-

Posts

242 -

Joined

-

Last visited

-

Days Won

5

Go Fleiter last won the day on December 10 2022

Go Fleiter had the most liked content!

Reputation

116 ExcellentAbout Go Fleiter

- Birthday 05/03/1951

Profile Information

-

Gender

Male

-

Location

Düsseldorf, Germany

-

Interests

My Plymouth 1951

Modelrailroads -

My Project Cars

1951 P 23 Cranbrook Convertible Club Coupe

Contact Methods

-

Biography

born in Münster, grown up in Milan / Italy, Studies in Göttingen, Köln, Buenos Aires -Argentina

-

Occupation

Dentist, retired

Converted

-

Location

Düsseldorf, Germany

-

Interests

My 51Cranbrook P23 conv., Model railroads,

Recent Profile Visitors

3,166 profile views

-

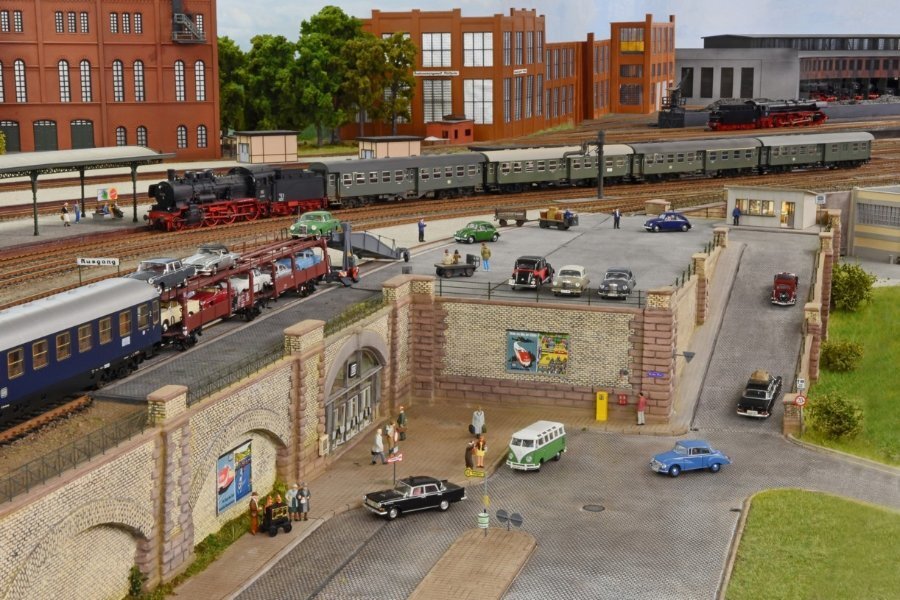

both are perfect plans to retire! I can´t move since 1982, because of a stationary model railroad. So, I must make do with 3 Garage places 3 mintutes in bicicle from my house plus this summer awning in my yard as shop and for the cats. If interested in my friends Egon and mine model-RR, here is the index of my postings: https://www.drehscheibe-online.de/foren/read.php?10,6607746,6607803#msg-6607803 Here is a choice: I love 50ie´s cars! Greetings from Düsseldorf! Go

-

beautiful posting! Enjoy!!

-

Hallo For now I presented Your worthy hints to my mechanic. I will see. Thank You all !! Greetings from Düsseldorf! Go

-

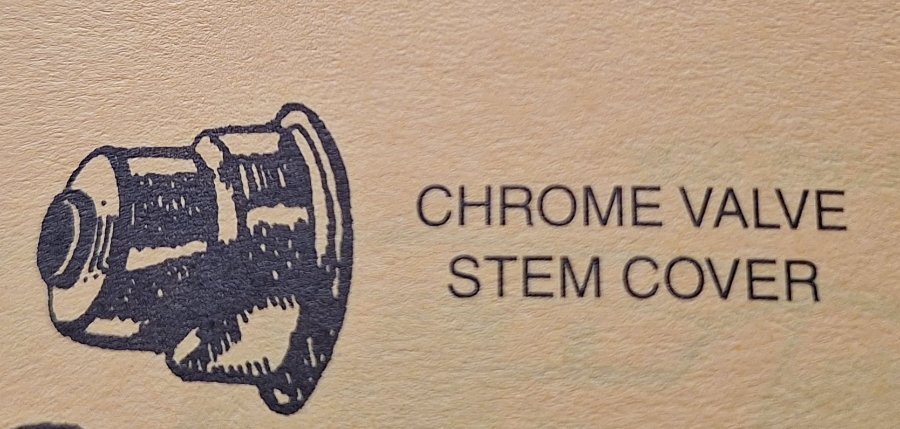

While repairing a flat tire, my mechanic found remnants of a disintegrated rubber (?) part, of which I know neither the name nor the appearance. It is different from this Valve Stem Cover (see foto) made of metal. I guess it was supposed to be put over the valve of the tire tube and pushed through the rim with it. It should probably prevent migration of the tube. My other wheels don´t have this part but the metal variety only. Any hints?? Greetings from Düsseldorf! Go

-

The breaker contacts I had bought before ~2007 failed each after ca. 1000 km. I helped me buying original Bosch breakers for Citroen (nothing other available) and transplanted the very contacts to the Plymouth points. It worked well, but I didn´t trust my work on the long term and didn´t want to repeat the transplant again. I have a pertronix unit since than: no more problems with ignition. They made me two 6V neg GND units, and sure, one is in the trunk!

-

maybe You should test the starter directly: 1. connect the clamp of a heavy jump cable to the starter's terminal. 2. Be sure to have the transmission in idle! 3. Touch the active battery pole ( "minus" IF POS. GROUNDED!) with the other clamp of the same cable and see wether it spins or not. 4. if not: disconnect that clamp from the batt. 5. use the second cable/ clamp combo to give direct ground from batt passive GND pole to starter (Connect to a cleaned nut or bolt) 6. touch the active batt pole again. Batt voltage may fall under 5,5 V and when released rise again to 6,4 So You know if starter is ok or not. 7. Starter SOL must click when activated. if not: try direct connection from active batt pole to SOL activating terminal (can't search for its correct name here with holiday equipment) Beware: even if reading 6V at the SOL outlet to the starter when unloaded, its contacts (or old Cable connections to starter or batt) may not let pass 40-60 Amps when loaded. Next would be the switch and its cable connections... Good luck! Greetings from Portofino! Go

-

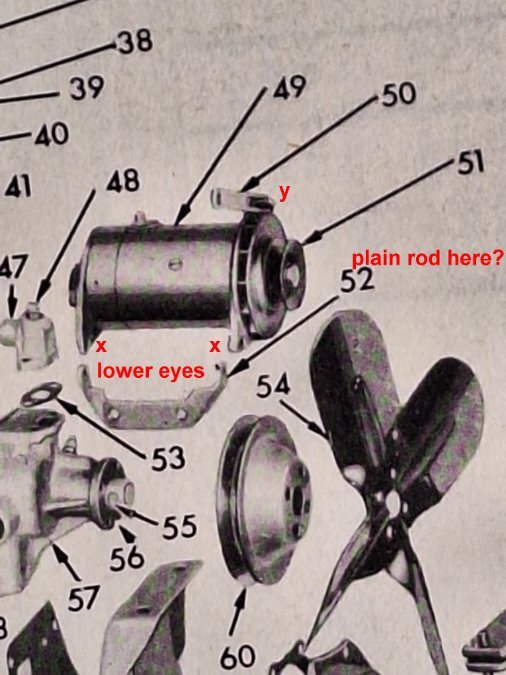

?? lower Generator mounting: plain rod or threaded one??

Go Fleiter replied to Go Fleiter's topic in P15-D24 Forum

Thanks all, so it seems, that the GEN must be fixed thightly at the bottom too! -

Hello all! The alternator at the bottom sits in its bracket (#52) with 2 lower eyes (red "x") and a rod. On the front top it has an upper single eye ("Y") for the screw that provides proper V-belt tension in the tensioner strap (#50) slot. I cannot find the lower rod itself in the Parts book or the Service manual, nor a description of the mounting procedure. Question: I have received conflicting advice how to mount the Generator. Which should I follow? a) to fix the generator thightly on its top slot strap AND on the bottom (threaded rod is suficient) to its bracket (very difficult to put and fasten the nuts!). b) to fix the generator ONLY on its top slot strap thightly, leaving it FREE at the bottom on a smooth rod, (securing the plain rod only itself with nuts on one end or both). How was it originally? Thanks for Your help! Greetings from Düsseldorf! Go

-

I use a 12 V fuel pump with 6 V (years ago I couldn´t find a 6V one) parallel to the mechanical one. To only prime, fighting vapor lock, it´s power is sufficient. 6V may not be sufficient to substitute a failure of the mechanical, however.

-

strange to me, Keith, that You have so many bad experiences with Pertronix! As suitable for my P23, I use a 6V minus grounded unit since 2007 and 25 000 mls without any problem. I can recommend it strongly, if not the originality is first - but the driving! The original setup failed constantly because of inferior quality of the point contacts. I even have a spare unit in the trunk. Above all, since 23 years starter motor, ignition coil and (since using it,) the pertronix too gets 12 V from two 6V batteries in series while starting. I never tried how much Voltage the 6V Pertronix would stand, but liberately estimated, I didn´t want to go over 8V. So, again while starting, a V limitation circuit keeps the Pertronix at 8V. Yes, and a spare circuit is on board too... I never needed the spare units, but other users seem not to have such luck. btw.: my car is not presented to be judged for originality, I just drive it for the fun. And I love not to be blocked by trivialities of old technology Greetings from Düsseldorf! Go

-

hole in generator´s oilite bearing needed??

Go Fleiter replied to Go Fleiter's topic in P15-D24 Forum

Thanks for all these very helpful informations! -

hole in generator´s oilite bearing needed??

Go Fleiter replied to Go Fleiter's topic in P15-D24 Forum

Porosity is the key word! Maybe my bearings are not oilites! I have 3 unused NOS, they have a completely homogen surface like polished and do not seem to provide the slightest permeability. They seem to be far away from beeing able to hold any, not 20% of oil. Thanks so far, anyhow. -

ANSWERED "One of these things is not like the others..."

Go Fleiter replied to Bob Riding's topic in P15-D24 Forum

Bob, this is my actual problem (generator) Greetings from Düsseldorf! Go -

Hallo, I had reported from our Italy trip here (link, scroll down): the generator had failed loading and had developed sporadic bearing noises. After the car had been towed back home, I initially only had time to install a replacement generator and could only now look for the defective one. The Oilite bearing at the rear end was completely gone, the shaft was flapping in the back plate and showed strong signs of overheating. The rear cover does have an oil pocket with channel (red/white in photo) to the bearing seat, but the bronze bearing has no hole from the channel to the shaft. I also haven't found any indication anywhere that you should drill a hole after assembly. I assume that none was drilled when refurbishing the generator either. Question: Does the bronze bearing need to be perforated from the oil cup after assembly? The bearing material seems to me to be much too compact to allow oil to seep through. Although the bearing noise had only been intermittent, I fear that the rotor may have damaged the windings. I have not been able to see this properly yet. In any case, he tore off the insulating tape wrapped around some of the wires (see foto in 8 o'clock position). Next I will then have to look at the oil lite bearing of the spare generator so that its shaft does not suffer oil starvation too! Thanks for help! Greetings from Düsseldorf! Go

.thumb.jpeg.28cb36506a6b17cd30e7d4a22504384d.jpeg)