-

Posts

34,511 -

Joined

-

Last visited

-

Days Won

514

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Plymouthy Adams

-

My First Car -- P15 1947 Plymouth Deluxe

Plymouthy Adams replied to NickPickToo's topic in P15-D24 Forum

for sure....it only take a short bit of time and of course always the proper tools to do things proper in regard to long term fix on body panels. Learn early in life to do it right and forge ahead never looking back or worrying about when that bondo is going to pop off or that rust hole reemerges. You are at the age you need to learn the right methods and not pick up bad habits...the worse of these bad habits is complacency...cutting corners will quickly bite you in the butt....many pick the fruit from the low hanging limbs only because they never try to reach higher... -

next tip...tell folks what you have done or tried....cut down on useless stuff already done/tried...starting out with is this front or rear.....if rear...not uncommon....these get stuck on there pretty good...what length cheater bar and how much grunt has gone into this...

-

back off on the adjusters...

-

Air Cleaner / Air Filter help

Plymouthy Adams replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

not that I can tell...it is pretty clear here in my area....of course we had some rains that may well have cleansed the air... -

did you count to 13 the number of fasteners removed....bottom center is very hard to get to and often as hard to see...

-

chrysler Another wagon followed me home

Plymouthy Adams replied to Bob Riding's topic in P15-D24 Forum

I an not sure without a closer look if the wood by thickness alone would dictate where it goes of if the gate and seat are molded in said manner to allow the same thickness of wood on application...either would work AS LONG AS the two surfaces were parallel when used as a floor extension….- 60 replies

-

- town and country

- hemi

-

(and 3 more)

Tagged with:

-

dang cars are ugly as sin...I can say that though as I own two of them......

-

My First Car -- P15 1947 Plymouth Deluxe

Plymouthy Adams replied to NickPickToo's topic in P15-D24 Forum

muriatic or other etching acids I do not recommend......that acid always needs neutralized....that acid will dry in cracks and hidden places as will most all products and when wetted later rain or car wash...reactivate. Phosphoric rinsed with water is all that is needed, no other agent to stop its process. Also there are added unnecessary health risked involved with the other acids. All acid treated metal should be washed and blew dry and with that you get flash rust...so what to do...magic eraser with wetted acid cloth but NOT a full wet application...The stronger the concentration the better and quicker removal of rust. The 55% I use will actually brush on walk away come back and it has done its job and actually flakes off when dried. You can quick brush this on and walk away , apply another coat if needed till rust is gone. This will continue to work even if left in the weather ...it reacts only to rust and never removes good metal. Many folks consume phosphoric acid in their daily diet. As with all things...each person is responsible for the manner it is used and safety involved. I recommend that you read a few white papers on the use of Phosphoric acid and develop your own process from there. -

My First Car -- P15 1947 Plymouth Deluxe

Plymouthy Adams replied to NickPickToo's topic in P15-D24 Forum

Los...I have used the Ospho and while it is effective...the added agents that create the black inert oxide is a favorable side effect...I just prefer the cleaner finish of the straight phosphoric acid. One can easily do their final wipe with this conversion product after metal is clean as steel panels are microscopically porous...this is a good step for storage between prep and prime.... -

My First Car -- P15 1947 Plymouth Deluxe

Plymouthy Adams replied to NickPickToo's topic in P15-D24 Forum

POR15 is an amazing product and has it uses....however it is most often use by many as an eliminator to applied elbow grease. There is very little POR15 will do/hide that a bit of labor will not fix properly. Phosphoric acid is my single most common go-to for rust busting. Phosphoric acid can be accelerated but I will not go into that here as many cut corner as it is and safety most likely would be compromised by many users. Phosphoric acid as bought across the counter is often not concentrated enough to handle the average body repair and sold mainly in light concentrate as a prep wipe only. I buy mine across the counter at 55% and can get it commercially at 85%. Most of the solution from the store as I said are very weak solution and cost big coin...yet the 55% is just 13.00 a gallon. You don't need to be related to Einstein to do that math. My favorite POR15 product is the patch product in tube...great for sealing small gaps when fitting panels and holds better than seam sealer. It is perfect for drip rails. Do your research, read a few papers, excellent product. -

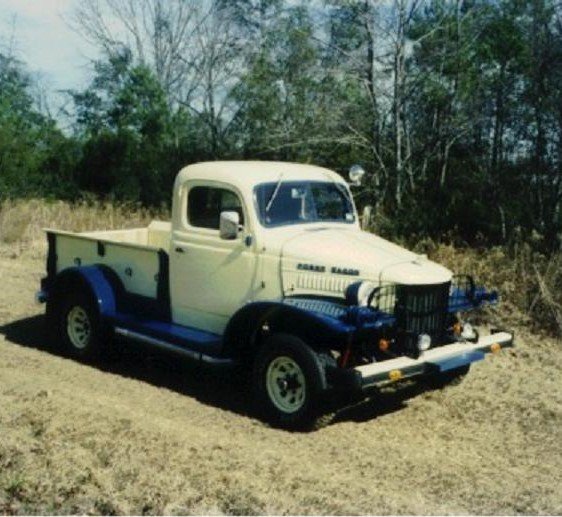

one of only three vehicles I have ever regret letting go...my Austin America....my 41 Dodge truck (PW rendition) and my Porsche....I got my Porsche back after 28 years gone...story in itself, now got 3 Austins and a sister MG body style ADO16 and the truck has never been replaced...here it sits....big block and 4 on the floor..4WD and Porsche instruments in the dash..plate for removable winch on the front bumper....(they like, go missing otherwise)

-

this is what you use your left over brake lines for....small fuse sized cut lengths.....it amazes me yet I still find this done in some of the older cars at the junk yard...they are easiest found as most look like a hunk of charcoal.

-

made a quick note to the above post as I did not address R on the switch.....

-

Per my 39 schematics...yellow wire is out from the light switch to the dimmer as the single feed for the selection of high/low beams and attaches to H terminal of the switch post B input is brown wire...A and R feeds the parking lights A to front terminal strip and R to the rear lights....and not sure but are not these front parking lights part of the h/l assembly for 39 and while not low beam but JUST park light instead. D will feed the switch for the instrument lights. amended

-

not to add any more confusion but the build I am currently deep into will not allow the use of the stock dimmer switch....the work around is done by suing a relay where NC and NO contact do the high current deed but in addition the dimmer switch is the main change. It is now a small momentary switch built into the shifter knob and triggers a bi-stable relay. Smooth easy fix, the head light will always default to low beams when head lights turn on...these are also feed by a 8 circuit fuse box to upgrade a car that factory had but three fuses and one of which is an inline.

-

yes...not the modern rotary we have on so many but through the 80's for most part still had the pull knob....this knob is released from the switch by a spring loaded button...one you release this you can eliminate the knob from the shaft and position you exiting knob in place once the length is determined correct....you may however find that the retainer is often female on the later switch and not male like the older...this may not set with you cosmetically....often there is a trade of. Personally I feel these older switch are still good components when you remove the high current and allow the switch to control the relay coil and the relay do its job of controlling the high current. The subtle wiring change is never noticed by anyone unless they look under you dash..then a quick karate chop is smoothly executed by yourself...all problems solved.

-

there in lies the very success also of cleaning your wiring contacts...it is often loose or high resistance dirty connection that pull excess current...also the contact within an older switch with these contacts worn and tension comprised along with dirt/corrosion over the years adds resistance and in turn, added current. This is the single most argument for switching the headlights themselves as the highest current consuming items to be fed from the relay and allow the switch ONLY TO CONTOL coil circuit pf the relay.

-

First....it is confusing how you state the colors for low beam and high beam on the H/L switch when the selection of beams is a function of the dimmer switch fed by a single wire off the H/L switch. I am thinking you are confusing park lights circuit for what you calling low beams. You also mention using H/L relays...as in more than one...you do not need but a single relay and you have two manner in which you can control that current, supply to dimmer....or dimmer to relay and utilize the NO and NC contacts as they were designed to function. you should have main feed B+ coming in and note that the H/L switch function as a buss bar and the fuse or breaker as equipped interrupts this buss. this buss will feed to courtesy lights if equipped and also to the brake lights, could be other constant power circuits picking up power you will have wires feeding dash lights at first step of the switch and on to parking lights, then you will have the main heavy wire out for headlight that feeds the dimmer. as for the concern of fuse or breaker...you can easily put an inline breaker to the main input and the RV stores in your area have these if you big box does not...

-

oh no...! reading required..? Tooljunkie is right, and one should follow instructions as they are written for a purpose...in this case the purpose is correct procedure to ensure correct positioning and extended life of the sleeve....you can continually revisit the scene of the crime but a bit of attention to detail goes a long way in making repairs.

-

Interesting photos I have run across.

Plymouthy Adams replied to Don Coatney's topic in Off Topic (OT)

yeah...ashes to ashes...dust to dust...sinfully ugly and full of rust...crushing this thing falls under MAKE AMERICA BEAUTIFUL -

first...is it standard thread into the carburetor.....? and if so....are you looking just for the flaring nut? I am assuming this is for the needle/seat if you do not have a thread gauge for metric or SAE suggest walk in at the big box store and check the premade lines hanging on the rack...could be the new stuff is for metric....

-

47 Dodge Turkey Truck Build

Plymouthy Adams replied to Young Ed's topic in Mopar Flathead Truck Forum

-

would not the carb doctor best answer this.....I am not at familiar with his kit even to the point that it could be an oversize thread repair...?????????

-

chrysler Another wagon followed me home

Plymouthy Adams replied to Bob Riding's topic in P15-D24 Forum

two too many doors...…oops gotta keep my distance......?- 60 replies

-

- town and country

- hemi

-

(and 3 more)

Tagged with:

-

did you check the forward silent block on the vehicle also the rear shackle bushing are notorious for wear to the point they knock the driveline out of phase......in this era the SB mount is a riveted mount...and not tweakable with shims as is later style....bushing are replaceable big box store item and are inexpensive Mopar A-body units...you will have to trim a bit as the older springs are a bit narrow.