-

Posts

3,462 -

Joined

-

Last visited

-

Days Won

193

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by keithb7

-

If anyone knows the story, I certainly am interested in learning about the holes punched into the strut on top of the carb bowl. Odd little shapes that have meaning at Carter I’m sure. Production dates & shifts maybe.

-

Thanks in part to many here, my You Tube revenue goes right back into betterment of my ‘38 Mopars. Recently I acquired a digital Ultrasonic cleaner. 15L (3-ish gallon) size. I completed my first project with it this last weekend. I disassembled my Chrysler carb as far as I could. I soaked it in the tub basket for 90 mins. Little implosions did their magic. I reassembled the carb with new carb kit parts. It looks like a million bucks. Will it perform as such? We shall see. I’m currently playing hide-and-go-seek games with another machine shop. “We’ll be done with your head in 1 week”. That was 11 days ago. They won’t answer the phone. They won’t return messages that I leave asking for an update. What is it with good old fashioned customer service? Are we past that now? No longer required? So we wait for the cylinder head before we can test run the carb. Anyway, thanks for your support folks. Thanks for watching my videos. You are contributing indirectly to keeping my ‘38 cars alive and on the roads!

-

The man revealed! The face says “don’t play games with me”. Ya’ll see my mug a lot, I am glad to see yours.

-

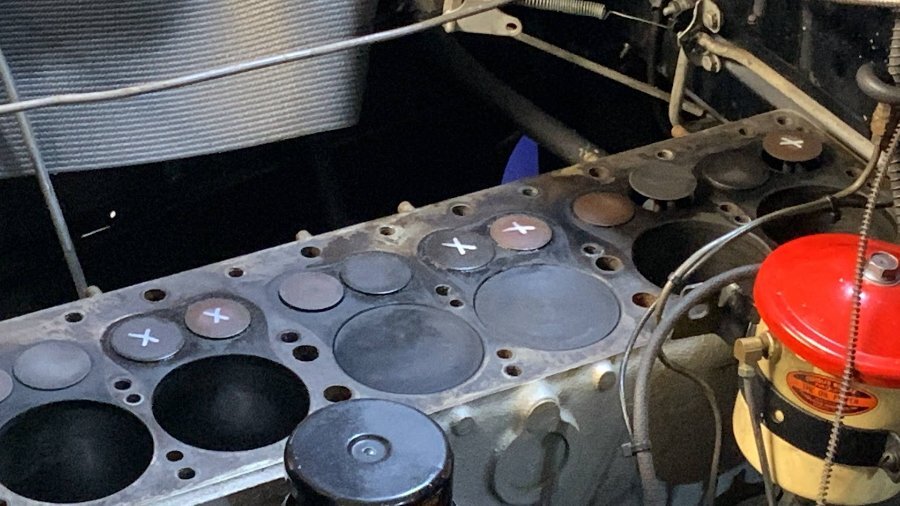

My results: 251 engine #1 .022 below beck #2 .022 below #3 .023 below #4 .020 below #5 .023 below #6 .021 below Upto About .005 difference between front and rear of piston. My numbers could be more accurate likely. I did what I could with my tool. I cannot speak to any machining as the previous owner rebuilt the engine. I guess he’s not as OCD as us here. He didn’t have records how much was cut away from any areas inside the engine. I measured 040 over on the bore. I’m gonna “run what ya brung” on this engine and “just send it”.

-

Flathead Engine Keyboard Warriors? Or Maybe I have some learnin' to do?

keithb7 replied to keithb7's topic in P15-D24 Forum

@BryanI will set my magnetic base dial gauge on the block and get you precise measurements today! I will report back soon. -

Recently I deleted a post I made in a Facebook flathead engine group. As you know, I like to share my project progress and enthusiasm for old Mopars. I believe it helps the hobby. Below here is the photo. I was about to make some unfriendly rebuttal comments but chose not to. Here's the story. I recently found a crack in the cylinder head, near the thermostat housing in my '38 Chrysler Royal. I pulled the head and I am swapping it out. My spare head is at the machine shop today getting crack tested, sandblasted and milled. While the head is off, for about 30 more mins of my time I can remove the manifolds. I'd test all valves for leakage. Indeed I found 5 leakers. The previous owner of my Royal told me the engine was rebuilt about 8000 miles ago. Not massive valve leaks, just allowing a little kerosene to pass through. A little kiss with some lapping compound was my planned job scope. A statement on FB was made: "If you are that far into the engine and only doing valves, the engine won't handle the increased compression". One guy admitted that later after a valve grind he developed a knocking rod bearing. Maybe, on a high mile engine that you are patching up. Or the engine bearing was about to fail any day and it happened to after he did a valve grind. Other comments were made about the general misunderstanding about lapping compound. A guy went into a dialogue about people should not be attempting to fix valve leaks with lapping compound. That the grains in the compound will get deep seated into the valve seats and stay there, then cause the valve to continue wearing quicker. "You should not/cannot lap hardened inserts", someone said. Further comments about the engine pushing oil past the rings after a valve seat clean up. Keeping in mind this is only FB and there are subject matter experts behind every keyboard. I do trust and have confidence in the experiences shared here. I tend to skim past FB opinions, however maybe there is a learning opportunity here. I don't want to wander the planet ignorant. Deep down I was thinking, "Dude I hope you don't waste your money on a gym membership. You get plenty of exercise quickly jumping to conclusions." Yet I kept my mouth shut. Lol. My thoughts: - My engine is not a high mile example. I'm just kissing the valve sealing surfaces to tiddle them up slightly. Removing hardened soot and or carbon build up. - Yes I agree a high mile engine is likely to burn oil after a valve lap. Consider worn rings and tapered cylinder walls. Again, my engine is not a high miler. - I do understand the use of lapping compound. To frost up the mating surfaces to closely inspect the seating area. Also A final sealing to get a nice tight seal. - Lapping grains remaining in the surfaces to cause expedited valve seat wear. Really? I am having trouble accepting this theory. - Yes indeed you can reseal hardened seats. I have done so in the past. Yes is takes a lot more effort by hand, but you can successfully hand grind and lap-in exhaust valves. A general question about machine shop valve grinding. When I recently rebuilt my 1938 Plymouth engine I had the machine shop perform a valve grind. I provided them with a full set of new, single cut 45 degree stock valves. I asked them if they hand lapped valves for final sealing I was told no. I did not inquire as to why. I just assumed I would have to do the final sealing myself, and did so later. Is it expected that when a machine shop does a proper valve grind, they achieve a 100% seal? I am doubtful. I did have to seal up my new valves in the newly machined block when I got it home. Learning as I go here.... Thanks.

-

This can't be the same Sniper in the Avatar photo..Lol. I need to reprogram who I envision in my brain when I read your posts.

-

I wonder if the flathead era Mopar parts situation is the same at the Pacific Northwest swap meet in Portland? Anyone been lately? Last couple of years were cancelled I believe. https://www.portlandswapmeet.com/

-

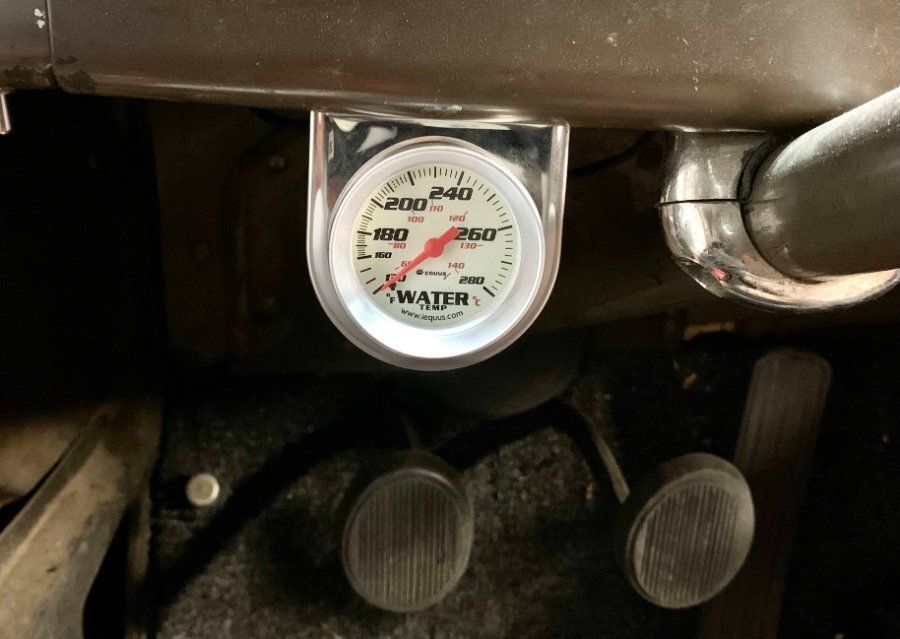

I am not knowledgeable on the long term effects of 200F+ temps on these flathead engines. Although I have never experienced it, I have heard talk of warped cylinder heads or damaged head gaskets. I have not researched to learn at what temps this might become a concern. My stock gauge was pinned to the top under certain hard driving conditions. My Old gauge read to 212, my needle was above that on a steady long slow hill. My new gauge shows I am maxing out at 200F under the same conditions. General around town driving 170-180 . Based on comments here, this seems pretty normal for these era cars. I am not boiling the coolant. I am likely fine to leave well enough alone. Smaller projects like moving the fan blade ahead with a spacer is easy. Some rubber trim around the outer edges of the rad won't hurt either. I will do these. A shroud, maybe if I lived further south. I don't think I need one for the brief 100F ambient temps that we generally see around here each summer. It's pretty easy to just enjoy the car in the morning and later evening on those days. I run a thicker viscosity detergent oil. 20W40 or so is my preference in the summer. I've enjoyed the conversation here. It's great to hear other owners experiences.

-

I have not used it…Yet. When I first installed my engine I used just water. Figuring I may have to do something to again drain the cooling system. Like address a leak or something worse. My first hi-way drive, an expansion plug popped out. I lost a lot of coolant. I was glad I did not have Evans in there at that point. I may still switch to Evans.

-

@capt den What PSI radiator cap are you using? 50/50 glycol and water raises the boiling point. So does the pressure maintained by the rad cap. I know anxiety builds when you see that needle pegged. You don’t know where the boiling point is. Maybe try an experiment. Get your car good and hot. Then drive home. In your driveway leave it idling. Let the gauge pin past 212. See what happens. If your system the system starts to boil shut her down. Maybe your Windsor cooling system can maintain 215 then it won’t go any higher? My car can maintain an upper limit cooling point without boiling over. If I leave the rad cap off and try the same? It indeed will boil. This is why I am pondering my options. Is it necessary to run 180 under all of the toughest conditions? 212 is not a lot higher than 190. The engine oil can handle 212 on those hot summer days. For the sake of discussion is 212-215 hard on cylinder heads or gaskets?

-

I have been doing a little more investigation into engine cooling issues. Over the past 3 years I have been working to get my car back to spec. I have done all the things I can to address my cooling system. I've rebuilt the engine. Complete hot tank of the block, all sediment removed. New brass water distribution tube. New water pump, rad cap and 170F thermostat. All new hoses and belt. New water pump. Rad re-cored. As mentioned earlier I have learned that my stock temperature gauge is inaccurate. With my fresh new 237, I am not babying the car. I work it now more than before it was rebuilt. Including my recent 300 mile hi-way trip. Over and back a mountainous pass. Yesterday I removed the stock temp gauge capillary tube from the left rear of my head. I installed a new capillary type gauge. I proceeded to work my car hard. Get it really heated up until I notice the oil pressure drops a few pounds. This tells me the oil is good and hot now too. Then go climb some big hills. Long hills with steep grades. I am talking 15-20 minute climbs with your throttle wide open with the ambient air temps above 80F. So your car is just able to maintain 35-40 mph with all she's got to give. A winding steep 2 lane road. Not a hi-way. This indeed tests the limits of your cooling system. The old cars with no fan shroud, with a belt driven fan, rely on air flow from the car in motion, to help cool it. When you are working the engine hard, a good load, burning lots of fuel on a steep long hill, airflow becomes an issue. You are traveling slower now. You are making a ton of heat. The engine fan is possibly turning slower depending what gear you are in, dictating engine RPMs. The 80F ambient air is not helping very much. The cards are all stacked against your cooling system now. Most of these old cars did not utilize a shroud around the rad. An open fan is much less efficient than a fan with a shroud. I have read up to 38% less efficient. The fan draws air from all around it, not necessarily from in front of it. Yes some air comes through the rad, not all, efficiently. In addition to that the outer edges of your rad, outside the span of the fan blade, those fins get little to no air moving through them at lower speed travel. At stop and go traffic, none. A fan shroud could help tremendously depending on your driving conditions. A shroud controls the air movement by the fan. It has to come through the rad. A venturi effect is also is created, pulling air through the rad at a higher rate of speed. At low speed, high-load hills, your car could really benefit from a shroud. The stock system in these old cars was adequate in most all situations. Moving at speed really helped a lot. Yet as each part of the cooling system weakened with age and lack of maintenance, the system may not keep up. Unable to cool adequately in all scenarios. Band-Aids are available. Electric fans. Larger rads. Larger pulleys etc. My 1938 Plymouth cooling system is not stock. The 23" engine was removed. A 25" 237 is in the car now. A different rad was installed so it could be moved forward in the nose cone and accommodate the longer 25" engine. The fan on my engine is not as close to the rad as I'd like to see. The 237 likely creates a bit more heat than the stock 201 engine. I am seeing temps a little warmer than I'd like on the long hills. I am not boiling the coolant. It is 50/50 water and glycol, pressurized with a 7 psi rad cap. The 237 performs awesome in this car. The increased torque and power make it a pleasure to drive. Yet, i am convinced it makes more heat. I suspect I would benefit greatly from a fan shroud. Building a spacer to to get the fan blade a little closer to the rad. There are limitations as the crank pulley and generator pulley must all line up. Moving the rad closer to the fan, would be a good benefit. Hmm...Things to consider.

-

Piston rings will rust to the cylinder walls. Just from regular moisture in the air. The engine is often considered stuck at this point. You may need time and patience to break it free.

-

-

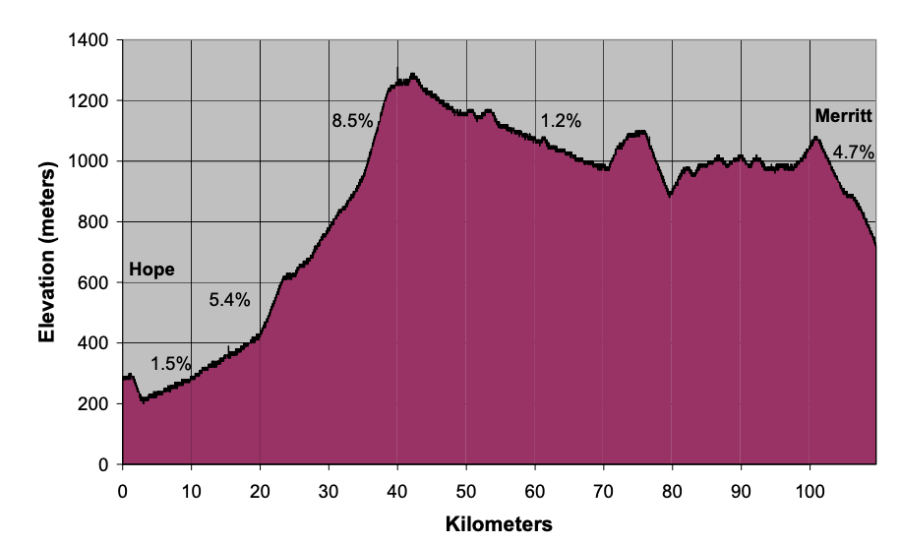

I enjoyed a nice trouble free trip. Just a tad under 300 miles total travel. I took a GPS along today check my speedometer and odometer. Seems I am traveling about 5% less than what my speedo reads. Not bad considering the car's age. I calculated my fuel economy. I am getting about 16.5 MPG with bias tires and my 237 ci engine. The car performed very well. I know my temp gauge is out about 15-20F. I took some caution today just to be safe. Heading back up a long mountain range home, there is a long grade. For many miles. It was a pretty warm day. Over a period of 20 mins I watched my gauge slowly creep up and up. The steepest section was yet to come. My temp gauge was pegged past the 212 mark. I would estimate I was actually under 200 still at that point. A profile of the hi-way home is shown. When I got to about the 800M elevation mark, I pulled over and shut the engine down. I waited until the temp gauge read 160F. I fired it up and without any trouble we climbed up and over the pass, maintaining 50 mph in 3rd gear. 1:1 tranny output and 4.11 rear end. The temp never did read higher than 210 (in reality probably 190F) all the way up. The car performed beyond my expectations. For my own peace-of-mind I may install a new accurate temperature gauge. Maybe bolt it down on the bottom edge of the dash. I pretty well maintained 50 MPH the entire trip. Glad I did the trip. I look forward to more. The engine oil level never moved. The car show was fun. Just one other old Mopar car. A 1937 Dodge, convertible. Pics seen below.

-

I am packing the trunk tonight. I'm inspecting my Plymouth sedan closely. Checking everything. I am indeed taking it on a road trip. About 3 hours drive each way. Farthest trip yet for me and my Plymouth. This trip if I come back unscathed, will take me over the edge. Beyond any reservations I've had about traveling outside earlier comfort range in an 84 year old car. I've packed up some tools, extra gasoline, hi-way triangle warning signs, checked the jack and spare, (It was flat, never checked it before. Oops) Extra Oil, brake fluid, water and more. She got all new hoses and belts last winter. Rad rebuilt. New water pump. She's good to go. I am going to get under there with the grease gun now and hit every nipple. I had planned to make this trip 2 years ago. Forest fires kept me home. Then the engine came out for an overhaul. Sorta glad I never went 2 years ago, knowing what I know now! Lol. The engine had broken top piston rings. Could have been a mess. Just me & the pooch and my AAA card. Should be a fun day. I'll depart at 5AM local time and hit the super hi-way over a mountain pass. I'll meet my brother and his vintage car at a large car show. We'll go in together and hang out for the day, talking cars all day. My big brother was a car guy before me. Only because he turned 16 first. We rebuilt a couple engines together when we were in high school. Outside, laying on plywood in the backyard, lining up trannies and clutches. Good times. We got 'er done though and it gave me the confidence to keep at it for the rest of my life. Really looking forward to the road trip. Some alone time, a hot coffee on the road. Hangin out with my brother. Will post pics of any Flathead Mopars at the show or of me on a tow hook. Lol. We shall see!

-

Works for me. I mounted a 6V to 12V converter tucked up behind the glove box. Tied into the fuel gauge power wire. Powered by turning on the ignition switch. 2 years later it still charges fine for me.

-

I’ve been reading a book on American Automobile history. Written in 1965. It’s perfect for me. I’m not overly interested in anything newer than that. Lol. My 1938 Plymouth is an example of the 10th year of the Plymouth line. Henry Ford had totally dominated the low price car market for many years. No other car manufacturer seemed to be able to compete with Ford’s mass produced assembly line, low cost, Model T. He was losing the gap though. Eventually he had to accept that it was time for a change. The Model T had run its course. In 1928 the Ford factories closed as they re-tool’d and prepared for the newest, upgraded Ford. What a perfect time for Walter Chrysler to release his new low-priced Plymouth line. I suppose you couldn’t buy a low priced new Ford in 1928, but hey this new Plymouth looks pretty swell. And loaded with features! Was the 1928 Plymouth a choreographed release for Chrysler? Or just pure luck? The next year the 1929 Ford Model A was revealed. Walter had already won a lot of new customers by then. His entry priced Plymouth started at $670. The 1928 4 dr 5 passenger sedan was $725. My 1938 Plymouth 5 passenger P6 Deluxe sedan was priced at $803. Here we are at the pump tonight. A fine, fine summer evening cruise. I’m getting great value back on that engine rebuild. 212 miles.

-

@Sniperwhat power brake bleeder? Do tell.

-

Trouble installing new handbrake band on 48 DeSoto

keithb7 replied to MarcDeSoto's topic in P15-D24 Forum

I sent my brake band to local rebuilder. Right off the top he said, "I know I don't have the proper thickness brake material. All that I can get is either too thick or too thin. It's difficult to source. I have not been able to get some for a long time. If you want it right, I will cut a thin metal spacer band. It will go behind the material and shim it to the proper thickness needed". I was grateful and indeed gave him my permission to build the shim, and make it right. He did so. It was a great fit. The brake works awesome. When I first installed it, I too set it too close to the drum. 15 minutes into a drive I could smell this odd burning odor. At a stop light I saw smoke drifting up aside my door window. I immediately pulled over. I rolled under the car, in the gravel. I cut the lock wire off and backed out the adjustment screws. All good, until I got home later and set it up properly. That was 3 years ago and its been great ever since. Good chance, based on this info, the aftermarket sellers today aren't going the extra step to shim it. I'd wager there are plenty of folks out there buying aftermarket relined driveline brake pads that perform mediocre at best. Too thick material it won't fit. Too small, it won't work all that good. I have found some aftermarket sellers to be pretty dirty. Be careful. -

I know we are bit infected with our old Mopars.Today I drove 2.5 hrs each way to go the the largest car show in my region. Walked around and never saw 1 old flathead era Mopar. I thought I saw a couple trucks. Nope hopped-up V8’s and such. Not sure I recall seeing more than 1 stock old vehicle. It was a 70’s VW. I guess I should have entered one of my old cars. Very good chance I’d have won “Survivor” category at least. Lol. I’ve pretty-well lost interest in all the hot rods and muscle cars. There’s just so many around. Saturated market it seems. I guess I am sick.

-

Lately these dumb ads keep popping up here in my P15-D24 pages. What purpose does this serve anyone? I guess it helps the fuel pump and fuel injector folks make a living. Mechanics too I guess. I can’t say I’ve ever searched or clicked on anything to lead to this type of directed advertising. Just dumb.