-

Posts

54 -

Joined

-

Last visited

-

Days Won

2

TFC last won the day on May 29 2019

TFC had the most liked content!

Reputation

26 ExcellentProfile Information

-

Gender

Male

-

My Project Cars

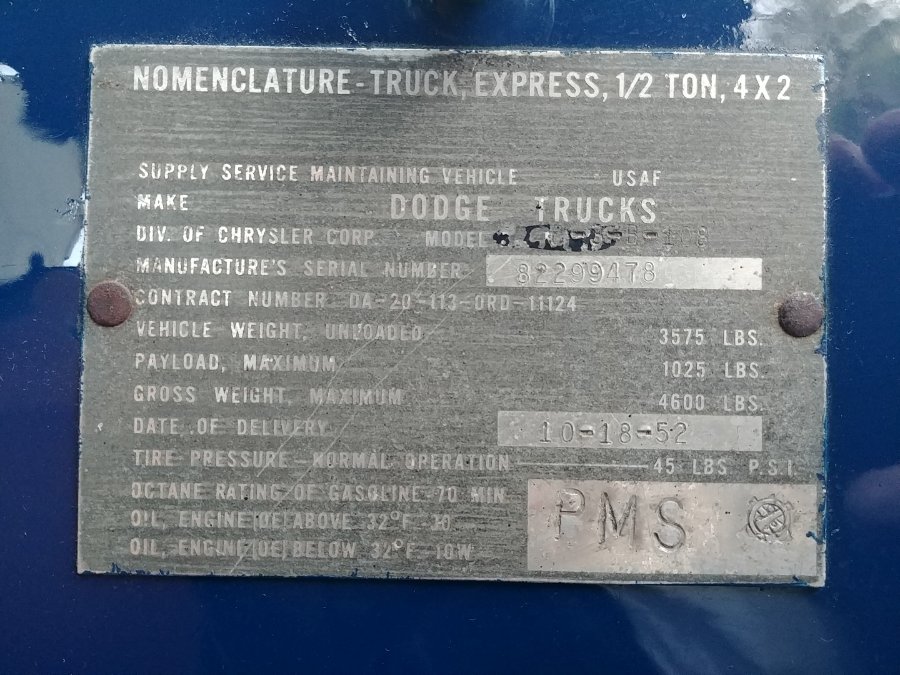

1952 Dodge B3B

Contact Methods

-

Biography

Retired computer guy

-

Occupation

Retired computer guy

Converted

-

Location

Parsonsfield Maine

-

Interests

old cars, woodworking

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

My two cents: This is a bit late as you have ordered a tool. I have used/tried various flaring tools over the years with mixed results. When I got my 52 B3B a few years back and realized I need to replace all the brake and fuel lines I went for a good tool, one that worked quickly and easily, it was a good choice and so worth the money. https://www.summitracing.com/parts/kti-70081?seid=srese1&ppckw=pmax-tools&gclid=Cj0KCQjwxYOiBhC9ARIsANiEIfZPUzPl2EWosXE200qeB7ZxNF9Vn3dvsoYX3weYiEUtxcFfGJsjj8AaAqn6EALw_wcB

-

-

Another Yikes!!! Thought I would wait until the brass plugs I ordered came in before addressing this, think I'm going to put in the temporary rubber expansion plug now and see where I'm at with this... FTR: My vehicle karma has not been good this summer, about a month ago a crankshaft broke in another old car I have, yes I did said crankshaft.

-

Yikes!!!! I hope I don't head down that road!!!!

-

Poking around I found Dorman 550-023 is the right part#, this item is made of steel, anybody know the manufacture and part# for a brass version? A brass version is Melling# MEP-14B

-

Thanks, I did work on the rebuilt of this engine but did not install the plugs(installed by machine shop), did not realize just how shallow the seat is. Todd, I did not consider the pressure that can build up when the thermostat closes, when it happen I was driving up a slight hill at about 50mph, yes she was working , makes total sense. Great information, thanks to all.

-

Out on some errand this morning, truck running great, heard a loud distinctive "PING" followed by the strong smell of engine coolant and a very sharp rise in temp, shut her down quickly and drifted into a convenient driveway, opened the hood and this is what I found, lower freeze plug top missing, looks like it failed at the fold and the top blew off leaving the pressed in part still in there. Never saw this before??? Anybody else had this experience??? Makes me feel like the other plugs maybe headed for this too as they were all change a few years back when the engine was rebuilt.

-

Almost a year later: Finally got into to the oil leak issue, fixed now!!! I did replace the input shaft bearing with a NOS Mopar one if found on EBAY, the bearing I took out seemed OK and was shielded, had the idea it was not shielded and that was causing the leak. What I did find that I think was the cause of this leak had to do with the spiral oil channel cut in the bearing retainer. Made a modification to the relief at the end of the channel based on information I preened from a thread on this forum, see attached image. When I got this vehicle and started working on it found the inside of the bell housing caked thick with oil and dirt, pretty sure this had been an issue for a long time for my truck. So nice to have a smooth clutch and no transmission oil leak.

-

JBNeal thanks for the response, finished the installation over the rainy Memday weekend, looks good plus now I do have a spare tire available if...

-

Finally installing a spare tire/carrier in my 52 B3B, have a carrier that I got off Ebay that I cleaned-up and repainted also have new mounting hardware from DCM. Looking over this project I see 2 groups of 4 holes each in the major frame crossmember that line-up with where the tire will contact this member, wondering what goes in these holes? Maybe some sort of bumpers? Thanks

-

512 cid C series on Dakota chassis- build thread

TFC replied to Radarsonwheels's topic in Mopar Flathead Truck Forum

Always enjoy your posts... -

Had this issue with my 52 B3B, ended up that the throw-out bearing carrier ears were heavily worn where it contacted the fork, clutch shop built them up by welding and resurface, no more issues.

-

Yeah, with a little searching I did find part# and sources: Found original Mopar part# from Pilothouse web site(PDF of truck parts manual) 619167 Found cross reference part# from this site Timken or Federal Mogul 1207SL

-

Radarsonwheels, thought I would try brakleen and maybe get through the summer. Now I'm wondering if anybody has input on where to find a replacement bearing with a shield? Thanks...

-

Thanks dodgeb4ya, that seems like the problem, no shield on the bearing. Next question: Easy job to pull the input shaft and replace the bearing or do I need to disassemble the transmission to get this done right?