-

Posts

3,467 -

Joined

-

Last visited

-

Days Won

193

Everything posted by keithb7

-

Hot evening again. 100F here this evening. I headed out in my Chrysler tonight. Cruised around for about an hour. I took the thermostat out.You'll see why in my next video. All night the temperature gauge read 160F. Up the hill home it hit 180F. Surely there is nothing wrong with the cooling system in my Chrysler. It's 100% stock and is flatten'n the hills tonight in the hot weather! Just a simple summer evening cruise. Hard to beat.

-

The firm quick long term fix is indeed an electric fuel pump. Also a possible pressure regulator if needed. The longer I am here, I can see that @Sam Buchananhas been around the block a few times. I see some modern comforts in the one photo he posted above. I count 6 things that ain't what I find under the hood of my old Mopars. How many do you see?

-

@Crazyredyou made my day! I am so glad to hear my videos are giving people confidence to do the work themselves on these old Mopars. That's the main reason I put in the time to make the videos. You made great work of the valve lap job. Sounds like it needed it bad. Look at them shop towels doing a great job in the valve area! ? The 0.060 over engine bore now makes it a 209.14 ci engine. There are a few reasons why you may have what appears to be lots of carbon build up. Leaky valves may contribute to incomplete inefficient combustion. Dirty by-products are left behind and you found them. Your engine will thank you and run better now. Now that the head is off how does the top of the cylinder feel, any ridge? How about cylinder wall scoring, any present? I think higher combustion pressures make more heat. How much I can't say. .060 over on the cylinders with the same size combustion chamber in the head, you are definitely getting a little more air into the cylinders, then compressed by the rising piston. This year is my 3rd summer with my 1938 Plymouth. Previous 2 summers it had a 228 ci engine. Cooling system was able to keep up on hot days, climbing the hill home. I rebuilt the engine last winter. I had it bored over to 237 ci. This year I have a spotless block, higher HP and torque. Now the cooling system cannot keep up on hot days. I have no records or proof that my engine is now generating more heat, only seat-of-the pants experience.

-

Hooray! You figured it out.

-

If you can take a break from the problem for a while that might help. Clear you head. Find renewed interest maybe? I tend to stop, drop and read. Double down and research the theory so I can think logically and problem solve my car troubles. I am not a mechanic. I am just stubborn and cheap so my cars have never visited a garage. Time and tools. I can throw tons of my time at a problem. My hourly rate is free. If I need a tool, I find a way to get it. Although I have been to Raleigh NC, I live a long ways away. Otherwise I'd love to come an help you out. Is it your 1950 Chrysler that won't spark sometimes? Do you want some more tips on what to check?

-

To clarify: Assuming you drive to the store. Upon arrival the engine is fully warmed up from driving it. You shut off engine to go into the store. 15 mins later you come out to start the engine. It's still very warm from the drive to here. The engine starts fine, however there is hesitation under load when you driver away? It coughs and sputters? Then after it has run again for a while, seemingly the engine gets hotter again, the hesitation clears up and it runs perfectly fine again?

-

When I took apart my engine the top ring was broken on #1 piston only. The second compression ring was intact. I don’t know when the top ring broke. I can’t say how long it ran like that. Nor how long it would continue to run. I suspect it could run for a long time. My limited experience tells me as carbon builds up behind the top compression ring, the ring cannot easily compress as it travels down the worn, slightly tapered cylinder wall. As carbon continues to build up, the ring will likely break from this stress. Multiple factors may lead to Incomplete combustion and excessive carbon build up. Low compression is a big one. As piston rings wear and cylinders wear compression drops. Increased oil burning would also be a big carbon contributor. Improper valve lash also causes unfavourable combustion conditions. An engine running too cool. Poor carbureration. Float setting. Sparkplugs and gap. Strength of spark. A plugged air filter. Timing dwell. So many contributors and variables will effect complete combustion. Potentially leading to carbon build up. Inevitably getting behind the top piston ring, sitting in its groove. I’m unsure if any type of oil can prevent this. How much oil ends up at the compression rings? I tend the think not much. Isn’t it scraped off cylinder walls by the oil rings? Changing detergent oil at regular intervals gets abrasive by-products of compression out of the crankcase. Preserving your delicate bearings, cam, tappets, rings and cylinder walls. I do appreciate metal on metal wear like tappets and cams and could benefit from higher quality oil. The use of oil & air filters, regular engine oil changes, keeping your car in a good state of tune including valve sets, in my opinion exceeds any decision of what brand of oil to use. Just my .02 cents.

-

So far my limited trials have produced no improved results. The smaller diameter pulley runs a wider groove pulley. If I got to a wider belt, then the crank pulley also needs to come off and be changed out. I found a spare wider groove crank pulley in my parts stash. Yet the seal surface is worn pretty good. A speedi-sleeve would be required. I put the 7", narrower v pulley back on. I will likely order the 6V Maradyne fan as posted by @Sniper. Put it on the front of the rad. Likely a manual switch so I have control of it. A relay will be utilized. I doubt I'll run the current through the ammeter though. Sounds like an upcoming winter project for me. Pending electrical system test results 6V alternator might be in the radar. It will amount to a fair amount time and money. Just I can deal the brief 100F weather each July and Aug.?

-

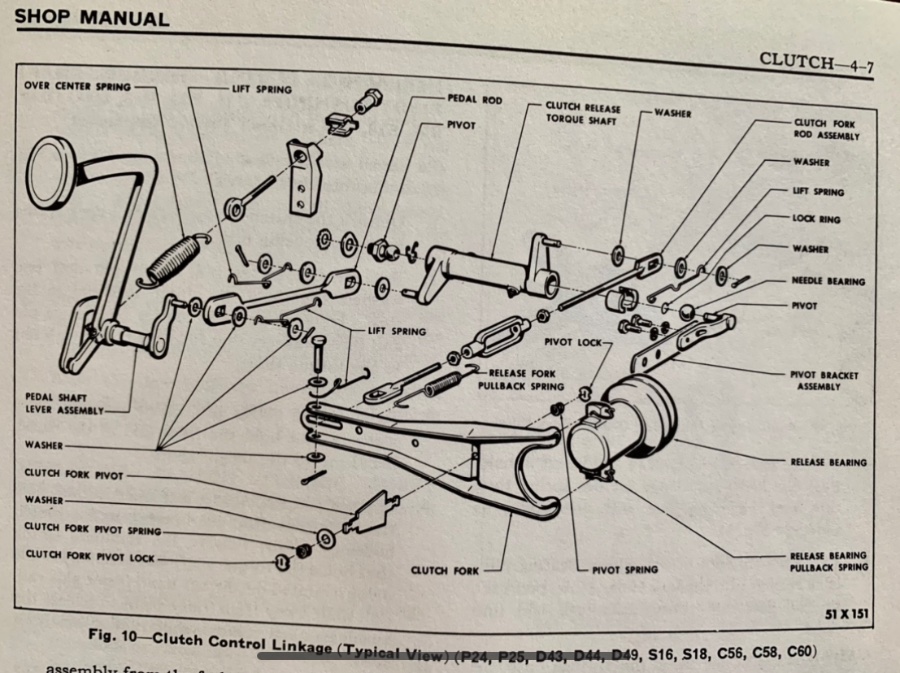

I found this illustration in another parts book. It utilizes a turnbuckle. Looks pretty different than yours Unsure if it is of any use for you. Thought I post it anyway.

-

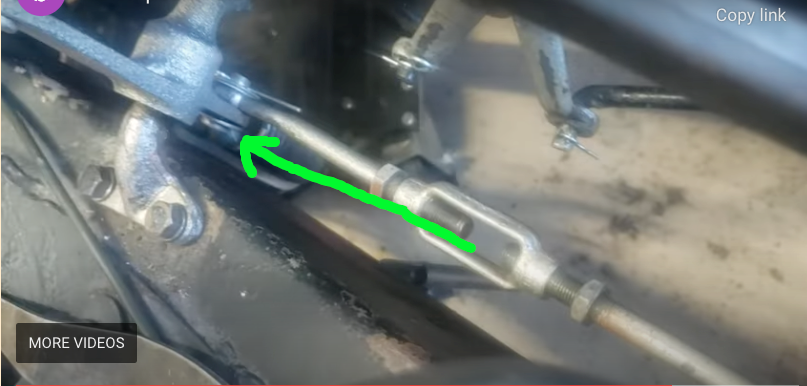

Maybe it's an optical illusion but is the rod that threads into the turnbuckle bent slightly? It looks little skewed off straight too. Could it be that it is supposed to mount on the other side if the pin? As per the image below. I looked in my '53 parts book. It's another different design again by then. I look in my '49 parts book. Seems different too. No turn buckle shown.

-

My suggestion is to study the linkage system to understand how its supposed to work. What pulls the pedal back? If it can’t come back what’s hindering it from returning? Take photos of the assembly before you take it apart. Look for heavy linkage use and wear as indicated above. Sometimes partial reassembly helps find the root cause. Get the linkage cycling and returning, maybe with partial parts installed. Keep adding parts and cycling the pedal. Once it binds up you have ID’d the part causing the problem. Understanding how it works is key to troubleshooting and fixing it. Not sure if that helps, but is what I do when I get stuck.

-

We live in a bit of a summer desert here in Kamloops. Watering restrictions are enacted every summer. Is having a green lawn a carried-over trend from the palace of Versailles? A sign on wealth? A notch in society? Lush lawns and gardens can be rewarding. Stress reducing. Cooling. Visually appealing. They can be a PITA too. This year we let our lawns dry up to become basically straw. We indeed have conserved a lot of water and carbon in the process. Carbon? How so? Well no 4 stroke lawn mower running every week. No 2-stroke weed whacker running weekly. No 3/4T Dodge diesel truck taking away bio yard waste to the compost facility. I’ve had more time to tend to my flathead Mopars too. I’m less grumpy as it behooves me to drive my truck across town and back to adhere to city rules to recycle bio yard waste. $20 in diesel fuel for one trip. Sure I could accumulate clippings and make less trips. Bagged fresh cut grass turns into rotten stinking silage in about 10 days in 100F weather. Then it spreads just like manure fertilizer in your truck bed. The smell stays there for about 6 months. I could mulch it with the mower which means cutting it more often in 100F weather. So none of that this year. Good thing too. Because right now the lawnmower won’t run. Carb main jet is plugged with old dried up ethanol residue I’m sure. My ultrasonic cleaner will fix that problem later this fall. The grass will turn green again in the fall. Morning dew returns. Less intense sun. Cooler days. 1, maybe 2 cuts in the fall and we’re good ‘till next spring again. I am procrastinating on the carb work. Headed back to tend to my Mopars again…

-

If anyone has a favourite “points grease” please share. What are you using? Where do you buy it? Thx.

-

I did check them while hot and running. You can feel the right tug of the feeler gauge. I'd shut off the engine and to make an adjustment. Then fire it up again and test the gap while running. It was an interesting experiment. However, I also have achieved great results when setting them cold and adding .002" to the spec. If you do want to set them hot keep in mind hot coolant temp does not mean the oil and block are hot. It takes quite a while to get the oil hot, the block fully warmed up. Take off the inner fender access panels and go for a drive. If you can drive up some hills it will heat up quicker. Flat driving, it'd estimate 20 mins of run time to get everything up to temp.

-

Sorry the post was unclear. The larger diameter is what was on my car. I went through my parts stash and found the smaller diameter pulley. I’m trying it.

-

Still a ‘hunnerd Fahrenheit here today. Hard to believe we are competing with southern areas of the USA. I’m doing what I can. No electric 6V fans around. Have to order-in. By the time that arrives it’ll be time to install a hotter thermostat. Bigger pulley is being utilized! So many little intricate differences over the years. FYI the water pump shaft diameter is 1.1134 ish inches.

-

I'd be shocked to find any flathead era Mopars in a scrap yard around here. Long gone I am sure. The reasons seems clear to me. This weekend I entered my car in the local big annual car show. 550 or so cars. There were 2 flathead era Mopars. Mine and the 1928 Dodge that the Vintage Car Club here owns. I maintain my own spare parts pile out back. Also pats are binned and stacked in the attic. More parts on the shelf in my garage. The auto wreckers can't make any money on old cars like this. I have the market cornered. Lol. ?

-

Somebody get this man a beer! Very accurate assessment.

-

10W30 20W30 15W40 20W40 20W50 Don’t run synthetic Add zinc! Use oil designed for diesel engine! Use Hot rod oil with zinc already added! Add lead to fuel! Run synthetic oil! 0W50 Add Marvel Mystery Oil to crankcase! Add marvel mystery oil to fuel tank! Run SAE30! There yes indeed, there is your single firm, solid answer. If anything if might prevent 25 more posts in this thread. Maybe. Maybe not. Lol. ?

-

I do have a crank for a 25” long 4 1/16” stroke Mopar FH engine. Of little use to you from way over here though.

-

Oh boy. Quite a corroded mess. I had my fingers crossed for something a bit better looking. Must have been out there in the forest for many decades. I'd be looking around for more engine options. If you are patient they are out there. I have had many options for used engines cross my path over the past 4 years.

-

What is that little "weep hole" on the bottom of my water pump?

keithb7 replied to MarcDeSoto's topic in P15-D24 Forum

Rub the brown crud extruding from the weep hole between your fingers. Is it grease or is it rusty coolant water? That’ll give you clues as to your next move. -

Annual car show day in my town. Just this one familiar flathead mopar in attendance. Tons of folks enjoying the car.

-

Andy I was successfully able to match bearings, seal, shims gaskets. I did not need to replace worm gear or sector shaft roller so I did not attempt to match them or other parts up. I am fairly certain you could match up any parts needed. The name popped into my head this morning. C&G Ford Parts. Seen here. https://cgfordparts.com/steering/sector-related.html I see that their web site has been redesigned. Not for the better it seems. Its harder to match up parts as it is now. @andydwhat year and model is your car? Having my 1940 Motors Manual was key. It listed all the years and various car manufacturers that utilized the same Gemmer steering gear box. I can try and look this up for you if you supply your info. I might have cross referenced a bit in my Hollander exchange as well. Let me know. I’ll try and help you out. I still have these references. Priceless info for us folks. I also have a spare worm gear and sector shaft set for a ‘37 if you need it.

-

I may have thought about it for 5 seconds. The bugs are atrocious. Suspect it would be hard to get non-ethanol fuel. Any car show might be just me and my other car. It’s definitely cooler. You get about 4-6 weeks of bad snowmobiling per year. A large portion ½ way up the white area shown, is really pleasant in Aug and Sept. North of that I’m definitely out. ?