-

Posts

509 -

Joined

-

Last visited

-

Days Won

2

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Veemoney

-

Meadowbrook, For your approach to keep crap off the crank I would do most work like initial measurements for size and taper, removing any ridge at the top of the cylinders and then vacuum the cylinders. Pull piston rod caps and move the pistons up toward the top of the bores but do not remove till the next step is complete. I would use some rags like old t-shirts &r plastic garbage bags to drape over and wrap the crank to deflect or capture contaminants before pulling the pistons all the way out. Once you pull the pistons confirm measurements and touch up cylinders as needed. I like to use a ball hone at a minimum to scratch/deglaze the cylinder walls. It doesn't take much and will help the new rings seat. Once you have the cylinder prep complete & have cleaned the cylinders vacuum the lower areas around the crank to remove anything on the rags below. During the repair & cleaning refrain from using air to blow off the areas as this can move contaminates to other areas of the engine. Also since you have the head off you could have it milled to give you a little more compression if it has not been done previously to the max. Don has posted the head milling info and process for measuring and head milling is the best bang for the buck in my opinion if you have the head off. Hope this helps

-

Yes we all could be as well. Good eye. 34 Plymouth body, frame, axle and suspension with the driveline & other components being 70 dodge era.

-

My flat black 34 showing body panel details and no pin stripe or busted tires. Never entered it in a show in the 16 years since I put it on the road but drive it all the time and most anywhere. Best trophy for me is smiles from kids young and old as they wave or get to sit on the those tires for a picture. Don't mind touching up the sticky prints from them toddlers with ice cream either.

-

That is a nice multi-colored specimen to start with. looks pretty solid too with good trim.

-

Howdy! New member here with a retirement project

Veemoney replied to Paintman27's topic in Mopar Flathead Truck Forum

That is a good find. Welcome, I am looking forward to seeing your progress also. -

Jimmy would be wearing a dress shoe to compliment a suit. Looks like a working man boot from possibly a 1 legged carnnie.

-

nicely done

-

A very odd and interesting case...front end - steering issue.

Veemoney replied to James_Douglas's topic in P15-D24 Forum

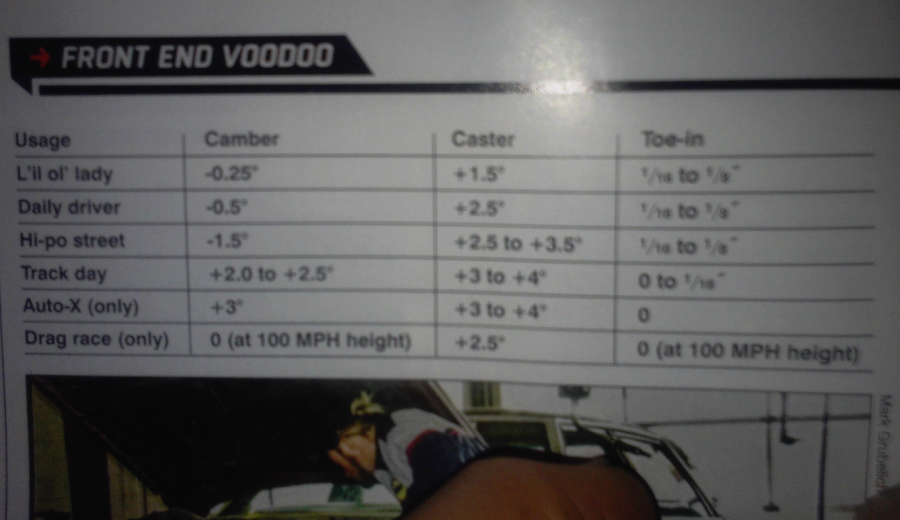

I agree with Dan that it sounds more like caster issue. The original specs for alignment are for the bias ply tires used back in the hey day of these vehicles. Some things to consider: If you are running bias ply tires then the original specs can be used but I would lean alignment settings toward the highest positive caster setting the spec calls out. With zero caster the car would not have much influence to center on it's own and at speed could be your twitchy issue. If you are running radials then you need modern alignment specs which include negative camber and additional positive caster. Below is what I use for my old cars now running radial tires. -

Container is looking good. You mentioned roof between the barn and container. If you come off the barn to the far end of the container so it covers the top of the container it will help with condensation inside and keep it cooler. Add some insulation between the roof and top helps as well. On construction sites they would lay these containers side by side and end to end and stacked 2 to 3 high to create side walls then bring in roof trusses and walls for the front and back of the building. Kept equipment storage and toolrooms in the containers as well as crew . We called them Sealand Cities

-

I think I had some pants that looked just like those covers, just can't find them??

-

I have the E-8902 pump installed on my truck. That is all I use and it has worked great for many years. I like to have a fuel filter on the inlet side and change it out annually.

-

The wood is in beautiful condition. Nice find

-

Here is a work-around I used for setting my brakes without the Amoco tool. You will need a good 12" scale, O.D. spring caliper, 12" Dial caliper or Vernier A magnetic indicator base set-up with ideally a 1" travel indicator and to fabricate a collar with a nut as shown below. I just welded a nut to a collar made from pipe so I could screw the Magnetic base components to it. Below is how I do my brakes and depending on if you have a truck or car you will have some variances so review your manual but here are my basics and your ability to measure accurately will determine your success with this method. A manual gives the detail you need and some info for presets on cam arrows but that type of detail needs to come from the manual. Here are the basics and concept with this tool Measure the drum ID. A good machinist should be able to get within .015 with a scale but the preferred method as we are dealing in thousands of an inch here so to be right on the money use a Vernier or dial caliper, I.D. mic etc. Install the indicator setup on the axle and use washers as need and the axle nut to secure indicator so it will not rotate. You want to rotate the axle only for these adjustments and measuring. The collar is not centered on the axle perfectly so it needs to not move once tightened down and all indicator readings are done by rotating the axle to rotate the collar. The idea is to set the brake shoes concentric and to .012" less than the drum ID. That is .006" less at each shoe for .012" total (for my application). Use the spring calipers to measure diameter of the pads so you don't have to compensate for the axle. Use the indicator to get the shoes concentric. When going from shoe to shoe I use my finger to prevent the indicator from springing. This may take a couple adjustments back and forth as moving one adjustment will have some effect on the other. Once you have the shoes concentric and -.012 less than the ID of the drum all the way around I move the toe of each shoe in toward the axle another .006" using the toe cam (minor adjuster/s) Button things up if you like a little drag on the wheel as I do adjust the toe cam (minor adjuster/s) If you have someone that can do some machining you can make a pin to go in the indicator collar and a pointer (extending perpendicular to the shaft) for the other end of the collar shaft. It makes it easy to rough things in and set the radius (half the drum I.D. minus .006"). Plenty of variations on this approach to make it simpler. Hope this helps some folks as those brake tools are not readily available.

-

From what I have always understood the piston rides on the rings at the top and that is why the piston is smaller at the top by the piston grooves. It does allow for expansion but the rings maintain the compression barrier. The lower portion of the piston barrel 90 degrees out from the piston pin towards the bottom is where you should measure diameter for bore size as some pistons are barrel cut and may give a smaller measurement at the bottom of the skirt when measuring inline with the pin. Hope this helps and makes sense.

-

Below is roughly how I do it using an adjustable painter's pole as a "Go/No Go" gauge technic. No scale required Jack up and loosen the tie rods if you don't think you will have room with it on the ground during measuring Make sure ground is level and you have the same amount of air in each tire. Roll vehicle forward to load the frontend with forward movement(all frontends have some slop and you want to remove it before measuring) Position 2-bys as shown below. I recommend using 2 longer 2-bys that span the measuring area and they actually stay in place better but for the purpose of the sketch I used 4 short ones. This gets you measuring at the same elevation at the front and back and allow you to complete the measurements by yourself. Snug up the adjustment on the painter's pole so it is firm but will allow adjustment. Position 1(front) - Set the adjustable pole on top of the 2-bys with the side away from you in the center of the tire or the highpoint of the convex surface. Now set the adjustable pole length by moving the pole back and forth (side away from you is pivot point, side closest to you only gets moved) to find the highpoint on the tire closest to you and tighten the pole. Double check that the pole in position 1 is just barely toughing at the high spot. Move to position 2 (back) - With the pole set from position 1 check moving back and forth to find the high spot. If you were heavy handed at position 1 it should feel the same or touch slightly less than that at position 2 You are looking for zero to 1/16th gap max at position 2. (Please double check the spec for your truck) If you need to adjust I leave the pole in position and adjust half the amount required. Example- if I have 1/4" gap in the back I would adjust to take the gap showing to 1/8th for zero toe Adjust as required and remember after the adjustment roll vehicle to load the frontend correctly again before measuring and confirming correct toe adjustment and then tighten up the tie rods.

-

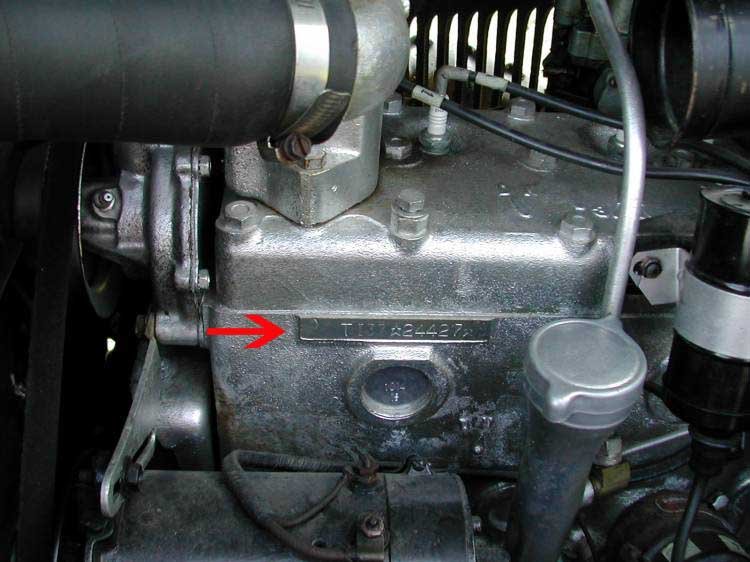

What I can tell you: My 34 Plymouth PD is titled using the Serial Number for the VIN on the title. That Serial Number Tag is on the passenger side door opening upright closest to the rear tire. My 41 Bus. coupe is titled using the Serial Number for the VIN on the title. That Serial Number Tag is located on the passenger side door opening upright closest to the front tire. You have already located your tag for the Serial Number so just check to se if it matches the number in the VIN on your paperwork. My 47 WC pick-up was titled using the Engine Number for the VIN as located on the engine pictured below. It will be either the Serial Number or the Engine Number that is shown on your paperwork when you purchased the car. One or the other typically and when purchasing any registered vehicle you should check the paperwork you are being provided with the numbers on the vehicle to make sure they match upfront as good practice. If neither of these 2 numbers match your paperwork It is possible your engine was changed out at some point and next I would look at the frame as Casper50 provided the picture with location. If you cannot find a matching number in the 3 locations mentioned I would say a prayer before going to see the DMV, light a candle, rub a rabbits foot and anything else that brings you luck since P. Adams has identified the PA DMV as tough to deal with. Good Luck

-

Not sure if PA provides titles or just registration paperwork. I would look at the number currently identified on the paperwork you received with the vehicle and provide that number # etching.

-

You don't realize how much a limb weighs till one falls asleep or goes AWOL. If you put in the work the body will make the magic happen.?

-

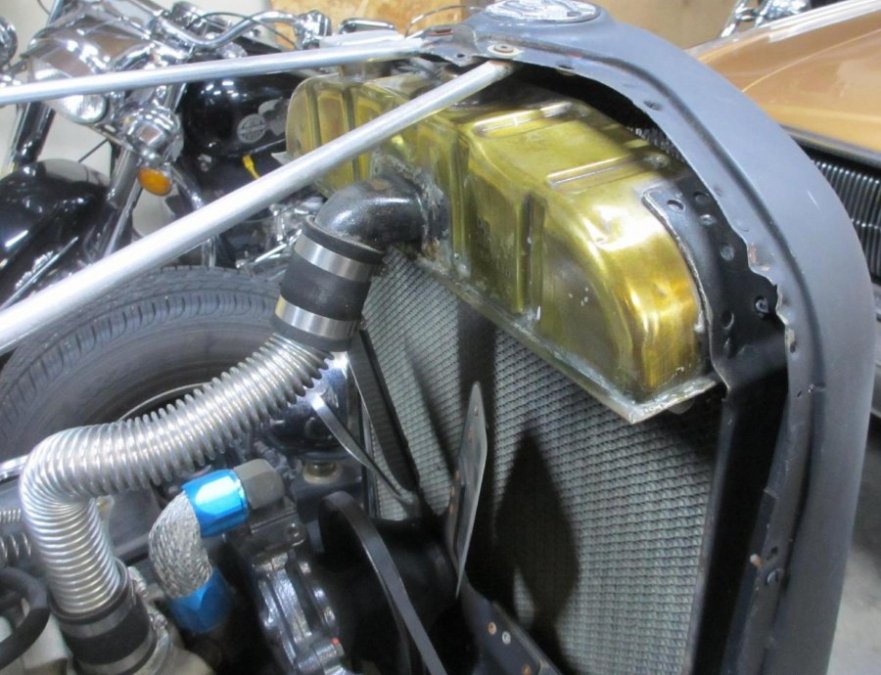

Woodrow, Those radiators look great polished up. I did the same to mine about 14 years ago, a year or so later I used some high heat engine clear over the brass section so I would not have to keep polishing it. It has just recently started to yellow but still not bad.

-

Tie-wrap crimp, interesting but no duct tape WTF.

-

Sorry no info on adapters but sure would like to see a picture of the interior with the current set-up

-

Stay strong and gods speed to better healthier days. I always enjoy reading your posts for the information and humor.

-

'47' rear bench, storage drawer done

Veemoney replied to kendall's topic in Mopar Flathead Truck Forum

I saw your truck in another thread before you added the rear bench. It is wild and extreme with great workmanship on both the truck and the bike. Seems we have similar taste in vehicles also. I have the 47WC in my avatar and purchased the only new bike I ever owned a 1998 Heritage Springer on August 21, 1997. The next 4 months I spent on Hutchinson Island, FL and my spokes along with some chrome parts started peeling like bananas. Not sure if you have had any problems with salt and corrosion living in Florida? -

For "A" Bodies Only

-

I used the link over to the HAMB and your car looks amazing. Super interior and detail all over. The front DeSoto bumper really accentuates the front of the Plymouth. I am looking for the trim that runs down the side of the hood and body line if you have any leads on where to find some.