Kilgore47

Members-

Posts

426 -

Joined

-

Last visited

-

Days Won

11

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Kilgore47

-

Optima battery suddenly too weak to crank on 48 DeSoto!

Kilgore47 replied to MarcDeSoto's topic in P15-D24 Forum

After 40 years that's got to feel really good. I have a video from when I first got the 47 P15 stated. I would attach it but the file is too large. Had a smile on my face for days after that. -

Optima battery suddenly too weak to crank on 48 DeSoto!

Kilgore47 replied to MarcDeSoto's topic in P15-D24 Forum

Turn the engine to TDC on the #1 cylinder on the compression stroke. Remove the distributor cap and note where the rotor is pointing. Move the #1 spark plug wire to that location and then re install all the other spark plug wires in the normal firing order around the cap. This will get the timing close to the correct spot. Close enough to start and then it can be fine tuned once you get it started. The engine will run fine like this. The engine doesn't care where the wires are located on the distributor - it only cares that it gets spark at the correct time. Or you could re index the oil pump. The oil pump may have been installed in a different rotational position than recommended. -

All you young 60 year olds rebuilding engines. I'm 70 now. When I got the 47 P15 the PO told me that they had put a rebuilt engine in the car when they pulled it out of a field in the mid 70's and put it back on the road. And that it only had about 10 thousand miles on it. After all the work I've done on the car it looks like they told me the truth. However it leaked oil from everywhere oil could leak. Most of those leaks are fixed now. I shouldn't have to rebuild this one.

-

Thieves...Thwarted! A Friendly Reminder To Be Alert & Aware

Kilgore47 replied to keithb7's topic in Off Topic (OT)

The tow strap is probably stolen. Hope you find them -

The first time I washed clothes in the new top loader there was a ring on the top of the tub. The front loader had been doing such a bad job. Gross - had no idea - so I ran them through again. Granted the top loader uses more water and isn't as gentle on the clothes. But I would rather have clean clothes.

-

9 degrees F here in East Texas yesterday morning. There is a large ice ball at one of the hose bibs now from the drip. Back to the 70's next week and all will be good again. I'm sure I'll reminded about this cold when the utility bills get here.

-

Chisels are great for cutting multi strand cables. Lay the cable on the anvil and hit it a couple of times. You'll get a nice clean cut.

-

That's what my neighbor has - a front loading computer. My last washer was a front loading computer. The electronics kept sending error codes. Replaced that part and it would send another code. After spending 400 dollars (this time) trying to fix it I had to call it. I replaced it with a top loading industrial model. The kind they use in laundromats. Me too. I always try to fix stuff but I had already spent almost as much as a new machine and it still didn't work. The first time I worked on it - hours were spent trying to figure out how to get it apart. The next time I called the repair guy and he had it apart in 5 minutes.

-

A few days back my neighbor called and asked if I could help him work on his washing machine. I gave him the number for the appliance repair company I use. Told him that I would rather work on a grubby old greasy car. Working on washing machines is not something I like to do. Give me an old car any day.

-

Getting the engine ready to start on bare chassis, 48 DeSoto

Kilgore47 replied to MarcDeSoto's topic in P15-D24 Forum

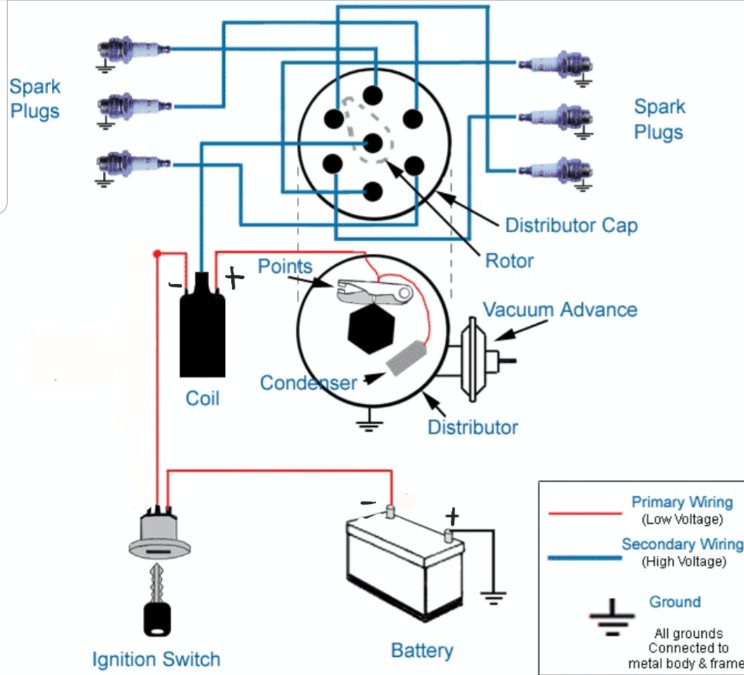

Pictures always help me. In your case since you don't have the ignition switch installed you will go directly from the battery to the coil. To stop the engine you just need to remove the wire from the battery. Make sure the transmission is in neutral. -

Don't have AAA but my car insurance includes towing. And there is a tool kit in the trunk with spare distributer parts.

-

1951 dodge Coronet wheel bearing preload torque

Kilgore47 replied to nr1freak's topic in P15-D24 Forum

Another thing to remember when working on bearings. Keep it clean - no grit allowed. While growing up I had a friend that always complained about wheel bearings going bad. I was at his house one day when he was working on the front brakes. When he took the drum off he laid the outer bearing on the ground - in the dirt. Mystery solved. -

Getting under the dash is not a big problem. Just kind of fall into place. Getting back out is the hard part. I make sure my phone is where I can get to it in case I need to call someone to grab my feet and pull me out.

-

The clutch pedal on the P15 stopped returning to the top one day. I went under the car and this is what I found. The linkage shown below was about to fail. I was able to weld these up and re use them. There were other worn areas also. After the repairs were made the clutch works as it should.

-

Wear old clothes and cover your eyes. Once you have the majority of the old grease and dirt cleaned up then you'll be able to see where the leaks are coming from. Fix those as you have time. One of the other culprits on these old cars are the five hundred (I lost count) or so lubrication points that need regular maintenance. We would pump grease in one side until it came out the other side. Then just leave the extra grease - and over time it would turn into the monster you are dealing with now. After you have the majority of the old stuff cleaned you'll find that working under the car will be much more pleasant.

-

Outer axle seal replacement on a 51 Cambridge

Kilgore47 replied to motoMark's topic in P15-D24 Forum

Also while you're at it check the vent on the rear axle. Make sure it's not plugged. Simple to do. Just unscrew it so you can check it on the bench. If the vent is plugged the rear end grease will be forced past the new seals when everything heats up and cover your new brakes with grease. I learned this lesson the hard way. -

Can't believe you found the parts after mulching your keys

-

I gave the fixture to my friends son before I knew what the lights were. So the nice housings stay with his project. I get the 6 volt bulbs and I'll figure out another way to mount them. Going for a steam punk look. The 6 volt meter and indicator lights will work when it's complete.

-

A few years back I found an old emergency light in a pile ready to be thrown away. I was working at a pipe fab shop at the time. So I rescued it, cleaned it up and put it on a shelf. A few days back a friend's son was looking for a light for his room. Told him I have just the thing. We stripped all the old 6 volt charger, battery and lights out of it and plan to go back with LED lights. Turns out the lights are 6 volt sealed beams. They are GE 4510-1 auto utility bulbs. 4 3/8" diameter. In good shape. I think I can turn these into fog lights for the 47 P15. There are a couple of old antique tractor light housings in my parts bin. I think these can be cleaned up and used for fog lights. Just need to build some brackets.

-

I've never checked for leaking spark plug gaskets - Great - now I have to worry about that. Maybe not. ? I have a solution for rain water in the spark plug wells on the 47 P15. I try to not drive it in the rain. Everything leaks. Windows, doors, floor, hood. Got most of the oil leaks fixed so now it's time to work on the water leaks. This could take a while. I can fix that - I think

-

That's not a ball bearing to be removed. It's a plug. That's at the accelerator pump jet. Go to Sniper's link to see how to remove and clean that area. The link in Sniper's response above is a great go by for these carbs. The bent area is part of the spacer. Not sure if it's supposed to be there but I don't think it will be a problem.

-

I wear disposable rubber gloves when hand packing wheel bearings. Much cleaner. Also keep a roll of paper towels near by.

-

Your carb looks good. You should probably use a thin wire to clean out all the passages. There could be corrosion left in the small areas. I use small gun cleaning brushes where they will fit. Then use compressed air to remove the remaining dust. I would have thought that you were going to have to soda blast that carb but it looks like vinegar did the trick. Thats a lot of solder on that float. Could have been repaired at one time.

-

The last time I had the intake and exhaust manifolds off the P15 I blasted and painted them with high heat silver engine paint. It's been a few hundred miles and the exhaust has changed color and smoked a little at first but the paint has stayed on. Be careful with the intake. You don't want to get anything in there that could get into the cylinders and cause scoring. Time will tell if the paint will last. But it couldn't hurt

-

Yep - Came into a little extra cash and decided to fix the house before I spent it on more cars and parts.