-

Posts

9,962 -

Joined

-

Last visited

-

Days Won

174

Dodgeb4ya last won the day on January 31

Dodgeb4ya had the most liked content!

Reputation

3,706 ExcellentAbout Dodgeb4ya

- Birthday 08/11/1952

Profile Information

-

Gender

Male

-

Location

Woodieville, Wash

-

Interests

Restoring cars, trucks, heavy equipment, welding ,fabrication of many things, helping people on projects and more!

-

My Project Cars

1946 NewYorker Straight "8" 3 Passenger Cpe. (Sold)..... /1952 Imperial 3 Passenger 331 Hemi Cpe/ 1948 and 1950 Chrysler Town and Country woodies/ 1950 Chrysler woodie wagon(sold)...../ Several Dodge trucks..dually 1 ton PU to 3 and 4 tonners....306/377 and 413 sixes.

Contact Methods

-

Biography

Been into the Flathead Mopars since 1968.Have 15 Mopars up to 1953.

-

Occupation

To keep all of the above running!

Converted

-

Location

Woodieville Wa. Part of the Great Northwest!

-

Interests

Old Mopar-Cars,Trucks and old AC and Massey equipment.

Recent Profile Visitors

15,688 profile views

-

The seal shown is the only seal... There is only an extremly strong bottoming/over travel diaphram spring behind the snap ring and washer in the barrel part...

-

AFAIK the seal is inside that housing the shift rod operates in and out of. There is a snap ring to get into it....but if you get into trouble guessing on trying to get at a seal you might end up pulling the 400lb diff out!😫 Clean it up and run it....had a lot of 80/140 gear oil in it!

-

There shouldn't be any oil on the axle vacuum side. I have never taken apart the shifter shaft and sleeve assembly in one of these Timkin rear ends. I'm sure there are one or more oil seals in there. No service information anywhere that I could find. The rear end pictured pictured above worked flawlessly with the oil in it. Shifted great. I was suprised to find the oil in it.

-

Dodgeb4ya started following Freeze plugs , Hemi V8 in 1951? , Clutch options and 4 others

-

And with the upper line 131" WB New Yorker and Imperial power brakes were std. Power steering and windows plus a real torque converter were optional starting in 1951. I had a Fluid Torque Drive Saratoga. It was easy to smoke the tires from a dead stop in that short WB Windsor. I have also had a couple of the upper line 51-52 New Yorker and short WB Imperials. Luxurious cars.

-

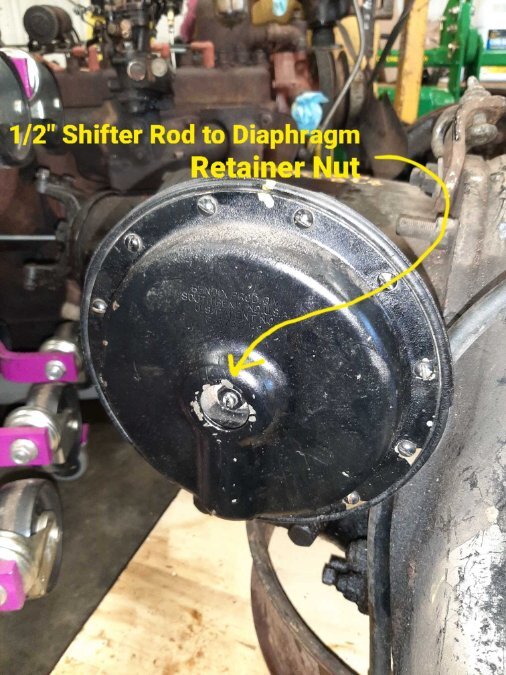

I doubt Whitepost could supply or replace the diaphragm. The diaphragm's and base mount were sold as a complete assembly...no separate parts from MoPar. This is what the leaky situation probably will be....there is a very strong spring in that vacumn chamber.... Once the 1/2" nut in the hole of the outer cover and the 12 screws holding the diaphram are removed....those parts are likely to go flying. Use two 2" long safety screws to control the cover and diaphragm's gradual release off the shifter rod.

-

There should be no oil getting into the rubber shift diaphram. It will cause damage the hose and to diaphram. There is no servicable seal in the shift rod. I have never had that rod apart or seen a seal in it. If there is excessive oil and it has damaged that diaphram you have a bug priblem. I definately would check the shifter rubber diaphram for oil contamination and possible swelling or splits. A compromised rubber diaphram will cause axle shifting trouble...which you have had trouble with. You might want to remove the 12 screws to be able to be sure that diaphram has no holes or cracks from oil damage. It might be A-ok too.

-

$45.00 is cheap for a good quality MoPar to bearing. Chinese bearings are garbage. Buy the $45.00 bearing if it is the correct one.

-

ANSWERED 1953 Dodge B4B 1/2 Ton Brake Drum Max Diameter

Dodgeb4ya replied to Dan693's topic in Mopar Flathead Truck Forum

MoPar started posting maximum drum oversize's around 1956... I know most drums machining limit is at .060" OS. A maximum safe cut on the drum lathe bit is at .030" ....means the drum ends up at .060". But I also know some late 50's model Chrysler 12" drums are spec'd at a max drum oversize of .090". Shown is a MoPar pic of some center plane brakes maxed at .060" oversize cut. Anything over .060" will require over size linings for proper shoe arc'ing and long lining life. More meat on the drums is a good thing.? -

Did your machist fab up a torque plate for honing the block? Wonder how much distortion of the cylinder walls will be after the head is torqued. Answer to question # 1....no. It would be a $$$% custom fabrication. I'd assemble and run it. You are digging way to deep IMO. Modern engines....be real careful.

-

Photbucket files to be deleted soon

Dodgeb4ya replied to ggdad1951's topic in Mopar Flathead Truck Forum

I thought PB was gone....they need to be. Screwd people of millions of pictures if not billions. -

What adhesive did you use? Is it used to just hold the cap centered or to help hold it tight to the cap itself?

-

Remove plug...carefully wedge the bulb out. Simple.

-

Sadly last summer I scrapped out 2500 lbs of 1946-50 straight eights I've save for 35+ years. I saved the good parts. Cranks and manifolds and couple pieces of tin. Yep those things are heavy. Messed with many.

-

Jesus...been thru this way too many times here. Moparts is full of sh*t in regards to the use of brass in iron engine blocks and use of brass core plugs. Period.