-

Posts

3,462 -

Joined

-

Last visited

-

Days Won

193

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by keithb7

-

I had the carb off earlier this week. I installed a heat sink base plate. I ensured I had the proper gaskets and routing in the base plate all aligned. The symptom was present before I installed the heat sink plate. It remained after. The purpose of the heat sink was to divert heat away from the carb bowl. I will check for any leaks in the area however I am doubtful. The gaskets were in good condition. I'll re-check the gaskets and everything in the area again to be sure. I think Sniper is onto something with the plugged fuel inlet holes right above the throttle plate. We'll see soon enough.

-

I'd never heard of one either. I need to do more research. Looks like a deep fryer. I assume you submerse the carb and leave in there a few days? What is the cleaning solution?

-

Adjusting the screw has no effect on the off idle condition. At idle, the engine rpm will falter as the screw is adjusted in or out.

-

Thanks Sniper. At the green arrow area? I’ll take a look at this area. I suspect the holes would be quite small. Easy to varnish up if left for years, and engine started very little. I forgot to mention that I had the bowl cover off earlier this week. The accelerator pump appears to be working fine. @Merle Coggins I see my carb marked: Carter E6M1.

-

I have been tuning/ tweaking and test driving. Including tweaking the timing, both advanced and retarded, locking it in place and driving. As well as the A/F mixture screw. Process of elimination. I haven’t nailed it down just yet. I just keep testing and removing variables where possible.

-

I am interested in learning more about how fuel is delivered at a specific point. Just off idle. 1938 Chrysler. Stock carb. My understanding is at idle when the throttle valve is closed, fuel is delivered thru the small orifice just below the butterfly valve. On the bottom side of the valve, closer to the intake manifold. Fuel delivery here is adjusted by the idle air fuel mixture screw. Just as the throttle valve starts to open up, the low pressure point below the throttle valve lessens. Now fuel, I think, must be introduced into the venturi at another place higher up the carb. Is this via the main jet at this point? Or is there some type of intermediate jet just off idle, then later as the throttle opens further, then the main jet takes over? At this point just off idle, I think I am starving for fuel. If I just wiggle the throttle up from idle and hold it there steady, then engine runs rough. Held there long enough it will stall. Blipping the throttle past and his point it will run on and rev up. So I can drive, but it ain’t right. This lean symptom can be lessened if I partially close the choke. To me that means I am cutting air flow down, forcing a richer mixture. A band-aide for the issue. This fuel delivery issue creates surging when cruising around town at low speeds, just a hair off closed throttle. For example 3rd gear 25-28 mph or so. Tweaking the idle A/F mixture screw both in and out offers no improvement. Dwell is bang on, 38 degrees. Brand new spark plugs installed. Removed spark plugs looked good and even across all 6. Vacuum advance is working. Verified with a vacuum gauge and witnessed with a timing light. Timing set at spec at 0 deg TDC. Adjusting and tweaking timing offers no improvement. Timing is jumping around a little bit, not too bad. Witnessed with the timing light. I suspect maybe due to worn distributor parts. I am not convinced my symptoms are related to my he ignition system. Maybe I’m wrong. Maybe I need to pull and clean/rebuild the carb? Its not seen much use in years. I’d like to understand fuel delivery at this very point just off idle. Float was set at 5/32. Not correct. I fixed this and set it to spec, 5/64. This had no effect on the off-idle stumble. Engine starts well without touching the throttle. From outside the car, I can lean in thrunthe window, hit the starter button and it fires right up. Engine pulls good up the hill home under load. Runs good on the hiway. (Higher rpm, not just off idle) The car has exhibited this symptom since I acquired it. Just takes a while to get past the honeymoon stage and start identifying little issues. Your comments are appreciated.

-

I had a look at my spare carrier to learn and follow your tip @Plymouthy Adams on the top housing I only found the letter “E”. Looked all over. I see a casting part number. Only sign of ratio is on my crown gear. My assembly was built in Canada. Who knows? Could be different. We sometimes like to do things a little differently up here.

-

Usually marks are found on the crown gear outer edge. Try turning it until you see the ratio stamped. Or just count the teeth on both. Unless of course it's still installed. Then nevermind.

-

I finally got into the carb recently. I found a couple of things. The carb mounting nuts were loose. I would certainly have a vacuum leak there. Especially when cold, I noticed something wasn’t quite right. I could feel it. This is where experience and intuition can guide you. From memory my ‘38 Plymouth was running better, I knew it. Just had to keep digging to get it sorted. The float was set to 5/32. Supposed to be 5/64. Way rich. That explains a few things. I also installed a heat dam at the base of the carb for preventative measures. See photo. Careful with these. Ensure gasket and plate cutouts are in the correct place for vacuum orifices in the carb base. The gaskets are cut with odd openings for a reason. Also, not done yet but I will also install a heat shield plate over my mechanical fuel pump. Test drive coming up!

-

Following up to say my 6V + ground LED headlight bulbs arrived today. The seller is in Arizona. USA, I was half-ways expecting a decent product. Upon opening the package I see a “Made In China” sticker. On my packing slip it reads Non-Returnable. Non-cancelable. No warranty. Hmm. Not good I’m thinking. The light assembly quality was total garbage. Which is where they ended up here. In my trash bin. Cheap junk. Oh well. I gave it a shot. Not a total loss. At the least, I was reminded to be more diligent in my research.

-

The last few times I went to a local bearing house to match up bearings I left frustrated. They made a lousy effort to try. They really were not interested in helping me. I do the work myself and get the results I need. I’m old enough to remember when a good partsperson was very valuable to someone who worked on automobiles. That person was able to earn a decent living too. Before computers dumbed down the partsperson trade. Do you get what you pay for? Today you may need to work a little harder to earn what you get in value. If you would rather just flop out $100 bills and buy parts with little effort you’ll get what you get. Might be good or could be bad junk. If you aren’t interested in doing any research, odds are you may not be able to identify a good value part. I guarantee Richard Desoto recognizes good quality parts. I do my research. I have purchased parts manuals. Multiple service manuals. $100 for a vintage Hollander Exchange. $100 for another decent service manual. $50 for a parts manual. Another $50 for another parts manual. Another $100 invested in 2 Motors Manuals. Dyke’s encyclopedia and more. I’ve seen good sized home technical libraries where people have invested considerably. Some of us spend countless hours reading old technical text books and visiting sites like this one. Researching, and also helping others. I personally have countless hours producing You Tube videos to help others. Karma is real. I help others in the hobby constantly. Free info and good advice comes my way too. Scanned data and old reference material also finds its way to me too, free. I share what I have too. I am rewarded when I am able to help those who also want to help themselves. People who roll up their sleeves and get greasy, I have no problem helping ouy. Every dollar I’ve spent on technical books or any other technical literature was spent for my sole personal benefit. If it can also helps others, great! It's a hobby. I like surrounding myself with like-minded hobbyists. I like to share what info I may have and know. I like it when others do the same. We all win when combined, we share our knowledge and some resources too. Within reason. I won’t be scanning my entire 1938 Parts or Service manuals. Lol.

-

I have not matched that one up. I got my outer seals from Rock Auto.

-

Parts Tip: Rear inner axle seals. Your local Caterpillar equipment dealer has these. Direct fit replacement seal. Part number 2B-1869. Much savings $$$ too. These are a decent quality seal. There are probably 350 plus Caterpillar dealers in North America. Active and doing good business today. They look after probably a million pieces of Cat equipment. Likely thats a low guess. Economy of scale. They might be building 10,000 of these seals per year. Again, guessing. Call up your local dealer. Report back and let us know the price in the USA.

-

How does one ever get the countershaft back out once JB Weld has been used to seal it? I suspect that tranny may now end up being run to total destruction.

-

Good one! Pilot bushing. I did mine too. A $20 puller from Habour Frt is fine. Bread and grease tricks would not work for me.

-

Look at the centre of the clutch hub. It may say engine side or front. Etc. Mine had a front and back side that was to be installed properly for the clutch to work. Pull all the spark plugs so you can easily turn the flywheel by hand. When mounting the pressure plate don’t tighten two screw tight then move around to tighten two more. Apply equal pressure to all mounting bolts equally. Torquing in steps. A clutch alignment tool makes the job a lot easier. It lines the disc up. However I found a spare tranny input pinion was even better. It worked awesome to line things up. Yes, now is the time to also replace the throw out bearing. I agree with what was said above about cleaning up the flywheel.

-

Run 6V directly to the coil that actives the anti-stall system. Looks like they call it the lock out assembly on the bottom page. Is this where your yellow wire hooks up? Touch the housing area with a screw driver. Should be non-magnetic. Then send 6V to it. A temporary Jumper wire off the battery should work fine. Activate the solenoid. Does it now become magnetic? Screwdriver sticks to it now? This might help you diagnose if it is working or not. When the coil inside there becomes magnetic, a needle is lifted off a seat inside the carb bowl. Allowing extra fuel to flow. Preventing an engine stall. When 6V is removed the magnetic field disappears. A spring pushes the said needle back to its seat.

-

This evening I asked my wife to go out on date. Picked her up in the garage. Took her to McD’s for some fries. She said “ Our dates out haven’t changed much since we were 16. Same color old Mopar, green. (It was a 76-ish Dodge Dart 2 door). We got older so did the cars.” In the parking lot a nice old man approached. He looked to be in about his mid 80’s. He Shuffled over. Skinny and flopping around in his pants. Lol. Poor sweet old bugger. We’re all headed there. He says “I just wanted to tell you that your car is one of the most beautiful cars I’ve ever seen. “ I agree", I responded . "One of the most beautiful ever built". He said, "When I was kid, cars like your Chrysler were everywhere". Big grins. I thanked him and he shuffled back to his ‘92 Toyota Camry.

-

Good post @Los_Control one question. What is a stoof?

-

I am trying to keep the discussion on topic, in this Mopar section. Some great points have been made. An interesting point was made about stripping down a vintage club, letting it die. See if a new club with all new younger vigorous members develops. Sometimes maybe that’s what it takes to break old habits. To break down the barriers for the younger folks to take the reins. I did post a thread about age demographics among the members here. A few years ago. Looking at that poll today, the results trend similar to my YT channel. I used different age brackets, yet the heavy lift is 51 and up here also. 68.56% of 299 members here who responded to this poll are 51 and up. Ok for Mopar lovers, here we are. We are mostly older. Pretty experienced I’d wager. Easy going. Enthusiastic to help others. Pretty brand loyal too I’d say. I’m proud to be part of this group and very proud of my old Mopar cars. As far as the entire vintage car or vintage tractor hobby? I admit, I have no idea.

-

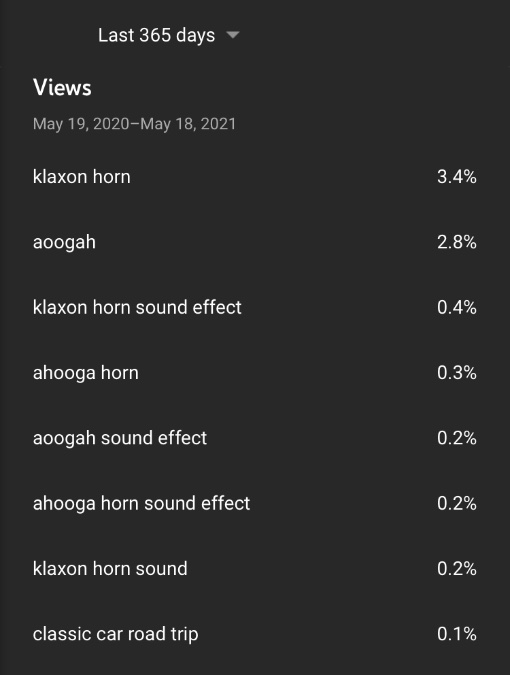

I suspect it would likely take 1000 younger folks in their 20’s , watching my videos on a regular basis, over several months, to change my statistics. You make a valid point about on the presentation and delivery. However, I somewhat disagree for a few reasons. I am a member of a vintage car club. Mainly stock cars. The age demographic is almost a mirror of the age stats above. I do agree if I presented differently, other groups may come out to the show. I’ve been listing and trying to sell my 1953 Chrysler. The inquiries I am getting, I’d say reflect the same age group very closely. I drive my cars around town a lot. I enter them in a few car shows. I attend multiple car shows as a spectator. The folks who approach to talk and show a serious interest in my old Mopars? Similar age numbers. One exception. My ‘38 Plymouth 4 dr sedan. It looks like it came off the farm. Stock. When I drive it, for some reason the 20-something kids really show extra interest. I can’t say why. Maybe It appears tired, mopey, approachable? Somehow they find it attractive. Yet it appears, on average, they certainly aren’t searching it out on YT. Perhaps they have no idea what it is? My tag lines for the search engines are too specific maybe? I doubt they see the car, then go search google for “vintage Mopar”. I’m only speculating here based on the YT stats and what I see in real life. YT does a pretty good job providing analytical data. The top 5 things people are searching for that lead them to my videos, all relate to the aoogah or Klaxon horn. I’m not sure Mopars ever had one. I happened to install one in my ‘38 ply and have a brief YT video on it. An interesting bit if info. This stat has been consistent ever since I uploaded the video well over a year ago. Seen here is a year’s worth of search data. Skewed as this only relates to all of my uploaded content.

-

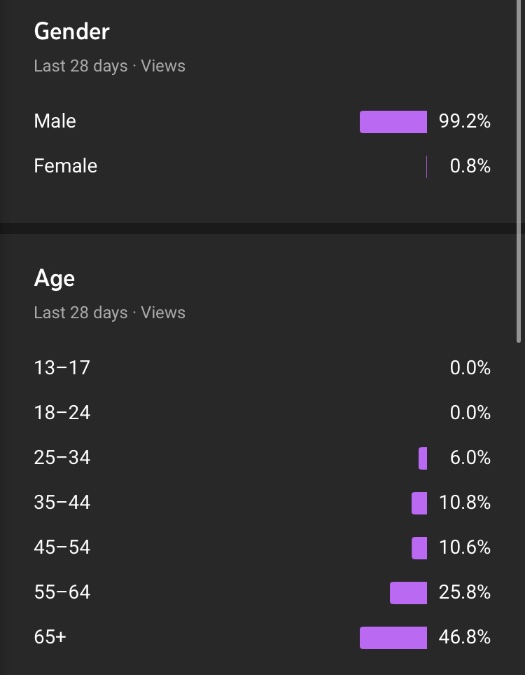

-

Check out these stats. I think this is a very accurate summary of the vintage Mopar car market. This is who we are. The old Mopar culture is 99% male, the majority over 65 years old. How accurate are these stats? Where did they come from? My You Tube channel. It focuses 99% on old flathead era Mopars. These stats represent my viewers. I’d wager the numbers represent us pretty accurately.

-

A grease pump makes high pressure. You can apply too much pressure to the area and damage the seal.

-

A couple of suggestions. Resist the urge to install a grease nipple. (zerk) You don’t want to be using a grease gun here. Seen here is a pic. A good tool box has at least a couple of syringes. Fill a larger syringe one with grease. Put the end into the hole. Add some grease under low pressure via the syringe. Larger syringes with a piece of fuel line are great for topping up tranny fluids and diffs under the car. You can also dip the hose down a half full jug of oil, suck out with the syringe and off you go! Smaller syringes are great too for topping up small reservoirs like brake master cylinder reservoirs in hard to reach areas. Works great. Clean. No drips. A little piece of hose over the syringe nipple, you’ll be dancing in the streets.