Kilgore47

Members-

Posts

426 -

Joined

-

Last visited

-

Days Won

11

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Kilgore47

-

I don't mind getting covered in grease while working on an old car but I just can't get motivated to work on a house. Not my thing. Guess that's why I put it off for too long. Give me an old car to work on and I will drift off to my happy place. For the past few months, I have had contractors working on the house. Replacing rotten wood, painting and re doing one of the bathrooms. Have used this group before and they do good work. But I am tired of having people wondering around here all day every day. It's almost done - another few weeks. What a mess and the yard is a disaster. It will be worth it when it's done. Really looking forward to having my home back when the work is complete. Venting done - - -

-

I have an Optima 6v battery. It's half the size of a regular battery so these hold downs don't work. I should make a hold down that looks good but I'm using the Road Kill method at present. Zipp ties. Doesn't look good but it keeps the battery in place. I have salvaged a couple of plastic handles from old gas powered lawn equipment that I think I can modify for a hold down. But other projects are more important for now so I'll do that later.

-

Stupid pizza pothole - It's always in the way

-

I was going to put this in the shop until I looked it up and found out that it's worth more than I paid for it. I picked this up at a garage sale for five bucks about 30 years back. Very mid century. Turns out it's by a well known artist and worth over a thousand dollars. If you could get someone would pay that for it. Someone will inherit it one day and it will probably end up in another garage sale for five bucks. That other thing in the picture is an antique coat rack. If you have seen the movie "Edward Scissor Hands". There is one just like it on the living room wall of the people that adopted Edward.

-

My what big cables you have. I have the same set up. Removed the generator and went with a six volt positive ground alternator and that fixed all the charging problems.

-

Yesterday I drove the P15 to brunch to meet several people I used to work with. One of the guys wanted to drive the car and I was happy to let him do that. After he tried several times to start the car he gave up and we thought it might be flooded. I had my friend get out and I scooted over and the car started right away for me. That's when I realized I was using a combination to start the car. Been doing it so long I didn't notice I was doing it. Choke cable in the correct position, throttle cable in the correct position and tap the foot feed at the correct time while the engine was turning over. When the car is warm it will start by just hitting the starter button but the car had cooled down while we were visiting and needed the combination to start. Brings back memories from my teenage years - I was the only one that could start the 61 Comet when it was cold.

-

I have driven the car a few miles now with the new pan gasket and that fixed the major oil leak. Turns out the rear main is not leaking. That's a good thing. There was a small puddle under the car after sitting for a couple of days. Put the car up on the end lifts today and that leak is coming from the transmission. Fixing the leaks in the transmission will be next. It's not a big leak so it may be a while until I get around to that. Cat litter works good for small leaks also.

-

Years back we had an office manager that had a habit of walking up behind someone that had their head down concentrating on a problem and toss a hand full of pennies on their desk. It was funny the first couple of times but people got tired of it and asked him to stop. He didn't. This guy always wore a nice pressed white shirt. One day I found some disappearing ink and put it in a couple of water squirt guns. The next time he did it we chased him down and covered his nice shirt. He got mad at us but after about 30 seconds the color went away. Then I told him the next time he tossed pennies at us that it would be real ink. Never happened again. That's good because I'm not sure I could have been mean enough to use real ink.

-

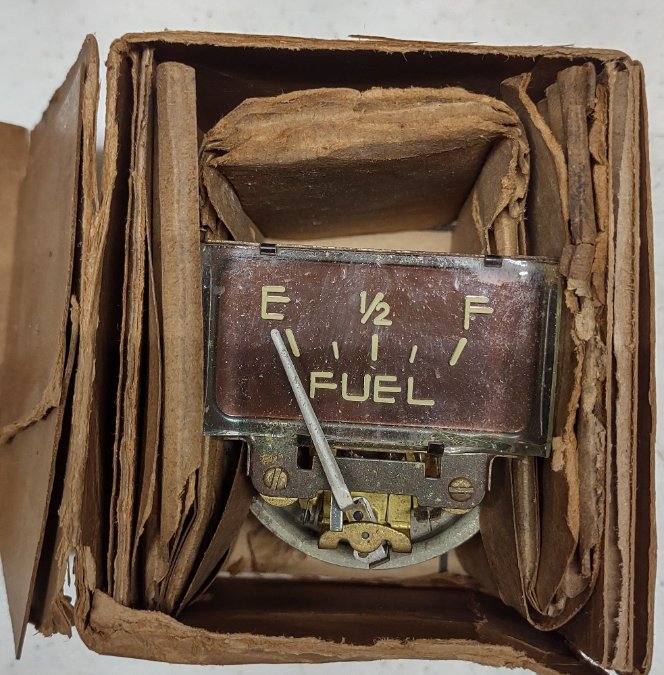

WOW the price has gone up in the last couple of years. I remember them asking about 75 dollars. DeSoto and Dodge use the same gauge (42 to 48). The face may be a different color but you can switch that with the gauge you have. I found an entire gauge pod minus the temp gauge for 150 dollars (I needed a speedo also). Also found a NOS fuel gauge for 10 dollars. Bought that one before it went away. And it was really NOS. It took many hours and days of searching to find these deals. Attached is a picture of the DeSoto gauge. Part number 974-636 is on the box.

-

Yep - that's what we did back then. On the dirt in the back yard. I jealous - you had a floor jack.

-

There is a video on line showing how to replace the boot without removing the pin. Just type in "ball and trunnion boot replacement" and you will find it. Not easy but it can be done. I destroyed the first one I tried. The other option is to use the leather boot that wraps around. The new rubber boots are not high quality. A couple of months after I installed the new boots they were already cracking. But a year later and they are still holding. Next time I have to fool with this I will have a new drive shaft built with modern U joints.

-

There is a bulb in the back yard that comes up towards the end of summer. They were here when I bought the place 18 years ago. When these sprout it's an indication that the dog days are over. Doesn't mean it's going to get cool - just means that the hundred degree days should be done for this year. Always look forward to the end of the dog days. The bloom comes up first and then the leaves. They are called Oxblood Lily. The bloom picture is from a couple of years back.

-

I saw an add for a T shirt the other day and this is what it said on the front of the shirt. IT'S WEIRD BEING THE SAME AGE AS OLD PEOPLE I need one of those!

-

I used a standard six volt wiring harness from Rebel Wire. Every wire was labeled every six inches with a note telling where the wire went. Came complete with a fuse block and is set up for turn signals. Good phone support. Not original cloth covered wire. It was less than 400 dollars. Install was easy. Just took time to solder all the connections. This was my first time re wiring a car.

-

The fuel line from the pump to the carb on the P15 has been re routed away from the exhaust manifold. No more vapor lock. And you should consider changing that plastic fuel filter for a metal one. The plastic one can melt and leak.

-

Here is a simplified diagram of how the ignition system works. And a color coded way to check the distributor for shorts that I put together in an earlier post trying to help someone with a similar problem. Maybe this will help. Orange - This wire is there to ground the body of the dist to the points plate. Check for continuity. Yellow - Check this with the points open. The wire from the coil to the points, the copper strap from the condenser to the points and the points should not be grounded to the body of the dist. The copper strap should be insulated so it will not touch the dist body. This could be done with heat shrink tubing. Purple - There is an insulating bushing here to insulate the points from the body of the dist when the points are open. Red - This is the wire from the coil to the points. It appears to be there but it is stuffed down in there somewhere. Reroute or replace this wire so that it does not ground to the body of the dist. Blue - This is where the wire from the coil connects to the dist. Check this through connection to make sure it does not ground to the body of the dist. You may consider replacing this wire also. It looks a little worn. Green - This area looks a little tattered. When you reassemble the dist I'm sure it will look and function better.

-

My car used to do the same thing. I would have to use the choke after a short cool down or it would stumble. After I adjusted the valves the problem was solved. I replaced the intake manifold at the same time so it could have been a leak on the intake. That is unlikely because I had replaced the gasket on the original intake a few hundred miles before that. But the car runs great now so it was one of those two things on the P15.

-

Check the end of your clutch fork rod. It may be worn. I had the same problem of the pedal not returning to the top. One picture below shows the rod and pin with excessive wear. The other picture shows that I was able to weld and repair both the rod and the pin. With the repairs made the clutch pedal returns to the top every time now. Check other areas for wear also.

-

With the repaired linkage installed the clutch pedal returns to the full up position every time now. Good thing because I was starting to wear a spot on the top of my left shoe where I would hook my shoe under the pedal to pull it back up. I see some other linkage wear under there but it's not as bad as the one I fixed. Guess I'll save that for a future project.

-

So it sounds like what I found is normal and nothing to worry about. Kinda scared me when I first saw it. Found the same gray stuff at the bottom of the by pass oil filter.

-

Lead. Never would have thought of that. It was a thin layer at the bottom of the pan. I was wondering why more of it didn't stick to the magnet. I'm sure the PO used leaded fuel as long as it was available. That's what everyone did back then. And keithb7. Your guess is correct. That's exactly the oil I'm going to use. How did you know

-

One of the reasons for pulling the pan on the P15 today was to check the rear main seal. When I would raise the front of the car oil would run out of the back of the engine. With the pan off I could see a couple of places where the gasket did not seal in the corners close to the rear seal. If the rear seal was bad wouldn't the fly wheel be covered in oil? It is not. And the clutch is dry. These pictures were taken before I dropped the pan. Guess I'll put it back together with a new pan gasket and see what happens. Now that I know it's easy to drop the pan. If I have to take it off again it won't be so grubby. Everything will be clean. I can fix that - I think

-

I finally got brave enough to pull the oil pan on the 47 P15 today. It was actually easy. Except for the really grubby part. Stuff falling in my face. Probably going to toss that T shirt in the garbage. When I adjusted the valves there wasn't any sludge in there. So I didn't expect to find very much if any in the pan. I found a little more than a quarter inch of sludge in the bottom of the pan. The pick up screen was clean. The surprise part is that under the black sludge there was a gray sludge. This gray matter is dense and around the outside and in the corners. It has metal in it. I was able to pick up the metal with a magnet. The other surprise part is that I also found small wire brush parts in the gray sludge. The wire brush parts were probably left over from the rebuild in the mid 70's. The other very fine metal flake looking stuff may be from the break in 45 years ago. Metal in the pan is never a good thing. But the gray sludge appears to have been held in place all these years by the black sludge. I checked the rods and there is a little front to back movement but no up and down movement that I could feel. The PO told me they put a rebuilt engine in the car in 1974 when they pulled it out of a field. They also told me that it didn't have many miles on it. I guess it is what it is. I'm going to clean everything I can get to and put it back together with a magnet glued to the drain plug. Drain the oil in a couple of hundred miles and see in any more metal has collected on the magnet. I'm also going with a detergent oil when I put it back together. Not telling what viscosity I'll be using. That would get too many comments? More news latter

-

Roll around peg board. I like it. I would have to build one that is shorter to go with the sit down creeper. It could be long instead of tall. I use the "pile of tools on the floor" method when working under the car. And they always move themselves under the wheels of the creeper?. One time when I was trying to push past a tool on the floor it turned out to be my phone that had fallen out of my pocket. Had to get a new phone after that.

-

Got the clutch linkage fixed. Decided to re use the original pin also. I finished the items to look much better than shown but I forgot to take another picture before I re installed them. There are a couple more projects under the car before I can put it back on the ground and go for a test drive.