Leaderboard

Popular Content

Showing content with the highest reputation on 04/06/2019 in all areas

-

Well after my 7th note from someone I guess I will wade in. I have no idea what Don's picture is or what the story line there is, but here Here is the answer to your question. Yes, every single dual carb dual exhaust manifold that came from the factory was equipped with govenors and balance tubes. You could buy the intake assembly which was the intake and balanced tube, the exhaust maifolds (front or back) as individual assemblies from dealers. Lots of stock car builders would drop the govenors. If you also drop the balance tube as many do, you will find you loose torque and hp. You will gain rpm if you are simply removing the balance tube from the truck engine that it came from the factory with. But and here is the key but, all of those engines that came equipped with the setup and purpose built cams. So you only need to take a cam from a 1952-1953 chrysler and put it into the truck engine to raise the rpm, keeping the torque curve. It actually will develop 8 more hp with nothing more than that cam swap. Again, I am not talking putting in a custom cam or making any other changes, beyond putting in the period car cam into the truck engine. The dual carb/dual exhaust intakes were all produced in Windsor Ontario Canada, and were available at dealers as parts starting in march 1952. I clearly cant speak to all dealerships but can say the Wellington Motors in Guelph Ontario Canada could still get you the dual carb setup in june of 1974. I have a receipt for a complete setup purchased that way.2 points

-

Hi - Well in the 25 1/2" block engines.. the 201 you maybe referring to was moved from USA production to the Windsor Ontario Canada plant when it opened in 1935 for the 1936 model year. that engine was produced for 14 months out of that plant. Among other things you may wish to consider.. The crank has smaller journals, the water jackets, are smaller. the oil galleys are smaller.. It really would be the weakest of all engines ever produced out of the Canadian Plant. When I say that I am quoting my Grandfather who would be the GM of that engine plant when it opened in 1935, reporting directly to Walter Chrysler (and not the VP of production) and he would still be in charged of the engine plant when the very last 25 1/2" engine rolled out of the plant on Nov 11 1959. The 230 was 23 1/2" block so not relevant to the big block discussion, beyond the small block has offset rods. With the 218 and I am assuming your are referring to the Canadian 25 1/2" 218 and not the USA small block 23 1/2" engine that are 217 that are often called 218s. The next generation block would actually be a changed version of the 228 ci motor which started in Windsor in early 1936. That is often referred to as a generation 2 block. Definately better than the 201 engine, but there would be a number of changes to the engine blocks and internal configurations. Even the 1946 250 ci motor has a different block than would a 250 ci motor made after August 1951. It would be that later block which has the best water jackets, best oil circulation, reworking of oil passages and on and on. By that point you could get a 218, 228 or the series of 3 7/16" bore which would be the 238, 250 and 265 ci motors. The difference is the stroke which is accomplished by changing rods, and cranks. 4 1/4" being a 238, 4 1/2" being a 250 and 4 3/4" being a 265. But there is no question the best ever flathead engines ever built are those generations. Among other things and I could give you a laundry list.. Your talking forged cranks balanced to 1 gram, forged pistons, rods, pistons and cranks as an assembly balanced to 1 gram. That never existed with any other flathead engine anywhere in the world. In fact my Grandfather often said - I defy anyone to find a more balanced engine in the planet that came out of my plant. So if stroke becomes where you wish to draw your battle line.. best try with the 238, 250 and 265 motors.. But by 1953 the vast majority of all orders for heavy trucks, commercial vehicles, municipal vehicles, industrial engines, for welders, water pumps, combines, and on and on were 265s. One can point ot military orders of 250s and I would suggest the reduction in price was the factor. They didnt want to pay the extra $. One last one, of total production of any single motor the 265 was produced in a volume larger than any other single motor configuation from the Windsor Engine plant. From 1946 until the end of the flatheads, the Windsor engine plants warranty numbers as a % of production was not only the smallest of any Chrysler engine plant by over 98% but the smallest of any engine plant in North America. The reason was simple.. Build it better, balance it better and you will get less back. Tim Kingsbury1 point

-

Where people get confused with this stroke vs bore thing is comparing theoretical figures to practical use. Yep, a short stroke high revving engine is theoretically capable of more HP per CUIN displacement. Think the 302 chevy and 340 MOpar both made great HP north of 6K. But, they can't compare to a 454/440 with the same sophistication of build. Maybe one could build a .75 hp/ci 201/218 based high revving beast. but that only gets you to the base hp of a mildly built 265 turning a happy rpm. And that is a weak maybe, as turning any flathead design faster always results in breathing issues. 90 deg turn to go up through the valve, another turn to head to the cylinder then another turn down to fill the cylinder just severely limits the potential. The torque developed is simply the pressure on the top of the piston acting against the lever arm of the crank. Longer lever at the same pressure is more torque. HP is how often than torque is exerted. of course that is a way over simplified example. Raise compression, add more fuel air, and turn it faster: More HP. But, IMO that is why bigger is better.1 point

-

This...right out of the B3 series DT Shop manual... Torque the head to 65-7- LBS in three steps... recheck hot torque once more.1 point

-

I know George Ache is the man - and once I have some spring stuff done I plan on making a drive out to see him in person. As you guys know - he isn't going to be around forever. That is why I am asking questions - the more knowledge we document the more these old beasts can live on once all the guys that have "been there, done that" are gone. Also - as far as parts rarity goes - it seems everything I want is always hard to get. lol When it comes to these carbs - I view things like jets and inlet valves as commodities that I can easily manufacture if I have to. The jets themselves would be very easy once I have some critical dimensions (through hole diameter) along with understanding the test conditions for the stated flow rates above. I could easily make these (or even drill out old smaller jets larger if needed). Truth be told I was even kicking around the idea of building installing an adjustable main jet if I found it beneficial. It looks like with some minor modifications to carb body it could be done (I'd do that on some common carb, not an E9K1). Honestly I think the shear number of variations of these carbs are why they aren't more popular. Pick up a Stromberg 81 or 97, or a Holley 94, etc... and you pretty much know exactly what you have. Grab a Carter Ball & Ball and it could be one of a few dozen variants. I feel like Forrest Gump with a box of chocolates. lol1 point

-

Very nice old Plymouth! Good pa(ul)tina too. (But keep your eyes open when you're at the lake.)1 point

-

Hmm, I do not have many pictures of it and don`t know, if it is worth to post ...dings and dents and has got pa(ul)tina * Posted some blurred pics here some weeks ago http://p15-d24.com/topic/53-lets-see-pic-of-your-trucks/page/32/ Post #797 * sorry Pflaming, no intention to blame you ! The opposite is the case. Paultina is an integral part of my language since that term came up.1 point

-

It took two tries at the bank to get the wire transfer competed. First go round I was missing some information from CHS. Even after I got the information the bank still had issues trying to get all of the requested information into the format required by Argentina. Needless to say it was an interesting process. This was my first and hopefully last international wire transfer. Now I get to see if I just threw away $500 or if the parts actually arrive. Stay tuned...... brad1 point

-

You all have fun today. Wish I could be there.1 point

-

Jan, No problem at all! You were helping me out! Your solution caused me to go back and review the engine oiling system. Later today I'll test the filter again and post the results. Do us a favor and post a photo of your '39 Plymouth truck. Jocko1 point

-

Get healthy Paul... we'll see 6a next year! 48D1 point

-

When I had a B2B pilothouse there was plenty of leg room. I am 6'2". Then I got a 47 WD-20 and the cab dimensions are all considerably smaller and a lot less leg room. I left the seat bottom as is. I took the back off and replaced it with wooden seat back. Presently there is no cushioning at all and it is pretty comfortable. I may or may not put 1 inch of foam and upholster it. But it works just fine and I have 6 more inches of room.1 point

-

Aren't there mfg gig hold holes that can be used as well? Seems those holes are shown on the frame schematic.1 point

-

1 point

-

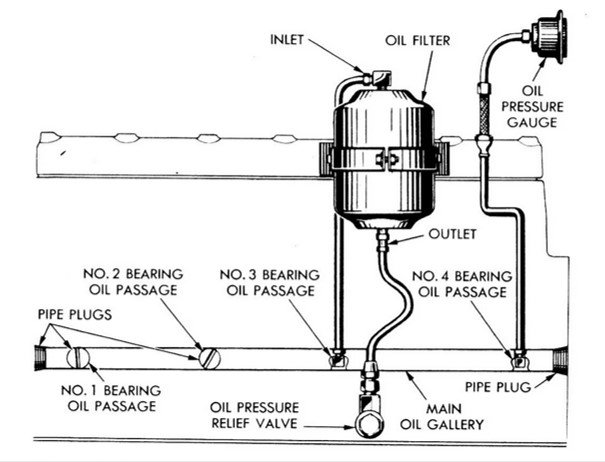

As Jan says, the oil pressure is good, but if the relief valve is stuck closed the return flow from the filter is blocked. Hence no flow through the filter. Can you freely blow air through the Outlet line back into the crankcase, with the engine running at 45psi oil pressure? (You'd have to block the outlet port of the filter) Or rig up a rubber hose from the outlet port and route it into the filler pipe. If oil flows out of the filter outlet test hose with the engine running you have verified that the filter is good, but the return is blocked through the relief valve. You could probably do both tests at the same time. Rig up the second return hose, and while running the engine to check for flow through the filter you could test the flow through the return line through the relief valve.1 point

-

Jocko, I assume that you have connected the filter correctly. Enclosed a picture to be safe there. The second picture shows details regarding the relief valve,how it works and opening pressure (sorry, picture copy is not of good quality) Since your engine has got a good oil pressure, I would check if the plunger is stuck. Also, as far as I know, there are different springs. Are you sure your engine has got the correct one installed ? There is also a little info about the Bypass oil filter system in the tech section -> http://p15-d24.com/page/p15d24/tech/tech_tips.html/ Just my thoughts, where I would start ... Jan1 point

-

I actually think, but admit I was never paid to think. Beating or "massaging" the headers, was a acceptable way .... way back when Radarsonwheels was in diapers. I personally do not want to say if it was acceptable when I was a kid, would be a hint to age. Myself, I will stand by and hand the correct size hammer for the job.1 point

-

Yeah, I think the load "dwarfs" the trailer... it is actually a 14k. tongue weight, photo must be deceiving, hardly touched the overloads. anyway, he is at home, we are in Gold beach, caught a glimpse of the gray whales migrating..... like Kenny Rogers said " got to know when to fold them" ?1 point

-

This ought to fix my car/truck throwout bearing issue until I can get my new tranny. My machinist made me a nice oilite bushing that will adapt the two pieces and keep me from tearing up bearings. I found this a while back and had another thread on it, but just got around to fixing it. Besides this I just need to finish tuning the truck and give the push rods another half turn. I only went a half turn off zero and they are noisy.1 point

-

THANK YOU Tim, It’s a great honor to be on this list of great guys. One of these years I am coming. I am 53 and still never stepped foot in California. Have a great weekend boys and girls this weekend and appreciate your host and hostess, it takes a lot to put something of this caliber on.1 point

-

thanks, Moses Lake WA (this BBQ run is a test drive for a longer trip in June)1 point

-

Well that sucks. I had a reply all typed ready to send and the p15-d24.com site started an upgrade and threw away my reply! In talking with Lares they indicated I could deal with any of the different company's with links from the website and might even save a little money but the gearbox would eventually be sent to them for rebuilding. Per my discussion with Lares, the base price for rebuilding the gearbox would be $415 plus shipping both ways. The base price only covers cleaning, painting, bearing and seal replacement with a lube job and adjustment. However if the worm and wheel are bad then the cost would jump about $500 for those parts. I'm 99% certain my worm is bad because of the large areas that are galled and pitted. My steering was extremely sloppy and rough so I can't picture them not needing to be replaced. Oddly enough the bronze bushings for pinion shaft are nice and tight so I they don't need to be replaced. Attached is a picture of the CHS kit. Now I need to decide what to do. Thanks, Brad 1951 B3B Richmond, Ky (formerly from Jefferson, Arkansas and Lincoln, Nebraska)1 point