-

Posts

3,468 -

Joined

-

Last visited

-

Days Won

193

Everything posted by keithb7

-

Lol. Sorry $1800 USD is making me chuckle here. If you keep looking and aren't in a hurry, I'd wager you can find the old flathead Mopar engine you want for between $100 and $500 US Funds. Just today I found a running 251 ci Industrial engine in a combine. Asking $675 Canadian. (About $520 US Funds) In my neck of the woods maybe the situation is different? I've had numerous opportunities to buy old flat head 6 mopar engines for under $500 USD over the past 5 years. People don't realize it costs $4K USD to do a half decent overhaul. That's doing all the tear down and reassembly work at home yourself! They put about 1/10th of the Mopars into the Canadian population, compared to the USA. Yet I can't complain about finding old Mopar engines. No, they aren't on every corner but they are out there.

-

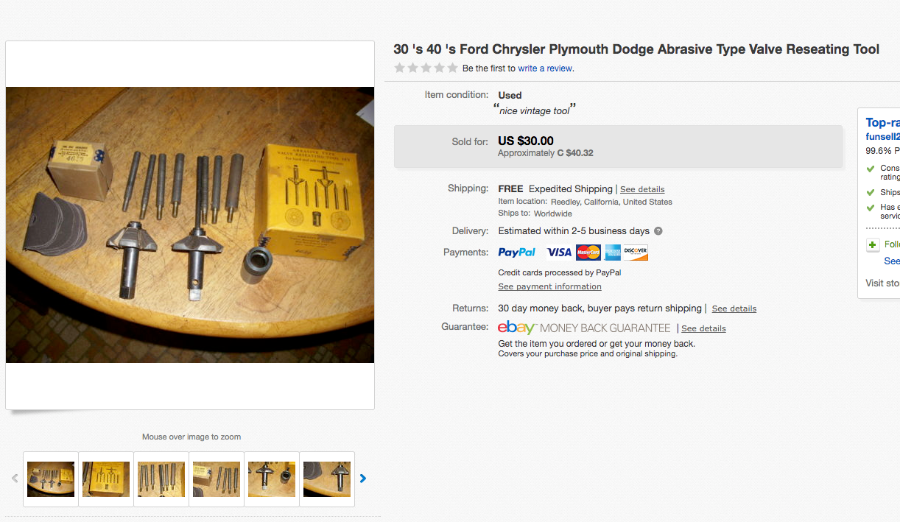

Great to hear you are giving it a go @47Jim. Getting grease under the fingernails somehow nurtures great understanding! If you want to sell that same valve seat cutting tool that I have, let me know. I am interested in securing more of the round abrasive cutting pads. Where did locate and buy the vintage seat grinding equipment?

-

@HotRodTractor tomorrow? How am I suppose to sleep tonight? Lol. Perhaps I will dream about two pedigree horses on the reins. While 8 smooth flat head Chrysler engines purr in the distance.

-

I agree sniper. Dry ice would keep them cold. They are a darn tootin' tight interference fit. I know my limits and level of risk. I didn't want to risk doing block damage the route I was on. There is no journeyman here to guide me along! lol. Some lessons are costly to learn. I'd screwed myself over earlier in life enough times to know when to stop.

-

Nice collection! Can we get a solo close up pic of the one that's B&W? It reads "Now 8 Basic Chrysler Engines". I'd love to read that one.

-

I did an in-car valve grind job. Valves are cheap. I bought all new valves and springs. I found a vintage abrasive cutting tool for valve seats on ebay. I hand cut the seats. The stellite inserts are stubborn and hard to cut. However I was able to do so. I was under the gun for time. I did not replace any valve guides. I wish I did. #1 and #2 cylinder had the little play. Even with the new valves in. The seats I cut to 45 degrees. Then lapped in the new valves. I checked for sea-lability with kersone. I kept lapping until the seats would hold liquid. The results turned out very well. My second attempt at this, was an engine tear down this past winter. Getting the guides out was easy enough with an air hammer and a chisel bit, that I cut down on a lathe to fit nicely into the guide. The guides came out. I attempted to use a similar method to install new guides. I froze the new guides to -54 degrees for a few days in a special freezer at work. I grabbed them. Rushed home and tried to use my same air hammer and custom chisel bit to re-install them. No go. The first one went in the easiest, but the guides warmed back up too quickly. There was no way they were going in. I destroyed 3 or so new guides and gave up. Lesson learned. I am sure there is a way to build a home made puller with some redi-rod, a few nuts, washers and some plate steel. Then you could suck those guides down into their seats in a controlled manner. Pressing them into place with the engine block in the chassis still. I did not do that. I took my block to the machine shop for all the regular machining work it needs and I said, "Here are 12 guides. Install them please". I gave him the specs and the proper indexing of the intake versus exhaust. Here is a pic of my seat cutting tool and a pic of a good lapped valve pattern. Got the tool for $30 on Ebay about 5 years ago?

-

completed projects....am calling it done...

keithb7 replied to Plymouthy Adams's topic in Off Topic (OT)

@dpollo Regarding the outside lift. A 2 post if I recall. Does the weather, affect its reliability? Rust, scale? Humidity? I sure want a lift. I'd consider an outdoor placement. Not ideal but better than nothing. We are pretty dry up here in Kamloops, but we get our share of snow each winter. The hoist would sit mostly unused for 4 months per year. Nov, Dec, Jan, Feb. The rest of the year, pretty usable. I am interested in hearing comments about how these vehicle hoists hold up outside. Thanks. -

@Dodgeb4ya, so if you mix up a cap or two, an align bore job can fix everything back to re-use? Like new again? I'm feeling a little paranoid about my caps. I did label them. But it would be like a bomb going off in my engine if 1 cap blew-out like the post above. Devastating.

-

Maybe lets see if we can have some fun with this thread and post photos of examples of Chrysler Industrial engines in use. The Air Raid siren kicked it off. Let's see what you've bumped into? What old piece of equipment have you seen with an Industrial engine?

-

-

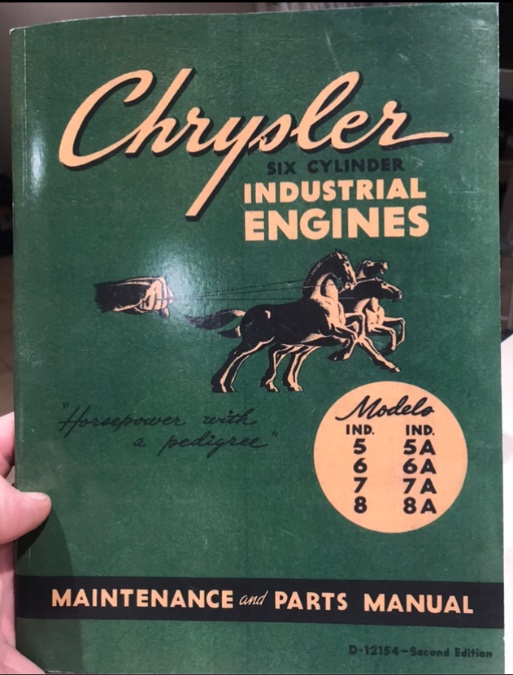

I don't think that is the case Marcel. My book is seems to be dated 1950. The following models are covered in my book: 5 & 5A is 217.8 ci 23" 3 ¼ bore 4 ⅜ stroke 6 & 6A is 230.2 ci 23" 3 ¼ bore 4 ⅝ stroke 7 & 7A 236.6 ci 25" 3 7/16 bore 4 ¼ stroke 8 & 8A is 250.6 ci 25" 3 7/16 bore 4 ½ stroke The Canadian manual shown above covers the same 251 seen in my book (250.6 ci) Add a little longer stroke yet and it becomes a 265 ci. The 313 I am not aware of. A V8 industrial power plant I presume?

-

I recently acquired the book seen in the image below. I thought I’d pick up a copy and see what I can learn from it. I have indeed learned a lot. And the info is sticking as I proceed on my vintage Mopar journey. I have a couple of questions. You’ll see on the cover, the book covers Model 5 & 5A, 6 & 6A, etc. I can’t seem to find what the difference is between an engine model, and the same model with an “A”. For example what is the difference between a 5 and a 5A? Does the “A” indicate something specific? Some new-to-me observations maybe worth mentioning: 217.8 ci and the 230.2 ci (both 23” length blocks) both share 3 ½” bores. The difference is the 230 has a ¼” longer stroke. The 230 enjoys a connecting rod that is ⅛” shorter than the 218. The book does not tell us if the crank throw for a rod on the 230 is shorter. Is it? I suspect so. A longer stroke nets the 230 just a slight bit higher compression ratio. 6.6:1 vs 6.7:1. Reviewing the parts lists, they are laid out nicely for quick comparison of parts. It is amazing how many same-parts are shared by all these engines. Chrysler really did maximize part commonality. In the 23” length engine, it appears that con-rods 1,3,5 are the same. And 2,4,6 are the same. Assume due to the siamese cylinder pairings? If a person wanted to try, could they actually ignore the con-rod position numbers and swap positions 1 and 5 or 3 for example, with no ill effects? Assume matching rod cap is swapped too, pairing with proper rod. And oil spray hole is correctly orientated. A fantastic selection of oversize pistons and rings in .010” increments all the way up to .060”. Which you filed the ring end gap to accommodate various wear sizes up to the .010” next size up. Aha! A light just came on. Is this why, when you bore your cylinder to say .020 over, and you order .020 over rings, you still must check and file the ring end gap? Because this .020 oversize ring can be used right up to .029” bore size? I suspect so! I knew a fair bit about the commonality of the 25” length block. As I am in Canada and it seems they saturated the market up here with the 25” Canadian block only. Interesting reading for sure, learning about the 23” length engines. Not a bad reference book to own, this one! I keep hearing that these old flathead engines are fantastic workhorses. I am beginning to truly understand that.

-

Is your removed 218 the 3 ⅜" bore, 25" long Canadian 218.06 ci engine? Or 3 ¼" bore 23" long 217.8 ci American engine? Big difference in the installation! Your new 264.5 ci engine is 25" long. Engine bay modifications may be required to move the radiator forward depending on what you have now. A 265 engine in a 23" 218 engine bay, sets the 265 fan blades right into the rad fins. Is your smaller 218 matched radiator able to effectively cool a 265 engine? The rad in my 265 Chrysler is lots bigger than the rad used in my smaller engine equipped Mopar. I wouldn't plan to install the smaller 218 carb on a 265 engine. Is your 218 9 ¼" clutch going to be able to handle the increased torque and HP from the 265 engine? For how long? Comparing Rated Torque & Brake HP: 23" 218: Torque 175 ft/lbs at 1200 RPM , HP 97 at 3600 RPM 25" 265 : Torque 218 ft/lbs at 1600 RPM, HP 119 HP at 3600 RPM If you can make it work, the 265 will have that Plymouth launching at fun cruising and travel speeds. Lugging up a hill with all that torque the engine will make lots of heat for the radiator to disperse. Bolting on an extra front electric push fan, will likely disappoint. Sure would be a fun car though with a 265 engine.

-

Good find. I like it. Congrats on another new old Mopar toy. Some day maybe the right truck will find me too!

-

I'm eyeing up all the trucks too. If I could walk up right up there, I'd be driving something home. The mid-30's sedan has my attention too. 1935 Plymouth maybe?

-

Your story sounds a lot like my 1938 P6 story. I wanted a good reliable driver to enjoy. Mine came with a replaced 25" long engine. It barely ran. I started out by getting it running and stopping. I spent the first year going over a lot of stuff. I rebuilt the original brakes. I replaced probably 60% of the electrical wiring. I got the fuel system sorted out completely. New tires. I dropped the oil pan, removed all the sludge. Everything in the ignition system, got replaced. Rear axle assembly rebuilt. Full tune up. It was a pretty drivable after that first winter of my efforts. I drove it the whole next spring/summer/fall (2020). I had a few periods where I had the car put down again that maiden year, while I addressed newly found issues. Issues that turned up once I started driving it regularly. My tranny synchro and bearings were shot too. I rebuilt the tranny. Replaced the clutch disc. The engine was a little leaky at the rear main, not too bad. As the weather heated up, so did the water in the block. I pulled the rad and had it re-cored, along with a new water pump and thermostat. By now she was pretty reliable. Going down hills, the exhaust showed little smoke. Compression was ok between 90-100 psi. Fall 2020 rolled around. I decided to dig into the engine. I pulled it and found a broken compression ring, some valve guide wear, and some pretty good valve seat wear. So I tore it right apart and ordered my engine rebuild parts. I am currently waiting to get it back from the machine shop. My car is a constant work in-progress. I get to drive and enjoy it along the journey. How much have I spent? I don't know. I don't want to know, so I don't keep a tally. It's my hobby. Aside from the block machining and a new exhaust system, I have done pretty-well done all the work myself. Lots of help here on this site when needed. I don't have a "shop" either. I have a 2 car garage with no hoist. The car is easy to work on. You can probably do everything you want right at home. Pending your health and body condition. A good old car "driver" without spending a ton? Well, thats subjective. If you do mostly all your own labor you'll be saving a ton of money. You already have some tools and skills? Well you are already well on your way. Body and paint? Well, thats completely outside of my skill set. It would indeed cost a ton to pay and have it done right. More money I think, then I am willing to pay out probably for my P6, at this time. In the future? Possibly. "Not getting run off the hi-way". In a 1936 car , I sure don't want to be driving faster than 50-55 MPH. Nor very often. Even in a 30's car with updated brakes, tires, suspension, steering etc...It's a 1930's car. At the time, a leading safety feature was laminated glass. That's about it. The stock 201 ci 23" long engine was replaced with a 1953 25" long engine by a previous owner. It will be re-built to a 237 ci Desoto engine. It will have ample torque and acceleration to keep up with average traffic. It will still have a 3 speed tranny with the 4.11 rear end. I still won't won't be driving faster than 50-55 mph. I'll just get there a lot quicker. Sure you can add an OD unit. It's not for me. I have zero interest in trying to keep up with anyone on an interstate hi-way anywhere. If you just want a reliable old driver, find a car already done. Someone will have spent $30,000 and you'll get it for $15,000. If you want to enjoy the old car hobby, learn a ton along the way, feel proud of what you've done, and meet great helpful people along the way.... Take an old car and do it up yourself. Don't keep track of the monetary costs. Measure it's worth by how much you've learned. How much fun you had. Your skills developed. The great memories you made driving it. The rewards. The experience. You cannot put a price on that. It will change you. Good luck whatever you decide. We're here to help. - K My '38 is seen here. Worth every dime I have spent.

-

Maybe that is part of some folk's train of thought. Climate change. Fossil fuels getting used up at record rates. Maybe they do have a different long term outlook. Housing prices are indeed going nuts in a lot of areas of North America. Up here in Canada too. It's hard to believe how much prices have escalated in 15 years. In my town we saw a 20% price increase in the average house sell price here, just in the past 12 months. Other areas here, even considerably more.

-

Yet Another Starter/Ignition Question - Dodge D32

keithb7 replied to Capt Jeff's topic in P15-D24 Forum

I’d certainly re-wire it. You can easily build your own new wires. Depends on your goals. Reliable nice looking driver? Or show winning originality? Begin with a schematic or layout diagram and a half decent multi-meter. You can build your own custom long length lead test wire. While your head is up under the dash tracing wires you can check continuity. Also find ground problems. The long test lead wire, one end can plug into your multimeter, the other at the far end of the circuit. Replace wires with new ones that you can make. Its not difficult. A soldering iron, a wire stripper/crimping tool, some various sizes of heat shrink, a heat gun, solder, various size wires, various connectors and your time is about all you need. Its quite enjoyable and very rewarding. -

I can’t figure it out either. Seems there are a lot of people with a lot of money to burn these days. Are more people wealthier these days? Compared to 40 years ago? Or do more people today just live for today, no care about saving money? Spend what you make, so its does not matter what prices are? No concern about their future? Retirement? Who cares? I have a conscience about how many paper shop towels I use on a job. Lol.

-

Its interesting how they all wear differently from car to car. It might be the painter that day went outside the formal guidelines, and mixed the paint a little different. Its lasted decades and held up really well. Yet the interior which is not exposed to elements, is worn out.

-

It would appear that by 1935 people in North America were indeed consumed by the automobile. The industry had a firm grip on American culture. This is 20 years before 1955. The period I would have more associated with the apex of American car culture. Its seems, the automotive boon lasted many decades. What an epic period of industry, travel & fun adventurous times in your car. I

-

Do tell us more! Model P24? 228 engine? 3 ⅜ x 4 1/4? Manual 3 on the tree?

-

Nice clean example of the early 50's Mopar. Was it built in Detroit or Windsor?

-

My suggestion was a way to quickly determine if there is fuel present in the carb bowl. Not to try and start the engine after stroking the accelerator pump. My experience is, with the air filter removed, looking down in the carb while cycling the throttle will give positive ID if fuel is present, or not.

-

Ideas for Rescuing Flatheads... from a Swamp

keithb7 replied to ChrisMinelli's topic in P15-D24 Forum

You are a smart man. Tearing into spare engines to disassemble and learn. I did the exact same thing. Fortunately for me I located tired old, assembled 1950's 218 engine in someone's shop for $100. I bougt it, brought it home, tore it down and learned a ton! I had fun along those same lines with a tranny too. Aside from having a Journeyman old Mopar mechanic here at my side to guide me, I am not sure there is a better way to learn and retain this stuff. Book reading, and lab experiments. So much fun. @ChrisMinelliyou are defintely up a few ranks in my books. Lol. Taking any engines apart in the field will the a pain in the buttocks. They will be rusted and frozen. Rusty valve train and piston rings are a struggle to get apart at home in your garage. Let alone in a field with limited tools and resources. You could get some ¾" plywood to lay down and support an engine hoist. Can you get your truck in there close, so you can hoist a pulled engine into the back? Keep in mind to get the engine out, you nee to pull the tranny. To get the tranny out you need to pull the driveline, possibly interior floor pans, etc... Easy at home. In the sticks where they filmed the Blair Witch Project? Not so simple. You have a soft spot probably for old Mopars. It is hard to see them sitting there rusting, mother nature slowly taking them back. In reality you are probably better off to seek out an old flathead Mopar engine in town somewhere. Set up a search for "flathead" in Facebook marketplace. They will send you a notice when anything pops up. An engine will come up. They literally built and sold millions of these engines. I'd be surprised if there is not one million of them, not yet scrapped and or melted down.

.jpg.58458a854d3d9c42b937f9960ada99e7.jpg)

.jpg.c1664769e71ef8b532cd1d2c2666cae3.jpg)