-

Posts

317 -

Joined

-

Last visited

-

Days Won

1

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Pete

-

I Find this car interesting, others may enjoy it.

Pete replied to Los_Control's topic in Off Topic (OT)

Here are the details: "Harry Truman's Excellent Adventure: The True Story of a Great American Road Trip" On Amazon: https://www.amazon.com/Harry-Trumans-Excellent-Adventure-Matthew/dp/1569767076/ref=tmm_pap_swatch_0?_encoding=UTF8&qid=1656332399&sr=8-1 Pete -

Dan, Did you try American Honeycomb Radiator in Bowdoin? He worked on the radiator from my 1939 Plymouth at a fair price. American Honeycomb Radiator 207-666-8111 https://www.oldusedradiators.com/ 885 Litchfield Road, Bowdoin, ME 04287 Pete

-

A few years ago I took my '38 Dodge pickup on an old car tour. It was in upstate NY and was 700+ miles in length. The truck has the original 218 engine. We pretty much kept the max speed to about 45 MPH as a Model A was leading the group. My mileage on that tour was a bit over 20 MPG. Pete

-

Could the engine be hydrolocking from fuel in the cylinders? Pete

-

I had the fulcrum pin "walk out" on me once. Shot the pump spring into the pan. Left me stranded. It was a China-made fairly new pump. Make sure the pin in staked on both sides. I now run an electric pump in addition to the mechanical pump on both my old Mopars. Pete

-

I have one in my 1939. It works great. No problems.

-

I ran into a similar problem on my '39 Plymouth. The idle mixture screw did not change the idle. In addition it seemed like the engine was running a bit rich. After a lot of trial and error I found the problem. Someone had replaced the idle mixture screw with the wrong part. They used a mixture screw from a 1 1/4 inch bore B&B carb in my 1 1/2 inch bore B&B carb. The screw did not reach in far enough to the port. It was like screwing it all the way in, but in effect it was like it was already a number of turns out. Replaced it with the correct mixture screw and all it well. Pete

-

I've used this tool to remove the main idle tube on a number of BB carbs. Some of those tubes needed extra cleaning even after the fuel bowl was run through an ultrasonic cleaner a couple of times with the tube installed and the plug removed. It takes only a few turns to get the threads on the tool to engage the threads on the tube to pull it out. Be very careful as the threads on the tube are very delicate. Use the "handle" on the tool to gently push the tube back in until it seats. Carbs ran well after removing/installing the tube using this tool. I've reused the tubes as replacements don't appear to be available. Pete

-

I know that Plymouths used distributors with vacuum advance as far back as 1936. Probably earlier. First thing to check on your carbs is the bore size. BB carbs came is several different bores. My '38 truck has a 1.25 inch bore and my '39 Plymouth has a 1.50 inch bore. The truck is a 25 inch Canadian engine and the Plymouth has a 23 inch engine. Distributors without vacuum advance were usually used on bigger trucks. Pete

-

Adding my thanks as well. Whenever I start I new project on my Mopars this is the first place I come for info. You folks are great! Pete

-

This is out of your budget, but it works for me. On my '39 Plymouth I'm running 600/16 Coker bias ply look radials with tubes. This summer I did two back-to-back tours of about 1,800 miles. Speed occasionally a bit over 60. It worked very well. No worries. Pete

-

That's exactly what I did. Worked like a charm. Make sure you use a piece of soft wood.

-

Thanks for all the replies. I think I’ll look for a replacement trans. The truck has its original 1938 engine and three speed trans. It’s been in the family since the 1970s and I’ve come to like it for its character and quirks, including double clutching. I think its non-syncro crash box is the last year before Dodge put the newer tranny in with its sychro in second and third gears. Any dodge trucks from 1937 and 1938 with the three speed trans from half to one ton would have this gearbox. It's a lot of fun driving it on the unpaved back roads here in rural Vermont. Pete

-

I’m looking for advice on a problem with my transmission. I found a crack on my engine’s front cover plate right by the front engine mount, so I pulled the engine to replace that part. As long as I pulled the engine, I decided to freshen it up and pulled the trans too to address some fluid leaks. I discovered one of the four “ears” through which the trans is mounted to the bellhousing is broken off. See pics. There was no bolt or stud for that mounting point, so the trans has been supported by the other three bolts for a very long time. The trans shifts well and there hasn’t seemed to be any alignment problems. The engine is a 1938 Canadian built long block. The trans is a three speed non-synchromesh “crash box” which appears to be original to the vehicle. Double clutching anyone? So, I need a plan forward. Should I just use the three bolts as it was when I pulled it? That doesn’t sit well with me. The chances of finding a good case probably aren’t too good, so I’m probably looking at getting another trans. If I go that route I’ll check my Hollander to see what fits without requiring too much alteration. Please let me know your thoughts. Pete

-

I've had mostly good luck with Coker. I'm running their bias ply look radials on my '39 Plymouth. On my first set I had a bubble appear under a whitewall after a few hundred miles. Coker replaced it for free and paid shipping both ways. I recently bought 2 more tires from them. My mechanic found one was out-of-round when he tried to mount them. Coker again replaced it for free and paid shipping both ways. I'm happy with the ride and their service, but there have been some quality issues that they made right. Pete

-

I've had my '39 Plymouth in a number of parades. They usually go at walking pace with a lot of stops for groups to do their things for the spectators. Not good for an 80+ year old car in 90 degree weather. Now my local car club insists we go first in the parade. It has worked a lot better. Peter

-

Made in Galion, Ohio. If I remember correctly the became part of Baldwin - Lima - Hamilton which became part of Clark Equipment.

-

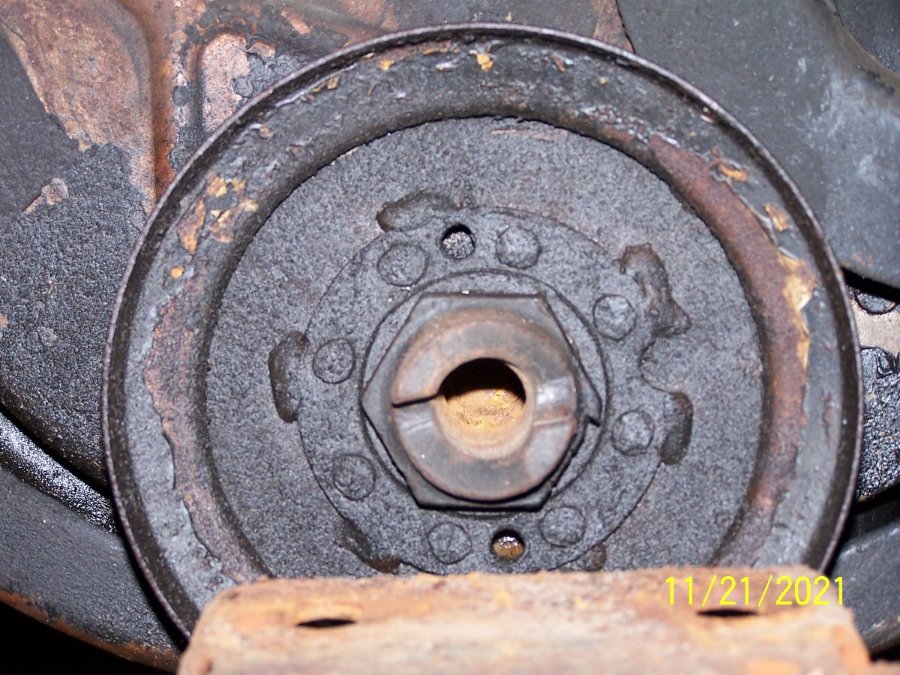

Hi all, I'm pulling the motor in my '38 Dodge pickup to do some freshening up. I noticed some weld marks on the front of the crank pulley. See the picture. Are these welds normal, or has someone made a repair? I concerned that this could affect the timing marks. Pete

-

My retirement started on 1/1/2021. People keep congratulating me on being retired. I'm not quite sure how to take that. Is it the fact that I outlived the bastards, or the fact that I'm not dead yet... Pete

-

The floor panel on my 1938 Dodge pickup was originally plywood. Someone replaced it with a poorly cut plywood one. It's time to replace it again. Pete

-

On my 1938 Dodge pickup the default was black fenders and running boards. Body color fenders were an extra cost option. Pete

-

Need some pics of original type interiors for 46-48 DeSoto

Pete replied to MarcDeSoto's topic in P15-D24 Forum

From Uniroyal's website: "In 1914, Naugahyde was invented at the U.S. Rubber plant in Naugatuck, Connecticut. It was the first rubber-based artificial leather ever made, and the first in a series of product innovations. Naugahyde is recognized as a global leader in high-performance vinyl coated fabrics and top coats." So I guess Naugas were once wild in Connecticut... Pete -

The problem I've had with Chinese 6v bulbs is that on two contact bulbs, the contacts are not dots, but elongated, so that when installed they cross over both contacts in the socket. Therefore they are useless. Pete

-

Need some pics of original type interiors for 46-48 DeSoto

Pete replied to MarcDeSoto's topic in P15-D24 Forum

Musclemaniacs on eBay is a reseller for REM reproduction parts. REM doesn't do retail sales, but a number of eBay sellers carry their stuff. https://www.remautoinc.com/ I've had good luck emailing REM directly with questions. I've bought some of their interior panels and also bulk fabric. I get the part number from REM for non-catalog items, then order it through Musclemaniacs on eBay. Pete -

The mechanic who did the front end alignment on my '39 Plymouth started with the specs in the factory service manual. He then made some minor adjustments to account for crowned roads because I drive on crowned roads 99% of the time. The car tracks well. I'm running radial tires on original 16" wheels. Radials like more caster than bias ply. Factory service manual specs: Caster: minus 1/2 degree to plus 1 1/2 degrees. Not adjustable. Camber: minus 1/4 degree to plus 1/2 degree. 0 degree preferred. Toe-in: 0" to 1/8". 1/16" preferred. My current alignment set by my mechanic: Left Front Right Front Camber 0.3 degrees -0.1 degrees Caster 1.2 degrees 1.1 degrees Toe 1/16” 1/16”