bkahler

Members-

Posts

1,947 -

Joined

-

Last visited

-

Days Won

39

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by bkahler

-

Jim, I'm curious as to why you set your throttle linkage the way you did. I've installed the same intake manifold as you did but when it came time to fabricate the throttle linkage parts I looked at bunch of other dual carb installs and I believe all of them had the linkage set just the opposite of yours. Here's picture of how mine is currently configured. I'm wondering if its possible when you're pushing on the gas pedal you're actually closing the throttle plate? Brad

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I'm happy to say I got a bunch of piddley things done today. Installed the choke cable, throttle cable, temperature control cable, defroster cable and fresh air control cable. I had an issue with the throttle cable in that I couldn't pull it out by hand. I decided to try and push the gas pedal first and then tried pulling the cable and it pulled out nice and easy. I never thought about it before but it makes sense pushing the pedal would eliminate the effort of pulling on all of the linkage. Anyway, it works and I'm moving on to other tasks I also put the electrical connectors on the wires that connect to the voltage regulator. And last I installed a couple of 1/4" welch plugs in the rear carburetor to plug the opening where the choke plate shaft used to be. Only the front carb has a choke. The parking brake interferes with the rear choke so I had to eliminate it. The dash area is pretty much complete with the exception of installing all of the connectors at the ends of the wires and connecting them. I'm hoping to spend time tomorrow and later this coming week to see if I can finish up the dash. At least it's progress! Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

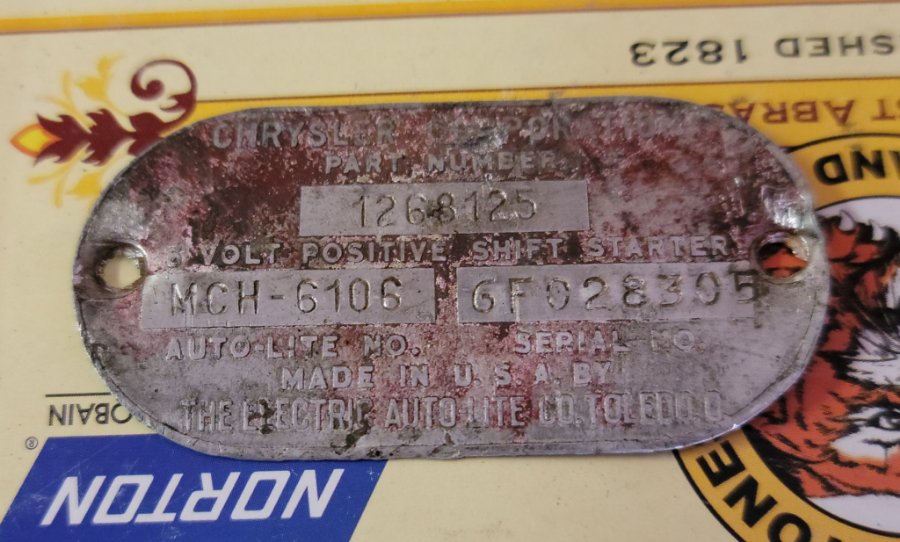

Same guy. He didn't have the tag for my starter so I sent him my old one and he's reproducing it at this time. This is the plate he didn't have available. I'm looking forward to see how well the reproductions look. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

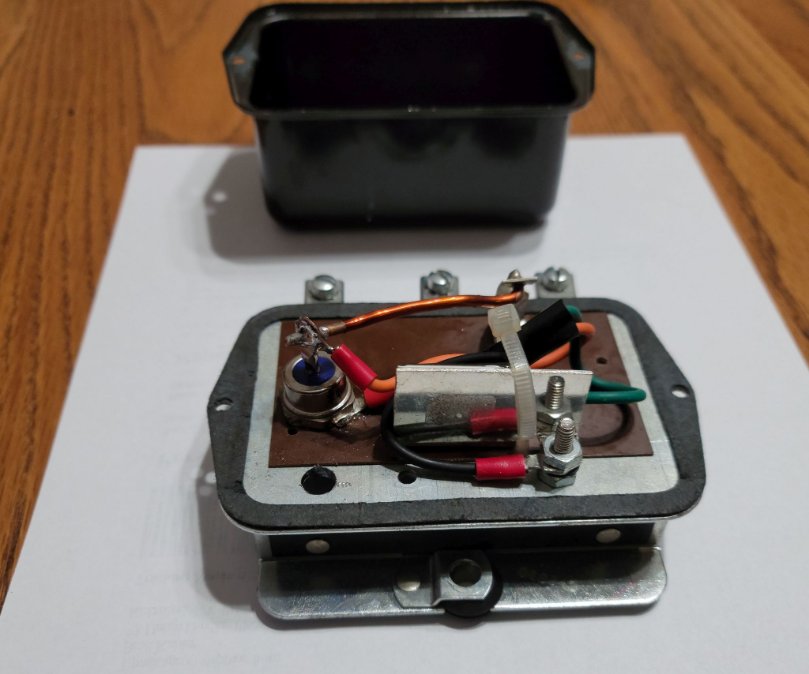

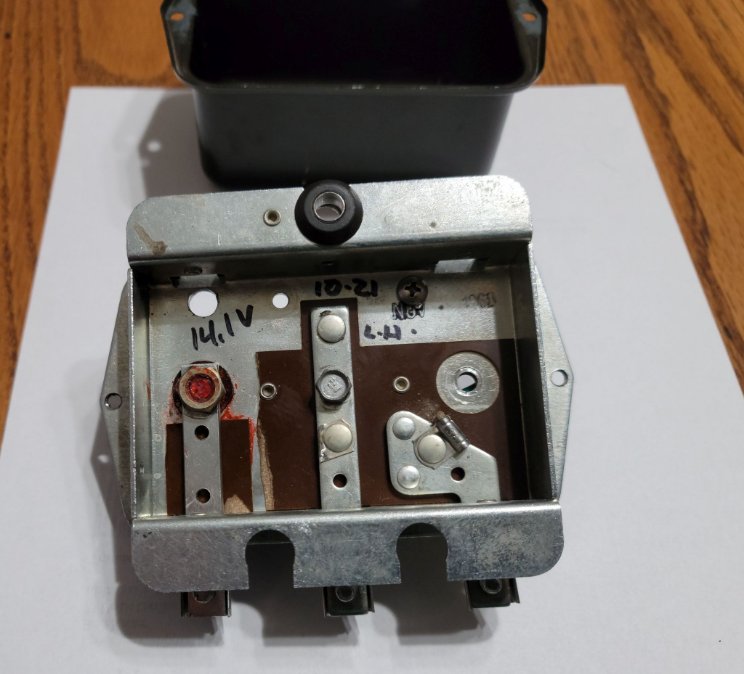

I'm probably past due in providing an update on my truck. Unfortunately not a lot has been done in the intervening months since I last posted. The good news is I'm really close to the point where I can try and start the engine for the first time. The starter motor is ready to install once I put the ID plate on. The ID plate is currently being stamped by someone in CA and I should have it in my hands in a few weeks. I'm in the middle of the generator rebuild and would really like to have it close to being done over the Thanksgiving holiday. Once these two components are installed the engine is essentially complete and ready to run. Of course I still need to add fluids to the engine, cooling system and transmission as well as either finish the engine compartment wiring or install some temporary wiring. I've made the switch to 12 volts and bought a new 12 volt regulator and had it installed. A few weeks ago I was looking at one of the sub forums here and ran across a post by someone who had their regulator converted to solid state. I contacted the company doing the work which resulted in me sending the new regulator to them so they could convert it. Here's a few pictures of the new regulator. I guess time will tell if the conversion was worth it. Brad -

15th Annual Clements Tailgate BBQ, in Clements California

bkahler replied to 48Dodger's topic in Mopar Flathead Truck Forum

Well......I've put the date on my calendar and mentioned to my boss that I might need some time off next spring. However being realistic about things I'm not sure I can get the truck in drivable and presentable condition by the departure date. Minimum 3 days each way with over 2,400 miles one way means I really need to think this through before I can make any sort of intelligent decision! I do know I work better when I have a goal to work towards so who knows Brad- 99 replies

-

- 1

-

-

- bbq april 2nd 2022

- bbq april

-

(and 5 more)

Tagged with:

-

Ditto

-

Here's what I have documented on my 1951 B3B. Drivers side rear lower bushing is LH thread Drivers side front lower bushing is LH thread Passenger side rear lower bushing is RH thread Passenger side front lower bushing is RH thread All upper bushings are RH thread

-

It's good to know my mind was in the right place Thanks!

-

I'm resurrecting this old thread because I've had too much time to think about this subject which is a really bad thing When I think about the differences between Unibody vs Body on Frame construction I start to wonder which method of seat belt anchoring would be best. The two choices are the seat belt mounts bolt directly to structural (i.e. frame members) or using large metal backing washers and bolting through sheet metal. I started thinking about this issue several years ago as I was rebuilding my 74 Argosy motorhome. The original seatbelts were anchored to the structural part of the cab but not directly to the frame. No shoulder harnesses, just lap belts. The later style of motor home seat mounts now have the seat belts integral to the pedestal so it now depends on how well the pedestals are anchored and where. Typically they are anchored to the structural portions of the cab but not directly to the frame. In other words if the cab starts to separate from the frame then the seat goes with the cab. I have a Triumph TR6 that had one end of the lap belt bolt to the frame, the other end of the lap belt bolted with a large backing washer through sheet metal. The shoulder mounting was also done with a large backing washer through sheet metal. In this case if the sheet metal body separates from the frame the seat belts would likely rip out of the sheet metal although I'm sure the driver/passenger would certainly pay a price for that separation. For my Dodge B3B bolting to the frame would be relatively difficult to do and would require some extra fabrication to get it done. As most seem to have done I would use large backing washers for the lap portion of the belts. One concern I have with using seat belts that bolt to the frame of a vehicle is what would happen in a crash where the sheet metal body of the vehicle starts to separate from the frame? In a case like this it would seem that your body would now be the soft part that would be trying to keep the two pieces together. In other words it seems like you would get sliced in two by the lap belt. This may not be the case but I haven't been able to come up with any logic to say otherwise! I guess what it gets down to is I can't see a good justification for fastening direction to the frame when you have a sheet metal body that can separate from the frame in a crash. To be totally up front, I don't have a clue which is better so you won't get any answers as to what is best from me, I'm just looking for input from others! ? Brad

-

FINALLY - My 1948 B-1-D Build Thread, 33 Years Later

bkahler replied to billrigsby's topic in Mopar Flathead Truck Forum

It's always been my understanding the original radiators had honey comb cores. The core pictured looks like the new one that was recently installed in my radiator. -

My truck is crapping on it self.......ideas?

bkahler replied to Jeff Balazs's topic in Mopar Flathead Truck Forum

I can guarantee I never would have considered any thing like that. I've never had a fluid drive and never driven one. I'll bet you don't do that again ? -

Starter options when converting to 12 volts

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

This is probably one of those cases where I'm over thinking things, I do that a lot This post by Don Coatney is what prompted me to ask the original question. I had always planned on using the 6-volt starter with the 12 volt conversion. After reading Don's post my mind went into overdrive and I decided to look at the options. I think I'll just stick with what I have and if I have problems I'll address them at that time. Thanks! -

I've made or am in the process of making the change to 12 volts. I really like the foot pedal starter arrangement and want to keep that configuration and don't want to use a starter that requires a starter solenoid. With that in mind I've been planning on using the original 6-volt starter. Just recently I got to wondering if there was a 12 volt starter made that used the foot pedal configuration? If not is it possible to swap the armature and fields from a 12 volt housing to a 6 volt housing to allow retention of the foot pedal when switching to 12 volts? Thanks! Brad

-

FINALLY - My 1948 B-1-D Build Thread, 33 Years Later

bkahler replied to billrigsby's topic in Mopar Flathead Truck Forum

PM sent. -

For some reason I'm not able to see any of the pictures......

-

Hopefully where the brake line runs from front to back there is a rubber section installed

-

I bought a manifold bolt/stud kit from DCM Classics for about $65.

-

Interesting, plastic escutcheons. Back in the 90s in all of my parts hunting trips I don't think I saw a plastic escutcheon either. I looked at plenty of trucks and always grabbed the ones that looked decent and they were all metal.

-

Horn ground wire from the button on the steering column.

-

Personally I like supporting vendors that take the time to support my truck when possible. I buy from Vic's and DCM as much as I can. So with that in mind I'd probably go with the Gilbertsons Machine Shop kit. Besides, having a product drop in or close to drop should make life a lot easier and give you more time to deal with other build issues on the truck. Looking forward to seeing which choice you make and how it works out

-

Dual single carb linkage, planning stage

bkahler replied to lostviking's topic in Mopar Flathead Truck Forum

https://p15-d24.com/topic/51357-51-b3b-build-thread-after-all-these-years/?do=findComment&comment=595503 -

Interesting. To be honest I was rather surprised at the type of damage I've seen on the steering worm gears. Instead of wear it's more like gouges in the metal. Based on your description it sounds like JB Weld would be worth trying. Probably the worst that would happen would be for the epoxy to break off and fall to the bottom of the gearbox and you'd just be back to what you had before.

-

l don't know that JB Weld would hold up to the stress from the mating roller. There's got to be a reason why the worms wear like they do. Mine was worn the same way only worse.

-

That groove in the worm is likely to be what's causing the catch in the steering. There's nothing wrong with putting everything back together and hoping it works but don't be surprised if the steering sucks.