bkahler

Members-

Posts

1,947 -

Joined

-

Last visited

-

Days Won

39

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by bkahler

-

I came to the conclusion a few days ago that a complete respray of everything except the interior and engine compartment is the only workable approach. This approach will also allow me to fix a few things that 21 years ago weren't higher on the priority list, mainly the two angle strips that are fastened to the inside of the bed walls. The originals were somewhat chewed up but still serviceable if need be and at the time I had no idea where to source replacements or if they were even available. Now that I have all of the correct bed rails in hand I might as well install them properly which means painting them as well. My only real desire or requirement now is to at least get the exterior color to be a reasonably close match to the interior. The sample I have from PPG isn't even close. I don't expect to hear anything back from the painter for a few days or more on the search for matching paint. He's currently occupied with painting the bumpers and a few other misc. parts black. If I have any hope of making it to Clements I need to get the painting issue resolved soon!

-

Time to talk exhaust and it's gonna have to be custom

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I'd like to hear an audio of how that exhaust sounds! Why don't you record a short video of the engine running and put it on YouTube? -

Sure sounds familiar I guess since mine was transported from Lincoln to Texas to Arkansas and finally to Kentucky it has been outside but, only long enough to make each trip at which point it was quickly shoved into a shop or garage! There is definitely a strong dependence on computers anymore to do any and everything. Computers were supposed to make our lives a lot easier.....NOT ? The one can of original paint that I have left was about 1/4 full but over the intervening 20+ years it is now more of a Jell-O mix

-

I guess I need to clarify the current condition of the paint. It looks brand new as far as sheen and color goes. The truck has never been outside and has no weathering or associated wear. I don't mind respraying the truck and as a matter of fact that's what I'm now expecting to do. What I want is to find someone that can take one of my existing small panels and create/mix a match to it so I can respray. Yes, I am willing to pay to have the painter travel with one of the panels to get it matched. We haven't given up finding something local just yet but so far it's been somewhat disappointing not being able to find something local. I believe the painter is making a trip today (60 miles or so?) to a shop to see what they can offer. It just seems odd in this day and age that it's this difficult to match a paint color. I guess maybe I was just expecting to much....

-

Time to talk exhaust and it's gonna have to be custom

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Hmm, I've worked with guys like that before ? There is one place that I would consider going to here locally but they are so back logged it's not worth the effort and I've noticed the last couple of times I had them work on my vehicles the work was rather sloppy with no attention to detail. I'm going to be generous and pass that off as they are just to busy to worry about the small stuff.... Based on the location of the two manifold dumps the front dump is about 3" closer to the frame rails than the rear dump. That means the front pipe can run to the rear beside the rear pipe with about a 1" gap between them. I found a Y pipe that that has 2" inlets with a 2-1/2" outlet. The inlet pipes are on about 3" centers which means there is about 1" between the two pipes. In theory that should match up with my two pipes fairly well. I'm still waiting on a call back from Steve at which time I'll see if he can provide the rest of the piping in 2-1/2" size instead of the standard 2". More to come.... -

I've reached a dilemma with the paint on my truck. 22 years ago I had it painted using Sherwin Williams 1952 Dodge Truck Green. After 22 years of having the parts transported all over the country they have ended up with various scratches and scraps along the way. Enough so that all of the body parts including the cab exterior need to be resprayed. I have zero plans to respray the interior of the truck or the engine compartment/firewall. A friend of mine is going to be doing the prep work and painting but first we need to find paint that matches the Sherwin Williams 1952 Dodge Truck Green paint. The issue that we've run into is finding a source for the paint. Sherwin Williams tells us that the paint code I have is no longer available in their system. Our next attempt where we actually had some paint mixed was with PPG. They indicated that they could cross over the 1952 Sherwin Williams paint code to their system and so I bought a pint of their paint to use as touch up, hoping that at that point a respray would not be needed. Well, the PPG paint isn't even close to the Sherwin Williams paint. Not living where there is a custom paint shop on every street corner we're struggling trying to find a place that can correctly match the paint that I have on the truck. I see places online that advertise the ability to color match from an existing sample but none of the shops around here seem to have that sort of capability. Looking for suggestions on how to proceed. Thanks! Brad

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Kind of went off on a tangent this pass week or so. Last week I contacted an upholsterer about recovering my seat cushions and made arrangements to drop them off last Friday. While there we discussed the rebuild process and I mentioned that I wanted to paint the spring assemblies after he removed the covers. So I left his place (hour drive) and after I got home I gave him a call to ask a question about clips. He informed me that he had the cushions stripped down and so I made arrangements to pick up the spring assemblies Saturday morning. I now have the spring assemblies in my shop again and I spent Sunday drilling out the spot welds holding the bottom frame to the spring assembly. Between the bottom frame and the spring assembly there is some sort of cardboard sheet that needed to be replaced. The main reason for replacing is it smelled a lot like mouse urine which I guess shouldn't be all that surprising after 70 years of use and storage I'm planning on using 1/8" Masonite to replace the carboard sheet. I'm also planning on adding in the valve for the "Air-O-Ride" mechanism that I had salvaged from a seat at the junkyard years ago. I realized after dismantling the springs that I would not be able to weld the spring assembly to the bottom frame because of the Masonite so I ended up buying a spot welder which means I can assemble things properly. We'll see how that goes....! Pictures to follow later today.... -

The cross bar (wheel to wheel) is just a hollow tube so be very careful with that 100 ton press! You'd be better off using a large vice, a couple of 2x4s to straighten it.

-

Time to talk exhaust and it's gonna have to be custom

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Yep, dual inlet single outlet is one of the things I'm talking to Steve about. It might simplify things but until I have the details it's all a guessing game. Thanks! -

Time to talk exhaust and it's gonna have to be custom

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Brian, I've thought about doing that but the few places that are reasonably close I wouldn't trust working on a go-kart let alone my truck. What's made things even worse is all of the shops are literally swamped and you have to take your vehicle in for them to evaluate, they give you an estimate as to how much and then give you a date when you can bring it back to get the work done. This is mostly due to them not being able to hire good help and get them to stay. Sound familiar? The more I look at the two exhaust manifold dumps and talk to Steve at DCM I'm pretty sure buying the kit that he sells with an extra custom sized down pipe will just about do the job. Only thing that should be needed is a Y pipe and some welding on my part. I'm waiting on a call back from Steve on a few other details, but that probably won't happen until Tuesday. -

Time to talk exhaust and it's gonna have to be custom

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Yes, I have several different sizes. -

No, just the new chain around the new sprocket. A chain is going to stretch so if it basically fits the sprocket now even a few thousands stretching should happen immediately. It sure sounds to me like your cam sprocket is the odd duck here.

-

Time to talk exhaust and it's gonna have to be custom

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

That's kinda what I'm hoping. it would be really nice if this could turn into a semi-bolt in setup. Yes, I will have to weld where the front down pipe leaves the flange and I think I will have him leave the rear flange to pipe connection loose as well so I can just move things around to where they line p with each other and then do tack welds before removing for complete welding. I'd really like to have the exhaust in place before starting the engine but we'll see how things go. -

You should be able to wrap that chain all the way around the new crank sprocket. If it doesn't then somewhere in the mix there is a problem.

-

Time to talk exhaust and it's gonna have to be custom

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

This is one Y Pipe I'm considering. Two 2" inlets and one 2-1/2" outlet. The way the front manifold dumps both pipes should be able to run side by side under the firewall. I also noticed DCM Classis's has a complete exhaust system so I plan on talking to Steve about possibly building a hybrid kit. Shipping isn't going to be cheap so buying everything at once should at least save a little in shipping costs. I measured the height difference and it's 1-1/4" with the front needing to be 1-1/4" longer on the down section. It's also 9" farther forward than the rear dump so the overall length will need to be 9" longer. I'll know more sometime tomorrow morning -

Time to talk exhaust and it's gonna have to be custom

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Dave, thanks for the info on the tubing rollers. I've never used one and hadn't looked at the specs to see what they were capable of. Your comment got me to thinking about where to get appropriate pre bent parts and that led me to check out DCM Classic's and they listed the down pipe as a separate item. So I called and talked to Steve about what my situation is and what I'm trying to do. Between the two of us we worked out a potential solution to the first part of the equation which is getting two pipes from the manifold(s) to under the cab. Tonight I need to take some measurements and tomorrow I'll call him with the info. What it looks like I will be doing is buying one original down tube assembly and then buying a second one where the flange is not actually welded to the pipe. This would allow me to swivel the front pipe to an orientation that will allow me to bring the two pipes together after they pass under the firewall. The point where the front down pipe connects to the manifold it's a little higher than the rear so I need to find what that difference in elevation is and also I need to measure how much longer the down pipe needs to be in overall length since it is farther forward than the rear down pipe. So hopefully sometime tomorrow I'll know about how much the two pipes will cost and get an order placed. Oh yeah, currently planning on 2" down pipes as that's what he has to offer and it just simplifies things for me. What sizes for the downstream pipes I'll worry about later. Stay tuned.... -

Have you checked with Coker Tire? They are big into remanufacturing tires for the antique and hobbyist. Whether they have tires as large as you're looking for I don't know.

-

If the chain fits the crank sprocket just fine but not the cam sprocket then I would think the cam sprocket is the odd duck.

-

Wow. Never saw an issue like that before. Everything seems to point to the cam gear being defective. I'm really curious as to how this works out in the end. Good luck!

-

I zoomed in on the picture and it looks like the black wire on the left connects the top and the bottom. Just kinda hard to see.

-

Time to talk exhaust and it's gonna have to be custom

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Something I had not considered is whether or not the factory undersized the original exhaust system. The 454 in my motorhome uses 2-1/2" pipe per side into a two input port muffler then to 3" on the outlet of the muffler. The header down pipes are around 1-3/4" or so (maybe 2") and then all four combine into a 3-1/2" collector. So it's pushing 227 ci through 2-1/2" where Dodge was pushing 218 ci through 2". Your argument definitely has some merit. For me the only problem with 2-1/2" pipe is the HF tubing roller only handles 2" which means I'd have to find an alternative for bending 2-1/2" pipe. Yes, I do want a quiet ride. I like to hear the wind, not the exhaust ? Thanks! -

There comes a time with every project where if you want to drive it then it's going to need an exhaust system Since I have a split exhaust manifold I have to come up with a totally custom system. First off, I do not want to run a complete dual exhaust system. I want to run two into one before the muffler with just one tail pipe running out the back. I realize there are arguments for and against dual exhaust but for me a single muffler and tail pipe is what I'm looking for. There are several issues that I will have to deal with and the first is pipe diameter. I have the remains of an original exhaust flange with a short section of pipe still attached to it and it's 2" pipe. The person that added the 2nd exhaust dump keep the pipe size at 2" but the flange has different bolt centers compared to the original flange. 3-3/8" on the original and 3" on the new flange. I've been searching for a while and have not been able to locate any new flanges that will work with either of those patterns which means I will likely have to fabricate my own flanges. Next issue is what size pipe for the down pipes from the flange to where they merge. I'm not an exhaust expert but I've previously been led to believe that since the original pipe was 2" for 6 cylinders that I should down size the two down pipes to about 1-1/2" each and merge them into a 2" section. Since the exhaust flanges are 2" that means I would need a reducer section coming off the manifold, i.e. 2" to 1-1/2". Something like these only with 2 bolt flanges. Building the exhaust system is something I would like to try and tackle myself, at least until I prove that I can't handle it and then take it to the pros! I've been looking at tubing rollers and surprisingly this Harbor Freight roller actually has fairly good reviews. So I'm considering getting one of these and giving it a go. Thoughts anyone?

-

I don't think the posts are positive and negative per say, but the battery should be connected negative to one post and positive to the other post. I don't think the metal casing is connected to either of the posts. It's been a while so I could be wrong.....

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

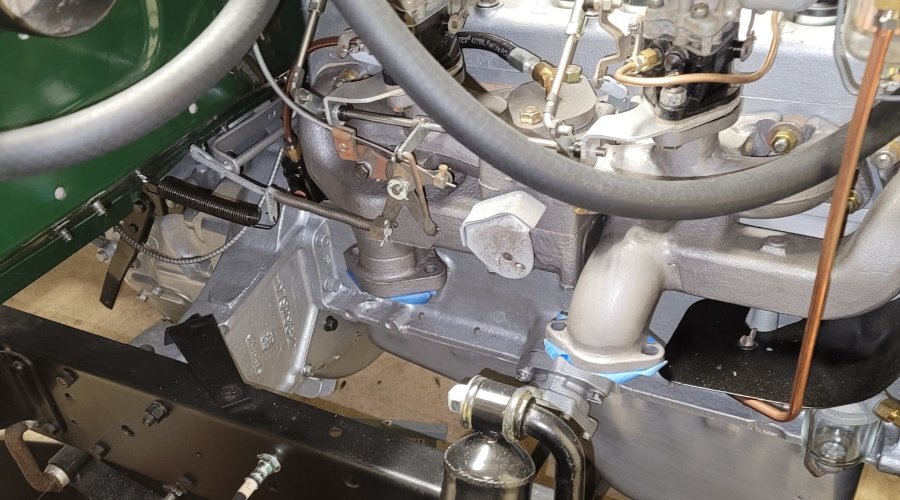

Yeah, our filter assemblies are the same but different....! After I got home last night I managed to get my camera in the right position and angle to take a picture of the side port. It does say outlet. So the plumbing is correct which certainly makes me feel better. It also means that I can just pull the sock and pour some oil into the can and it should drain down into the oil passages. That's a lot easier than using a pump oil can Thanks all! Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Well nuts. I think my oil filter plumbing is backwards. Would someone care to confirm this suspicion for me?