-

Posts

4,314 -

Joined

-

Last visited

-

Days Won

43

Jeff Balazs last won the day on October 25 2021

Jeff Balazs had the most liked content!

Reputation

1,257 ExcellentAbout Jeff Balazs

- Birthday 02/26/1955

Contact Methods

-

Website URL

http://www.heartofoakworkshop.com

-

Occupation

Woodworker

Profile Information

-

My Project Cars

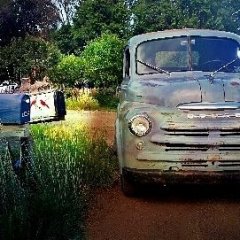

52 B3C daily driver

Converted

-

Location

Coto de Caza, Ca.

-

Interests

Fishing & vintage Brit Bikes

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Convert 12V alternator to 6 volt

Jeff Balazs replied to nkeiser's topic in Mopar Flathead Truck Forum

I fitted a 6v pos ground alternator from Quality Power when I built my truck. It has worked great this whole time. Pretty much a fit and forget item. Makes running a 6 volt system totally painless. Jeff -

Electric Fuel Pump Mounting Question

Jeff Balazs replied to desmondmonster's topic in Mopar Flathead Truck Forum

Well if I were totally convinced that the original fuel pump was a reliable solution I certainly would not have bothered modifying my truck. The thing is that they were probably fine back in the day but fuel formulations are radically different these days. I know of several people who have found out the hard way what can happen when their rebuilt pump has a catastrophic failure. Just so you know it has happened to folks on this forum not to mention guy's I know that have other sorts of vehicles. When that diaphragm fails the path is open straight into the oil sump. If you do a bit of searching you will find other issues with these pumps as well. I won't go into a lot of detail but several L6 owners have had the arm come off. And then there are the very common over heated fuel / hard starting issues that many folks have experienced. Personally I think this should be enough for owners to "re think" the fuel delivery system on these engines. I suppose if I only used my truck once in a while and on lightly used secondary roads I might be able to look past all this. But quite frankly it would be just asking for problems here in the very heavy traffic I am regularly in. I do get why one might want to retain the original look of the components. I think if I were at all concerned about this I could come up with a fix that looked right but did not actually function as the old system does. Falsies if you will. I am sure I will probably take some flak for this. That is ok.....I get it. But I think stuff like glass bowl fuel filters belong in a museum and not out on the road. Jeff -

Electric Fuel Pump Mounting Question

Jeff Balazs replied to desmondmonster's topic in Mopar Flathead Truck Forum

Fwiw. I have been running a full time electric pump for more than 7 years and 30K miles. The arrangement I have is similar to what B Kahler has shown. It has worked flawlessly this whole time. I don't understand why anyone would want a "primer" type system. If the diaphragm in your mechanical pump fails you can wipe out a set of main bearings in a hurry. Jeff -

Your tires ought to be around 30" diameter.....makes a huge difference!!!!

-

John; I am running the large Carter rotary type 6V along with a Holley regulator. A very important item is a good filter ahead of the pump. Dirt getting into these pumps is the leading cause of failure. My fuel delivery system has been completely trouble free for more than 7 years and at least 35,000 miles. Try it you will like it Jeff

-

Well I suppose having your memory fail is better than having your fuel pump fail and dump fuel into the crankcase......again. ?

-

Uh huh. At least if mine goes bad it cant dump fuel to directly into the crankcase................seems to me that "someone" on this forum had that happen. Wish I could remember who that was? Jeff

-

Update 6 years on and in daily use. Electric fuel pump is still working fine.........? Jeff

-

1940 PT105 - Electric Fuel Pump

Jeff Balazs replied to Splitpi's topic in Mopar Flathead Truck Forum

Fwiw I would not concern myself with a return line. It just isn't required. A couple of other things that should be considered are deleting the mechanical pump....which is a potential source for fuel in the crankcase. And the use of sealed canister type fuel filters which reduce the chance of leaks. A pressure regulator makes a lot of sense. Keep it all simple and easy to maintain. You will be happier in the long run. Jeff -

1940 PT105 - Electric Fuel Pump

Jeff Balazs replied to Splitpi's topic in Mopar Flathead Truck Forum

IMO the return line is not needed. Good filtration and the use of additives has worked well for me. 4oz of MMO every other tank gets the job done. Hth, Jeff -

1940 PT105 - Electric Fuel Pump

Jeff Balazs replied to Splitpi's topic in Mopar Flathead Truck Forum

I have a full time 6v Fuel pump on my 52 B-3-C and it works great. One thing that is very important is to a good pre filter ahead of the fuel pump. When I built my system I came across info that indicated that the main cause of pump failure was dirt getting into the pump. Mine has been in daily service for over 7 years with no problems. I also have a pressure regulator ahead of the carb and another canister type filter there too. Like I said no problems at all with the fuel system this way. Hth, Jeff -

Hub Caps - Which one fits what year?

Jeff Balazs replied to bkahler's topic in Mopar Flathead Truck Forum

I was able to polish my single piece caps to get them decent looking. Made a jamb chuck and mounted them up on my wood lathe. Made a big difference. One of them did not shine up too good but 3 out of 4 isn't too bad. One day I will find a better one. Jeff -

I have been running the Quality Power 6V pg unit on my truck for over 7 years now. Works perfect all the time. Fit and forget!!!!!!!! Hth, Jeff

-

51 B3B build thread - after all these years

Jeff Balazs replied to bkahler's topic in Mopar Flathead Truck Forum

There are a couple of things you can do to make it a little easier to R&R the starter motor. I slotted the heads of the two mounting bolts to allow the use of a screw driver. This makes it a bit easier to get some turns on the bolts when they are loose. I also have a wrench that I cut down that helps some too. It is always going to be a PITA job .......but it can be accomplished with the fenders on this way. Just have to be a bit creative.... Hth, Jeff -

How to withdraw B3-B steering gear sector slack.

Jeff Balazs replied to Fernando Mendes's topic in Mopar Flathead Truck Forum

You are welcome. Hope this works well for you. Jeff