-

Posts

3,466 -

Joined

-

Last visited

-

Days Won

193

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by keithb7

-

Thanks Doug. The radiator in my Plymouth is pressurized with a 4 lb cap on it. I’ve thought about my heating issue for some time now. Weighing options. Recently I met a guy with a ‘38 or so Buick with a straight 8 engine. Overhead valve, rebuilt stock engine and stock cooling system. Tip top shape. Same type of overheating complaints as me. He had more of a heating issue than me It seems. I gave him all the advice I could. I passed along all the learning I have picked up. Every little detail. He’d tried it all. To no avail. We chatted, leaning over his fenders for a while. Our heads in the engine bay. It was fun! My final advice that he agreed to try was removing the thermostat. Just to test flow. To learn if it is somehow impeding flow. He agreed to try that next. I thought about affixing a rad shroud. Nope he said. Waste of his time. Did nothing. More fan blades? Nope. Didn’t work for him. All band-aides it would seem. Just attempts at patching up the real root of the problem apparently. The electric push fan the on front of my rad was my next experiment. I was thinking. Well he tried that too. No improvement. He took it back off as it was impeding hiway airflow. I Guess my plan to try that is out the window now too. Another friend had a custom radiator built for his ‘48 NY’r. 4 core rows deep. He told me to budget about $750 US. That in theory should do it I suspect. My current rad is 2 core rods deep. I’m considering just going with a thicker rad, higher cooling capacity system. As they say “There’s no replacement for displacement”. I’m thinking of another phrase for a rad: “Ain’t no room for apathy in capacity”. I can double the rad depth I have now. Twice the cooling rods. “Spare the rod spoil the child” also applies it seems. Doubling down on the rad capacity is at the fore front of my mind now to get to the root of the problem. Yes, ya gotta pay to play.

-

Is there an explanation offered for this phenomenon? Premium gas causing dirty oil and carbon on plugs?

-

Indeed. When it comes to the car’s various systems “Rebuilt” has many definitions. “Rebuilt engine” might be the biggest mis-leading statement of all.

-

It can take a long time to build enough confidence to take the car on long trips. I can't say for sure why. Everyone's personal risk level is different. I have AAA including towing coverage for about 250 miles. They'll tow my car might right to my door step. I have yet to use it, but it is nice assurance. The tow coverage is not enough to allow me to throw my cares into the wind and head out on longer trips. For me it took time to work out all the little bugs. Trial and error. See what happens when I do this, or that. Fix this. Check that. As a full time employee, a part time dad, and full time husband, plus another car taking up my time and effort, it can take a long time to get though every possible thing on one specific car. In time, you get there. I am 16 months into my '38 Chrysler ownership. It took me until today to feel confident on my 250 mile trip from home. Last summer I took the car out on the hi-way. An hour from home. It surprised me and died on the road. In the end was able to drive it home. My recent trip was trouble free. Saying that, I am not sure how I'd ever build up the confidence if someone else were working on my car. Once you gain enough experience and tools, it feels like the only way to do things right is to do them yourself. Today I was headed to visit a friend, far from home. For the first time ever I could choose either of my old Mopars to drive. Both are hi-way ready and I have the utmost confidence in them both. That's a new feeling for me. One or the other needs this or that little thing fixed. Not today. Either car was good to go. It takes a lot of time and effort to get there. I'm now wondering, what I am going to do with all my spare time and money? Lol.

-

My buddie just drove his 1948 NY’r across Canada. We met today. Not much to report. A solid reliable car.

-

Today I’ve taken my Chrysler on a road trip. A 250 mile trip. All hi-way driving in the interior of British Columbia. 2 lane non-divided hi-way. I took my thermostat out to experiment. The engine maintained between 150 and 160F at hi-way speeds. Ambient temps about 80F. Running a bit too cold probably. I’ve burned a bit more fuel than I expected. I suspect partially due to the cool engine operating temps. I am also thinking that my float is a touch low. . I engaged overdrive as soon as I left the driveway. Once in 3rd plus OD, I cruised at 60+ mph very comfortably. Not once did I downshift for any hills. It is plenty hilly around here, so that is impressive. The shocks and springs were noticeably good. A very nice ride. The hi-ways are also twisty in places. 55 mph was about the max comfortable speed I maintained on turns. Otherwise my skinny stock sized tires squeaked defiantly. 30 psi in them. They are radials that look like old bias tires. This was my longest out of town trip in my Chrysler. There is a big difference between my Plymouth and my Chrysler on longer hi-way trips. OD being the biggest factor. The Chrysler front steering feels a lot lighter. Not as good road feel. Maybe its the radials. My Plym has stock bias tires. Maybe I prefer the stiff road feel with the old leaf springs. Stiff tire sidewalls. Less lean maybe. My Chrysler has a more modern front steering geometry. Perhaps I need to tweak the sector gear a touch. I will look into later for sure. The 251 engine my Chrysler doesn’t feel any more powerful than the current 237 engine in my Plymouth. Could be due to power to power to weight ratios or the gear ratios. 4.11 in Plym. 3.93 (or something close) plus OD in my Chrysler. It definitely gets there faster though. As 60-65 is very comfortable. Not so in my Plym which really feels strung out at those speeds. A great day and a real nice opportunity to compare two 1938 Mopars. Some very different features and engineering in a few ways.

-

Welcome. You found a great spot here for flathead era Mopars. Your '34 Dodge is wonderful. I too like it as is. A very classy car design. The long nose and the rear cab. By the next year the style was gone. Followed by long curving lines. 1935 Dodge Coupe:

-

My '53 Windsor had two different portions of the radio. The head unit with the tuner that had its own power supply and tubes. Then there was the amplification unit. It too had it's own power supply and tubes. This was located at the speaker area. Is it possible you have this style? The tuner could be wired to the ignition switch. Yet the other power unit could wired directly to the battery. A clamp style multi meter that reads DC amperage is a great tool for troubleshooting this. You can check the amp draw to the radio when the key is off. If it's not the radio, you can carry-on and check other wires to find the amp draw. It's a good tool to own. https://www.amazon.ca/UNI-T-Current-Capacitance-Resistance-Measurement/dp/B01FNMCA6Q/ref=sr_1_100?crid=W2M6EBZ43DYB&keywords=DC+Ammeter&qid=1662042594&sprefix=dc+ammete%2Caps%2C157&sr=8-100

-

Good to hear! Just headed to bed over here hope to hear more good news when I get up.

-

Thank Stargrinder. When you own a couple old cars there is always stuff to do. I could literally be doing projects every weekend. Its healthy to take breaks occasionally. Making the time to enjoy the fruits of your labor. I enjoy driving my cars. Showing them to the public. Talking about the cars. Educating people, whether it’s in person or on my YT channel, or on forums like this one here. It’’s all rewarding. Somehow fulfilling.

-

I feel your pain Steve. For a typical member and avid visitor here, there really is only 1 practical (ahem) solution. Own 2 flathead Mopars. Planned maintenance and repairs keeps one car up and running at all times! ? Never miss another parade. Never be absent from a “must attend event”. Never have spare time or money! Keith

-

Drat. I’d be pulling the flywheel again. There is a lot of force on the pressure plate. I’d want it balanced right. Especially after all the work you have done to fix your transmission. I’d also also be networking like to mad to try and find a home hobby type person with the tools to get it out. Friends with hobby machine shops are very dear friends to have! Are the threads of the bolt extruding above the flywheel flat surface? Or did bolt break off down in the hole? Extruded threads are a bit easier to deal with in my experience. You thread on a nut ,at least partially then them fill up the nut with weld matrix. Stick weld has worked for me. Allow to cool. Then simply turn the mess out. The heat from the weld does amazing things to a seized bolt too. Comes out like butter after the bolt is red hot. A recessed hole a bit trickier. A drill press may be ideal but not necessarily required. Drill out a hole in the bolt. Reverse drill bits work well. Or insert an e-z out extractor and twist out. Like they say, “a 20 minute repair becomes a 2 day project after 1 broken bolt”. ?

-

Rebuild pump. Install pump. Crank engine over. Watch fuel spew out of a hose from pump into a bucket. Then hook up a pressure/vacuum gauge. Crank over engine. Read fuel pressure.

-

I pulled my engine. Completely rebuilt it. The brand new rear seal leaks. Lol. I’m still learning too. Every repair I learn more. I’m thinking I may try the rear seal again. This time I’ll drop the tranny. Remove clutch. Remove flywheel. I really want to double check that I properly sealed up the rear main oil gallery plug. The Oil pan then comes off. Then the rear main cap. That’s a lot of work for an oil leak on 83 year old car. It probably leaked the day it left the dealer back in ‘38. So to be honest I’m in no hurry to tear into that seal again.

-

Here’s strike 3. I tried. No go. Pin was seized in there and a hydraulic press was unable to move it. The boot was still in half decent shape. So it remained on there and is still functioning today.

-

You are going to buy plasti-gauge. 1-4 thou or so size. You pull off a cap. Wipe oil off cap and crank journal. Place a 1" or so piece of plasti-gauge. Reinstall cap, and torque to proper specs. Then again remove cap. Measure width of plastigauge. This is how you test oil clearances, and taper wear. The plasti-gauge will be fatter at one end than the other, if the wear is tapered. You need to do this, one cap at a time, for all con-rod caps and main caps. This will tell you exactly what is going on in the bottom end. Do not take off all caps at the same time. Mark them so they go back on the exact same way they came off. If you have a knock, very good chance you will visually see the disaster unfolding, without needing plastigauge. Best practice is to measure them all though. Definitely report back with your findings!

-

Below here is my '38 Plymouth. I pulled off the 4 lane hi-way here in this pic, to take a break. The engine was a little warm, not hot. I was about a climb a long steep hill. I took a proactive 45 min cooling-off break. Then hit the hill. She pulled at 50 mph all the way up. No problem. Many folks overheat on this same hill. I did not. If you have driven to LA from Bakersfield, you know the type of hill I am talking about. Lots of folks overheat on that one. Imagine a 1938 Plymouth shooting past you while you are in the shoulder boiling over in your 2000 year car/truck. Lol. 4 lane hi-ways around here are pretty civilized. Speed limit is about 70 mph. Folks go 75-80 most of the time. Me at 50-55 mph, it's fine. They breeze right around me. The two lane hi-ways are the biggest concern for me. Impatient folks right up my rear. Taking chances passing, to get around me. I pull over a lot and let anyone go by me. I get out of their way as much as I can. I'd rather be on a divided higher speed hi-way than a 2 lane, undivided hi-way, anytime. 4 lane seems safer to me. We don't have LA or Dallas type car congestion on our 4 lane hi-ways. Far from it. Dallas at 3 am has more traffic than we do at 5 pm on the Friday of a long weekend. In that way, I am spoiled. My Plymouth has stock brakes, 3 speed transmission (no OD). 4,11:1 rear end. Stock size new, bias Coker tires. Stock worm gear steering. Stock driveline and suspension. Original 6V system. No seat bets. Vacuum wiper. Her biggest upgrade is a 25" long 237 ci engine. She pulls pretty dang good. Great car. I. enjoy driving her a lot. The coil spring seat does take a toll on my back after 4-5 hours of driving. Easy fix. 600 mg of Advil as needed and I'm good to go.

-

I’m out on a Sunday morning drive in my Plymouth today. Again looking for possible photo ops with period correct backdrops. Lately I’ve been reading the Grapes Of Wrath for the first time. Although it takes place before my ‘38 car was built, I feel I have more appreciation for travel in the 1930’s. People were tough. Cars also tough. Times were yet tougher. A great period of car evolution was in full swing. By contrast, today we watching a massive change in transportation. Perhaps the most complex automobile evolution since it’s inception. Electric vehicles. Momentum is growing. The change is in full swing. As the decades pass, the early days seem more attractive to me. I am fortunate to be able to relive them in my own limited ways with my 1938 Mopars. Perhaps yet an earlier period car is in my future….Maybe some day. Odometer 683 miles.

-

How long was carb in ultra-sonic cleaner? Air leaks indeed could be suspect. How about an unlit propane plumbing torch? To check for leaks. There are passages in the carb base throttle plate spacer and gaskets as Sniper mentioned. Indeed I agree, could a hole inadvertently be plugged by improper reassembly?

-

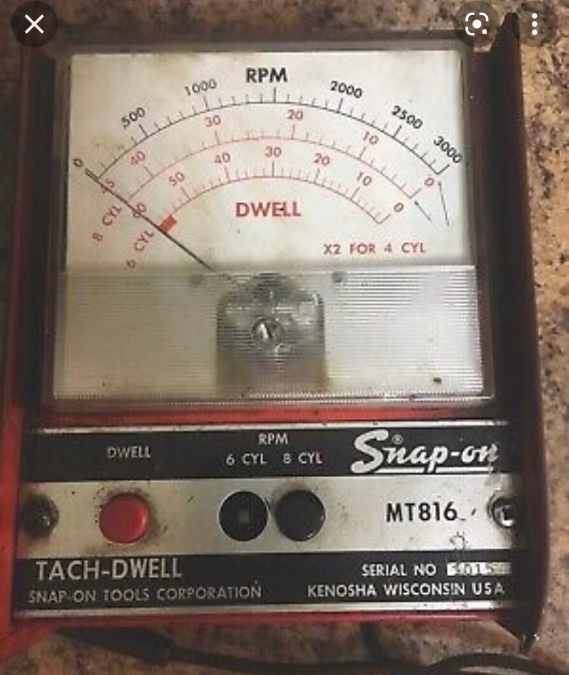

My mid-70’s Snap-on Dwell/Tach meter box works well. However I have to hook it up before I start the engine. Hook it up while running? The tach is erratic and way out. I couldn’t figure out why. A friend gave me this tip. Now it works perfectly.

-

Yes the distributor housing is grounded. It is supposed to be. The entire block is grounded. Anything metal that contacts the block is grounded. Ground can be explained as simply the return path to the battery. The small wire from the coil cannot touch anything metal (ground), over the entire path from the coil to the breaker plate. This is the plate that holds the points, inside the distributor. The wire fastens to the breaker plate via the little tab sticking out of the side of the distributor. Is is isolated so it cannot make contact with ground. The little coil wire cannot make contact until the points precisely allow it. When the points close, the wire from the coil is connected to ground. If the exact millisecond that the wire is supposed to contact ground via the points is wrong, things don’t work right. A Boom out of the carb is a possible result. The Piston is supposed to be on stroke 1, travelling down. Intake valve open. Fresh mixture of air/fuel is being sucked in. The spark is surely not supposed to fire at this point. If it does boom! Combustion yes, but escaping noise and exhaust gases head up through the open intake valve, via the intake manifold to the carburetor. This is a clue that your timing is wrong. Yet could it be valve timing? Timing chain sloppy? Broken? A sprocket retaining key sheered off? Put #1 at TDC, using timing pin hole and wood dowel, over #6 cylinder. View the valve tappets and lash. Are both valves fully closed? Do both tappets have some up and down wiggle room if you grab them? Both should. How much? The published spec amount of valve lash. Do you have a multi-meter? Use continuity setting. Check for path to ground at little wire from coil to distributor cap. Confirm the wire only contacts ground when the points close. Perhaps it never contacts ground. A clue! Points are set too wide, not closing maybe. Points set too close together? Not enough dwell time. Also no-bueno. By chance do any of your spark plugs show hairline cracks in the porcelain? How about up inside the distributor cap? Carbon track line? Saying that, the #1 thing I tell people to do first when troubleshooting a flathead Mopar: Compression Test. The results will guide you where to go next.

-

Have you considered rebuilding yours? Or maybe you don't have a pump core to rebuild? If rebuilding I recommend these folks. Good quality kits in my experience. https://www.then-now-auto.com/product-category/fuel-pump-kits/chrysler-fuel-pump-kit/

-

I feel somewhat responsible for the outcome here. Lol. I'm leaning toward a loose tappet to valve clearance if it sounds more like a "tick" than a knock! Hard to tell from here thought. It appears Bob that you have not yet decided if you need to rebuild or simply refresh your engine. Your compression numbers are respectable. I suspect #4 has a valve seal issues. Do you have any idea what the oil pressure was when the engine is running? Plan a refresh, then take the head and oil pan off. Take some measurements of cylinder taper and out of round. Top cylinder ridge? Any cylinder scratches or grooves you can feel with your fingernail? Disassemble valve train. View witness marks on valve sealing surfaces once you lap them a few times. Nice wider, even, round sealing ring? Or thinner in some areas and off-square? Try and measure valve movement in guide? How much is there? Measure crank end thrust. Over 7 thou? Pull rod and a main caps and use plasti-gauge. Clearances? Tapered clearances? Inspect crank bearings and journal surfaces and measure. Grooves? Nicks? Wear ridge felt? Journal taper wear? The list above will tell you if your block needs machining work or not. If all appears well. Perhaps a refresh of new rings, lap valves, roll-in new rod bearings might be all you want to do/ It might be just fine with minimal intrusive repair work. If wear is excessive new parts won't help much or last very long. Ending up wasting your time and money invested in new parts. If you're going in this far, might as well budget front and rear crank seals. A speedi-sleeve may be required on the front crank pulley to seal it up so be sure to clean it up an inspect. Then there is the timing chain. Sloppy? Starter. Heat riser mechanism in exhaust manifold? Carb rebuild? Generator up to snuff? How old is that mechanical fuel pump? If you don't know the history, the rad should be sent to rad shop and thoroughly cleaned and tested. Any refreshed or rebuilt engine will love an efficient rad. Good luck whatever you decide. We're here to help if needed.

-

No. My Stock Chrylser runs cool. My Plymouth here is what it getting too warm. Sorry about the confusion.

-

Hot evening again. 100F here this evening. I headed out in my Chrysler tonight. Cruised around for about an hour. I took the thermostat out.You'll see why in my next video. All night the temperature gauge read 160F. Up the hill home it hit 180F. Surely there is nothing wrong with the cooling system in my Chrysler. It's 100% stock and is flatten'n the hills tonight in the hot weather! Just a simple summer evening cruise. Hard to beat.