-

Posts

358 -

Joined

-

Last visited

-

Days Won

6

Everything posted by johnsartain

-

I thought these were pretty cool, Not original Mopar but Priced pretty good. I had to use my Die grinder and drill press to make them fit the stamped tail light bracket DCM sells. https://www.amazon.com/gp/product/B01CQCQ9AE/ref=oh_aui_detailpage_o06_s00?ie=UTF8&psc=1

-

You might try one from a Singer Home model if you can find a parts book for it. Maybe try a Fabric outlet or hobby store. All of the commercial models I have ever seen had a Flat head machine screw. I worked as a sewing machine mechanic from 1978 - 1988 and the moved to automated apparel equipment till 1998. I left that when apparel moved off shore and went into computers and networks. They tended to stay away form anything more than a machine screw because of the OSHA requirement for a needle guard. I also did a couple short stints in Furniture and Upholstery.

-

I'm not sure that switching to a new 5 or 6 speed tranny, you'll be able to keep the tranny mounted e-brake. I went had to go to a newer type NP435 4 speed and lost that part on mine. I ended up swapping the differential for a Cherokee 3.55 differential, I still need to come up with the cable to go from the T handle to the e-brake linkage if there is anyone who has any recommendations, I'm listening. Anyone have a cable that will fit for sale?

-

I think the 120 degrees was the main problem, I experienced the same. Whatever came over me to paint, medium reducer, my truck in mid August in Arizona. I know! I had the fever to get it on the road and drive it. It's all good though. Nothing a sanding and clear coat won't take care of.

-

Depends on the buyer. If the buyer is looking for a restoration, then yes they will offer less or turn their nose up and walk away. If the buyer is looking for a resto-mod and your modification has improved upon the factory specs, then you may have increased its value. If you're keeping it for yourself or want a show stopper. Who cares about value. If you have the original parts to the truck, hold on to them and keep them in good shape. For a restoration to have good value, attention to detail is your greatest concern, If you use modern fasteners in place of the original fasteners, that in itself can decrease the value tremendously. If you use reproduction parts, that will take away from the value. Even if you do a complete detailed restoration, you still have to find a buyer to pay your price. I saw an ebay ad looking to get $50,000 for A 1949 Model B in the Ebay, Craigslist and External Site Referrals P15-D24 forum. This is the most I have ever seen someone value a Pilothouse Truck for I hope he get it as it sets the bar higher for value of our trucks but truth to be told, he still likes a lot being able to call it a restoration.

-

I am totally envious

- 371 replies

-

- 1

-

-

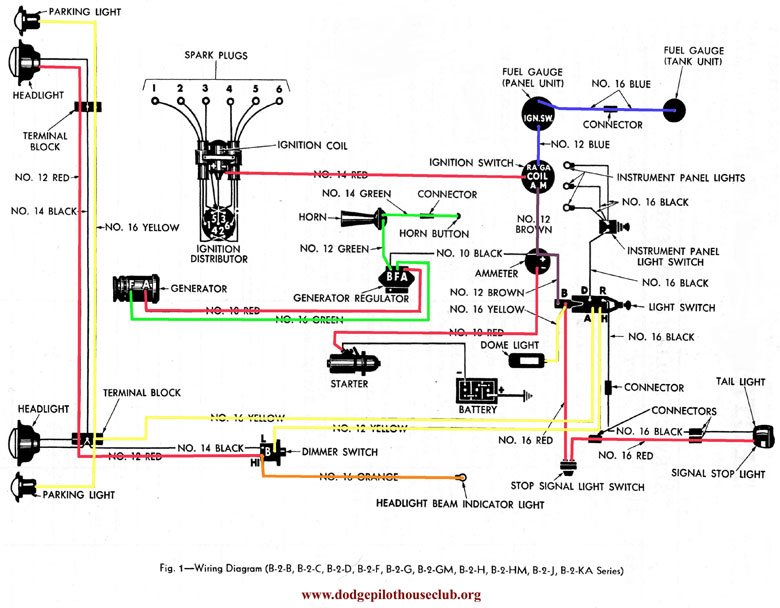

1951 B-3-B need to jump coil to start

johnsartain replied to downhill-bill's topic in Mopar Flathead Truck Forum

With your key on, is there power to the coil? Next is there power to the ignition switch? Check power to the Ammeter. If the wiring harness is original, Power is fed from the starter terminal to the ammeter, from the ammeter to the ignition switch, and from the ignition switch to the coil. Using an test light check power from each component to ground. Wherever you lose power, isolate the component and check the component. Considering the age of the vehicle it could easily be a wiring issue, Old cloth insulation becomes brittle over time and cracks. This can cause shorts and burnt wiring harnesses. The ignition switch can go bad or if the truck was jumped from a 12 volt system, the Ammeter could have been damaged. A quick check of this would be to jumper the ammeter contacts and try to start it. You can also jumper the ignition switch. Here is a wiring diagram that may help you along the way. -

1954 flat head throttle linkage help!

johnsartain replied to Gman's topic in Mopar Flathead Truck Forum

I looked when I got home this afternoon and found the hole, or a hole. Next question is if it is the same size of spring and does it attach to the eye of a cotter pin like the other? If the spring is different is there a length of the coil or something, that could help out in getting the right part or reasonable facsimile. -

1954 flat head throttle linkage help!

johnsartain replied to Gman's topic in Mopar Flathead Truck Forum

Dodger, do you have a picture or video of where the spring from the carburetor attaches to the inner fender? I see the hole in the carbs throttle linkage but am curious as to what the attachment to the inner fender looks like. That could explain some things. -

1954 flat head throttle linkage help!

johnsartain replied to Gman's topic in Mopar Flathead Truck Forum

The picture below shows where it hooks to at the carburetor. The other end of the spring hooks up to a cotter pin through a hole in the floorboard, no sh!t. Look for the hole directly behind the linkage in the upper part of the removable floorboard. Never mind the call out. The spring in question is in the lower left corner. -

I had looked for a few months for mine but every price i saw made me cringe. I had run up on some on eBay at the very outset of my search and had dismissed the price of $1300 for a restored set of bars as too high. After about 10 months ad figuring different ways out of my dilemma, buying old and restoring, buying steel bars and having them chromed. Making them out of aluminum, getting bead roller dies and rolling my own... I decided the $1300 wasn't too high after all. I looked on eBay and there were none of the restored bars to be found. On a chance I called the guy, Eric Bannerman I believe the name was, and he had just got some back from restoration. so I just went ahead and pooled all my money and just bought them. Like LC says, "the 48-49 grill is what makes the world go round" even on my 1950 model. That year Steel bars were stock and stainless was an option.

-

I am working on Christmas pics, but there was a car show this weekend and the Christmas parade. It was my trucks first of both. Here is a link to the parade, I'm at around 9:10. and some car show pics below. The Car show is sponsored by a local dealership and is a charity event for Catholic Community Services. Entry fee is cash or gift for a child with all proceeds going to their foster care program. With all the gifts and money raised, some kids will have a Very Merry Christmas.

-

I like the caution on a Fleets Enema that reminds one "Not to be administered orally"

-

You can buy a reamer that is adjustable. It will only adjust in thousandths increments. There will be a t-handle on one end and a screw and nut on the other. Adjustment of the screw expands the center portion of the reamer to the reamer will have to go completely from one end of the reamer section to the other to do its job correctly. Another solution is to use emery cloth. You can cut a piece of bar stock of the diameter that will fit through the hole with a wrap or two of the emery cloth around it. the bar can be slotted to slip the emery cloth into the slot. the shaft can then be inserted in a drill and run the emery cloth back and forth through the hole. It's sort of a poor mans reamer but we used it to knock off burrs after pressing in a bushing. If you use this be careful not to get carried away and over do it. Also don't favor one side of the hole too much. Adjustable Reamer:

-

Keep this going guys. I will be doing this on mine over the winter. I can tell there is a lot of slop in mine after getting it on the road and loosened up.

-

if you are talking about the stepped portion, you'll have to check yours. Mine was a 1950 b2b and it was there. I did the conversion kit so I didn't have to worry about it. Had I bee able to get the factory drum brakes going I may have considered it. All things considered, I am satisfied that I made the conversion. I completed the installation in under 2 hours and couldn't have asked for it to be any easier. Hardest part was drilling and tapping the backing plate on the spindle and drilling the control arm.

-

1/2-20 seems to be the standard size when doing a conversion. It is the size of the stud used in the disc for the Rusty Hope and other conversions and it is the size stud found on the Cherokee rear axles. If you intend to put them into the hubs of a b2b you will likely have to drill out the old hole before pressing the studs in. You wheel lugs were 1/2-20 lug bolts. Look carefully at the hub flange and make sure that there isn't a stepped portion on the back side. If there is you will need to machine the flange to allow the stud head to fully seat against the flange.

-

The pad, is not the same as what goes between the cab and frame. it can be a rubber pad or rubberized fabric pad. Either is about an eighth of an inch thick. I know someone who substituted a piece of conveyor belt but be careful on what you substitute because the running boards must align with the holes in the rear fender and at the same time maintain a consistent gap between the bottom of the door and door jamb to the running board. There is a little room to fudge but not much.

-

B1B Project / progress thread

johnsartain replied to John Rogers's topic in Mopar Flathead Truck Forum

And don't give up on just one Ace Hardware. I have found items in the Bisbee store that I couldn't find in Sierra Vista, and vice versa. -

There are 6 volt starters to fit your engine. You will also have to change the coil to a 6 volt coil to get the best spark. The 265 is about 2 inches longer than the 218. Measure to make sure you have the clearance needed to install the motor. I know in my truck with a 218 there is about 1/2 " between the fan and the radiator. There is some adjustment on the radiator support where I may get an inch or so. the radiator could be mounted differently as well. Do you research and have a plan before you begin. There are two flywheels that i know of, a 146 tooth and a 172 tooth. I ran into an issue here as a previous owner who had disassembled much of the truck has a 172 tooth mounted to my engine. The truck requires a 146 tooth to match the bellhousing and starter. I didn't find this out until I had bought a new starter, I originally thought it was the wrong bendix on the starter. I got lucky as I found I already had another flywheel that had the correct teeth. Another Issue I had with 6 volt is that I got stuck when my generator wasn't working. Getting jumped is risky with a 6 volt system when everyone else is 12 volt. I had a jumper box with a switch I could turn on just long enough to jump and switch it back off. Just don't hold the brake while you have the 12 volt hooked up or you will be replacing bulbs. If you decide to jump off from another vehicle, make sure that they don't touch as your car is likely positive ground and the new er vehicles are negative ground. Touching metal bumpers results in a direct short.

-

Having organization in your tool chest is not a bad thing for a parent teaching their kids the virtues of taking care of the tools. Mine know that all it takes is a glance to tell a tool is missing. After listening to me a few times they learn quick to put it back when you're done or you can't use the tools again till it gets replaced. I haven't replaced a tool in some time unless I broke one.

-

California & The Internal Combustion Engine

johnsartain replied to Bingster's topic in Off Topic (OT)

Oceanfront property in Arizona, can't wait! -

If you're not messing with the Ol Dodge, or thinking about it, if you're not working turning a dollar. Its time wasted, it's all a matter of perspective.

-

Not car related but I got a kick out of "Joe's Apartment". There's just something about a love story and singing cockroaches.