bkahler

Members-

Posts

1,948 -

Joined

-

Last visited

-

Days Won

39

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by bkahler

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

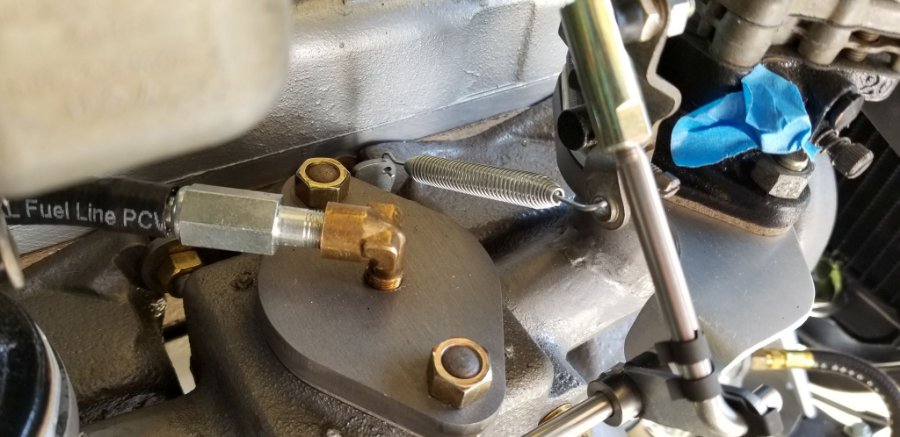

Finally got some things done on my truck for a change! Between yesterday and today I managed to get about four hours of quality time with the truck. In that time I finished the PCV tubing installation, finished the throttle & carburetor linkage, finished the carburetor and fuel pump tubing, retimed the fuel pump so the distributor rotor was in the 7 o'clock position and installed the radiator hoses. Just need to finish the starter and generator rebuild s and I could probably try starting the engine Not sure when my next chance will be to work on the truck again but at least things are still moving forward. Brad -

Here are a couple of posts I've made on my thread with pictures of the overload bumper: Overload bumper Overload bumper I can take a close up this evening as well if you want a better shot. Brad

-

The factory helpers on my 1/2 B3B have rubber bump stops. I was lucky in that the rubber pieces were still in serviceable condition.

-

My point was I ordered parts from his catalog over the phone for a 51 B3B and the shackle brackets were nowhere near correct. Over the years I've made many purchases from Roberts, some of the parts were correct and some were not. I ordered a pair of sun visors that were supposedly for a 51 B3B. What I received were sun visors for a 50s Chevy. They are similar but the Chevy visors are a lot longer. Maybe things have improved over the years but I've had issues with Roberts and Bernbaum's when it comes to "correct" parts for my truck. I realize there aren't a lot of Dodge parts that are being reproduced, at least correctly, so it is what it is. I'm not complaining, it's just buyer beware.

-

This was back before the internet really got started, the order was over the phone.

-

Years ago I ordered rear shackle brackets for my B3B from Roberts and they did not fit. I'm not sure what year they were for but they definitely weren't for a 51 1/2 ton. Hopefully you'll have better luck.

-

When I got my 51 it also had the grain door fabbed into the tailgate. I looked high and low for a tailgate and finally found a good used one in Phoenix. That was 24 years ago, now I kinda wish I had hung onto the original tailgate and used it instead. Now I think they look kinda cool and help tell the story of the truck. Brad

-

That will be one stout bed with the 2-1/4" oak!

-

I'm surprised by the 2-1/4" thickness you're using. On the 1/2 tons I think the bed boards were in the one inch range. Did the 1-1/2 tons require boards that were so much thicker? Brad

-

What 1 barrel carbs are people using on dual intakes?

bkahler replied to lostviking's topic in Mopar Flathead Truck Forum

John, Any suggestions as to what size main jets should be used in a dual B&B setup? Enquiring minds need to know..... -

JB, now you have me wondering just what filter I have on my truck. To my eye th is looks just like the filter you've pictured in this thread. The Chrysler decal is just something I bought from one of the suppliers as that's what they were offering. So, is my filter housing the same as yours? Brad

-

"Ran When Parked" 1954 Dodge C 3/4 Ton

bkahler replied to DrFate77's topic in Mopar Flathead Truck Forum

I also swapped to the Grand Cherokee rear diff and briefly considered using the GC parking brakes until I took a closer look and felt they looked like a total piece of junk. So I opted to stick with the original transmission mounted parking brake. Just my opinion of course Brad -

That's very similar to how I built my cart years ago. I might have had larger castors but that's about it. Progress is good

-

Door Check Retainer Replacement for Pilot-House Cabs

bkahler replied to JBNeal's topic in Mopar Flathead Truck Forum

Everything you wrote makes sense except for this last sentence. I didn't realize there were inclines in Texas?! ? Hopefully I won't have to go down this path, yet. My passenger side was still intact and back in the 90s I managed to find a truck with a good check strap retainer and I liberated it. Thanks! Brad -

14th Annual Clements Tailgate, in Clements California BBQ

bkahler replied to 48Dodger's topic in Mopar Flathead Truck Forum

This year would be nice but I'd really like to be able bring my truck and I'm pretty sure it won't be on the road by April. There is a lot better chance of that happening next year! -

14th Annual Clements Tailgate, in Clements California BBQ

bkahler replied to 48Dodger's topic in Mopar Flathead Truck Forum

One of these years I'd like to make it to the barbeque unfortunately it won't be this year. I'm hoping to retire at the end of this year which means 2022 or later is a distinct possibility Brad -

Yep, I wish to heck I had installed the cowl vent before doing anything else with the cab. Even more so after installing the first seal only to find out it was a piece of crap and had to remove it. Latest seal came from VPW and is cut to length. Unfortunately, still not installed yet......

-

Forgot to mention the brake MC. I ended up used a Jeep Cherokee MC mainly because I had to do a rear end swap due to a bad ring gear so I ended up with a Jeep Cherokee differential with disc brakes. Since I was now going to have discs front and rear I figured a newer master cylinder would probably be appropriate. I made an adapter plate that put the new MC in the same spot as the old MC. Needed new plumbing and the pushrod need to be shortened. Brad

-

Jim, I finished the Rusty Hope installation a few months ago but have not driven the truck yet. The kit comes with the caliper mounting bracket that have been CNC cut out of plate steel. He also provides the necessary bolts to make the conversion. The calipers, rotors, bearings, brake hose, etc are purchased by you at whatever place you buy parts from. Personally I source mine from Amazon, ebay, the local parts store and probably a few other places as well. The kit comes with a complete list of parts needed and which vehicles they were sourced from. You will need to drill 9/16" or 5/8" (can't remember which) in the steering arms on each side. You will also need to tap two holes in each spindle assembly for I think 9/16-18 threads, again I might be off on the size. It's been a while and I can't remember what I had for breakfast this morning! All in all I think it's a good kit and a good way to go. Just be prepared to drill some large holes and to tap some large holes. Here's a link to my thread where I installed the kit. Brad

-

ggdad1951 truck project montage: FEF!

bkahler replied to ggdad1951's topic in Mopar Flathead Truck Forum

What? Only one picture? If it was a photoshoot I would have expected a lot more pictures, even a few more of the truck would be nice....... ? -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Well crap This afternoon I was sorting out the spark plug wiring and it would appear I installed the oil pump incorrectly. I think it was early this spring that I had determined that the oil pump was installed incorrectly (wrong!]. I'm used to rebuilding Triumph sports car 6 cylinder engines where you set the distributor so the rotor physically points to the #1 cylinder. So when the dodge manual states "rotate crankshaft until distributor rotor is in firing position for number 1 cylinder." I interpreted that to pointing to number one cylinder. I guess the good news is the number 1 piston is still at TDC with both valves closed so all I need to do is correct the oil pump installation. But, I need to order another oil pump gasket before I do anything. Two steps forward one step back..... -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Worked on a couple of small projects this morning. First was for the carburetor mounting. The Rusty Hope dual intake has exceptionally large holes where the bolts go, .455" where .375" bolts are used. This allowed for a lot of slop in how the carburetor could be positioned. So I searched around online and found some .375" ID x .4375" OD x .555" long aluminum bushings. I had to trim about .120" off the length but they worked great as spacers to take up the slop in the bolt holes. The other task was to try and salvage the rubber sleeve grommet I (stupidly) removed from the headlight bucket. During removal I tore the grommet and for a while I didn't think I would be able to reuse it. Truth be told, I'm still not sure but I'm giving it a try. The original 2-wire bundle had frayed ends and wasn't really usable so I made up a 2-wire harness and wrapped it with wire wrap and then I slipped a length of shrink wrap over it. So far the results look seem like it just might work. I used Gorilla glue to hold the torn piece of rubber together. The directions recommended 24 hours curing time before handling so I'll let it sit overnight. If it looks like it's going to work I'll seal around any gaps with black RTV. Brad -

I would have loved to see those pictures. Any chance of reposting them?!

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

The ball joints on your mower are only 1/4"? That seems awful small.