-

Posts

10,002 -

Joined

-

Last visited

-

Days Won

181

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Dodgeb4ya

-

I like "LOCK-N-STITCH" .http://www.locknstitch.com/index.html Expensive but always will do the job 100% by a competent person. I had a 413 MaxWedge job..the block was cracked down both sides I had to save all casting ribs and raised letters/numbers matching #'s car and engine. Grind down and hide the repaired areas. L&S uses a reverse thread design and special thread tooling that pulls the crack tightly together. Most any accessable areas can be pinned. Older systems used tapered threaded pins...these could slightly expand and stress the repaired crack if not done right.

- 181 replies

-

- engine running

- engine rebuild

-

(and 1 more)

Tagged with:

-

Get one of these "Shift-Rite" down shift knobs. You have complete control of when the M-5/M-6 transmission upshifts or downshifts. You can also take off and accelerate and shift smoothly thru all four gears ..just like the old BW T-10 days!?

-

Yeah.. That front motor mount plate/timing cover has the one bolt and nut that needs to be removed for easier front of pan installation. I learned of this pan install tip from a old Chrysler Dealer mechanic back in the early 70's. Yes...never cut off those front/rear cork gaskets. Let them stick up with the side pan gaskets laying over the top of the cork gasket ends.

-

The above picture is correct. Use studs as shown for retaining gaskets in place. I use pins at gasket to cork ends to hold them together tight. Small amount of RTV at corners only. Make sure pan flange is perfectly flat too.

-

Use the floor jack under the lower A-arm way to R&R the coil springs.

-

It's a 3.54 ratio for the std. 131" WB C49 Imperial 4 dr. ...same as a 1950 NewYorker and Saratoga with the Prest-O-Matic transmission and FD. The Crown Imperial...too rare to discuss.

-

25" Dodge truck cable Tach drive distributor used with Stewart Warner Tach. 30" Moly Block engines are different.

-

Possibly as is some what common the oil pick up float is rising too high and sucking some air because no one checks the adjustment tabs when rebuilding or R&R'ing the oil pan. There are limiter drop and rise metal tabs that get bent because of rough removal and installation of the oil pick up or oil pan with baffles. To do a quick diagnosis of this problem make sure the engine is full of oil then add one extra quart of oil to see if the erractic oil pressue issue is solved.

-

You have to use the correct car rear sump pick up to fit the rear sump pan. 1948 on up 218/230 front sump truck oil pans and pick up's are wrong for car applications. There are two styles of correct rear sump oil pans for your car... Baffled and non baffled. Either will work. I'd want the rear sump baffled oil pan.

-

Did you put a couple drops of light oil on the input shaft for the two inner/outer pilot bushings? NOT Grease!

-

Pin type if in good condition are much smoother shifting.

-

I just ordered my 1948 Chrysler 8 kit last Wednesday...got it last Saturday. I called them to order it. I had to call twice till someone answered the phone. Fast service.

-

If it is a pin type "PT" will be stamped into the machined flat area by the side of the shift cover. You will need to clean the surface of any grease or corrosion th read the small lettering. Date of manufacture will be there too. Car Pin type syncro's started believe after 1952 or 53.

-

Seems to be a some what common problem these days... It's critical the new/rebuilt shoe or clutch linings be no thicker than OE specifications listed in the factory shop manual.

-

That double beveled brass insert is for 1946-48 original MoPar car tanks. 1949 thru 52 use your style fittings. New repro tanks....follow manufacturer's line connection instructions if any.

-

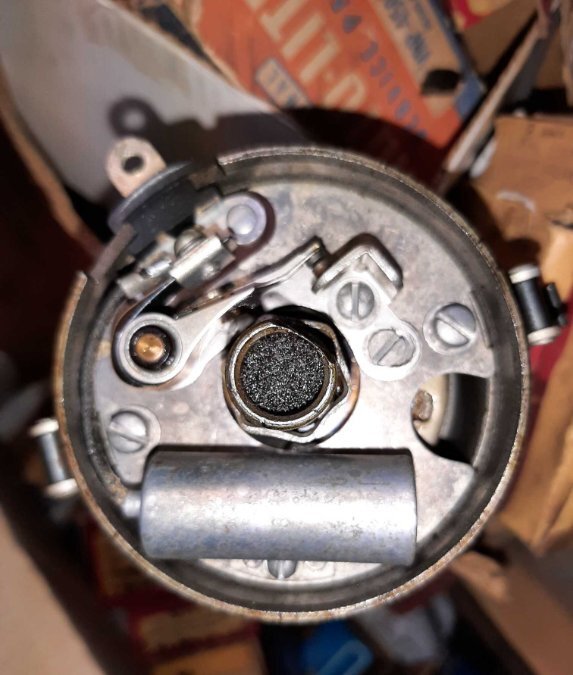

It's a AC 590 pump. "Then and Now" has a video on your 590 pump on how they rebuild it.

-

"One of these things is not like the others..."

Dodgeb4ya replied to Bob Riding's topic in P15-D24 Forum

It will most likely hit the steering linkage. -

Looks like a typical 588 Airtex or AC pump. Very common pump. The new replacement pumps have the rocker arm pins fall out. I'd rebuild that one with a quality kit.

-

"One of these things is not like the others..."

Dodgeb4ya replied to Bob Riding's topic in P15-D24 Forum

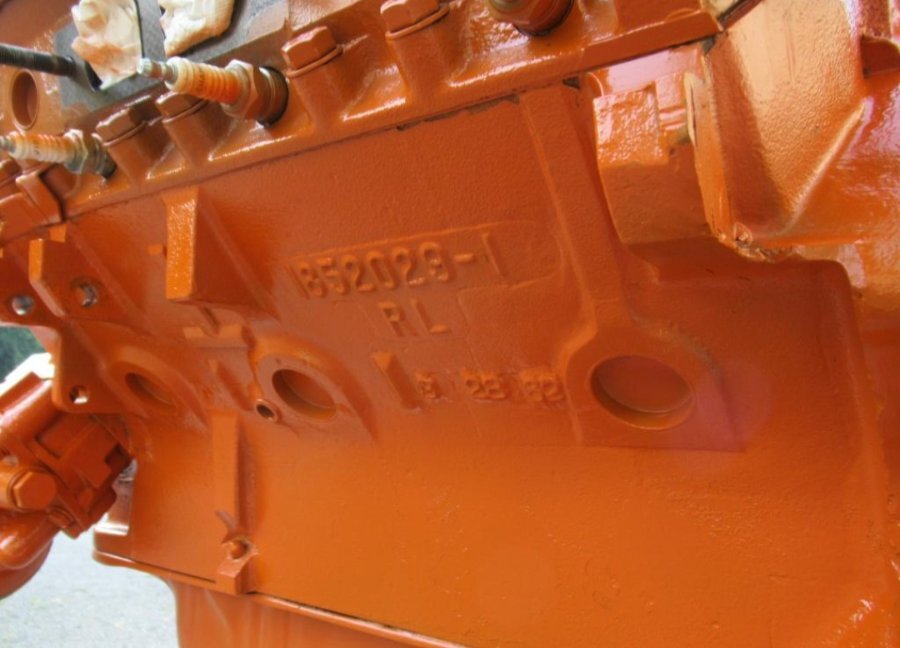

Why the 55/56 front oil sump into the 52 wagon? It needs to be a rear sump? Nice job on the engine for sure. -

Your air dome is on the correct side to the rear of the engine but clocked at 7 o'clock not 9 o'clock as originally designed...easy to fix that. Some pics of the factory eight heat shield...

-

Yes, I did use a old cut off crank bolt from some other engine and welded a 3/4" grade eight cut off bolt that slipped inside the crank bolt. The washers need to be hardened for the nut to turn easily and force the pulley or hub on easily. I realize most cannot weld or fab up this tool easily. Only economical way to make this tool is using an old crank bolt as to find a 1-1/8" bolt but it would be costly. Then get a fine thread 3/4" bolt to weld to the hollow cut off crank nut. The pictures just to show how I put pulleys and hubs on these MoPar flat heads. Maybe MoPar NoPro will steal my tool and start producing them for sale or rent.?

-

-

If your pump is old I would rebuild it or have it rebuilt. There should be three stand off studs to support the heat shield and a little air dome to quiet the pump pulsations. Then and now has a video of rebuilding this same pump...they will do a great job. Or they will sell you a kit. There are some of these pumps online NOS or they will rebuild your core but very costly. A NOS pump will probably fail because of ethanol fuel. Get one or yours rebuilt. You should also replace the flex hose at the pump. This reminds me I need to order a couple fuel pump kits for two of my straight eight cars. I rebuild my own. This is what your standard 1946-50 Chrysler 8 fuel pump (AC590) should look like...all 1939-50 Chrysler 323 eights same.

-

The 11 bolt is all you get in your 1/2 tonner. 8-1/4 ring& pinion...same as the six cylinder Plymouth, Dodge ,DeSoto and Chrysler std. wheel base cars.

-

Bare wire in the distributor grounding out as vacuum advance moves the base plate?