-

Posts

2,561 -

Joined

-

Last visited

-

Days Won

83

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Sam Buchanan

-

I removed the entire mechanism, plugged the holes, and installed a stainless steel block-off plate between the manifolds. Here is the method I used to plug the holes where the shaft used to be. I think it was a 5/16" bolt that was a good fit in the holes.

-

Several years ago I needed a fuel cap gasket for the kit car. I ordered a piece of viton from McMaster Carr and cut a new gasket.

-

Installing a Spin-on Bypass Oil Filter (photos)

Sam Buchanan replied to Sam Buchanan's topic in P15-D24 Forum

A bypass filter has a much finer element than a full-flow filter which is possible due to the much lower flow rate. Here is the data for the WIX 51051: https://www.wixfilters.com/Lookup/PartDetails.aspx?Part=155265 I'm assuming this finer element is necessary to achieve similar filtration to what a full-flow system can provide since it takes a lot longer for all the oil to pass through the bypass filter. -

Engine noise identification and black carbon

Sam Buchanan replied to wagoneer's topic in P15-D24 Forum

Probably also due to the use of non-detergent oil for many decades. -

Hmmmm.....that's a tough one. Have to wonder why welding occurred on the axle nuts. Was it because the threads on the axle are shot and the previous "mechanic" wanted to make sure the nuts don't give way and the wheels come off? Drastic action can be taken by cutting the nuts off the axles but what will be found once that is done? If the threads on the axles are worn away then the axles will have to be repaired by a machine shop or replaced. I can certainly understand why your guy is hesitant to touch this one. I can relate to this problem because the first time I pulled the drums on my P15 the threads on the left axle were heavily worn and the nut was barely holding any torque when I removed it. I was so concerned about ever being able to fully retorque that axle that I made a special trip to a fellow forum members house to salvage axles out of his old Dodge rear axle. Turns out I worked around the problem by buying new axle nuts at a John Deere store and the sharp threads on those high-quality parts gripped the old axles enough to allow full torque to be applied. Whew! But I have a set of good axles on the shelf now in case the old threads pull during future maintenance. My suggestion-----If your rear brakes are working properly now you might want to postpone pulling the drums until later down the road after you have chased other maintenance items. But this is going to have to be addressed at some point.....

-

Installing a Spin-on Bypass Oil Filter (photos)

Sam Buchanan replied to Sam Buchanan's topic in P15-D24 Forum

If your filter is plumbed into the original bypass loop, are you using a bypass filter? If so, what small bypass filter did you find? -

I had great hopes for that vacuum bleeder but was never able to get it to work properly. Air may have been leaking past the threads of the bleeder valve, maybe teflon tape on the threads might have helped. I gave up on it and went with this pressure bleeder: https://www.amazon.com/gp/product/B00O6FZJFG/ref=ppx_yo_dt_b_asin_title_o07_s00?ie=UTF8&psc=1 This device worked great and no air compressor is needed. I took a spare master cylinder cap and threaded a barbed fitting into it so the pressure hose could be connected to the master cylinder. All you need to do is put fluid in the pressure pot, pump it up, then go around to each wheel cylinder to bleed out bubbles. I bled the whole car by myself in ten minutes once everything was hooked up. This thing was worth every $$$$ I spent on it.

-

If the motor needs rebuilding I know a good video that'll show you how to do it. ?

-

Some folks are taking this video waaay too seriously. The guy admitted he is no mechanic and I don't think any reasonable person would consider this video as a step-by-step guide on how to rebuild a flattie. This is just a guy showing how be brought a junk engine back to life in his backyard with common hand tools any handi-person would have. If you check out his channel you will see more rescues of junk, he isn't trying to be Wayne Carini. ? I found it hilarious in spots and wish him great success in rebuilding his junk finds. Here is the very entertaining video where he drags the old Plymouth home: https://www.youtube.com/watch?v=IzP2bYAwwNE&t=6s By the way, the guy is a fireman. Here he is showing his little boy how to tear down a wall in his old garage: https://www.youtube.com/watch?v=cL1vxWGTy-4

-

Now wait a minute....who said he did it wrong...besides you? If the engine runs well and he is able to put his '48 on the road reliably and enjoy it with minimal cost then there is nothing wrong with the way he repaired the engine. Matter of fact, for his particular situation...I'd say he did it right!

-

I suspect the overhaul in the video (which I got a kick out of watching) is a fair representation of how thousands of these engines were rebuilt back in the day (by people without internet training ? ). Due to them being over-engineered and under-stressed, those engines no doubt transported countless families for many years. If you want to see amazing repairs done on a blacksmith level, check out this YouTube channel: https://www.youtube.com/channel/UC64FbxoHfUWd5hykYk5_BvQ

-

My First Car -- P15 1947 Plymouth Deluxe

Sam Buchanan replied to NickPickToo's topic in P15-D24 Forum

Nick, the headlight switch fuse is a SFE 30a which is 1/4" x 1 7/16". This is longer than the more common AGC fuses. I bought a box of them at the local Napa store. -

Maybe the battery cables aren't large enough.....

-

Sounds like a plan. ?

-

Here is the info you need for adjusting body gaps: http://www.imperialclub.com/Repair/Lit/Master/025/cover.htm As mentioned earlier, the Mopar engineers did an amazing job designing superb airflow through the cabins of their cars. The air movement is far better than modern vehicles which weren't designed to be driven with open windows. Hoping your brother-in-law will be able to enjoy this car with you in years to come.

-

I understood this question to be in regard to whether or not the life of the electric pump would be shortened by intermittent use. I don't know for certain....but I doubt it. I can tell you that on my aircraft the Facet electric diaphragm pump that is only used for takeoffs and landings as a backup to the mechanical pump is still working fine after twenty-one years in service. The full-time mechanical pump has been replaced twice. ?

-

My P15 has no momentary switches, bypass lines, pressure regulators or gauges, or antique mechanical pump leaks. The fuel system is one place where additional complexity is not a good thing. ? I do agree the Carter rotary pump can make a little noise. Here is how I soft-mounted mine so the only time I hear it is when I first turn on the ignition...the sound tells me the pump is running. After engine start I no longer notice it.

-

My First Car -- P15 1947 Plymouth Deluxe

Sam Buchanan replied to NickPickToo's topic in P15-D24 Forum

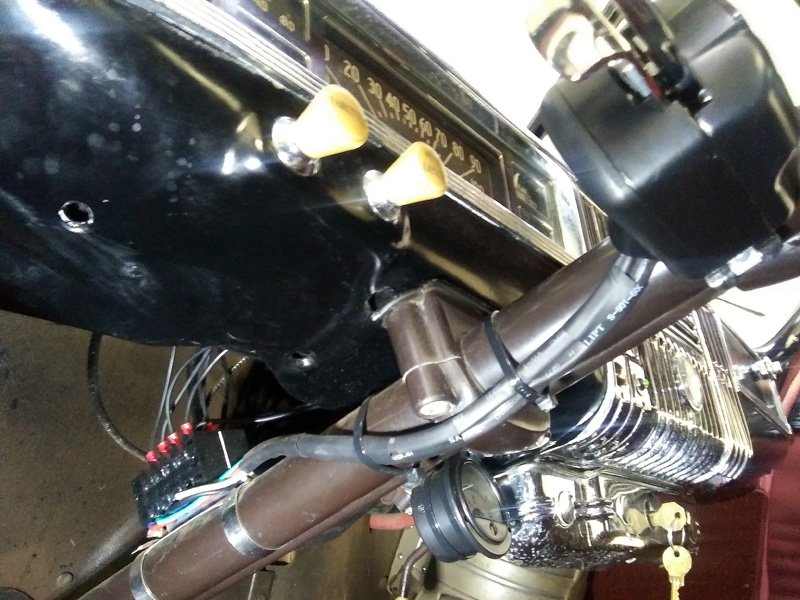

Nick, it can go quite a bit higher than that and still cohabitate with the shifter. Look at my installation again: -

I recently had to replace the thermostat on the P15, it was stuck open. Car would only get to about 120*F on a cool fall day and the engine wasn't happy. Installed a 160*F thermostat and now the old car runs at indicated 160-165* and purrs like a kitten. Keeping the thermostat in place while lining up the radiator and bypass hoses was sorta a pain. Just kept fiddlin' with it until it all fell into place. If I'd thought about the rubber band trick that might have simplified things a bit, I'll use it when I replace the new thermostat in thirty years or so.... ?