Leaderboard

Popular Content

Showing content with the highest reputation on 06/28/2018 in all areas

-

I'm thrilled that my 18 year-old son has chosen to embrace the old car hobby. He's just bought his first car... a 1967 Triumph Herald 12/50. It's got an 1147cc (70 Cu In) 4-cylinder motor, front disc brakes and an incredible 25ft turning circle. And it's almost exactly the same size as a VW Beetle, so it's a perfect little car for running around the streets of London. We just grabbed this picture in the sunshine...7 points

-

FWIW I have seen bonded shoes delaminate and linings tear up hardware inside the drum...contaminated shoes of indeterminate age may be excellent candidates for replacement as new shoes would be cheap insurance against complete brake failure if that rear axle crossover line ruptures2 points

-

It's great to see interest by any youth these days in something other than video games. Keep up the encouragement!2 points

-

2 points

-

I bet if you look real close you will see a shirt pocket liner ..........2 points

-

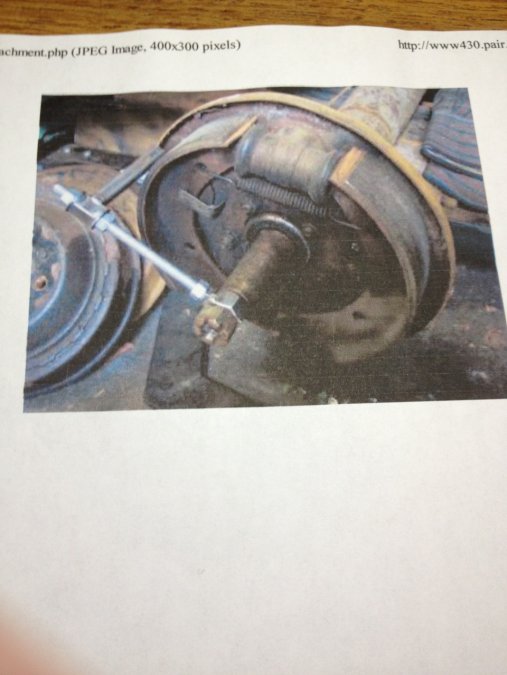

Well the replacement puller arms delivered today. I ground clearance to allow radius support and applied pressure. With some big hammer application, impact wrench and whacking the end of the puller shaft the drum popped loose. I then turned my attention the other side and after applying the same it too popped loose. ☺️ There is no noticeable ridge from shoe/drum wear but there is a lot of brake fluid contamination. After being soaked in brake fluid for an extended period are the shoes toast? Or can they be degreased and cleaned up? I figured I might just replace them. Is there anyone out there who will let me lease the tool to correctly set the shoes? Now let's discuss the master cylinder. ? With the brake line attached as pictured above it is impossible to thread it through the framework and parts of the truck to install. The steering box is in the way. So I removed the bellow and clevis hardware and got it installed. Then I couldn't get the bellow reinstalled on the back of the master cylinder. Worked with it for more than an hour. There is limited space and much grease and dirt on the underside of the truck. So the master cylinder had to come back out for reinstall of the bellow. In doing so I spilled most of the fluid, a lot of it on me and the remainder on the floor. ? Net result I lost my fluid and bench bleed. So I emptied out the fluid, removed the brake line, reapplied the bellow and reinstalled the master cylinder. Then screwed the clevis pin into the back and reinstalled the brake line. I'll have to gently bleed the master cylinder after I get it all back together. Whoever "restored" this truck did a great job on the sheet metal and interior but just painted black over everything underneath. I can scrape 68 years of grease off surfaces and I often find surface rust under washers and other areas of the frame and suspension. I wish I had the space, time and equipment to remove the body and completely restore the frame.2 points

-

skinny bike tube....cut tube and connect the ends to the inlet/outlet...pressurize through the Schrader valve.....the tube will expand keeping the pressure low but viable for a submersion type leak test.2 points

-

Yeah, but how's your spaghetti tasting these days? "Don't worry honey, I wiped it out real good with lacquer thinner!"1 point

-

Something is wrong with the way your trans e-brake band is mounted to the tail shaft housing... one bolt is holding it to the trans tail housing not two as should be... It might not even be the original transmission or e-brake ???? Evidently there are many different 3 speed transmissions depending on serial# and probably production dates used in the C-series trucks... looks like typically all thre 3 speeds were short cases unless a 3 speed overdrive. The type of trans will change the e-brake setup. I don't know the C-series but here are the e-brake setups offered for the C1 and c3 series trucks... this out of the factory C1 and C3 parts books... You will probably just have to make something up yourself for a return spring.1 point

-

I'll merge the two, how's that? You can take the motor to a rebuilder and have a new wire put on (best bet IMO)1 point

-

If you plan to retain stock 15" wheels, use the Rustyhope kit. Mine went on effortlessly and works very well. Make sure to remove the check valve from the master cylinder and you're good to go... Adam1 point

-

I've seen these come apart as JBNeal describes. I agree, not worth the potiential problems.1 point

-

Nice looking car for Henry. Glad he is interested in things automotive. Cool that the colors match so closely. Now.....enjoy and have some fun.1 point

-

1 point

-

There have been tons written here on this swap. Just do a search with disc brakes as the search criteria.1 point

-

I was sorting through some more old tools down at my shed this morning and thought I'd bring a few more home to clean up. The little set squares and bike wrenches cleaned up well. It turns out that the brass tool at the bottom of (attached) photo is a saw tooth setter - Eclipse No. 77, Made in England. I'm thinking about storing all of these old tools in a tool box in my truck as I reckon they would be a good conversation point at some of the cars shows which I attend.1 point

-

1 point

-

The video that DJ194950 reply is a great video of door adjustment for these old cars and trucks. I enjoyed watching.1 point

-

1 point

-

As Doc said, unless you know for certain that your Caddy has hardened seats then I'd be using some sort of lead additive.........andyd1 point

-

See this from Mopar repair books. http://www.imperialclub.com/Repair/Lit/Films/075/index.html DJ1 point

-

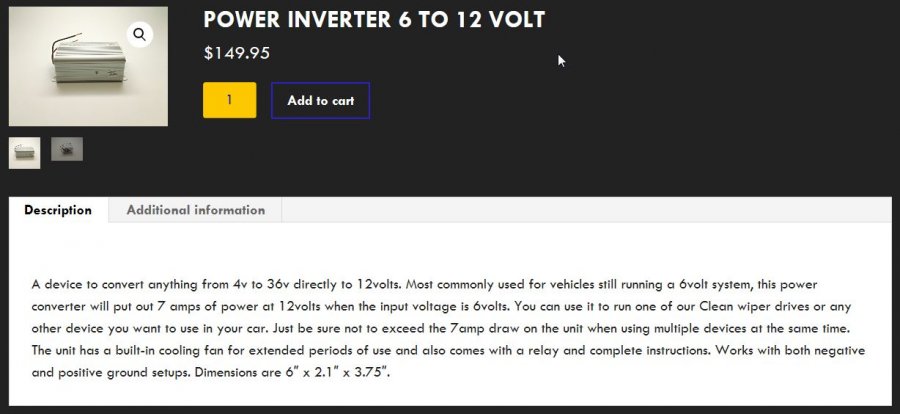

I used the Newport engineering wiper motor in my 1950 Plymouth with 6V +ground and used the Newport 6 to 12V power inverter. I followed the wiring instructions and it works like magic. I did not have to isolate the wiper motor from chassis ground and I have +12V available to power a usb charger and a little Bluetooth amp so I can play tunes from my phone.1 point

-

No you cannot have a positive ground and negative ground together. You can have 6v positive ground and 12v positive ground together. Or You can have 6v negative ground and 12v negative ground together.1 point

-

1 point

-

Yes there is You have to remove the inside door panel and there are three bolts on each hinge that can be loosen. Pull the door back and re tighten the bolts. You have to be careful to make sure the door lock assembly is not to far out of adjustment other wise the door will drag on the door pillar. there are three bolts per hinge inside the door that provide door hinge adjustment.1 point

-

looks to be the spitting image of the very puller I have and at the same price I had paid for mine. Rest assured it will do the job, careful centering and staying equal on the three attaching lugs is key to even pressure and effective action of the tool. I have pulled a number of rear hubs with mine and will use it again in the next few days.....I think you should try again....you may also try some of the local big box parts stores that have loaner tools for the customer, they may have a similar model that you may find easier to use. Do you have a avid Volvo mechanic or shop in your area, they utilized a disc style puller with a 5 bolt contact plate and the Volvo has the same bolt pattern as the Mopar....1 point

-

I had that 5" disc in the scrap bin and tried to make it work with my gear puller. But it disappointed me. So today I ordered one of these using eBay's 20% off discount. Hope it will be beefy enough. Because the wheel cylinders are leaking the hubs have to come off. Thanks for that link with the brake repair details.1 point

-

Gaslight Square was the location for the largest slot car track set ups when a teenager. Raced 1/24 scale cars and the turns were banked. Was not a snap together plastic like the one Batman has. I have a 1/32 scale model track and cars still today.1 point

-

1 point

-

I would check jegs,,,summit and auto meter for that speedo convertor,, i know ive seen it,,and im sure no where near 4 bills,,auto meter may be your best bet,,,you could try a place call street and performance,,,there web address is hot rod lane i believe,,, he does lots of conversions of all types of stuff,,,first guy to do a 5.7 hemi in a jeep1 point