-

Posts

612 -

Joined

-

Last visited

-

Days Won

9

HotRodTractor last won the day on June 12 2021

HotRodTractor had the most liked content!

Reputation

356 ExcellentProfile Information

-

Gender

Male

-

Location

Cable Ohio

-

Interests

Things with 4 wheels

-

My Project Cars

1948 P-15

1948 1-1/2T

1949 B2B

1950 B2C

Contact Methods

-

Biography

Farmer, Engineer, Maker, Overlord of the Universe

-

Occupation

I make stuff - some digital - some physical, all real

Converted

-

Location

The Alps of Champaign County Ohio

-

Interests

Antique Trucks, tractors, anythign with wheels.

Recent Profile Visitors

3,490 profile views

-

HotRodTractor started following The Vintage Mopar Market: A Summary , 25” engines , Industrial engine displacement and 5 others

-

I've been looking for a Massey 25 or 25a combine in good useable condition to restored condition..... they had Mopar flatheads in them as well... but that is probably a subject for another thread. My IND265 engine came out of an Oliver combine. You're correct that they aren't hard to find if you are somewhere where used industrial or farm equipment can be readily found. I've found them in tow motors, generators, combines, payloaders, tractors, etc... Lots of options, especially if you are patient.

-

I think you need to double check your stroke measurement. Something is off.

-

B-1-F-170 Farm truck in the making.

HotRodTractor replied to HotRodTractor's topic in Mopar Flathead Truck Forum

The 6.7L should pull the trailer quite nicely - especially with the upgrades I have planned.... but that is a subject for another day. -

B-1-F-170 Farm truck in the making.

HotRodTractor replied to HotRodTractor's topic in Mopar Flathead Truck Forum

Time to knock the dust off of this old thread. After stepping back and evaluating what I want and need this truck to do - combined with some other factors - Its time to take this project in a very different direction. 2006 Ford F550 4x4 chassis with 4.30 gears, 2009 6.7 Cummins turbo diesel engine, 2004 ZF S6-750 manual transmission with 271 manual transfer case. Picture it all coming together on modern tires of the "correct" height (I'm probably going with 37s) - and set at factory 1948 ride height on a substantially shortened chassis and maybe a 12 foot bed (still TBD after I get the cab and driveline set). I'll have the chassis in the shop before Halloween to start getting serious on measurements and cab mount fabrication. I'll be taking a page out of Mark's book on TODD and probably go full tilt front end just for the sake of access to the engine compartment. I'm leaving the patina on the cab. Its character and history that I simply am not ready to loose. The interior will get some updates over time. For the sake of functionality it will see the most changes - which does somewhat break my heart. It needs full insulation, A/C, navigation, and probably a full digital dash (only because its easy and cost effective for a full set of gauges on CANBUS. A modern tilt column, modern seats, hung pedals, etc.... The truck will be used around the farm and on future project retrieval missions. The plan is to have it functional and working the bugs out of it by late spring 2022, probably some more tweaks and updates over the winter, and then some long road trips with a large gooseneck in tow going to several antique tractor shows in 2023. 2023 is the 100th anniversary of the John Deere D and I have a pretty early tractor build in August of 1924 that I intend on taking to several shows along with some other tractors of mine as well as the neighbor's. Tentative locations in 2023 include shows in Illinois, Tennessee, and northwestern Ohio with the potential for more to be added. -

I've done a tune up on a couple of Model As - they are no different than anything else - make sure you have the basics and it will run. Fuel, fire, compression, timing. It sounds like you already know it doesn't have power getting to where it belongs and that is a huge first step.

-

Its more that I think of some people that are attracted to vintage iron are also technologically adverse. Sure some of that is a preconceived notion based on stereotypes, but there is a grain of truth in it. I'm still a bit surprised at the number of people posting on this thread in a short period that they build their own machines. It seems quite high. Its not a bad thing at all though. I was fortunate that we had a PC when I was young. I took an interest in computers in elementary school, and my parents had a need for one with the businesses that they ran at the time - so they bought one and I also benefited. It was an IBM PS/2 50z with a 286 processor. (1988 probably....) Quite the technological marvel at the time. It was purchased from the original Micro Center location on Lane Avenue in Columbus Ohio. One of the best things was my parents did not pay to have anything installed (which was a normal expense to have people setup the machine and install the software for you). We learned how to do it ourselves. Our first OS built on top of MS-DOS was Lotus Magellan...... which took longer to use than to just use MS-DOS because at the time none of us knew how to write a batch file to boot up into that piece of software. lol

- 48 replies

-

- os 10

- winodws 10

-

(and 1 more)

Tagged with:

-

I'm more or less forced to use Windows 10 to natively use some of the software that I use on a daily basis (namely SolidWorks). I used Win7 right up until I couldn't any longer. We have been on Win10 here at the office for some time.... and honestly I am not noticing that big of a difference between it and Win7 - but its all corporate controlled. At home - I notice some differences, but not enough that it bothers me. I also have a lot of the crap turned off, that helps immensely. I've messed some with various flavors of Linux and I honestly could see myself using Linux Mint on a daily basis and be perfectly happy with it - if I didn't have to run SolidWorks through a virtual machine..... I know many people do, but it just seems like its an extra step and another layer of crap needed for an already bloated and resource hungry program. Whoever invented ribbon menus should be drug out back and shot. I turn them off it at all possible on software I used daily. I'll fumble with them if its a software that I rarely use. I'm honestly surprised at the number of people posting that build their own machines on here. I wouldn't have guessed that many did so. I built my first one in 1999 and have built all of my machines except one since that time. In fact I'm starting to think I need to go through the exercise again for a new CAD machine.... but I might just upgrade the graphics card (if I can actually find one to buy) and limp it along for a couple of more years and build one out more towards the end of Windows 10 and let that take me through the first 3 or 4 years of the new OS while they work out the bugs on the general population.

- 48 replies

-

- os 10

- winodws 10

-

(and 1 more)

Tagged with:

-

I still call it Don's car. lol I've done nothing but fix a few minor things and continue with much of the work that he already started. I was glad I was able to keep my promise to him and get the car on the road while he was still around to see it in person. I certainly miss the chats we had both before and after I picked up his ride.

-

My old girl is alive and still making the rounds.

HotRodTractor replied to Don Coatney's topic in Off Topic (OT)

I have no idea how I missed a couple of these threads. I'm glad I could put a smile on Don's face a few times while he was still around. -

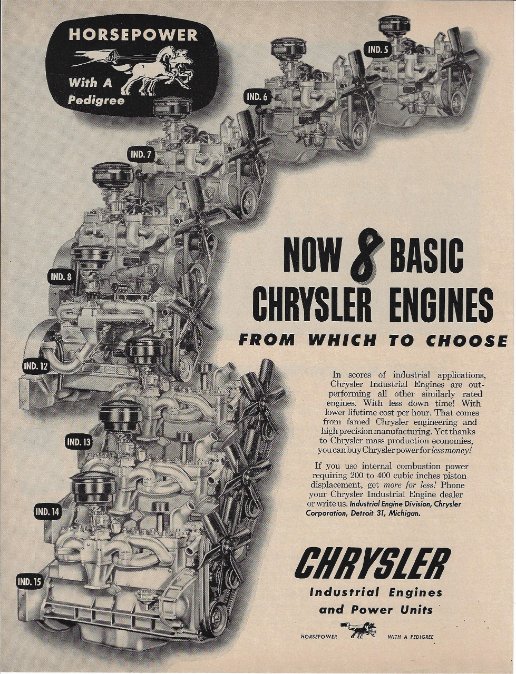

To further add confusion - I was under the impression that the Industrial engines were red - hence the Chrysler Industrial Red that you can buy in the paint isle today. Many of the industrial ads also showed red engines. Granted those are ads and not actual photos. I'm also pretty sure they would paint an industrial engine any color you wanted if you ordered enough of them. That red "Spitfire" engine with the red ribbing on the bottom of the block looks industrial in origin.

-

Correct. They are going to build up the road base before the chip and seal. They learned their lesson last year when just chipping and sealing a road with a crappy road base..... they are completely redoing it.

-

Well the equipment started showing up today to rework the road base in preparation for the base coat and chip and seal.....

-

I want to take a moment and just focus on this. I'm 39 years old and have had the luxury of being in antique vehicles and antique tractors since I was young. I bought my first Pilothouse over 25 years ago. My first antique tractor was nearly 30 years ago. Almost all of my life I have had conversations with elders about how good it was that I was interested because the hobby (pick whatever) was dying. No one "young" was interested. In the three decades in antique tractors and over two decades in antique vehicles I have found that to be utterly untrue. The hobbies themselves change and quite often the people in them do not. Not to pick your vintage car club, but I'm going to assume that its the same people running it, doing the exact same thing they have always done it, and for the most part the people that show up and participate is more or less the same group that has always done it. At this point I have seen this same scenario play out a dozen times. A fantastic real world example that I am living right now in the antique tractor world: 4 years ago a national tractor club and magazine publisher announced they would no longer be doing a national show as it was just too much work for not enough reward. In less than a year a new fresh group of people with new fresh ideas started a brand new club - that club is going to have a national show in June and I expect it to be one of, if not the largest single brand tractor show in history. New thoughts, new ideas, new ways of attracting people. The demographic of the show participants as well as the visitors is very different between the show of old vs the show of new.

-

You might be right that there is some correlation - but YouTube demographics might also have to do with your specific videos, your presentation, your style, etc... You present in a way that attracts that specific audience. If you presented in a way to attract a larger audience you might also deter that group from watching. Just some armchair thoughts from a 39 year old considering making new regular videos because so many of my friends from across demographics have been pushing me to do it because of their own YT revenue. What is your YouTube link? I'll see if I can't help those numbers out some for you.