-

Posts

4,947 -

Joined

-

Last visited

-

Days Won

42

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Los_Control

-

My big concern with facebook was being tracked or personal info being saved ... somehow it was intrusive in my life blah blah blah. And it is all true. Same time, do you have a cell phone? Same story you are already able to be tracked. Do you use google? Yup there ya go Do you order from Amazon? They hold the contract with the CIA to supply the data storage for all this electronic information. Only point is, facebook is just a tiny corner of the entire spider web. I once thought that I would not use facebook for these reasons, Now I feel like the boat is already sitting on the bottom of the lake, is way to late to try to bail water out now. May as well use it ... your tax dollars did help build it. Just keep a open mind about what it is, and use what you want while not sharing what you do not want. Yes I am labeled as a conspiracy theorist and I wear the hat with pride.

-

I agree with desoto 1939, thanks Sam Buchanan I think I opened a thread on this once but never really got a solid answer on it. I may just go ahead and leave my brass plugs in for now. I did put them in dry and they did leak a bit, I think they are no longer leaking at this point. I have the new steel plugs sitting here on the bench. Maybe is just the little devil in me. I am only the care taker of this truck, preserving it for the next person when I am gone. I think it would be selfish of me to deny the next care taker the enjoyment of replacing the soft plugs in the future .... ?

-

I certainly plan to live longer then that .... original last over 20 years .... todays china steel you may be right

-

I thank you for your question to the public ... I will give my humble reply. While a manager in a bandag retread shop ... and our buffer was down for repairs and mechanic was there to fix it. I asked mechanic, Why is there such a crappy brass screw block on that shaft, obvious it wears quickly. Mechanic replied, The brass screw block cost $300, The six foot long screw shaft cost $3k ...he asked me which do you want to replace? He then went on to explain that engineers design machinery this way, A sacrificial piece to avoid replacing the prize piece. This is the same attitude I use to the brass plugs and cast iron block today. I may be wrong, but the steel plugs will easily rust out after I am long dead and ashes spread around. The next care taker should have same fun I am having in replacing them.

-

My two cents .... I first bought cup plugs instead of the flat .... they looked stupid as they hung out of the block 3/16" So I went back and bought the welsh plugs (convex) I installed them and looked much better. Because the old plugs were installed with the dimple in, I installed new ones same way .... wrong! You need to install with the dimple out, then when you smack it with your favorite tool, the dimple will be in, and the metal plugs will expand to seal. I bought brass, and after I installed them backwards .... yes they do leak. I read one persons opinion about not using brass because of dis-similar metals. When you put brass into the cast iron block, something is going to rot ... since the brass will not, the block will. Granted, will not happen in my life time. But to help preserve the block for the next generation, for my next and final attempt to install welsh plugs, I bought steel. Much cheaper and easier to replace the plugs then fix the block.

-

I wonder if a cover from another heater would fit? Mine is a model 61. Just saying you might refurbish it and use it, keep your eyes open for another cover. I measured aprox 8" from top to bottom not counting the tabs. is 7 & 3/8" wide and tabs are 4 & 7/16" apart

-

-

Let me add to this ....This advice is 100% correct, do not forget to backup your photos. I had a old beater computer in the shop, something did not really care about, hard drive died and I lost all of the photos I have been taking along the way. Now I am struggling because I lost the photos I had taken to help me. In the computer world, geeks say, "there are two types of computer users ... those with backups and those who wished they had backups"

-

If you hold your tongue just right, inhale and exhale, you will make a really funny sound as you suck in air and expel saliva .... plus your wife will be calling 911 If fluid is coming out, you are guaranteed air is coming in.

-

little bit of playing, here on linux I can open almost anything. I tried to convert to jpeg, pdf and simply the file itself has issues and not the file extension. To answer your question, windows photo viewer should open it for you .... still I think is bad file not a issue on your end.

-

Just saying, if I had your parts ... would throw mine away

-

fwiw, I plan to pull my engine at a later date, not this date. I removed the water pump and radiator, snaked a piece of flat bar through the grill into the dist tube and rodded out the calcium and lime. Removed the oil fill tube, distributor, and the soft plugs. Then snaked Ford wire up into the block and pulled all the sand out. Be amazed how much sand comes out ... people claim it is left over from when the block was originally cast'ed, they just never cleaned it out. Why everybody has same issue .... I do not think hot tank cleans it out. Just sits there. Total cost is gaskets and 5 soft plugs ...maybe $20, just labor to get er did. And now in West TX is a great time to fix this.

-

My 218 flathead when I first got it running after sitting 20 years. it warmed up and continued to climb straight to over heat level. Then go to remove T-stat and was already 1 bolt broke in the T-stat housing. I think this is why my truck was taken out of service for a long sleep. I found the water distribution tube clogged, and the block was filled with original casting sand. If you open your block drain plug (located near distributor) no water/coolant comes out, most likely you have casting sand also ... think most all do. I fixed these two problems, now idle in driveway with no T-stat installed for 45-60 min, it runs at 160. Then it will start to creep up to 180, fast idle and drops right back to 160. I imagine if I drove it, the temp would not reach 160 with the air flow. I need to install a T-stat to get to 180 operating temp. These engines normally run cool. If you are reaching 200, I suspect you have a circulation issue. I have been hanging around these forums for a few years, is common to use the modern T-stat you show .... I bought stant 13478 for mine. Is 180 degrees. Pull your t-stat out and see where it runs .... only takes a few min and think you will at very least, establish a base line and see what a T-stat will change.

-

imho ... think I have even read on adjusting newer trucks steering boxes. (60's-80's) Fords are terrible and every Ford I owned the steer box needed adjusted. On my 1987 I got it dirt cheap because it needed adjusted, took 2 min and drove it for 15 years afterwords. On my 1969, I adjusted it once, then 6 months later twice, then a year later the gears were so worn they broke. I believe you can only adjust them so many times before it becomes unsafe to drive. The gears are getting worn and sloppy, so you adjust and pull them together, then you repeat .... at some point they are to thin to be safe. My 1969 broke in the driveway, would have been a disaster if was driving down the highway.

-

273 ci V8 in ‘52 Dodge Coronet w/GyroMatic

Los_Control replied to Retrorudy's topic in P15-D24 Forum

Thanks kencombs for explanation. I was particularly thinking of a thread in another forum where a guy was putting a chevy 4 cyl marine engine into a model T ford. Dual 4 or 6 cyl may be more popular combo for the average joe boat. A Mexican drug cartel leader, may want dual 273 mopar engines .... Just not a impossible combo. If I was parting out a dual engines boat, I wanted one of the engines for self, which engine would I sell first? I just thought it worth mentioning, most boats would have single engine and a non issue then I suspect. Even then, is the marine engine like a stationary industrial engine? No vacuum advance, governed carb and sometimes a cam to match the use of a stationary engine? Just thinking that a marine engine is fine, it just may not be a drop in plug & play engine. If a guy is aware of what they have, could be very minor changes. -

Installing a new seat, I think you will want to remove the base from the floor of the cab. You also will need to reinforce the floor when you mount the new seat. I read your post as you are trying to adapt the new seat to the old base? I also need to choose a new seat, The original seat of my 49 b1b is 59" wide. I recently ended up with a seat that came from some unknown Toyota truck, I thought it would be fine, turns out it is 49" wide and just wrong. I do have it sitting in the cab temporarily, replacing the 5 gallon bucket I was using .... height is all wrong. I am a shorter person, and the Toyota seat tracks, sitting on 4x4 wood blocks is only 12" tall to seat, I feel like a kid trying to look out the windshield. While a guy 6'5" may think it is perfect. If you can mock up a height that you like, know your width, then take your tape measure to the wrecking yard and pick one. Right now I am leaning to dodge mini van front bucket seats with arm rest and build a console. My wifes dodge mini van is very comfortable, the seats sit on pedestals and seat is 16" off the floor. Just saying is height along with width.

-

273 ci V8 in ‘52 Dodge Coronet w/GyroMatic

Los_Control replied to Retrorudy's topic in P15-D24 Forum

Just curious, I have no clue, seems I read that some marine engines actually run backwards compared to a automotive engine. Then there may be a issue with distributor, cam vacuum etc. I guess it depends on the boat manufacturer and the out drive it was connected to? I just assume you already know this and checked into it, if not you may have a bigger surprise then just bell housing coming. -

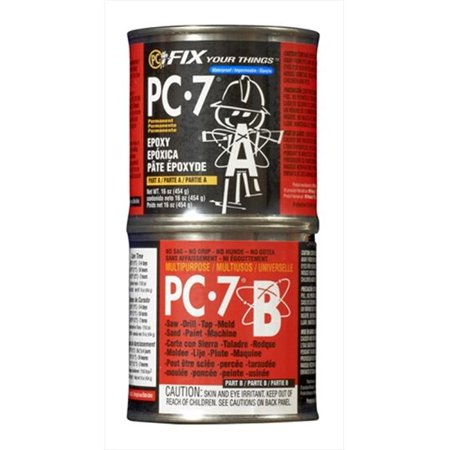

Curious what others think about this product to repair the steering wheel. it is a multi purpose product, so when you have it around the shop you never know what you might use it on. Oil pans, gas tanks, radiators, rust holes in sheet metal Wallmart sells it online, 8 0z cans for $14 .... I assume 2 parts = 16oz? No idea what por 15 product wants for theirs. $14 seems cheap to me. There is also pc 11, is a slightly better product, Walmart sells for $15, you can repair fiberglass boats under water, cracks in swimming pools, cracked plumbing drains, one advertiser claims steering wheels. Either way, pc 7 is often compared to jb weld, and jb works on steering wheels, I like that you can buy it in a can at a reasonable price, and not price gouged by little tubes of jb. oops .... I just saw this ..... carry on

-

51 B3B build thread - after all these years

Los_Control replied to bkahler's topic in Mopar Flathead Truck Forum

Pretty obvious in the photos of the rear axle, pinion is offset and one shorter then the other, swapping them to right side seems fixed to me Is a common way to narrow a rear end, use two short axles and cut down the axle tube to fit .... I suppose in this case, a guy could use 2 of the longer tubes and axles and widen the rear end, not needing spacers. Nobody is going to care about using the spacers though .... carry on -

51 B3B build thread - after all these years

Los_Control replied to bkahler's topic in Mopar Flathead Truck Forum

My worthless opinion, pictures can be deceiving. Imagine if you had chrome acorn nuts for your mag wheels, threads are not going to protrude out the end. You could put a cap on yours and have acorn nuts .... imhwo, what I see is not really uncommon and has been done for years. With that said, Looks like in the photo there is only a few threads engaging the nut. Maybe that is because of the magic of photography? We can not see how deep/wide the existing nuts are, possible there is plenty of contact surface, all we see is the threads left over. Just use common sense, would be real easy to change them now then fix broken pieces later. Looks awesome! -

No mechanic, just curious what type of ignition system, points or hei and have you checked the point gap if points?

-

Old trucks with old front ends & old grease

Los_Control replied to Los_Control's topic in Mopar Flathead Truck Forum

That actually is a good idea, may be possible to feed 2 wires through instead of coax. I was just kinda sleep walking and not paying attention to how important ground is with this system. Originally was thinking horn button was a switch and no need to think about ground .... I see now is very wrong. I find it curious how they put extra effort into creating the tabbed plate the horn button connects to.

.jpeg.a093737e8e8950b101612a54e593b704.jpeg)