-

Posts

4,692 -

Joined

-

Last visited

-

Days Won

35

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Los_Control

-

How do you remove seat from a B1?

Los_Control replied to Stinger's topic in Mopar Flathead Truck Forum

Air ride .... in my truck there is a plate above passenger side sun visor explaining how to operate. I do not have the seat ... no idea how well it worked if ever.....just controlled the air going into the seat to control soft or hard ride. -

I think @soth122003is correct in getting the wheels off the ground for further inspection. I think when you apply the brakes it goes away is a clue it is in the front .... The drums are flip flopping around from loose bearings .... apply brakes & it put things back in alignment. Drive train noises can be tough to track down, the noise can just as easily be a u-joint going bad .... the noise seems to transfer throughout the drive train & difficult to pinpoint origin without getting the wheels off the ground ..... I would try for all 4 at the same time if possible .... And possibly run it in gear while it is off the ground. I made a mistake recently diagnosing a noise .... it was a more serious clank clunk noise. We drove it on a 2 hour freeway trip the day before & parked it. Was no issues. Drove to the hardware store the next morning ... made it to the stop sign & limped it home two blocks. I swore it was the rear end .... I knew the noise was the rear end! I drained the oil/removed the cover on my daily driver cheby ...... inspected everything, no problems .... So I pulled the axles out and checked the bearings .... no problems. Now I'm getting worried it might be a issue with the NV3500 transmission. For giggles I jack up the front. I saw the left front wheel lean since the outer wheel bearing disintegrated. ..... Sigh of relief, I instantly knew where the problem was. I'm just saying, if I put all 4 wheels off the ground I would have found the problem instantly. .... Instead I spent 2 days concentrated in one area & I was wrong. Don't be Fred! On a side note, my DD truck has well over 400k miles on it, I found out my rear end has been rebuilt, 3:08 gears, no metal shavings & perfect condition. ???

-

I do not remember that box, have enjoyed shredded wheat though, just a bit of sugar in the milk to sweeten it.

-

Really it looks great. I did the same thing on my truck & it is holding up after a few years just fine. I'm backwards. I'm blowing my truck apart & painting everything underneath as I put it back together ... outside is just primer to be painted later. I just noticed with the paint I was using iirc bought it from Ace hardware .... May not be the same as Rustoleum. Possibly I mixed mine using more lacquer thinner then you .... I go by feel not by measurement. Just thin & stir til I think it is right. Something I want to spray. Just saying I noticed it right away on the first panel I sprayed. .... So I asked here for help. I never did respray that fender & it is fine. It was @Plymouthy Adams told me what my mistake was, and gave me a lot of advice. I say thank you again. So now I just use paint thinner to mix with to spray underneath .... be honest I just want it protected, not concerned with looks. When I am ready to paint the exterior, something I do care about. I will have a fresh gallon of gloss black enamel from tractor supply. They sell a reducer add 1 pint to a gallon of paint .... not expensive, a step above mineral spirits. Then from Napa I get a pint can of universal gloss hardener ... makes your enamel paint 1 grade better ..... supposedly. About the best you can do for enamel paint .... sooo I'm told. If you look at off topic post I made earlier today in "show your gardens" The 16'x16' shed in background is Rustoleum white mixed with paint thinner 3-4 years ago & holding up fine. The garden box is same paint 2 years old. My $16 hvlp gun has a few miles on it

-

Bad year for onions When I bought the onion sets from tractor supply this year, was a week after a winter ice storm ... freezing weather. They store them outside but they looked good so bought them. Turns out when onions go through a freeze, it tricks them into thinking they are in their 2nd year growing .... Their job on 2nd year is to flower with seeds. Thats what is going on, one after another. Only thing to do is harvest them early & salvage what I can. Think I will let a few go to seed to collect them ... grow my own next year.

-

The end product looks pretty good. ...... I am surprised though. While I use the same $16 hvlp gun, Rustoleum primer & enamel paint from Tractor supply ..... although not sure today who makes TS paint ... they made a change. The first time I sprayed the paint I used Lacquer thinner ..... I was left with what looked like orange peel. ... kinda odd, not obvious, but it did not look right. I then read some more, Lacquer thinner is not to be used with enamel paint. I bought a gallon of paint thinner from Ace hardware, used it to mix my paint .... it did come out looking better. .... I was spraying larger panels like inner fenders. Just saying that was my experience. .... Maybe with a wheel with some lumps & pits in it, you will not notice. On a larger flat surface, you would see something that maybe you do not like ..... Lacquer thinner & Enamel paint is advised they do not mix .... they do get the job done though.

-

I have to laugh at our fathers & Grandfathers. I grew up on a 75 acre parcel of land. While there were two houses A large barn, A 3 or 4 car garage with dirt floor. There was a few out buildings also ... including a outhouse. My father had a set of planks that extended over the hill, was some post under the ramps .... he drove on to the planks, then walked the trail to get under the car & change the oil .... Today I wonder if he even caught the oil in a bucket .... crude & rude. I'm only saying that qualified lifting & testing our fathers would get a good laugh. While it is good to see it .... common sense plays a big role.

-

Thanks for the reply's .... Turns out I'm a idiot My daily driver is a 1991 chebby truck .... These buckets are the correct seats for my truck. I have a split bench with a fold down console .... I'm not changing it. When I drive it, I'm looking 8" above the steering wheel. .... So am confused why I'm looking straight at the steering wheel in the Dodge when the measurements are the same. On closer inspection today, I realize my seats are moved all the way back on the sliders. The back of the seats are leaning against the back of the cab to hold them up. I can reach the pedals fine & drive it this way. ..... Just got the low rider look going on. My risers are 1" taller at the front then the rear. I think if I do a temporary mount of the risers so I can slide the seat forward, they will be fine. Guess I'm just getting antsy to work on it again .... Dodge is parked on the side of the garage. Been busy getting spring chores out of the way. My chebby is in the driveway for yearly maintenance. Change the engine oil, .... maybe change transmission , rear end oil ... flush the brake fluid ..... grease the front wheel bearings ... We see what we get done. At the moment, I just threw the seats in the truck to get them out of the driveway .... I need to spend more time on them.

-

Getting my 46 WD15 repaired and back on the road

Los_Control replied to lostviking's topic in Mopar Flathead Truck Forum

You all good Lost .... just way ahead of many including myself. Too get that shiny paint you need lots of prep work. Many can not even imagine .... or care the amount of time to achieve it. Me, I'm sorry the color match was not to your liking ..... I get it .... swing & a miss. .... against a professional pitcher. I can only imagine how difficult it is to get custom paint mix to match with a old custom weathered custom paint job. What you are doing is great work, nobody expected you to do better .... There are a few here that can hang with you in custom paint .... Not me. I love the job you are doing .... not many know or understand the effort it takes. -

I need too ask for help. I'm wondering what the stock seat height is. My original Base I have, never had the lower springs .... I have nothing to measure off of. I bought some bucket seats from a 1991 chebby truck .... They are comfortable & satisfactory .... just too low. I need to modify the risers they sit on .... raise them 3 or 4 inches. I'm asking if someone can measure from the floor to the top of seat to give me a target. 13" is just too low.

-

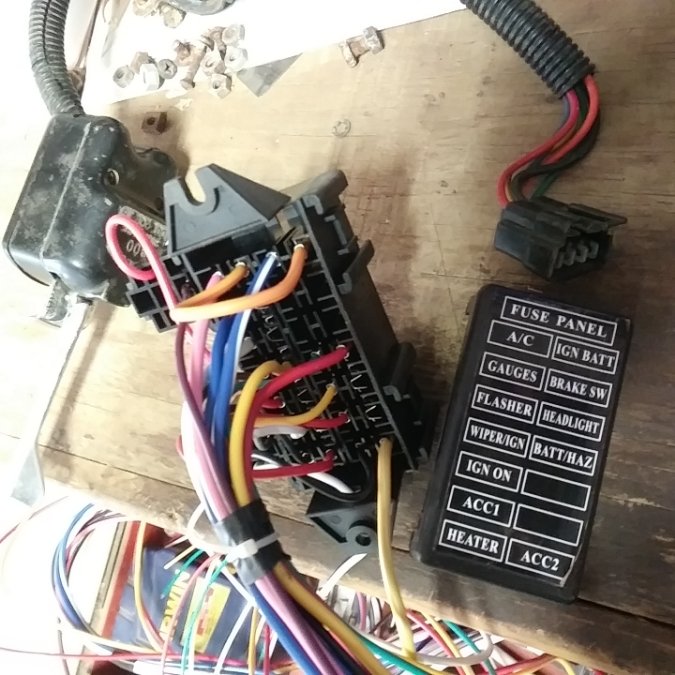

Time is money, I have more time then money. Having the brackets already made is well worth it. I read a review someone did on the cheap generic wiring harness's available. His qualifications, He works at or owns a shop that builds Hot Rods .... he has used all of the brand name wiring harness & he could nit pic little things about all of them. He had a project where he wanted to try one of the cheaper generic wiring harness .... His end results was, The wire grade was acceptable, the fuse box will work .... he was satisfied with it for that project .... shop truck? He would use them again. Not in a $50k Hot Rod, but on a project appropriate for the cost. I bought a cheap $50 harness from Amazon .... I agree with the guy with what I have seen. It is decent wire, well connected to the box, not going to fall apart. We can make this work dependably. My issues with it would be different then yours. ...... I have a truck with a stomp starter (no starter system) vacuum wipers. Very basic wiring needs. My goal was to de-pin the connectors from the box & wire it the way I wanted. Cheap box, the wires are in there to stay .... thats a good thing .... unless you want to modify it. It has 2 relays for turn signals & 4 way flashers ..... I can not use as is, can not move the wires around ..... I can cut, splice new wiring though. The box is labeled with a sticker, ..... it is wrong & does not match the way the box is wired. .... pull the sticker off, the lid is stamped, I saw sun roof ... does not match our cars. But the box & wiring will work. ..... You just need to pay attention & wire your car correctly, label as you go. The fuses are so cheap, when I pull one out, they box is tight and grabs the prongs of the fuse ... the plastic fuse cover pulls off ... you need pliers to remove the prongs individually. ...... You need to replace the fuses with a known quality brand .... I imagine the relays also .... Box & wiring is solid though. They have lots of wire .... I'm excited about that ..... Hard to buy that amount of different colored automotive wire for $50. I'm cutting out my box, creating a custom box using the wire .... again can use as is. Just saying, you can use the cheaper generic wiring harness .... you will need to work for it .... name brand will be easier. I've decided I'm cutting the wire loose & building a custom fuse block I can modify as needed .... If you can find a wiring harness made for your vehicle You are golden ... I personally will build one that fits me.

-

6 pages here .... I'm not reading back ..... Have we checked the obvious? I had some issues on my truck. Others pointed out that the pins going into the wheel cylinders were the wrong length. They were longer then the original pins ..... You could install the original pins or cut down the new pins. KK your drums are .020 under, shoes are over .... Those drums are precious .... turn only if absolutely needed Shoes are not cheap ..... Having them ground down is not cheap. What does a wheel cylinder cost? ..... take the pin, cut it down so your shoes fit. What would a farmer do back in the 1940's? ..... What did you hurt? .... what would be the consequences of shortening the pin? I get it I'm a hack. You have full shoes, you did not damage your drums ..... 10 years from now your shoes may be wearing down, the pins may be too short to push the shoes out ..... Now you need new pins or wheel cylinders to get the pins. Whats a replacement wheel cylinder cost? .... I have my original stored away. I have extra pins. I love @keithb7video on doing brakes one set at a time, front or rear. Let them wear in, then do the next. You will not need expensive machine work to get good brakes .... unless you have a different issue. I'm only suggesting a different way to fix this issue ..... throw lots of $$ at it .... or trim the pins to fit. As a old farmer, my garden is doing very well this year

-

Not sure exact date mopar came with electronic ignition .... late 70's .... 1979? There are several threads here on converting the slant 6 distributor. To oversimplify it, you use the shaft from your flathead distributor & swap it into a electronic slant 6 distributor body. Your oil pump has a slot for engagement ... slant 6 has gears. So you need to swap the shaft. The body of the slant 6 needs a little massaging to fit, I believe you can do this by hand with sandpaper. Do your research & read the threads on it. Just suggesting you do not need a machine shop to accomplish this. I plan to buy a spare distributor to donate the shaft, Rockauto you can buy the reman slant 6 for $120. Will also need the ignition control module to mount on the firewall .... $20 Now if you need a cap/rotor/plug wires .... you can get them from a local parts store .... might have to wait a day if not in stock ..... This photo is for a 1980 Plymouth Volare. This is my choice because I have had bad luck with points & condenser quality the last time I changed them. Was on my Uncles International truck. Went through 3 condensers from Napa, all bad out of the box. I pulled a used one from a junk engine & it worked fine. The plastic nub that rides on the cam to open the points .... is made from lesser quality material. As it wears you constantly need to adjust & eventually replace the points. I remember the days of having quality parts, and stopping into a parking lot on my way home from work to re-adjust my points in a 1969 mustang .... just to get home from work. Just a constant ongoing job to maintain the ignition system. Electronic ignition in a flathead will not make it go any faster .... sure does cut down on time spent maintaining the ignition system so you can spend the time elsewhere.

-

Sounds like you plan a new wire harness. The first thing would be to evaluate the condition of your harness. If it is original cloth covered .... probably needs replaced. If it has been replaced already & still 6 volt & in good condition .... will work fine for 12 volts. I think 12 volts does have advantages. Big reason for me is to do the slant 6 distributor hack to get oem electronic ignition. Points & condensers are hit and miss today with overseas quality parts. Yes you can still use 6 volt pertronix ..... I prefer oem available from any local parts store. Myself have not done the conversion yet. I chose what I thought was a Chevrolet internally regulated alternator. ...... Ended up with a externally regulated one. No big deal, $20 more for the regulator & I have to rewire it all anyways. I have it hanging on the upper bracket to size it up. Biggest problem I see is fabricating the lower bracket. Everything needs to move forward 3/4" to line up the pulleys. ..... this is where a kit would be handy, the mounting brackets are taken care of. The upper bracket can be heated & bent in a vise .... The lower bracket will be easy, just a zillion different ways to do it. So that is my view ..... A kit is easier installation. My way, have to fabricate mounts .... alternator is available at any parts store. Think I paid $48 for the 65 amp alternator, $20 for a solid state voltage regulator. If I was smarter, I would have bought the internally regulated alternator for the same $50 & saved $20.

-

Restoring an old 1946 - 1948 Chrysler Glove Box Door

Los_Control replied to Tom Skinner's topic in P15-D24 Forum

-

I can imagine the torque that thing puts out .... your arms will be tired. There are times you just need the big tool to get the job done. Once on a home remodel, it included removing existing sidewalks and adding new .... this meant a jackhammer. My employer rented & delivered a small jackhammer .... he thought it would be easier to handle. We tried all morning, first my apprentice & then I took over .... all it did was beat us up with the shaking, but broke no concrete. I went to lunch early at 11:00, turned in the small hammer for the big daddy .... 90# hammer. By 1:30 I had all the concrete broke, over 100'. ..... Employer sent me to return the rental tool, flipped me $20 to buy a beer, sent me home with pay. .... He, my apprentice & the laborer spent the day loading the broken concrete into a dumpster. Sometimes, only a big tool will work. @Uluare you sure you need that big tool for this job? I have a 4" Makita with a 5" brush that does a great job of removing the same crud your 7" is doing. The times I have used a 7" grinder that takes two hands to operate, That is a job.

-

My long winded story about driving cross country with a bad fuel pump .... things don't always fail in the ways we expect them to ..... they make you scratch your head. Making it possible your mechanical pump works for awhile, then you need the electric pump to get back home. Exactly. One way to justify the cost ..... they are fairly cheap. Today you can find them, couple years from now they may be hard to find. If it fixes the issue so be it., if not .... you now have a good spare pump you can pack away and carry it with you on road trips in case needed in the future. I think trying the coil is a pretty decent shot in the dark assuming it was bad and overheating .... if it was a ignition issue, the electric pump would have no effect.

-

51 B3B build thread - after all these years

Los_Control replied to bkahler's topic in Mopar Flathead Truck Forum

Here is a photo of it if you did not see it. Looks like they had some sort of tie downs installed so there are extra holes to weld up .... pretty simple to fix. Paint looks pretty rough, will take lots of sanding & prep. .... To be expected. It needs work, from photo it looks pretty straight. Possibly your painter could take care of the repairs. I see your location as Richmond, I was thinking VA .... a little closer then Kentucky. I'm not a big fan of facebook .... I use it mainly for marketplace. I did buy my truck from FB marketplace. I have bought parts from a seller who advertises on FB ..... Just another tool in the tool box for these old trucks. There is a seller named Douglas Crozier who I have bought from .... he ships everything. Probably have to ship it through fastenal. Is it worth it? I dunno, He would know because it is his business. I see DCM sells new low side bed sides for $800 each .... maybe someone sells the standard beds? -

My experience with a bad fuel pump was on a 1993 Caravan with a electric pump in the tank Father inlaw picked the wife & I up in Albuquerque Heading to Washington state. ..... He said he had a fuel issue on the way. Was strange. Problem was we could drive all night in cool air but come about 10:00-11:00 AM, the black asphalt was collecting radiant heat, the fuel tank was heating up ... the pump would still run, but not move any fuel. ...... Were talking 80F-90F daytime temps. Leaving ABQ the hottest part of the trip in the afternoon, we only made it a few hours til it crapped out on us. We waited til dark then drove all night into Utah. Utah we had a bad tire, slept in the van at walmart, when they opened we got a new tire. It was a light rain that day, we were able to get almost to Idaho in the rain. Then the weather cleared up the sun came out .... acted like vapor lock again. We sat till dark. Then we made it into Oregon overnight, by 10:00AM-11:00AM it got warm ..... we hung out in the park all day like bums .... waiting for late afternoon. We drove all night again and made it to our destination in WA the next morning. We changed the fuel pump & never had the problem again .... We drove it from WA to TX a few times after that. Only saying I have seen first hand how we drove 1/2 way across country with a bad fuel pump. The OEM pump would not pump fuel when the weather got warm, work all day long in cooler weather. ..... We could hear the electric pump motor working. Must have been something to do with the rubber diaphragm stretching when it got warm?

-

IMHO, just seems to early to have issues with vapor lock. The symptoms you described could be vapor lock .... just not warm enough here in Texas to see this. But with a warm engine heating the fuel ..... Who knows. Because I never driven my truck yet I never seen vapor lock. I'm adding a return line to the fuel tank to prevent it ..... Before it happens. What you describe sounds exactly like fuel turning into vapor. Todays fuel is absolutely crap ..... Are you sure it is just not your fuel heating up inside your fuel line & turning to vapor?

-

I'm thinking is always 4 0'clock somewhere.

-

IIRC, Ford actually had a few blocks they did this from the factory ... for racing ..... or large truck blocks. the idea is the same for any flathead. Just improve airflow. While I can not point to any Dodge racers that did the same trick .... sure there are a few. I really thought it was incredible to watch a Dude do it free hand with basic power tools used on wood. It took 2 or 3 passes to get them where they wanted to be. When finished you could throw the tools away .... they did their job.

- 181 replies

-

- engine running

- engine rebuild

-

(and 1 more)

Tagged with:

-

As a old wood butcher .... I'm surprised to see this task accomplished with a hand held router & a carbide bit ..... I guess it works. The only idea is to move air quicker sideways ...... Overhead valve were way ahead of the game. The Legend goes .... speed kills. Drive a Ford & live forever. I have a newer Ford engine then what @Snipershows ..... I'm not sure I'm brave enough to relieve the block myself ... No question about it .... that was a big thing to get more power out of a flathead.

- 181 replies

-

- engine running

- engine rebuild

-

(and 1 more)

Tagged with:

-

Well, last time I put on a show in Seattle .... I went to the hospital to visit my mother. It was quite the show when the 1972 T-bird caught fire in the parking lot. There was 2 firetrucks & a EMT vehicle ... a few police cars .... was a show for sure. Been a long time since I've been back though.

-

51 B3B build thread - after all these years

Los_Control replied to bkahler's topic in Mopar Flathead Truck Forum

For giggles, sometimes it pays to buy spare parts. This was posted on Facebook 5 hours ago .... $200 for everything ..... + shipping .... or located in PA. Just 1 decent side bed If you need it, or pay a panel beater 6 times that? https://www.facebook.com/groups/618593728345382/permalink/2100515440153196/ I saw this thing for sale 5 years ago for $200 & bought it .... Thinking I might need spare parts like suspension, brake drums ... might be fun to have a matching trailer to pull behind my truck .... today I have no plans for it. It is pretty straight & has a decent tailgate. .... It is not roadworthy, sure is a pile of spare parts though. I would bet a nickel, your truck being used to haul grain. It was always backed up to the grain pile & loaded by a tractor with a bucket. Then the operator would bump the bed side to get all the grain to fall out of the bucket. Would they then drive out to the field, open the door on the tailgate & leave a trail for the cattle to come eat?