-

Posts

6,969 -

Joined

-

Last visited

-

Days Won

73

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by JBNeal

-

It might be easier to remove the shoe to get a pipe wrench on the cam end of the pin then work the nut back and forth to break it free, using plenty of Marvel Mystery Oil or equivalent penetrating lubricant is highly recommended. Take your time and the parts should be able to wiggle apart without chewing the pin head or breaking off the alignment tab. additional information - horseshoe clip detail additional information - horseshoe clip removal

-

Aw man I wish that was the case but there was all kinds of shenanigans that I was subjected to: my new desk was from ikea that my keyboard and monitor barely fit; mgmt wanted me to go paperless but would not spring for a laptop or tablets, they just figured I could make mental notes; I had to scrounge around for pens to fill out official paperwork because mine were constantly disappearing from my remotely located desk; but the worst thing was my desk had to be against the wall with my back to the door, and at least once a week some impromptu meeting would assemble right behind me in that storage room, with the participants oblivious to my presence so that at least one guy's kiester would be brushing up on my shoulder...try problem-solving when ya got dude butt in stereo ?

-

Actually, I googled "dodge flathead oil pump rebuild kit" and found some good results on this site...the site search engine has trouble with words less than 4 letters, but google can make up the difference. True story: I had been at one engineering job for not quite 3 months when I was tasked to design a specialized piece of equipment...I did a google search, sent out some emails, within an hour had a quote for the very piece of equipment that was needed for $5k, something that had been on the market for decades...the next day, I was tasked with cleaning the production area while in my office clothes, including making multiple trips to the dumpsters on a blazing August afternoon; the next week, I was formally threatened with termination for pointing out that some military hardware that was about to ship technically was not functional (they shipped it anyway and BOY HOWDY did we land in some hot water!); the next month, I was moved out of the engineering office into a storage room on the far side of the building "to improve efficiency"...about that time, while researching for another project, I found a project expense summary that laid out how management had spent $10k over 5 years trying to internally develop that piece of equipment that this dumb hick had found for half that cost, in about an hour--OOPS made some mighty important ppl get all butthurt vindictive after inadvertently exposing their glaring incompetence...so my google skillz can be simultaneously helpful and maddeningly problematic

-

additional information - oil pump rebuild kit

-

Ya might not be able to get the nut back on that shaft, but what about a tight fitting sleeve? Maybe wrap copper wire or aluminum foil on the threads then sleeve with a custom fit piece of steel, bored out to keep that tube from mushrooming while cranking on the puller ?

-

Call out for Reelcraft for excellent customer support...

JBNeal replied to P15-D24's topic in Off Topic (OT)

I recently snagged a small Reelcraft from one of my downsizing neighbors, along with the story of how he liberated it from a dumpster with several others when the company his son worked for abruptly closed shop...it's a model that has been out of production for years, but Reelcraft still supports this and was able to download repair info and order a new swivel. I've worked around these for a long time, and ya get what ya pay for as these are quality devices that can take years of abuse ? -

split lock washers also increase frictional force at thread engagement, helping to resist any fastener movement even through vibrations

-

Build threads are great

-

According to the 1948 Pilot-House sales poster, the fresh air heater was a new design

-

maybe the head is not completely true, once everything cools off there might be a gap in the wrong place...examination of the head gasket could yield further evidence

-

I snagged a rebuild kit from Terrill Machine cuz they're just over the hill, but ya might have another local source available to ya (have your pump model ready for ordering)...once rebuilt, I could fill the glass bowl with gasoline then actuate the lever manually and gasoline would shoot a good 10 feet...all it takes is a small tear in the diaphragm and PFFFFT no more pump pressure

-

If there be oil weeping from the gaskets, then taking a peek at the innards when replacing the gasket might not hurt, just to see if there is any obvious signs of excessive wear

-

Who has all B3-B shift diagrams?

JBNeal replied to Fernando Mendes's topic in Mopar Flathead Truck Forum

additional information - B-3 Driver's Manual the transmission section near the end of the manual has the gears labeled for the 3spd -

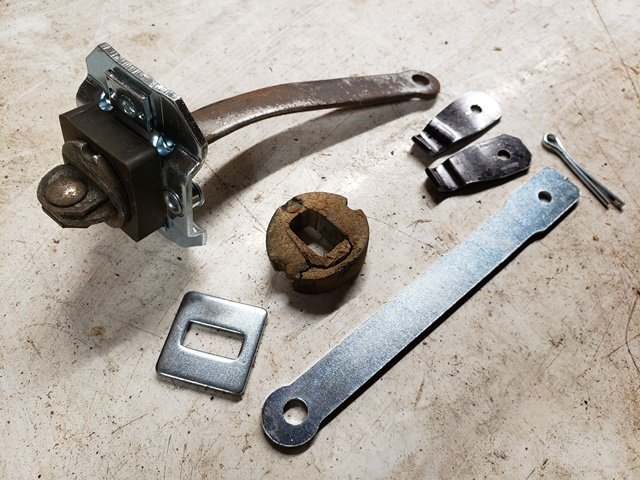

I've been stewing on a fix for the door check retainer that I have found busted / missing on every driver door on every Pilot-House cab that I have ever laid eyes on, after splainin its function awhile back. I'd look at modern alternatives when I've been at the salvage yards while working on other projects, and had narrowed down a close alternative to the last few model years of the Isuzu Rodeo, but those are like 40 bucks a pop new for something that sorta worked...not exactly what I was looking for, so I took a step back to think outside of the box for awhile. Then a few weeks ago, I spotted something in the LMC Truck catalog while researching other makes of similar vintage to see what they were using for a door check...the '60-'66 Chevrolet truck doors used a door check that looked verrrry similar to the Pilot-House door check, but no dimensions were available. I did some more searching, and found a very similar part available from several other vendors as well as on eBay. Since I already have an account with LMC, I ordered their door check for less than 20 bucks, and a few days later it showed up, made in Taiwan with dimensions that looked to be a good candidate for a direct replacement. First was to remove the original door check arm, which requires removing a riveted headed pin. I used a dremel cutting disc to eat away at the underside, then popped out with a 1/8" punch...gotta be careful here, as I bent that bracket a tad before I realized it, had to knock it back into place a few times before that old pin finally popped out. Next, removing the original door check spring rivets...easier said than done. Kinda hard to get the dremel inside the door and see what I was doing simultaneously, so I had to grind away at the back of the rivets by feel...took my time, just nibbled away at it, checked my work frequently to make sure I was only grinding on the rivets. Once the rivets were flush with the door frame, I took the 1/8" punch to pop the rivets down and out from the outside of the door, which was no cake walk either. I then took a 1/2" punch to flatten out the metal where the check arm had tried to pull through the door. Now it was on to the bench vise to disassemble the new door check. But first, I straightened out my original door check arm, as it was a bit twisted. After taking the new door check apart, I swapped out parts. The original door check arm is riveted together, and I'll eventually replace that rivet after swapping out the old circular washer with the new rectangular washer...in the long run, that rectangular washer will make the rectangular rubber last longer, but for now, I'm just doing a proof of concept. A wooden clothespin turns out to be an almost perfect alignment tool to center the backing plate to the door cavity. I marked the centers of the threaded holes, then did a quick pencil layout to see how much room I would need for a 7/16" socket to clear the sheet metal. Drilled some 1/8" holes to give some relief for the dremel cuts, then for pilot holes for the 9/32" holes for mounting the backing plate. I had some 1/2" x 1/4-20NC hex head bolts and flatwashers in my hardware collection, and those fit just right...I'd probably put blue thread locker on them bolts, or go to a longer bolt with helical lock washers, either way will work. Replacing the riveted headed pin shouldn't be that big of a challenge, probably could make another one out of another bolt... Total time to rough this new part in was about 2 hrs, but I'll spend more time to clean up the opening with a rotary rasp, flat file, touch-up paint, etc. I thought about making a nice clean template for cutting into the sheet metal, but working with the door on the truck is quite a challenge, especially with my back acting up again, and as long as the finished cuts look decent, then only the nitpickers will have a problem with this butchery The finished product works out OK, as the driver door opens 8° less than the unchanged passenger door. But the door check does its job and holds the door open when the truck is on an incline, which is reeeeal nice...and sophisticated

-

I did some work on the QuadCab a few years ago, and the alignment guy forgot to adequately tighten all of the adjustments, something I didn't find out for a few hundred miles of highway driving until the truck wanted to veer into oncoming traffic on a regular basis. After the alignment was reset, I went back a few hundred miles later with the same problem, swapped sides of the front tires, and the pull went the other way...so those brand new tires had gotten the radial pull, not eligible for road hazard warranty claim (which was a load of baloney), so I had them put those tires on the rear for 25k miles, which helped with steering but reduced the treadwear...something to bear in mind on steering issues

-

I ran into a similar problem with The Blue Bomber awhile back as the yoke did not seem wide enough for the replacement U-joint, by maybe the width of the snap ring. I verified that new had the same dim's as the old, so remembered a trick I saw at the Waco driveline shop back around 2000. They chucked the yoke in a press, overdrove the U-joint slightly, installed the snap ring, flipped the yoke over and pressed the U-joint home to seat the other snap ring. I think the yoke flexes enough that the U-joint has to be worked into place with a press.

-

truck picture B-4-B-116: it was 35°F all afternoon while the Spring Special was blanketed with the rare snowfall ⛄

-

additional information - vintage sharpening gauge

-

Back window on truck question.................

JBNeal replied to lonejacklarry's topic in Mopar Flathead Truck Forum

You could probably make it fit but it's a lot of work making that pinch seam just the right size for the window seal to work...I looked at a '60 V8 fleetside with the big rear glass up near Amarillo a few years ago, a nice original, but I was struck at how little structure the cab and hood had. All that glass gave excellent all-around visibility but the A- and B-pillars looked flimsy, and there was the typical floor rust because of the leaky windshield/A-pillar areas, so I passed on that beaut. So to make that big back glass fit, ya gotta cut out a chunk of steel that might compromise the roof integrity when flying down the highway ? -

"Ran When Parked" 1954 Dodge C 3/4 Ton

JBNeal replied to DrFate77's topic in Mopar Flathead Truck Forum

additional information - radiator replacement -

1951 B3B VIN/Serial Number Plate Question

JBNeal replied to racertb64's topic in Mopar Flathead Truck Forum

ultimately, the truck's build card would need to be inspected to verify original engine and cab match the serial number...Eric has has done extensive research to verify sheet metal numbers along with the flathead engine numbers, so he might be interested in the verfied numbers if ya pull the trigger on this buggy and get it registered -

1951 B3B VIN/Serial Number Plate Question

JBNeal replied to racertb64's topic in Mopar Flathead Truck Forum

Maybe that data tag was stamped late on a Friday by a guy who didn't get the memo about the model change...the real test is to see if the frame serial number matches the data plate ? -

Thinking about swapping in a 3.9v6 in my 50 Meadowbrook

JBNeal replied to flint52's topic in P15-D24 Forum

That would be something if the Meadowbrook body fit on the Dakota powertrain... ? -

Waddya think- use #2 Permatex on new transmission gaskets?

JBNeal replied to '41 Fat Bottom Girl's topic in P15-D24 Forum

additional information - Gear Oil RTV -

kinda looks like ya spotted another survivor... ?