-

Posts

4,986 -

Joined

-

Last visited

-

Days Won

43

Everything posted by Los_Control

-

little bit of playing, here on linux I can open almost anything. I tried to convert to jpeg, pdf and simply the file itself has issues and not the file extension. To answer your question, windows photo viewer should open it for you .... still I think is bad file not a issue on your end.

-

Just saying, if I had your parts ... would throw mine away

-

fwiw, I plan to pull my engine at a later date, not this date. I removed the water pump and radiator, snaked a piece of flat bar through the grill into the dist tube and rodded out the calcium and lime. Removed the oil fill tube, distributor, and the soft plugs. Then snaked Ford wire up into the block and pulled all the sand out. Be amazed how much sand comes out ... people claim it is left over from when the block was originally cast'ed, they just never cleaned it out. Why everybody has same issue .... I do not think hot tank cleans it out. Just sits there. Total cost is gaskets and 5 soft plugs ...maybe $20, just labor to get er did. And now in West TX is a great time to fix this.

-

My 218 flathead when I first got it running after sitting 20 years. it warmed up and continued to climb straight to over heat level. Then go to remove T-stat and was already 1 bolt broke in the T-stat housing. I think this is why my truck was taken out of service for a long sleep. I found the water distribution tube clogged, and the block was filled with original casting sand. If you open your block drain plug (located near distributor) no water/coolant comes out, most likely you have casting sand also ... think most all do. I fixed these two problems, now idle in driveway with no T-stat installed for 45-60 min, it runs at 160. Then it will start to creep up to 180, fast idle and drops right back to 160. I imagine if I drove it, the temp would not reach 160 with the air flow. I need to install a T-stat to get to 180 operating temp. These engines normally run cool. If you are reaching 200, I suspect you have a circulation issue. I have been hanging around these forums for a few years, is common to use the modern T-stat you show .... I bought stant 13478 for mine. Is 180 degrees. Pull your t-stat out and see where it runs .... only takes a few min and think you will at very least, establish a base line and see what a T-stat will change.

-

imho ... think I have even read on adjusting newer trucks steering boxes. (60's-80's) Fords are terrible and every Ford I owned the steer box needed adjusted. On my 1987 I got it dirt cheap because it needed adjusted, took 2 min and drove it for 15 years afterwords. On my 1969, I adjusted it once, then 6 months later twice, then a year later the gears were so worn they broke. I believe you can only adjust them so many times before it becomes unsafe to drive. The gears are getting worn and sloppy, so you adjust and pull them together, then you repeat .... at some point they are to thin to be safe. My 1969 broke in the driveway, would have been a disaster if was driving down the highway.

-

273 ci V8 in ‘52 Dodge Coronet w/GyroMatic

Los_Control replied to Retrorudy's topic in P15-D24 Forum

Thanks kencombs for explanation. I was particularly thinking of a thread in another forum where a guy was putting a chevy 4 cyl marine engine into a model T ford. Dual 4 or 6 cyl may be more popular combo for the average joe boat. A Mexican drug cartel leader, may want dual 273 mopar engines .... Just not a impossible combo. If I was parting out a dual engines boat, I wanted one of the engines for self, which engine would I sell first? I just thought it worth mentioning, most boats would have single engine and a non issue then I suspect. Even then, is the marine engine like a stationary industrial engine? No vacuum advance, governed carb and sometimes a cam to match the use of a stationary engine? Just thinking that a marine engine is fine, it just may not be a drop in plug & play engine. If a guy is aware of what they have, could be very minor changes. -

Installing a new seat, I think you will want to remove the base from the floor of the cab. You also will need to reinforce the floor when you mount the new seat. I read your post as you are trying to adapt the new seat to the old base? I also need to choose a new seat, The original seat of my 49 b1b is 59" wide. I recently ended up with a seat that came from some unknown Toyota truck, I thought it would be fine, turns out it is 49" wide and just wrong. I do have it sitting in the cab temporarily, replacing the 5 gallon bucket I was using .... height is all wrong. I am a shorter person, and the Toyota seat tracks, sitting on 4x4 wood blocks is only 12" tall to seat, I feel like a kid trying to look out the windshield. While a guy 6'5" may think it is perfect. If you can mock up a height that you like, know your width, then take your tape measure to the wrecking yard and pick one. Right now I am leaning to dodge mini van front bucket seats with arm rest and build a console. My wifes dodge mini van is very comfortable, the seats sit on pedestals and seat is 16" off the floor. Just saying is height along with width.

-

273 ci V8 in ‘52 Dodge Coronet w/GyroMatic

Los_Control replied to Retrorudy's topic in P15-D24 Forum

Just curious, I have no clue, seems I read that some marine engines actually run backwards compared to a automotive engine. Then there may be a issue with distributor, cam vacuum etc. I guess it depends on the boat manufacturer and the out drive it was connected to? I just assume you already know this and checked into it, if not you may have a bigger surprise then just bell housing coming. -

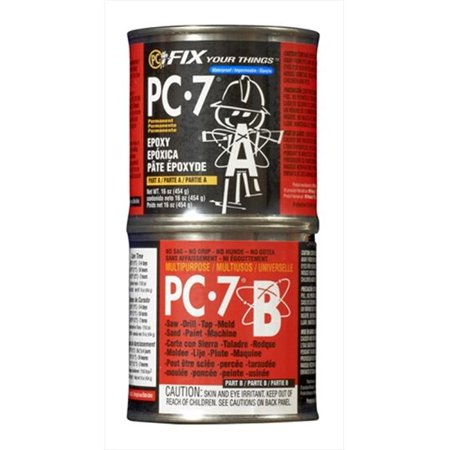

Curious what others think about this product to repair the steering wheel. it is a multi purpose product, so when you have it around the shop you never know what you might use it on. Oil pans, gas tanks, radiators, rust holes in sheet metal Wallmart sells it online, 8 0z cans for $14 .... I assume 2 parts = 16oz? No idea what por 15 product wants for theirs. $14 seems cheap to me. There is also pc 11, is a slightly better product, Walmart sells for $15, you can repair fiberglass boats under water, cracks in swimming pools, cracked plumbing drains, one advertiser claims steering wheels. Either way, pc 7 is often compared to jb weld, and jb works on steering wheels, I like that you can buy it in a can at a reasonable price, and not price gouged by little tubes of jb. oops .... I just saw this ..... carry on

-

51 B3B build thread - after all these years

Los_Control replied to bkahler's topic in Mopar Flathead Truck Forum

Pretty obvious in the photos of the rear axle, pinion is offset and one shorter then the other, swapping them to right side seems fixed to me Is a common way to narrow a rear end, use two short axles and cut down the axle tube to fit .... I suppose in this case, a guy could use 2 of the longer tubes and axles and widen the rear end, not needing spacers. Nobody is going to care about using the spacers though .... carry on -

51 B3B build thread - after all these years

Los_Control replied to bkahler's topic in Mopar Flathead Truck Forum

My worthless opinion, pictures can be deceiving. Imagine if you had chrome acorn nuts for your mag wheels, threads are not going to protrude out the end. You could put a cap on yours and have acorn nuts .... imhwo, what I see is not really uncommon and has been done for years. With that said, Looks like in the photo there is only a few threads engaging the nut. Maybe that is because of the magic of photography? We can not see how deep/wide the existing nuts are, possible there is plenty of contact surface, all we see is the threads left over. Just use common sense, would be real easy to change them now then fix broken pieces later. Looks awesome! -

No mechanic, just curious what type of ignition system, points or hei and have you checked the point gap if points?

-

Old trucks with old front ends & old grease

Los_Control replied to Los_Control's topic in Mopar Flathead Truck Forum

That actually is a good idea, may be possible to feed 2 wires through instead of coax. I was just kinda sleep walking and not paying attention to how important ground is with this system. Originally was thinking horn button was a switch and no need to think about ground .... I see now is very wrong. I find it curious how they put extra effort into creating the tabbed plate the horn button connects to. -

Old trucks with old front ends & old grease

Los_Control replied to Los_Control's topic in Mopar Flathead Truck Forum

Yeah, maybe I did not think that one through. I was in clean and paint mode, was 1/2 way done before discovered the copper base. Is just rattle can of rusty metal primer and gloss black paint. Probably easier to sand it clean then mask it off anyways. Hind sight I suppose should have just cleaned it then soak it in oil, since it never was painted from factory. Now it is cleaned, painted,sanded and soaking in oil. -

Old trucks with old front ends & old grease

Los_Control replied to Los_Control's topic in Mopar Flathead Truck Forum

Also curious about the horn assembly, I cleaned and painted it. The base seems to be copper and think I need to scrape the paint off for it to work, is this true? -

Old trucks with old front ends & old grease

Los_Control replied to Los_Control's topic in Mopar Flathead Truck Forum

I swear I have attention deficit disorder .... going to be a looong build. I got side tracked with mowing the grass, then thought would like to buy a riding mower and found a cheap rider that needs work at a estate sale. Came home with a few other items, one is a box of pullers .... funny how life seems to smile on us at times. -

You ever think about putting wipers in them holes? I have to admit Texas is pretty lax about safety inspection here, when I had my truck inspected the daughter was sick and at home, so father the shop owner just passed it with out moving from desk. If his daughter was there she would make sure the wipers worked and then lecture me on how old the rubbers were. Wipers are something I seldom use in West Texas, I sure would not want a car without them.

-

Not a pilothouse.....but man am I happy.

Los_Control replied to Frank Elder's topic in Off Topic (OT)

Some things never change, Dodge always had the ugly face only a mother can love. My 1949 or your 1979, ugly as sin. Boy they sure are good trucks though, congratz on your rare low mile find. -

I am really looking forward to fixing mine. My other truck and wifes car both have new stereos/cd players, and they are tuned to the local am radio station. It may sound strange in 2020, but living in a small town there is no local fm station, closest one is over 60 miles away. And am lucky they play decent country western, a mix from the 50's to modern ... I get to hear the local police reports, who got drunk last night .... local sales, news reports .... My fm stereo has been on am station for the past 2+ years.

-

Old trucks with old front ends & old grease

Los_Control replied to Los_Control's topic in Mopar Flathead Truck Forum

That is pro all the way, if I had a nice car that is the way I would want to do it. Same time would have to buy each tool and how often this old carpenter would use them again is questionable. I went to the hardware store yesterday, bought 3' of angle iron and all thread, (ready rod) I figure to make something out of it today. I needed the angle iron anyways to make the rear mounting bracket for the new Tanks gas tank. So use it as a puller then re-use it as a bracket. -

Old trucks with old front ends & old grease

Los_Control replied to Los_Control's topic in Mopar Flathead Truck Forum

I just went and checked, basically the area where you would drill is about 1.5" in diameter. I drilled a hole outside of that and is pure bakelite .. no steel. So if you drilled 2, 7/16" holes in the 1.5" metal for the puller ... they would be to close together for the puller. And would remove to much metal. Want to say this is a poor design, but possible to have proper spear action from the steering column, you need a steering wheel that can break away properly? -

Old trucks with old front ends & old grease

Los_Control replied to Los_Control's topic in Mopar Flathead Truck Forum

I would have to first pull it to tell if that would work ... I wonder what others think? I have no idea how thick the metal would be, if it could be drilled and tapped. -

Old trucks with old front ends & old grease

Los_Control replied to Los_Control's topic in Mopar Flathead Truck Forum

CO54 just gave me a really good idea of using a bearing spliter. I think something like this may be the professional way to go. And the kit seems to have the puller to go with it. He said he used it and worked for him to pull his wheel off. Offered to loan it to me and return it, I thank him but will not borrow tools. Still I think I may have parts laying around to make something like this ... not pretty but maybe will work.

.jpeg.a093737e8e8950b101612a54e593b704.jpeg)