-

Posts

9,999 -

Joined

-

Last visited

-

Days Won

180

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Dodgeb4ya

-

Rebuilding Original Water Valves

Dodgeb4ya replied to Paul Hatfield's topic in Mopar Flathead Truck Forum

Think it's better to go to the swap meets, garage and estate sales, craigslist and others to get way better deals. Otherwise full retail plus plus now days buying from the known MoPar old parts dealers. -

Rebuilding Original Water Valves

Dodgeb4ya replied to Paul Hatfield's topic in Mopar Flathead Truck Forum

Them is a he and helper. -

Those were the good days I like to remember....oh and the smell of fresh hot tanked engine parts!?

-

But wait....that's so easy to read with out glasses.

-

Rebuilding Original Water Valves

Dodgeb4ya replied to Paul Hatfield's topic in Mopar Flathead Truck Forum

I will guess the Mikey price....$569.00 And it won't work right..or it will leak. -

Bring it to me...I'll have it out in 10 minutes. ? It's necessary to have a stable and firm mounting of the timing cover set up. Concrete or a thick steel plate on the bench is necessary. Supporting the cover properly on a very hard and dense surface and have backside of the cover supported directly close and around seal. This makes sure all hammer impact is directed to the seal only and none wasted through the timing cover sheet metal itself. You need to transfer all the direct hammer hammer force directly to the seal. If the timing cover is bouncing while hammering on the seal most of the hammer force is wasted and going to the cover not the seal. This is something you learn thru years of doing this kind of stuff. if you can swing and direct the hammer blows in a kind and powerful way that seal will pop right out. Sorry I can't show it or explain it better. Heat should not be required unless red loctite was used...doubt that!

-

I just went out to the shop, pulled a timing cover off a core engine. I removed and re-installed that seal Have done tons of them. So here's some pics Marc... I usually use a press but the hammer and seal/race driver works perfect and easy on a solid hard surface. In this case on a 1/2" steel plate. This helps the seal drive out with one or two hammer blows. I also use back up proper sized steel tubes to prevent damage to the timing cover and makes the seals come out easier. Sized just bigger than the seal depending which way I'm driving the seal with gasket. I'm not say anyone has to do this...I do myself. I always use a full diameter driver of the correct size to prevent damage to the seals when installing. Same when removing. Chisels naw. Most replacement t/c seals won't have the raised portion that extends out the front of the cover. Modern seals usually look different and might seal in the timing cover different too. No ring gasket used as in the pic.

-

Oil leak under chaincase cover on 48 DeSoto!

Dodgeb4ya replied to MarcDeSoto's topic in P15-D24 Forum

Don't get any paint on that new seal surface...the new seal won't like paint. -

Do any timing cover bolts connect to water jackets on 48 DeSoto?

Dodgeb4ya replied to MarcDeSoto's topic in P15-D24 Forum

You have one of the bolts screwed in from the wrong side...maybe causing the timing cover from being seated tight to the engine support plate. -

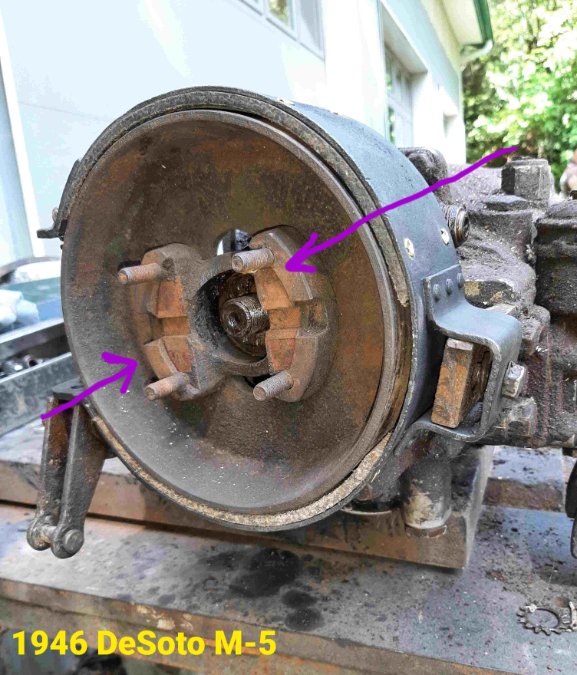

Some typical parts to look at or replace on the Plymouth/ Dodge shorty trans.. **Replace the front and rear ball bearings... **Front bearing is shielded and almost always worn out. **The two brass syncro rings should be replaced. **The needle bearings in the input shaft, reverse idler gear and counter shaft should be replaced if possible. Carefully check all surfaces those needle bearings ride on for galling, pitting including the end of the mainshaft end that fits into the input shaft needle bearings. A surface prone to needle bearing surface damage. The needle bearing surface inside of the input shaft can have galling/brinelling damage too. **1st and reverse sliding gear and the mating gear on the countershaft can have chipped or broken teeth. Small Reverse idler gears usually have a chipped tooth... Minor chipping won't be an issue. **If any gears are some what pitted....replace them... **Brake drum rear seal surface will need a speedi-sleeve if grooved or pitted. Have at it?

-

I couldn't see the original blocked video....the picture I screen shot was of that russian in the lathe.. Was that the original video posted and blocked?? Wouldn't have posted the screen shot if so...I did crop the screen shot to soften it up. But folks working around machinery really need it pounded into them these pictures/videos to fully understand the danger of rotating machinery and how wimpy a human is around it. Farm PTO equiment is the worst.

-

Quick update on your webmaster...

Dodgeb4ya replied to P15-D24's topic in Forum Announcements And Feedback

Thank you for what you do and wish you a quick as possible and complete recovery.? -

Are you sure the hub bolts are 18 tpi? Originally all 1946-54 Chrysler DeSoto six hub bolts were 5/16" X 24 fine thread. Doesn't really matter but have never seen one in course thread. Just took two off last week.

-

The clutch disc cannot be put in backwards on a Fluid Drive coupling. The driven plate on the coupling is pretty much flat. It would be apparent the disc installs only one way.

-

Just first remove the lower cast iron cover to look/see.

-

So why was the driveshaft wobbling... What exactly was the cause and what corrected that issue? Was one of the inner cup circlips missing, one of the wing joint crosses not correctly seated down into the machined trans flange groove? Maybe one of the wing clamps not positioned and holding one of the joint wings in place 100%.... The grease would not have caused your issue...just old dis-colored grease... Others with these odd "Soto" U-joints might like to know as possibly others..? As for the clutch dis-engagement issue you need to see the pressure plate separate (move away) from the clutch disc as you fully depress the pedal. And you do have 1" of top pedal free play?

-

51 B3B build thread - after all these years

Dodgeb4ya replied to bkahler's topic in Mopar Flathead Truck Forum

Have never seen a MoPar flathead six that didn't a least leave a drop some where after sitting for awhile. They should not leak a small puddle either after sitting with a recent good reseal job. Sad but true.