-

Posts

3,467 -

Joined

-

Last visited

-

Days Won

193

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by keithb7

-

Early Mopar engineering wins me over too. I'd rather drive it!

-

I own a Plymouth and a Chrysler. I suppose one is an entry level car, and the other a high end premium car. I imagine a shoe salesman heading work each day in the Plymouth. Suit and tie on. Very proud. Taking his family out for a picnic on Sunday. He’ll get good reliable miles on the car. Enjoying ownership for a fairly long time. In the Chrysler, laden with chrome and comfort I imagine a bank manager driving to work each day. Or maybe he has an Imperial and bought the Chrysler for his wife. She doesn’t work outside the home. The automatic makes it simple for her to go to the grocery store. Or take the kids to a birthday party. On Sundays their teenage son and daughter have tennis lessons at the Sports Club. With plenty of room in the car for a hat and stretching your legs, the Chrysler owner is proud too. Every 2-3 years he upgrades to a new model.

-

I do have another one I put together a few years ago.

-

I like to pop the hood, taking my time at the gas station. Checking fluids. Poking around under the hood, looking important. Most of the time friendly folks approach to chat. I so enjoy that part of the hobby. Out for a cruise tonight. Coffee in hand watching the sun set thru the windshield.

-

-

Very nice. I can hardly wait for retirement! I might actually have time to pull off such a feat.

-

That appears to be the countershaft. You are looking at the end of it. It's a mild interference fit. There is no seal there. Not sure what model of tranny you have there. Looks like a 3 spd manual. The tranny could be disassembled. A sealant applied to the countershaft where it enters into your tranny housing. It would hopefully seal it. While out, study the countershaft for wear, where it fits into the housing. It may be damaged, nicked, from poor handling by someone. Countershaft does not turn so this is not an area that normally sees much wear.

-

Today I rounded up some steel and hardware. I went to see my hobby-machinist friend. We tag-teamed a bit to build this con-rod vise. It should allow me to install, torque and crush the rod bearings. Then measure bearing to crank journal clearances. Fairly accurately I think. Better than plasti-gauge I think? It was a fun project. Bonus working with my buddy too.

-

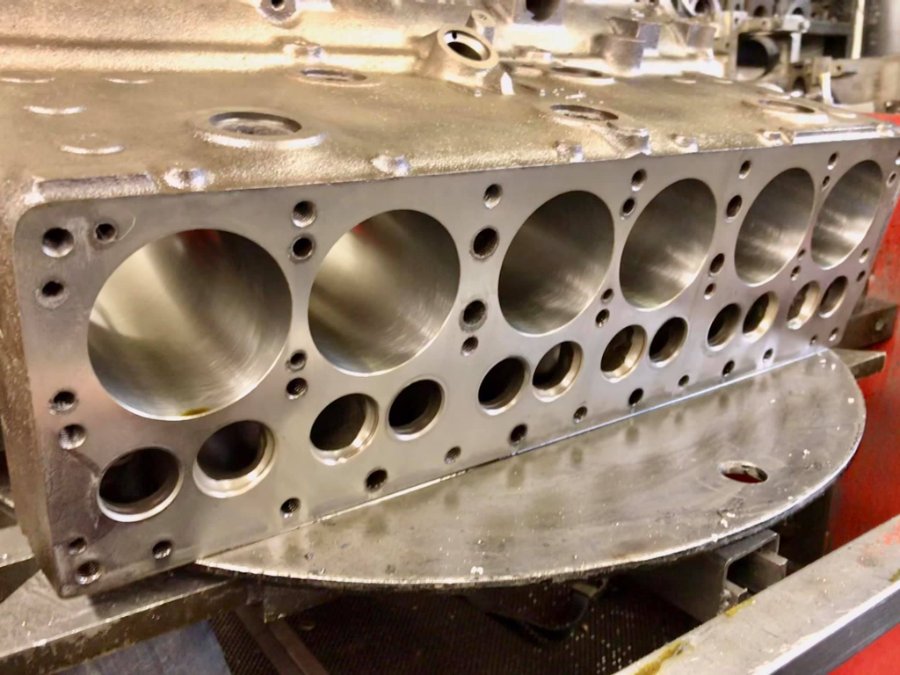

Someone forwarded a few pics from the Easter Cruise. On a related note my '38 block is looking good. 2 more weeks they tell me!

-

Wondering if a mechanical stethoscope help nail down where the knock is coming from? https://www.summitracing.com/parts/lil-52500?seid=srese1&gclid=Cj0KCQjw1PSDBhDbARIsAPeTqrdH41efySqXjt6IIZThpWmVWjClMXPYJKo86ZgqgfLjpHhxT466KPcaAohYEALw_wcB

-

@ChrisMinelliif you are still looking...I found a guy in NY state looking to give away free, a pulled engine and tranny. Zip 10927 haverstraw. NY. ‘48 Plymouth if I recall. Not sure if that’s within a reasonable area to you. If interested send me a message. Keith

-

Original MoPar Batteries 1929-42 from MoPar sales Literature

keithb7 replied to desoto1939's topic in P15-D24 Forum

Cool old stuff folks. Thanks for sharing. -

Your work gave me incentive to dig out my pressure washer and do some spring cleaning. I used my Mity-Vac vacuum, oil extractor to suck out the engine oil in the Honda engine and refill with new 10W30. Cleaned the plug and now she's good for the season. Spent some time cleaning up oil drips on my asphalt driveway from my old Mopars. A comment about POR 15. I used it on the backside of my 4 wheel rims. Looked good. Yet, brake fluid destroys it. Any brake fluid leaks, the POR bubbles up and flakes off quickly. Just be aware and careful when topping up your master cylinder. Keep an eye out for wheel cylinder leaks over the winter and get on them.

-

A fuse! Perfect. A simple fix. I tend to go straight to advanced troubleshooting. I do tend to jump past all the simple things, assuming folks have addressed them. My bad. Glad its fixed. Enjoy that car. It looks fantastic.

-

American built 23” long 218? Or Canadian built 25” long 218? Big difference between the two. If Canadian you can fit upto a 265 ci engine in there. 23” long? I believe the 230 ci 23” will drop in pretty easily. If you want to upsize to a 25” engine, it may be able to fit with some modifications. My ‘38 had a 23” 201 in it when new. It now houses a 25” long engine. Rad was moved forward.

-

I like participating in electrical discussions but its pretty hard to supplement what’s been said above. Great info. If you don’t have a digital multi-meter it’ll really be worth the purchase price to fix your issues. Do you have a shop manual with the electrical layout diagram? Also extremely beneficial to trace wires and electron flow.

-

How much CID does a .030 bore job add to a flathead 6�?

keithb7 replied to MarcDeSoto's topic in P15-D24 Forum

What is cool though, is my 25” long 228 ci Canadian engine, bored 0.060 over will become a standard bore 237 engine. Looking forward to it. -

These sorts of new projects are great for learning new things. Push yourself beyond of your comfort level. Then you’ll develop yourself. When you succeed you’ll feel very proud. When you pry on the flywheel ring gear you’ll get great mechanical advantage. This can be helpful. I’ve never worked on a straight 8. On my 6, there is a lower pan that you can remove to expose a good lower portion of the ring gear. Anything that moves with the engine might be contributing to the seizure. Stuck valves. Stuck tappets. Cam bushings possibly frozen to the cam. Timing chain. Piston rings. Rusted main and rod bearings too, in extreme corrosion examples. Likely just the rings, but it all adds up. I tried for a couple weeks, using your soaking method. Then I gave up and dug in, tearing it down. Others have had success, so keep trying. You’ll know when you’ve had enough. Is the rad still in the car? The engine too it sounds like? Is there room to get a large socket and breaker bar on the crank front pulley nut? ¾” drive would be nice. Then a decent sized piece of pipe to really get some torque on that crank to spin it. I look at it like this. People spend money to get an education in auto repairs. People also spend money on hobbies that make them happy. People pay mechanics to fix their old cars. Whatever you learn from all this straight 8 work, will be valuable to you. Spending some money, investing in yourself to gain experience and build confidence.

-

I feel your pain. I won’t go into details but I had a goal to have my engine rebuild completed for 2021 summer cruising....I now realize that has evolved into a pipe dream.

-

Sorry to hear that. Sounds like you are getting a bit of a run-around. The good news is you got your .002 bearings quickly. Lots of us would be delayed a month or longer waiting for parts to arrive. Then to find they don’t fit. You wanna talk about frustration? That’s when tools may fly, and the rye starts pouring. Lol.

-

Funny how us men with old Mopars are tickled fancy when someone stalks us for miles down an old quiet country road. ?

-

Whoa boy! Those valves are clean! Might not have run long after it was last rebuilt? FYI some valves there appear to be stuck open.

-

She was a grocery getter today. Then I realized, I don’t think I’ve parked her underground before. Photo op time.

-

See here:http://www.1948plymouth.info/1948p15/DocumentWeb/36-48PartsBook.php The password is "password"