-

Posts

55 -

Joined

-

Last visited

-

Days Won

1

Chris-R last won the day on October 4 2022

Chris-R had the most liked content!

Reputation

18 GoodProfile Information

-

My Project Cars

1948 Chrysler Windsor Highlander

Converted

-

Location

UK

-

Interests

Cars, lorries, bikes, boats...

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Reassembled Carter BB carb leaking from throttle shaft

Chris-R replied to Chris-R's topic in P15-D24 Forum

Thanks all. I was careful not to bend the float adjustment when disassembling/reassembling, with a view to ensuring/hoping the level remained correct. However the replacement needle valve assembly I installed may be dimensionally a little different to the original which could affect the level at which the float shuts off fuel. I'll try putting the old needle assembly back in and take it from there. -

I reassembled my Carter BB after stripping it for cleaning and putting in new dashpot plungers/needle valve, etc. and put some fuel into the system. On the plus side my rebuilt fuel pump works ?, but I've now got petrol leaking out of the throttle shaft at both ends - a steady drip, drip, about twice every three seconds. It wasn't doing this before I dismantled it, which makes me think I've reassembled the thing incorrectly or perhaps even left something out... can anyone experienced in these things advise me please? Many thanks as usual!

-

Thanks Sam - much appreciated.

-

Hi Sam - thanks very much indeed. I'm in the UK so does this look correct from the sizing point of view? I can't actually find anything described as '#12'... https://www.tcfixings.co.uk/product/12-24-unc-x-12-philips-pan-machine-screw-bzp/16874 (And any thoughts on material choice/compatibility? There seem to be mostly stainless and zinc plated options... I'm not sure what the carb housing is cast from!)

-

Chris-R changed their profile photo

-

Trying to put my carb back together having finally solved a dashpot problem, and the four bolts holding the top of the float bowl have mysteriously gone awol... does anyone know what size they are? Thanks in advance!

-

Aaargh... having waited two weeks for a CK2 carb rebuild kit to arrive to the UK from the Carb Doctor in Lake Jackson TX, it turns out not to contain any parts to rebuild or replace the dashpot plunger. (Despite the rebuild kit being listed as suitable for my EV2 carb on the website.) Rusty at the Carb Doctor says he can supply a replacement plunger at around $20, but there's another $30 for shipping cost to the UK - on top of the $30 shipping I already paid - and arguably more annoying is the extra two weeks I'll have to wait before being able to see if my engine might fire up for the first time in 30 years! (Apparently I should have ordered the CK442 kit which does contain the plunger...) Anyway, I understand (I think) the dashpot provides an anti-stall function during gear changes, so can I get by with reusing this original plunger to try and start the engine if I don't want to drive it? The leather collar feels worn out and hardened after being dry for several decades, and soaking it in oil hasn't brought it back to life noticeably. So it obviously isn't going to function at 100per cent... but how will that affect attempting to start and run the engine while parked on the driveway? I know the 'correct' thing to do is pay the extra $50 and do it properly first time, but I'm impatient to find out what the engine condition might be. (And if I say I need the kitchen worktop for another two weeks it's going to raise some eyebrows...) ?

-

How does that pump jet plug go back in after you prised it out? I watched another video where the rebuilder smeared it with JB Weld to fasten it but that looked pretty horrible to me, especially if it ever has to come out again.

-

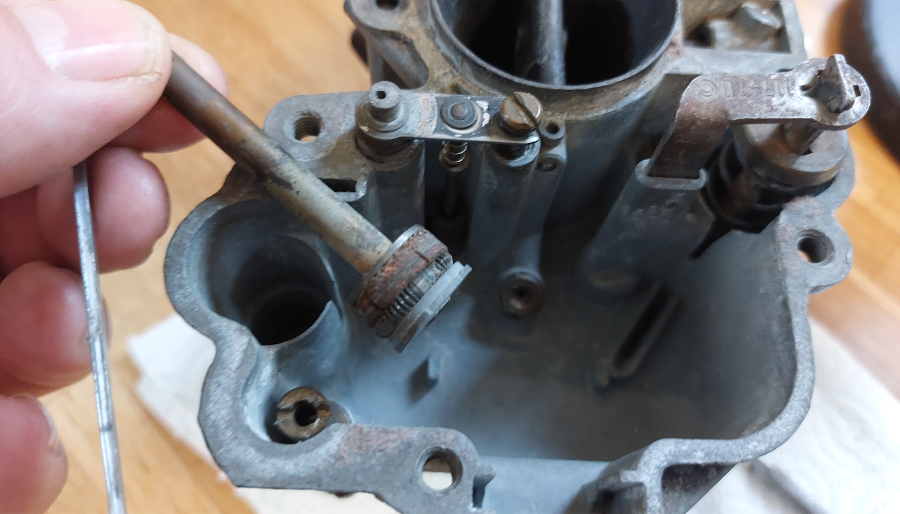

A couple of extra questions related to my strip down... 1. There's what looks like a small ball bearing in the centre of the first picture. Should pushing it down release the component it's attached to, allowing it to be withdrawn from the casting for cleaning - or is it something else? Mine seems stuck. 2. Pic 2 shows part of the casting with an unusual bend in it. Is this normal on a Carter BB or is it a sign of damage? Thanks!

-

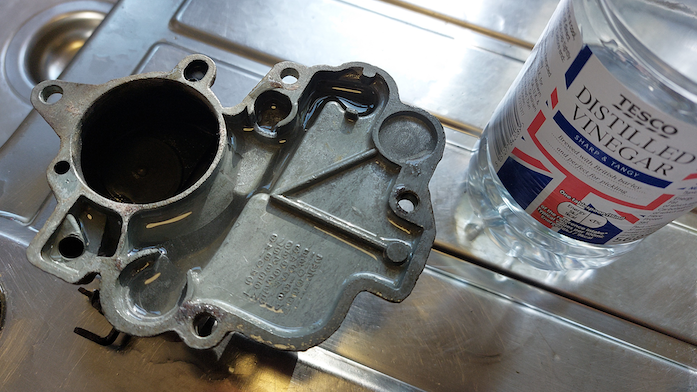

White vinegar worked a treat. I filled the float bowl cap with it, and after a few minutes tiny pinprick bubbles started to form as the vinegar did its work. I emptied and refilled the vinegar twice over the course of an hour and a half, and it came out as per the pics below. No scrubbing or brushing required to shift the previously immovable deposits - I just rinsed the vinegar out then gave it a wipe with carb cleaner. I soaked the float separately and it turned out the white deposits had formed over a big solder repair, and not the rest of the brass. Anyway, that all came off too, so now just waiting for my carb rebuild kit to arrive. Thanks for all the tips!

-

I thought corrosion too, but the same stuff is stuck to the brass float - so hopefully it's something that will come off. I'll try some vinegar though, cheers!

-

The inside of my carb is caked with white deposit, which is almost like a calcified layer. It doesn't want to come off with aerosol carb cleaner - does anyone have advice? The pic shows the top of the float bowl, but the float bowl itself is badly affected too. Everywhere else in the system the ancient fuel deposits have brushed or blown out as dust, but not here.

-

I've read a few comments suggesting manifold paint usually peels and flakes pretty soon... probably at a rate inversely proportional to the amount of prep. I'm liking the idea of a graphite coating that can be touched up simply, without necessarily having the perfect substrate. I think I'll try it after only a vigorous wire brushing.

-

Interesting... I've googled a bit on graphite dry lubricants and a downside seems to be it rubs off pretty easily, which probably wouldn't be much of an issue for me. Conversely you can spray or rub more on as necessary. We don't seem to have Slip Plate brand here in the UK, but there are plenty of other options to look at. Thanks!

-

I've lightly wire brushed the manifolds, which are showing some heavy pitting. Assuming there are no holes already (I can't see any), what's the best way to look after/preserve these? Or is it simply a matter of stopping water getting under the bonnet again. (Sorry, hood.)