a carb.

-

Why not use the Carter as your primary (only) pump?

-

You need three things to make this truck run. Compression Spark occurring at the right time Fuel through the carb You can scatter-shot your troubleshooting if you wish but the most productive route will be to take each of the above three and verify their quality. Easiest thing to check is compression--if decent then move on. If not, internal engine work is needed. I would then move to ignition. This involves voltage to the coil and distributor, points in good condition, gap and timing properly set, and healthy plugs. Then see if fuel is getting to the carb.....it probably isn't due to a clogged system.....repair as necessary. May involve a new fuel pump and/or carb overhaul....or maybe attention to the fuel tank and lines. But you can bypass these just to get it running. When you have compression, properly timed spark and fuel.......the truck will run. Oh....one more thing you must have.....a service manual.

-

Yes...your memory is faulty. ? If your tank vents properly with the mechanical pump it will vent with the electric, the tank doesn't know the difference. I think you are getting tangled up with something someone may have told you about a return line being necessary for an electric pump....but that ain't so.

-

A good electric pump can also function very nicely as the only pump.

-

The reason why the aviation community frowns on fueling from plastic cans is the nozzle isn't conductive so a difference in potential between the can and airframe isn't reduced and a static discharge can ignite the fumes. However, I have burned a lot of auto gas in some of my lighter aircraft but the precaution I take is always using a Mr. Funnel. This funnel in addition to having a filter that water will not pass through is conductive and allows the can to safely achieve the same potential as the fuel tank. Another thing I've done when using a transfer pump is use a ground cable. A clip on one end of a 1/16" cable is attached to the exhaust stack of the airplane, the other end is attached to a length of stainless welding rod which is dropped into the can. Is all this necessary? Don't know...but so far no fires.

-

Even though it goes against many of the impulses I've demonstrated in my experiences with motorized devices, I think more now about the implications of physics that Mr. Newton explored a few years ago. If my P15 is brought to an abrupt and complete stop at 70mph there is four times the amount of energy to be dissipated than if the stop occurred at 35mph. The primary way the old car can shed that energy is by totally and catastrophically compressing and/or sending bits and pieces in multiple directions. Of course my body will still be following Mr. Newton's implications and attempt to continue its current trajectory at 70mph. The p15-d24 forum will have one less subscriber. In spite of all that, I really enjoy cruising my '48 between 50-60mph (with a seat belt), but I try to drive with the same mindset I used many years ago while piloting motorcycles!