-

Posts

3,468 -

Joined

-

Last visited

-

Days Won

193

Everything posted by keithb7

-

See here:http://www.1948plymouth.info/1948p15/DocumentWeb/36-48PartsBook.php The password is "password"

-

-

You shouldn't give up due to the lack of a local person to perform a valve grind. You can do it yourself, in engine in frame, by hand, and get good results. I've done it. Cylinder taper and wear are something to consider. How's the ridge at the top? New piston rings are generally a little larger than needed. Which is why we often have to file the ends down to get the proper ring gap. Not by coincidence, this allows us to use new cylinder rings in worn cylinders. My understanding is rings can fit to work in cylinders worn to .009 over the machining spec when the engine was rebuilt. Cutting 0.010 out of the bore at the next rebuild means the next official up-sized 0.010 over, rings. If you have a cylinder top ridge, I believe you have to ream it off. Measure your cylinder and go from there. A cylinder hone and new rings could do very well for a typical fair weather, Sunday, local cruiser vintage car. I guess before going that far pull the engine, roll it over, and pasti-gauge the mains and rods. Mic all the crank journals. If they look ok with some wear, could a person put .001 or 0.002 over sized bearings in there and leave the crank alone? A little taper, and not too scored up...Not perfect, but good? New valves, new guides, new timing chain and gears. All new gaskets and seals. She might just be darn fine., Depends how it all measured up, how bad its all worn? How you want to use the car when done? Driving long distances at and hi-way speeds? Probably not ideal. Local cruising and the odd 200 mile trip? You might net many years from a refreshed engine. As opposed to full machining and thorough professional type engine rebuild. There are options. You may not need to spend $7K dropping the engine off at a machine shop and ordering the super sized full meal deal. As mentioned, depends on what you want from the car. These old engines take a lot of abuse. Get 'er free'd up. She may run. Plan on lots of elbow grease. Good cleaning. Seal things up. I bet she'd go. I bought a frozen 218 (Canadian 25") for very cheap. I tried tranny oil and soaking for weeks. I gave up. I flipped it over pulled the pan off and rod caps. I pounded the cylinders out with a 1x1 piece of wood and a 5 lb sledge. They finally broke free. Took a lot more effort than I expected. Here you can see what I was fighting.

-

The 201 engine is a pretty mild engine . The crank would be a weak point. I don't think I'd want a 201 crank in a 3 7/16 bore 237 engine. I'm imagining the 201 crank not lasting long with a 237 bore engine. FYI the 201 engine is 3 ⅛ bore x 4 ⅜ stroke. 237 ci engine is 3 7/16 x 4 ¼" stroke,

-

Yes I agree your crank is in spec. However, the ID measurement on the bearing halves, after the cap is mounted, torqued, bearing crushed is the one you also need. A trickier number to measure. I found NOS 0.001 bearings on E-Bay. See here. Maybe contact the seller. I see he has lots more engine bearings for sale including a .002 set. Might be perfect for you. https://www.ebay.com/sch/73revordnal/m.html?_nkw=&_armrs=1&_ipg=&_from=

-

For what it's worth, recently I could not source .010 rod bearings. My crank surfaces looked pretty darn good. I found .001 bearings to be used for a crank polish. So I went with those and am only having my crank polished. I have been informed a way to measure clearances is to first mic the crank journal. Then Install the bearings in the rod end and cap. Install cap and torque to spec, (with the rod properly secured in a rod vice). Then a snap-T gauge and a micrometer, or better yet a dial bore gauge is used to measure the ID of the assembled, crushed bearing, when not installed on to the crank. Compare measurements of torqued, crushed rod bearing ID to crank journal OD.

-

I pulled my tranny and even on the bench tried like a bugger to pull that seal out. An assortment of tricks and tools were tried. I gave up and removed the rear tranny park brake housing. Then the seal was quickly, and easily pushed from the back side out. A Hammer and a piece of scrap wood made quick work of it. Not simple, but I’d had enough failed attempts. Check your removed brake drum. Make sure there is no wear on it where the seal rides. If a little wear is there, no new seal with prevent leaks.

-

We brought a little positive attention to the old car hobby recently. https://www.castanetkamloops.net/news/Kamloops/330002/Vintage-Car-Club-of-Canada-s-Kamloops-chapter-took-their-Easter-drive-from-Westsyde-to-Valleyview

- 1 reply

-

- 5

-

-

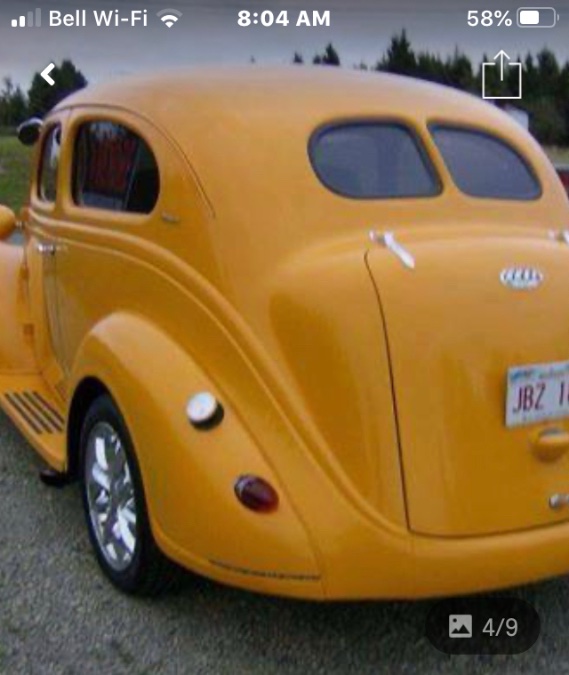

Make no mistake, I prefer closer to stock. I have no interest in owning that Plymouth. I have a pretty darn good idea what it would cost take any car to that level. Pretty easy to spend $30K doing most of the work yourself. Dropping it off a hot-rod shop and asking them to go for it and build your dream car? Whew man! Double that and then some. Although the restorer did seem to cut corners, at least by not re-chroming the hood ornament. Where else? Who knows. Those wheels are gawd awful I agree! Sad that is will turn out $11K or less when sold. I am well aware of situations like this. I just hate to see it no matter how unattractive or undesirable the car is to you or I. I have an alert set up on Kijiji. If any 1938 Plymouth, anywhere in Canada is posted for sale, I get notified. That's how I knew of this one for sale in New Brunswick. Most of last year it was listed for sale, then lately the reduced sell price.

-

Easter 2021: My local vintage car club has organized an Easter driving tour. My family want to jump in and ride along. I gave my wife free reign to do whatever she wanted to add some easter appropriate decorations. Here is what she came up with. We are headed out now.

-

Nice looking car! The arrival of spring is a welcoming time for any old car owner. For the first time, I was able to drive my car every month of the year. I took advantage of rare ideal driving conditions that appeared in each month over the past winter. Today is our local club's annual easter tour event. I am taking my 53 out today for the drive. Looking forward to it.

-

I saw this on-line classified ad. Someone poured a ton of time, passion and money into this 1938 Plymouth. The situation could likely be the result of someone passing. Sadly there are some clues. Zero information is listed in the ad. Yet a mile long list is easily seen. A woman’s name and phone number to contact is listed. Very low asking price. I’ve this same car for sale for some time. The original price was a lot higher. Personally I am not a fan of hot-rodding an old Mopar. The color isn’t for me. I see this car as a deal for someone into the hot-rod scene. If my guess is correct on the liquidation of this car, it is a sad situation. Someone will be getting a heck of a price on a car. Shown is the Canadian price. The US asking price is about $11,000. Not sure why I have mixed reservations about this one. I guess I hate to see a guy’s dreams and passion on the chopping block. The asking price is pittance compared to the skill and money invested to build this car.

-

Just in case, don't use modern GL4 or GL5 oil in the tranny.

-

Welcome to this group. There are an abundance of nice, helpful, willing people here. You’ll get all the help you need here and more. That’s a nice looking Mopar. You may be able to get the engine running without spending much. If you are prepared to roll up your sleeves and dig in. These old cars are excellent for learning new automotive skills. Pretty basic and easy to work on compared to modern vehicles.

-

“Not sure what to do with it”...Uttered by so few here! Lol. I’d make it reliable, safe, and drive it. No shortage of help here if you ask.

-

Clutch assy selection for 1948 Plymouth Business Coupe

keithb7 replied to dartgt's topic in P15-D24 Forum

Clutch diameter can vary. 9 1/4" seems to be the average for passenger cars. LWB and taxies got larger discs. Wouldn't hurt to check the number of centre splines. Best practice is to know exactly what is in your car, before ordering new parts. Lots of parts have had ample opportunity to get swapped around over over the past 70 years. -

Oil change and new differential carrier gasket p15

keithb7 replied to Cudan's topic in P15-D24 Forum

I think the procedure is described as “a can of worms”. To change carrier gasket: Remove: Hub cap Wheel lug bolts wheel cotter pin Axle nut pull brake drum remove brake shoes and hardware remove wheel brake cylinders remove brake backing plate Pull out axles get under car remove drive line unbolt carrier and remove Reassemble with all new bearings & seals! Yay! No, its not simple. Yet its not hard to do either. Just lots of steps. I likely forgot to mention a few steps too. -

My ‘38 Plymouth has a pair of bolted-in splash pans. One on each side of the engine block. Down low. I also have access To a 1928 Dodge. It too has similar splash pans. One on each side of the block. Both cars, bolted to the inside of the fender. Looking down in my ‘53 Chrysler Engine bay , there are no splash pans. I am interested in learning what their intended purpose really was. I can make a few guesses. Keep water and mud out of the engine bay? Prevent the distributor from getting wet? As I scrape away 80+ years of grease and dust, I discovered fluid gutters. It seems they wanted to direct water flow from the block drain maybe? Along the splash pans to a central drain. Maybe the pams idea was to assist with directing airflow from the fan? Guiding it along each side of the block, exiting the engine bay by the bell housing? When did they drop splash pans? It seems someone must have figured out they no longer served a purpose. What purpose was that? What changed? They do look cool when in place. Making a nice looking enclosed area around the engine.

-

-

What is the most difficult to find part for your project so far?

keithb7 replied to Marcel Backs's topic in P15-D24 Forum

So far, the proper 1938 Trico vacuum wiper motor reseal parts. No luck yet. -

What year/model Plymouth are you referring to? Thx.

-

Does anyone know when it became official when Chrysler focused on and produced industrial engines? I’ll guess around WWII? Since Chrysler had been paid to manufacture so much war machinery, perhaps they saw the opportunity? For powering pumps, generators, other equipment beyond automobiles? I saw interesting video featuring the rare Plymouth tractor. They made 200 of them in 1933. Oddly enough they had a 4 cylinder Hercules engine. The reason seems to be that the Plymouth tractor was not associated with the Chrysler Corporation. It was another company. I suspect they received a letter from the Chrysler lawyers suggesing name change. I don’t know this, only speculating.

-

Great to see photos of the old American manufacturing industry. The Massey photo reminds me of the massive Chrysler and Ford factories of the old days, that I have researched.

-

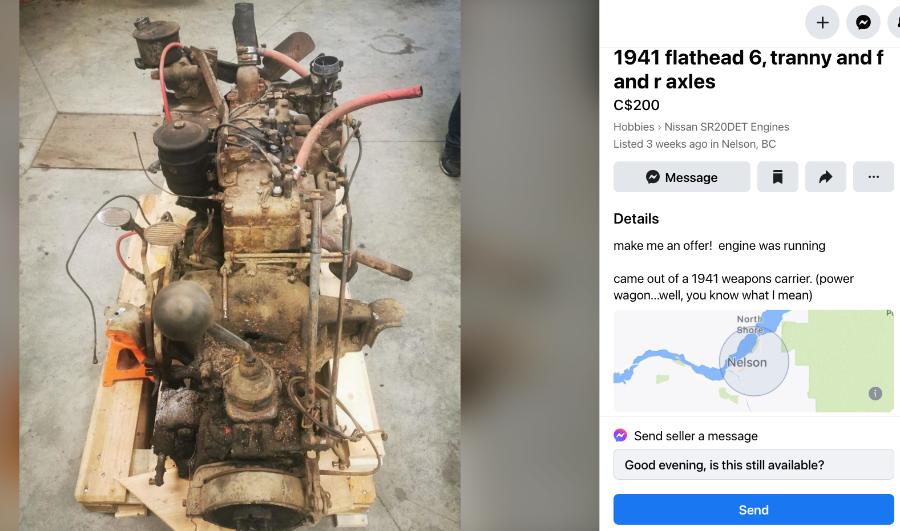

Just took another fresh look and found this one. Maybe I could ship you this for way less than $1800? Local to me. Asking $200 CAD. $155 US funds comes with a tranny!