bkahler

Members-

Posts

1,949 -

Joined

-

Last visited

-

Days Won

39

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by bkahler

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

The ball joints on your mower are only 1/4"? That seems awful small. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

The way I have it figured, this is the last time mine will ever look this nice. Unfortunately once I complete something I tend to neglect it and move on to something else. Just one of my many flaws I guess -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Thanks Actually they are Dorman Throttle Ball Joints. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I made a slight change to the linkage for the carburetors. Originally I had two fixed links going from the pivot shaft to each carburetor. Thinking about it and looking around at what others have done I realized that there would be no way to synchronize the two carburetors together so I modified the arms to make them adjustable. I still have a little more work to do on the overall linkage but it's getting close Brad -

I don't have any samples or pictures buy my 51 had the sewn seam down the middle as well. It was also the same light tan color. Brad

-

That sheetmetal may look rusty but it sure looks solid, I'll bet they clean up nicely. For some reason I thought you had lifted the cab off the truck. I guess I'm not paying close enough attention! Nice to see progress being made Brad

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

That's a good point, I just ordered some and will use it on the heater switch. Thanks! Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

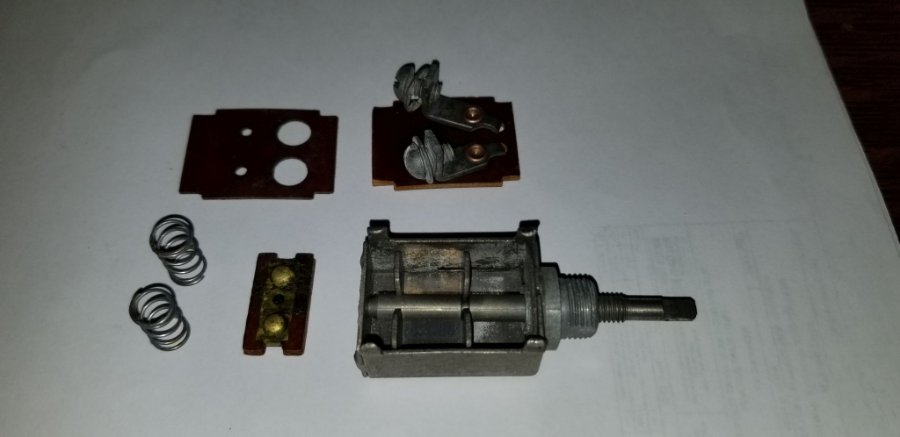

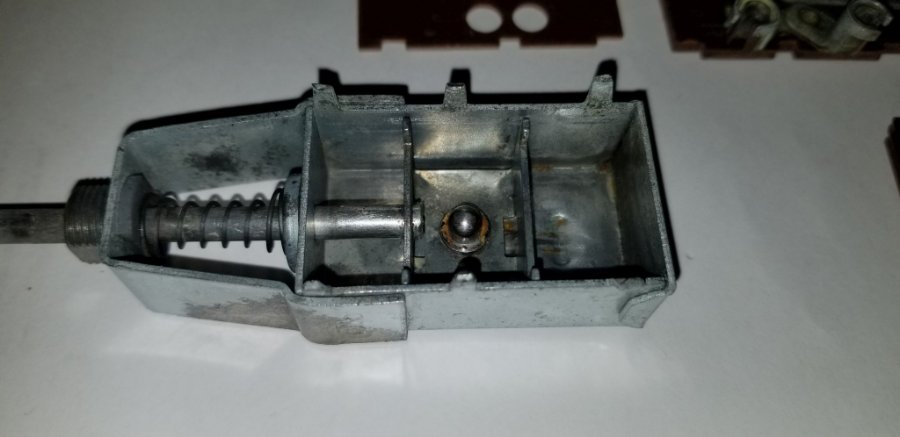

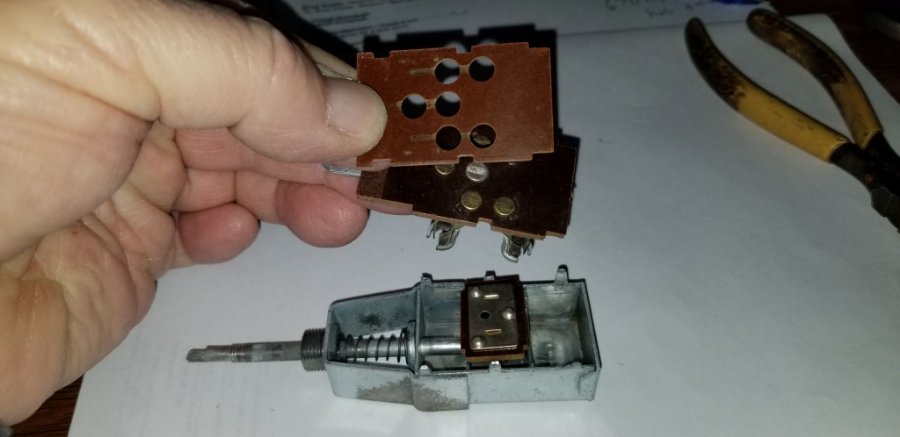

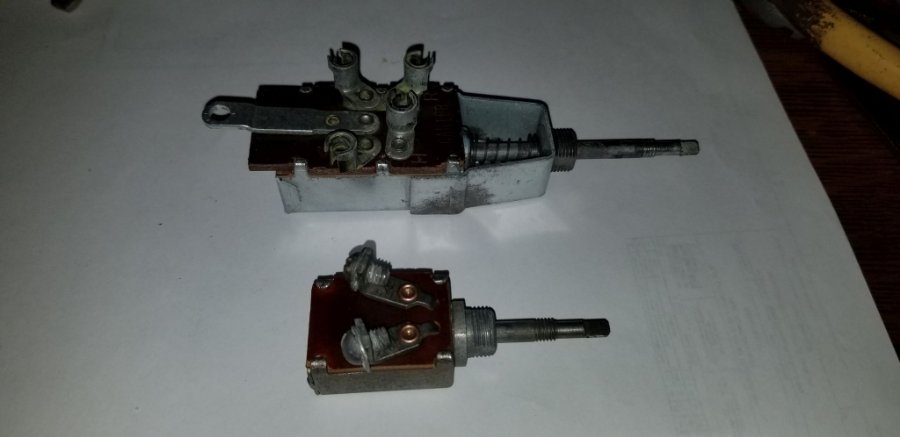

This time of year I tend to tackle projects that can be done at my desk when possible. Probably because I don't like working outside in the cold! Anyway, I tested all of the dash switches and realized they needed to be reconditioned. My original panel switch was busted but I got lucky when I went to buy the radiator for my truck as the seller had a broken panel switch like mine only it was broken in a different way. My original had the shaft snapped off inside so was useless. The one I just bought had the top piece broken but the rest was ok. So I pieced the two together. I cleaned the switches using Evap-rust and then reassembled them. The panel light and headlight switches are done and work fine. Previously you couldn't get a reliable connection with the headlight switch but that's good now. The heater switch is now dismantled and soaking in Evapo-rust and I should be ready to assemble it later this week. Fortunately I have two of the heater switches because one of the resistors is broken. Panel switch assembly: Headlight switch assembly: Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I'm not sure why but today I got the itch to install the spotlight. When I bought the truck there was a hole in the windshield pillar for a spotlight but the spotlight itself was long gone. Over the years I managed to scrounge enough parts to to make a complete MOPAR spotlight. I bought a newer Unity 12 volt halogen bulb to fit the 6" housing. I just need to route the wire through the dash and installation will be complete. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I tinkered with the throttle linkage a little bit this afternoon. I think I need to make a modification to at least one of the links between the shaft and the carburetor. Right now there is no way to individually adjust each carburetor. Adjusting one will likely cause a slight change in the other one. I think at least one link needs to be adjustable. Someone posted a picture to the forum showing their dual carburetor installation and I noticed that little feature. I think I'm going to have to copy it Also, I think I have a workable solution to a second return spring for each carburetor. The spring I currently have in place is to long so I need to find something a little shorter. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

So what you're telling me is you want me to to sprinkle drops of oil all over my nice shiny new truck..... ? -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I vaguely remember reading that in the operators manual a while back. At the time most of that information wasn't to important because I was a long way from trying to start the motor. However, that's starting to change Thanks! Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

That's a good point! I hadn't really considered that Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

There are good days and there are bad days and sometimes you have both in the same day. On Sunday I was assembling the front parking lamps and the first one went together just fine. When I was trying to squeeze the second one together to get the screw started I heard a snap. I knew immediately what had happened and I felt a little sick to my stomach. I had two NOS front lenses and for some reason I managed to crack the second one ? I suppose I was lucky that I had two new repro spares and had no issues installing one of those. But it still bugs me that I broke a NOS lense. I also cleaned, painted, assembled and tested the dome light that came with the truck. The other thing I did was test the throttle linkage / gas pedal to see if everything was going to work. Here's a video to show the results. I still need to trim a few pieces and install the push nuts and will do that in the near future. I just wanted to make sure that what I was doing was going to work. If you have your audio on you'll hear a slight scraping sound, that's the pedal push rod passing through the stem seal in the firewall. I'm not sure what to do about that yet. Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I couldn't agree more about angling the foot pedal slightly. What I was surprised about is the pedal itself is not designed to be angled. Both original and aftermarket pedals are designed for straight up and down fitment. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I got the kick boards and transmission cover installed this morning. I hadn't planned on installing them quite this soon but I needed to figure out how much stroke the gas pedal was going to provide so I can make the pivot arm for the carburetor linkage. I found it interesting that the gas pedal has a slight kick to the right at the top which made it a tough fit over the studs on the transmission cover. The replacement pedal that I bought is made identical to the original so for whatever reason Dodge just didn't line them up quite right. The transmission cover will need to come off again so I can install the boot but that's for another day. Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Made some progress on the carburetor linkage today. Still need to fabricate the arm from the shaft down to the pedal linkage. Also waiting on some 1/4" push nuts to be used to retain the linkage where it connects to the carburetor arms. Also, I think I've figured out how to add a second throttle return spring to each carburetor. I'm going to Ace hardware tomorrow to shop for some small springs. Once the linkage is done that puts me one step closer to starting the engine for the first time -

Good point!

-

Hmm.....I don't see a seat belt ?

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I save just about every picture of a pilot house truck that I run across. It's amazing some of the detail that you can glean from a single picture. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Talk about a steal! And $6 shipping, that's something that is long gone. I paid $160 + about $20 shipping and I thought I got a reasonable deal at the time. -

Did you receive them yet?

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

That's what I thought but for some reason I had flat washers in the bag with the original screws and j-clips. My guess is some PO swapped the square washers out for the round ones at some point in time. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Awesome! We will probably have the only two trucks with original floor mats installed. When/where did you get yours? Mine came from Franke Mitchell Motors back in 1998. The backing on yours looks to be the same stuff mine is made of. If you want to replace your backing I found the Jute backing used on my 72 TR6 is very similar in thickness and makeup and readily available. The only issue I have with mine is wrinkles in the rubber from having been rolled up for so long. Right now I have it laying on the floor with heavy weights over the wrinkles to see if that will take them out. Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

It's not a rumor, it's fact