-

Posts

3,466 -

Joined

-

Last visited

-

Days Won

193

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by keithb7

-

Very important point! The balls serve as inlet and outlet check valves.

-

Glass bowl down. So you can remove it and clean out all the sediment.

-

I had never worked on a mechanical fuel pump before. I knew little to nothing about them. Until I had one acting up. I bought a new fuel pump, as mentioned the pin fell out on me. Then I thought, I can do better than this. I had a few old tired worn out fuel pumps kicking around. Some car folks gave me their old cores. A couple cores came with boxes of spare parts that I came with old Mopar Cars that I bought. I bought a new seal kit. I tore one pump apart and rebuilt it. First time in there and the rebuild was a success. Easy-peasy. Later my '38 Chrysler came with a dual action fuel pump. Fuel pump on the bottom, vacuum pump on top. It needed rebuild too. I ordered the rebuild kit from Then & Now and tackled that pump too. I was unsure how it would all work out, being as I have never been into a dual action pump before either. I had little idea how the vacuum pump worked. Again, success right out of the gate. Fired right up and have been running great ever since. I still have about 6-7 spare old fuel pump cores. Maybe I should consider rebuilding them all and selling them. The moral of the story is, try rebuilding a pump core. It's not hard. Read up a bit to learn the theory while you are rebuilding it. You'll have it all figured out and be an expert in no time!

-

Depending on where the fuel pump arm was in relation to the cam lobe when removed, it may be a little more challenging to install. If the cam lobe was pushing the pump arm, it will be a little harder to line up and install the mounting bolts.The cam could be pushing the lever arm, compressing the fuel pump return spring. You will be trying to hold the pump in place, to line up a bolt to thread into the block, all the while fighting the return spring. This is why I am suggesting you look at the pump arm. Where it rides on the cam lobe. Turn the engine by hand so you have no pump arm leverage compressing a spring at installation. By chance you may have no pressure on the spring. Depends where the cam lobe positioning is when the engine was last shut off. Take a look, and think things through when you are installing it. The pump is not timed to ignition or valve timing. You can put it in the easy way, or the more challenging way. Up to you. Either will work. Depends how many cuss words you want to use up.

-

Annual Vehicle Average Cost/Value of Ownership

keithb7 replied to Eneto-55's topic in Off Topic (OT)

Battery post switches are cheap, easy installs. Yet I’ll wager the ECM’s won’t tolerate no voltage when parked. Bet a guy could sell that Camaro and get a couple real fine examples of flathead Mopars. Mine run every day of the week in any weather! (1 has a mild fever mind you. But its only temporary. Lol) plus I indeed will fix it myself. Camaro = No go! 1938 = go great! -

East Penn Batteries = USA quality. Go for it!

-

An average 6V battery is about $120? Average battery life 6 years. $20/year is pretty cheap. Pretty easy to get six or so years from a battery if you look after it and do don’t buy a cheap unknown brand. The Duracell brand name probably means very little on a car battery. Car batteries are not what they are known for. They’ll put their extremely well recognized brand name on one though, so they sell more. I’m doubting Duracell owns a flooded cell battery manufacturing plant. Look at Caterpillar, and Harley Davidson. They put their brand name on all sorts of junk. Imported battery chargers. Footwear. Tools. Whatever. Tons of junk that people think of as quality, due to the household brandname recognition. It means little.

-

My understanding is If you remove all the wires from a generator, then it wont create any output amps. The field coils are not energized if you remove all wires. The armature also gets opposite polarity. Current traveling through the field windings create an invisible magnetic field. I think the armature slices through the field winding’s magnetic field. Opposite polarity energized atoms are interacting. This creates DC amps. Lots of them. Depending on how many feet of looped of wire are in the field windings. A generator starts out with small amps feeding it. It gets excited, and then creates big amps! In principle it functions like a starter. When you polarize a generator you are just making sure the field windings are very excited, at the proper polarity. So when the armature's magnetic field cuts through the field winding's magnetic field, you get lots of out put amps! How much it puts out, is controlled by the regulator. Or something like that...I'm no electrical engineer. The details are foggy. I quickly and easily measured my generator output. Seen here.

-

Arm has to be on proper side of cam shaft lift lobe. Look at pump arm. Which side of the arm rides on the cam? Top or bottom surface of arm? Turn engine accordingly to line up cam lobe. Then install.

-

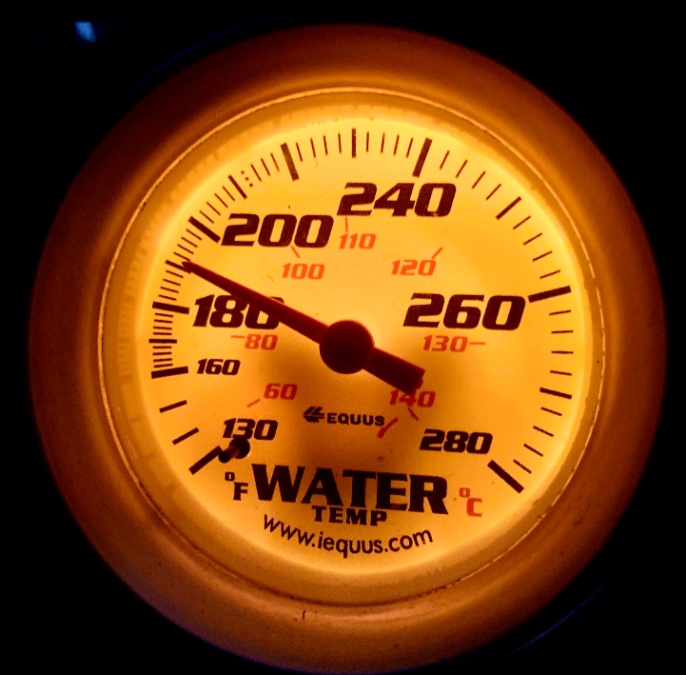

With the 180F stat in, I just went for a drive. I was at 180 on the gauge at the bottom of the hill. Hit it again hard. Pulled into my driveway at temp seen in the image. 210F. Current ambient air temps 62F.

-

Just put in a 180F stat in my Plym. I wonder what the symptoms might be if a person installed one upside down? Asking for a friend. Lol. It is possible I did this. I’ll never know. I took it out a month ago. She ran up to 180 nicely and stayed there on the down hill and flat roads. Nice to have heat in the cab again tonight.

-

A few more points to chew on: Last evening. About 50F ambient air temps. I flashed up the Plymouth to monitor and note some info. No thermostat in place. I took the car from my house partway up a big hill. Say about half a mile up. It hit 180F max temp. Turned around. Coasted down the complete hill. Say about 3.5 miles. Maybe about 10 mins going down. No throttle. Great airflow, tranny geared down for holdback. My gauge needle dropped all the way to the starting peg. My gauge shows that as 130F. Water temp could have been lower, needle could not drop lower due to the gauge pin. Once in the valley bottom I cruised on the flat valley bottom floor. Car maintained 140F at average cruising speed. Say 30-35 mph. 3rd gear around town. Good air flow due to travel speed. Then I pointed my car up the hill home and pegged the throttle. Full throttle. No down shifting all the way up. 3rd gear. 4.11 rear end. Stock tires. I’d say 2.5 or so miles up. Decent travel speed at 30-35 mph. I never let up the throttle for about 6 mins or so I’d guess. Decent air flow. Engine coolant temp hit 180F again max. She was grunting hard and performing well. I pulled into the drive way, my gauge at 180F. I stopped in front of my garage door. Engine now sitting at idle. Coolant temps immediately began climbing. I let it go, nearing 190F. I then rev’d up the engine a bit to get the fan speed up. I held the RPM’s up. Guessing about 1200 rpm. Immediately the gauge stopped climbing, and then began dropping. The fan was effectively cooling the water. I brought the gauge quickly back down to 180 and then shut the engine off. I had learned what I wanted. This tells us plenty. The fan works effectively when it’s 50F ambient. The rad flows well, the water pump works well. Coolant is circulating well throughout the head and block. The rear mounted temp gland immediately reacted to the cooler water temps and the gauge dropped quickly. A thermostat does not need to close to allow water to cool. At least in my example. As I had no thermostat. I believe my issue is ambient air, combined with a long hard steep climb on a very hot day. My cooling system as laid out, can only remove so much heat. To get more heat out on really hot days, on that steep hill home, I can: Bigger Capacity, additional core-row radiator Larger diameter fan Smaller diameter fan pulley Enclose fan with a shroud I’ll wager these options will do it. Each one compounding and adding more cooling capacity. All combined, a home run. Or I just move to a flat area, any flat area where temps can reach 110F. I think she could deal with that on flat land.

-

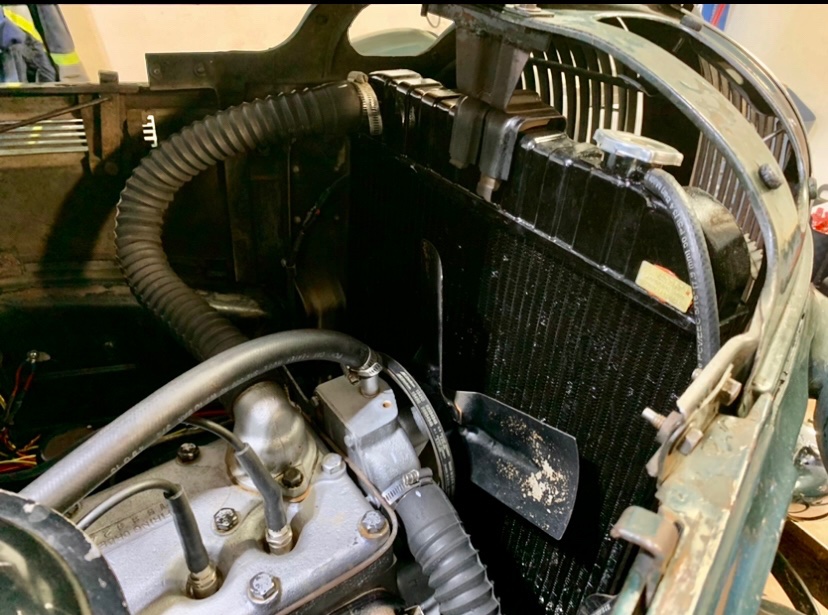

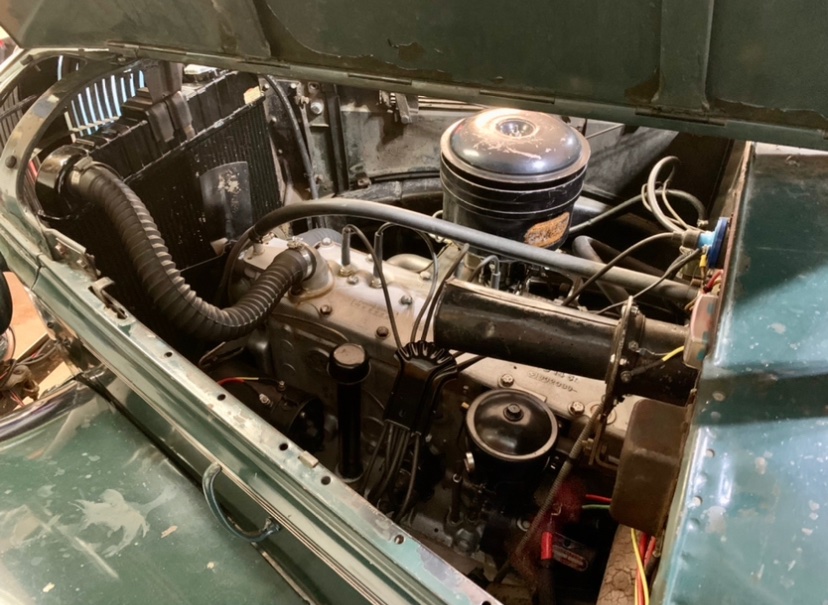

Here you can see the angle of my nose cone. Rad space gets smaller, the farther forward you place it. A pic of my engine bay space.

-

@Los_Control said: I see the difference is the bored cylinders = thinner mass & bigger pistons = more heat. ... nothing crazy. Then the shaved head = more compression which also creates more heat. ..... nothing crazy. The aftermarket radiator could be less than adequate. I do tend to agree that the smaller aftermarket radiator is likely under performing when ambient air temps are above 80F It probably cannot keep up. When ambient temps are lower, it can keep up. My two engine blocks are identical in bore. Chrysler Canada made all their 25" long blocks all the same. They were either 3 ⅜ bore for the 218 and 226 CI engine. Or 3 7/16 bore for 237, 251, 265 CI engine. The 265 block had a little less material at the bottom walls to allow more clearance for the longest stroke. My understanding is the only other difference between these various engine displacements is stroke length. Varied by con-rod length and crank throw length. I simply bored my 3 ⅜ block to 3 7/16 bore. Making it a 237. It has the identical bore now to my 251 engine in my Chrysler. There is no difference between my Plymouth and Chrysler cylinder walls or piston weight. My Plymouth coolant did run hot with a new perfectly functioning 180 thermostat once ambient air temps started to warm up this summer. I only took out the thermostat in August to learn if it may have been sticking closed and impeding flow. It made no difference when I took the thermostat out. Actually by taking out the thermostat the engine takes longer to heat up. Meaning short trips around town, were more manageable. Yet every trip up the hill home it was right on the boiling point by the time I made it to the garage door. With rad cap off, un-pressurized (again another test) she started to bubble and pop in the driveway right after I got home and turned the key off. Heat sink taking effect. Coolant not circulating. With the 7 psi cap on, it don't believe it ever did boil over. I am struggling a bit to accept the theory that the thermostat needs to close for a bit, to allow the coolant in the rad to cool down. Depending on ambient air temps, the thermostat stays closed for a time until the coolant reaches the thermostat's specified temp. The thermostat then stays open unless the ambient air, and wind going through the rad cools the coolant below the thermostat rated temp. Then it closes again. I'd wager that during summer hot ambient temps, your thermostat is not closing much at all. You have a radiator that is able to efficiently take the heat out of the coolant. Based on the rad's size and number of core rows, and flow rate. I am doubting the thermostat is playing any role once it opens in 90F weather, you're climbing a big hill, full power, and the coolant is fully circulating. The rad and the fan is doing all the work. The water pump pushing coolant on its way. The air has to move through the rad. Lots of it. A slower climb up a long steep hill on a hot day, traveling too slow for good air flow, a rad slightly too small, throttle down, not lugging, ignition timing right, and a fan that would very likely benefit from a shroud probably....Amounts to my situation.

-

Did you insure you got the pin back through pump fulcrum lever? Crank the car over to ensure its pumping gas before you applied the JB weld? I took the pump out and applied 3 layers of JB weld. One layer every 12 hours so it did not sloppily ooze away from the pin end. I got a good dose of it on each pin end this way.

-

I like all your input and comments. Keep it coming. I will attempt to illustrate for clarity. My 1938 Plymouth: Rad is not stock. A small bit narrower so it can fit further into the tapered nose come of the grill. Remember stock engine was 201 23”. It now has a 25” long 237 ci engine. The Engine sits on a slight front upward incline. Generally almost all old 6 cyl car engines sit like this in their cradle. The fan, bolted to engine, sits on same off-vertical axis. Bottom of fan further forward than top. A previous owner had the longer engine installed and the slightly smaller rad. The rad mounts were fabbed up so it sits perfectly vertical. So there is a larger gap between fan blade and rad at the top, versus the bottom. See exaggerated illustration below. I measured a 1.5” gap at the top fan blade. 0.5” at bottom fan blade. The current fan diameter in the Plymouth is 15”. A stock old Mopar fan. I installed a larger 17” diameter spare Mopar fan that I own. It fit. However keep in mind it was now closer to the bottom of the rad, compared to the top, due to said angle. I started the engine. No interference. All good right? It drove fine under power. Yet going down a local hill, when you let off the throttle, engine totsional forces change. The drivetrain is now pushing the engine. Dynamic braking occurs as the engine compression resists the rear wheels pushing it. The rubber engine mounts flex, ever slightly. The engine moved just a hair forward as the drivetrain flexes. Just enough so that the larger 17” fan blade kisses the rad core. I pulled over. Too late. Coolant was spewing out of my new re-cored low hour, radiator. $200 later it was repaired and went back in the car. Along with the smaller 15” diameter fan. I have the option to fab up some upper rad mount extensions. Get the rad at the same angle of the fan. Closer at the top for better efficiency. You may understand why I am a bit gun shy to do that. If you can believe it, things do move. My engine mounts are decent and new. See what happens when you try to outsmart a Mopar engineer? They got it right. I do have room for a larger capacity custom built rad. I figure build it thicker toward the grill. Away from the destructive fan. Larger capacity. Another row of cores is a good option. Get the curent rad on the same angle as the fan. Get the bottom nudged forward a little bit. Get the top closer to the fan. Same angle as the fan blade. Then I could utilize that 17” bigger fan. That may do it too, on the cheap. Sounds like a good winter project. Yet I have to wait until next July to test any improvements. Sorry about any confusion. I own 2 1938 Mopars. A Chrysler and a Plymouth. The Chrysler could create ice to appear in a hot coffee in the Sahara. The Plymouth boils it.

-

Some of the conversations are fun. This morning I took my Chrysler to the grocery store for the weekly refill. A friendly older lady approached to voice her approval of my car. “Is it a Studebaker?”, she said. I smiled and told her no. She praised the car and said “I guess you had to install seatbelts?” I replied “I don’t HAVE to install them. A stunned, confused look appeared on her face. “What do you mean, you don’t have to?”. I told her if the car did not originally come with seat belts, you don’t HAVE to install them. She paused and asked, “Don’t you want them?” I replied “Well, not really. I do wear one if I am leaving town on a hiway. Although I’m not convinced it would do anything to save my life.” I went on about how safety was far down a list, if at all in 1938. There was laminated glass in the car and that was about all the safety improvements I could think of. If someone hits me at 30 mph or less in town where I travel 95% of the time, I’ll likely be alright. Above 30 mph, I put the seatbelt on. Yet, I won’t be alright if someome hits me. “Its just some of the risks we take to drive these old cars” I told her. She was surprised. A trunk shot after I put a few items in that massive cavity.

-

By comparison my ‘38 Chrysler has no cooling system issues. Stock cooling system through out. Yet 251 ci oversized engine with .030 milled off the head. Stock, it has a bigger fan than my Plymouth. For experimental reasons I took the thermostat out of my Chrysler at the peak of our summer heat. Have not put it back in yet. 47F here this morning. Could not get my temp past the 130F mark. I sought out and tackled a good sized hill, throttle wide open. 3rd gear. 35 mph.I got it up to 140F. Time to put the thermostat back in. My Chrysler’s cooling system is proven. We get Texas style temps up here in July & Aug. Yet add the mountain terrain. The old flatheads are really pushed to the limits.

-

Sounds like a very practical plan to me. A good idea.

-

That end of the countershaft is an interference fit in the housing. Might even be slightly tapered. No seal. Previously I when had popped open a tranny. I pulled it apart for rebearing and reseal. I pushed the countershaft out the rear. (It only comes out 1 way toward rear). Upon reassembly applied a thin coat sealant at both ends of the shaft. No leaks. Your CS end does seem a little excessively recessed. How’s the other end look? Retainer plate locked in place properly?

-

I’’m doubtful. I think I’m getting great exhaust air flow. I have no way to test and provide data. We don’t have a mouse problem. I’d have to remove the muffler to inspect & verify. Engine makes very good power. A good thought but I am very reluctant to think mice set up a camp in there. I’ll keep it in mind. As mentioned my rad is not stock. It could be slightly undersized. Nor is my 237 engine stock in this car. A brand new stock type water pump was installed about 6 months before I rebuilt the engine. I tend to think its good. Again, no easy way of proving water flow. Anyone have ideas on ways to test coolant flow?

-

I have experimented with the timing. I begin with a timing light. A couple degrees before TDC . Then dial it in by ear. Adjusting it just back a tad so there is no pinging under full throttle and heavy load. I’ve also experimented too far retarded. The starter labors more to start it. Performance is reduced when driving up the hill home. To far advanced and the pinging is heard. I think I’m in the sweet spot with timing. The hill home provides generous “test & tune” opportunities. I’m thinking I am out of time for any further experimenting this year. Cool fall Canadian weather has arrived. I have been busy, with no driving time lately. I was in Alaska last week….Talk about cool weather! I’ll be driving my Plymouth more soon. I’ll reassess the situation but, ambient air is way down compared to July & August. The furnace will be on soon. I’m seeing that Momma is starting pull out blankets.

-

I wonder if heat is also a factor with oil mist. It takes a while to get the oil hot. It splashes around in the crankcase. Hotter and thinner. Hot oil mist moving around in there. Sucked up through the worn valve guides. Cold, the thick oil is not doing this?

-

It's unfortunate to see so many people break down with this same issue, after replacing their new fuel pump. The people who manufacture or sell these pumps seem to not care. This has been going on for years. Maybe the folks who own the largest tow truck company in North America also own the fuel pump manufacturing plant. Lol. There are so called Mopar supplier "specialists" selling these crappy pumps. One wonders if they cannot get a message back to the factory to do something about this. They got it right in 1930. Why cant someone get it right 100 years later? Like so many others, this happened to me 2 years ago as well. I quickly ran the lines to a 6V pump, while on the side of the road. Then drove my car home. Then I took the pump off and hit the pin ends with JB weld. Multiple applications over 3 nights. It has been problem free since. I also permanently mounted my 6V electric pump. It serves me well also. Under a couple of occasions it has pushed through vapor lock. Also great for priming the carb when the car has sat unused for several weeks.

-

Annual Vehicle Average Cost/Value of Ownership

keithb7 replied to Eneto-55's topic in Off Topic (OT)

I'm not convinced I want to know the annual average cost of owing and driving my vehicles. If I did I'd probably sell them all. Sell the house and move to a condo that is only a 15 minute cruise on a new e-bike, to work. I also do all my own vehicle work. I tend to run older vehicles. Buy them cheap and get them reliable & safe. I keep my costs low by buying my parts at good prices and doing all my own labor. My daily driver to/from work is 16 years old. It's never been to a paid mechanic while under my care and ownership. My Ram/Cummins 4x4 truck will be 25 years old in 2023. It's never seen a shop since I have owned it. Yes, they have all needed work but repairs are sure cheap when you do them yourself. I will admit my 3/4T Ram 4x4 diesel, is indeed higher to maintain. Parts are considerably bigger. Big brakes, tires. Big engine pan sump. I believe it takes 12L for an oil change. Bigger filters. U-joints. Whatever, it's all bigger. She pulls like a tractor and stops like a 1918 Dodge. Yet we love her and she works hard for us, reliably, when called to duty. My wife has her 1 car. A Honda Civic. I have 4 vehicles including my 2 old Mopars. True, total car ownership around this home is atrocious. I really don't want to know. I'll visit that topic when I retire some day.