-

Posts

9,371 -

Joined

-

Last visited

-

Days Won

86

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Merle Coggins

-

While I agree that it's a shame to do that to the car, I also find it to be an interesting attempt at a faux El Camino/El Ranch type vehicle. It's a shame that he didn't finish it and is now trying to sell it. I'd be half tempted to go pick it up and finish it, if I had the time and space for it, and my money tree was in full bloom. But since neither of these conditions exist, I'll have to let someone else finish it.

-

Well, according to the parts catalog the P/N's are different between 1 ton's and 1/2 ton trucks, and also different between 1, 2 series and 3, 4 series. However, will it fit??? Possibly.

-

It’s kind of hard to explain in words, but if you think about it, there is only one bearing per axle, and as it is a tapered roller bearing you need to have a way to keep the two pieces in contact. When everything is fully assembled the axle shafts work together with a bearing at each end and a thrust block in the middle. When setting your shims you need to have both sides assembled and you are shimming the whole assembly. The thrust block allows the inner ends of the axle shafts to be able to spin independently while holding the outer bearing cones into theIr bearing cups.

-

7 words you never want to hear on your maiden drive

Merle Coggins replied to JSabah's topic in P15-D24 Forum

I was going to say, “Hold my beer and watch this...” but that’s only 6 words. ? -

7 words you never want to hear on your maiden drive

Merle Coggins replied to JSabah's topic in P15-D24 Forum

I wonder if your voltage regulator didn’t disconnect causing power to back feed the armature. This would turn the generator into a motor. Since it couldn’t spin it is a stalled motor which can overheat the brushes and coils. It finally heated up enough to start smoking. Disconnecting the battery removed the current flow, but it would take a few minutes to cool back down enough for the smoke to stop. That’s my theory anyway... It probably wouldn’t hurt to have the generator and regulator checked by a professional. -

Here's a pic of the gear ratio stamped into the ring (crown) gear. Once you get it cleaned up it should be easy to find. Also look for the ratio stamped on the outer housing. I also agree with the others regarding leaving it together. If the gears look good after cleaning, and there is no abnormal bearing noises, I would replace the pinion seal and call it good. You could practice measuring gear backlash and gear pattern if you want to learn a bit about differentials, but otherwise don't tear it down unless necessary.

-

13th ANNUAL CLEMENTS TAILGATE BBQ, Clements , Ca

Merle Coggins replied to 48Dodger's topic in Mopar Flathead Truck Forum

I talked with Tim, and apparently he was having difficulty getting it uploaded from his Chromebook. Hopefully he'll have it up soon.- 159 replies

-

- bbq

- old friends

-

(and 2 more)

Tagged with:

-

TRUCK MASTER CYLINDER UPGRADE ADVICE

Merle Coggins replied to PT81PlymouthPickup's topic in Mopar Flathead Truck Forum

What is the piston diameter of your Jeep M/C compared to the original unit? If the piston is smaller you will need more stroke length to move the same amount of fluid. -

13th ANNUAL CLEMENTS TAILGATE BBQ, Clements , Ca

Merle Coggins replied to 48Dodger's topic in Mopar Flathead Truck Forum

Where'd it go??? There it is... ?- 159 replies

-

- bbq

- old friends

-

(and 2 more)

Tagged with:

-

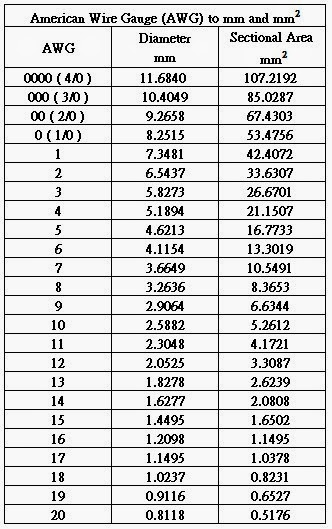

Yes. wire gauge sized haven't changed

-

I work with European wire diagrams daily and often see the wire size listed in cross section mm2. I use a chart like this to cross it to the AWG wire gauge sizing.

-

I'm a Honda rider as well. Here are mine. I took a road trip out through your neck of the woods, vikingminer49er, a few years ago with some friends. We spend a week riding around Colorado. Spent 1 night in Loveland, 3 nights in Leadville (loved that place), a couple nights in Durango, and a rainy night in Denver metro area. Here we are at the visitor's center at the top of Rocky Mountain National Park. Note the hail on the ground that we had just ridden through to get there. The ride from Leadville down to Durango took us through Ouray and the "Million Dollar Highway". However, it wasn't a nice scenic ride for us on a rainy, windy day. I was just focused on keeping the bike and camper on the road. And here I am on a day ride from Leadville to Aspen

-

59+ trucks and you finally realize that you may have enough? LOL!! ? ? Just kidding... It is a pretty impressive collection. And it sounds like several of them still get used.

-

Here is a thread from a few years ago about the earlier Cleveland style universal joints used in the earlier B-series trucks. I believe the W-series used the same ones.

-

Steve, Is that picture from before you removed the hoses? It’s hard to tell which way they’re connecting down below, but when I zoom in on it, it looks like the upper one may be going to the drain back port in the block. Here is a thread from last summer on this topic. Unfortunately Dodgeb4ya had some great images form technical pages showing the different filter flow setups, and the pictures are now gone. Maybe he can repost them for us?

-

B-Series Trucks Represented in Auto Museums....

Merle Coggins replied to 48Dodger's topic in Mopar Flathead Truck Forum

I believe the only I’ve seen was in the Chrysler museum in Detroit, which is now closed. I can’t seem to find any pictures from my visit there, at this moment. -

It will depend on how your filter canister is configured. Some feed in pressure from the bottom, flow oil from inside-out through the filter, then return out the upper side of the canister. Others feed in on the upper side, flow through the filter from outside-in, and drain out the bottom center. Some canisters are marked IN and OUT next to the ports, and some aren’t. Maybe some pictures of your filter canister will help identify which type it is.

-

My First Car -- P15 1947 Plymouth Deluxe

Merle Coggins replied to NickPickToo's topic in P15-D24 Forum

I usually have good luck eyeballing the clutch alignment, then using guide pins as described earlier I get the trans started into the clutch. Once it gets to the pilot bushing and won’t quite go, depress the clutch pedal to release the clutch disc. It’ll usually slip right in. -

I would suspect that if you are still using the flathead engine in your truck you will be quite unhappy with a 3.55 diff and overdrive trans. You’ll probably find that you can rarely use 5th gear of your T5.

-

What is the “Valve Tappet - Silencer package” for the tappet chamber?

-

1938 Throttle & Starter Linkage Clues and Questions

Merle Coggins replied to keithb7's topic in P15-D24 Forum

The trucks also have throttle linkage that routes across the back of the block, then forward to the carb linkage, as you explain. I find that if I spray down all joints and metal-to-metal sliding points with a good spray dry lube it removes enough friction so that the throttle can return to idle properly. I know I’m overdue for another spray-down when the linkage starts hanging up again. -

The gauge has 2 electro-magnetic coils inside that move the needle. One has constant voltage and pulls the needle to Empty. The other is connected to the tank sensor, which is a variable resistor. When the tank is low the resistance is high, which makes the second electro-magnet weak. The constant magnet pulls the needle to the Empty side. When the tank is full the resistance of the sensor is low, so the sensor side electro-magnet is stronger and pulls the needle to the Full side. There are 2 possible reasons that make the needle peg to full as soon as the key is on. 1. The wire to the tank sensor, or the sensor itself, is shorted to ground. Remove the sensor wire from the back of the gauge and check continuity to ground. It shouldn’t be less than 10 ohms (with a full tank). If you tank is closer to empty you should see up to 75-90 ohms. If. You have close to 0 ohms you have a short to ground somewhere. 2. The ground for the gauge is bad so the constant electro-magnet can’t pull to “E”. The metal back of the fuel gauge must be in contact with the mounting stud/nut to pass ground to the gauge panel, which in turn grounds though contact with the dash/cab. Check for continuity between the gauge back plate and a good chassis ground.

-

A shot across the bow, Exhaust Seats and Valve Guides

Merle Coggins replied to James_Douglas's topic in P15-D24 Forum

I only have had a problem one time with running hot while stopped on the FD in my truck. This past summer I was in stop-n-go traffic in St. Ignace, MI (Mackinac Bridge traffic). It good a good 15-20 minutes but I started to notice the temp nearing overheat range. I stepped on the clutch and revved up the engine a bit. The added air flow and coolant circulation brought the temp back down. I then just used the clutch more as we crept forward an inch or foot at a time. -

That Jeep commercial was about the only one I liked during the game yesterday. We've had a fairly mild winter here too. Only a few sub zero days so far, and not a lot of snow. We've got a few inches on the ground, but it was in the 40's this weekend and some melted down. The ice conditions on Lake Winnebago (largest inland lake in the state) are so bad that many ice fishing tournaments, and other on-ice lake activities, are being canceled this winter. Very unusual around here.

-

I've seen that picture before, and I agree that a Met wagon would be pretty cool. As I understand it, Nash/AMC never made a wagon version, but may have prototyped a couple. Or maybe Austin did it on their own? Otherwise, if it is truly a one off home build there is someone out there with a great deal of metal working talent. My wife has a '59 Met that we are in the process of reviving. That's already more metal work that I want to deal with, and it's not being modified.