-

Posts

1,612 -

Joined

-

Last visited

-

Days Won

13

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Bryan

-

Like your DIY system better..

-

Just a matter of how to go about it. I'm not impressed with the Power Wagon $85 system. Fitting out of round and loose..PCV valve doesn't seal completely one way, smart aleck sales guy. The special fitting hole is the same as a freeze plug..one could almost have threaded a hose fitting in a plug and tapped it into the hole with a little sealant on it.

-

Need some pics of original type interiors for 46-48 DeSoto

Bryan replied to MarcDeSoto's topic in P15-D24 Forum

None of the samples I've seen so far looked liked Junker's original. Brown stripe, 3 light gray stripes, brown stripe. -

Yeah, I think I'm in that category.. ?. Don't have a compressor, but I did give those 2 bolts several raps, at several different times with a hammer, alternating with heating with a Map gas torch (heating the bolt, sometimes the block where the bolt is), etc. Burnt the carbon out of the ports. Was using a torque wrench and wasn't exceeding a 100 ft/lbs. What got me is I thought the bolt was moving. I would tighten/loosen and saw it was moving about an 1/8" each way. Guess it was just flexing. I stayed rather calm afterwards, was just disappointing because thought I was taking enough care. Now a back & forth whether I should leave them for the shop or try myself..If a machine shop doesn't charge much I'll leave them..these days with prices I don't know.

-

-

Well, ordered a set of battery cables plus a 4AWG 36" cable I'll run from the battery ground to near the headlight terminal. I measured my old cables' copper diameter..was getting between .34 and .36 inch at the same point, but 90 degrees difference. Must be a little out of round. Looks like they were all 00.

-

I just tipped the glass up and drank to take care of the last three ales I had..?

-

Happy Thanksgiving and Happy Birthday month! My wife's birthday is today and anniversary in a few days.

-

Tech Tip 127: Chrysler industrial engine identification (foleyengines.com) not much info Industrial engine ID help - Dodge Trucks - Antique Automobile Club of America - Discussion Forums (aaca.org)

-

When my exhaust manifold cracked in half, I had put very little pressure on it with a fence stake behind it on both ends. Just wagging both ends alternately, not hard, and it cracked.

-

I thought there is a danger of cast iron cracking if it cools too fast. Brother was telling me that about old wood stoves.

-

Now I should probably ask, how many tried to drill it out and broke the bit off in it? Only did that in the late 70s on a Camaro. Probably will leave these for the machine shop. ?

-

Yeah, did that too, with tapping, heating, oil, tapping, still broke. How much does a machine shop charge these days to remove a bolt?

-

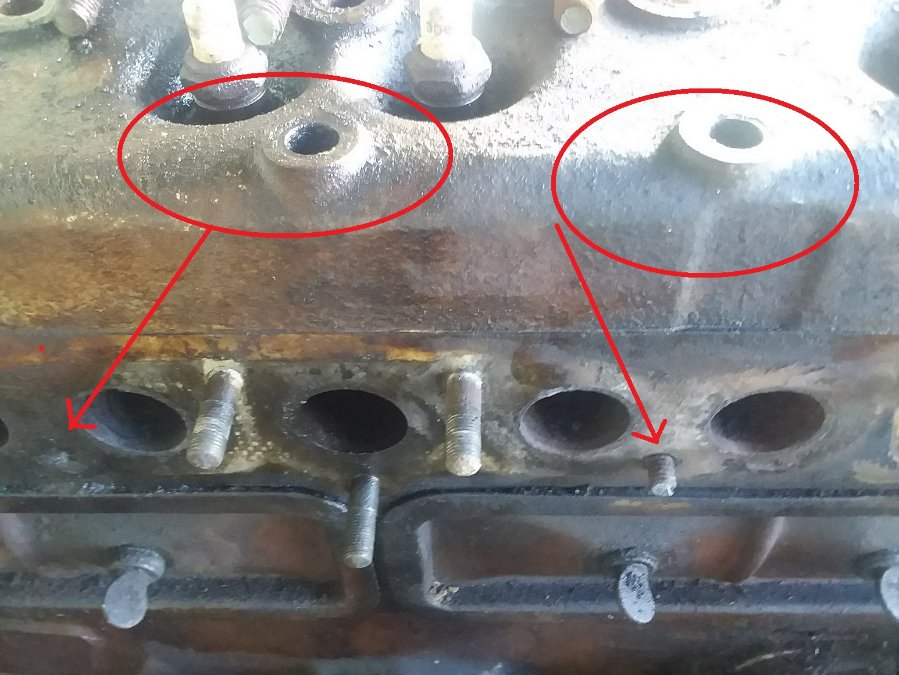

Okay: I managed to break 2 today. Was wondering, how many head bolts did YOU break off taking the original head off of your flathead? Don't include taking a head off of a recent rebuild. Bryan - 2

-

Well, reckon it turned out somewhat okay. Was hoping to get all the head bolts out without popping any. Managed to break 2. Thought they were moving a little back and forth, just popped. Same area as the manifold bolts I had problems with. We need to do a survey to see how many people have removed a head without breaking a bolt.

-

On lunch break to get warm. Decided to loosen the head bolts while I have it in the car. Imagine trying to do it on a rollable motor stand. All but 3 loosened. Using a torque wrench and not exerting more than 100 ft/lbs on it. Using oil, my Map torch, regular hammer to tap the heads. When I get one slightly loose, I tighten it back up to take tension off the adjacent bolt. Dang, when they pop it scares the crap out of me. Glad on videos people say that is normal.

-

It didn't post as a link, just text.

-

Like I said, if it's one cylinder where the spark plug is different (color, tip, deposits) than the others and especially if it's near the leaking bolt, then probably the head gasket for the smoke. If you had to pull the head (cheap if you don't break a head bolt, or screw the temperature sensor up) that's time intensive but just the cost of a gasket. Still haven't gotten my bolts loose. Solving the knock...that's harder..but if you have to pull the head, and had the oil pan off to clean it out, you're not too far from pulling pistons out (if there's not a ridge) and checking bearings...it grows into mission creep (expansion). That could eat into a lot of evenings. I don't know how long a bearing can knock before it damages the crank or rod bearing. Some of the more experienced guys might know. But you can't keep running it and let it knock.

-

Didn't really plan for retirement..knew it was time to relax some. Was overseas (1984 - 2014) mostly managing construction projects in Israel and Korea. I stay busy with projects but hard to complete some of them. Step-son's problems keep popping up. He's a good kid but keeps getting into issues with others distracting him..not bad things just time consuming. Wife and I were planning to travel more..got her son's problems straightened out, my step mother had health issues where we had to help out..now it's Covid. Sometimes I just want to drive and see the USA.. But even hanging around here sure beats arguing with Contractors and listening to Israelis screaming at each other in meetings.

-

Put my motor stand together today. Not much space to work. Took thermostat cover off to look, no thermostat. Tried heating and loosening a few head bolts, they didn't budge. Had 2 wrenches interlocked and flexing them, no go. Sprayed some more penetrating oil at the bolt bases from the thermostat opening.

-

All I would know is penetrating oil and tapping it LIGHTLY back and forth with a hammer. If there was any slight gap between the pieces maybe tapping a paint scraper blade after oiling. Be careful, I'm the one that has 2 broke off manifold bolts.

-

Somethings with the first plug to the left...electrode tip is not light tan like the others. Might not be firing completely. Most have a lot of carbon or soot on the base ring. Are you using normal unleaded gas? With pictures try to have the light source shining into the tip, not from the side at an angle. https://sites.google.com/site/kensautomachineshop/technical-information/articles-and-tips/tips---reading-spark-plugs

-

Hard to tell from the picture and the angle they are at. 2 middle ones look good. Need to see the tips and insulators with a good pic. Second one from right looks oily wet on outside, but hard to tell inside.

-

You don't "burn" sludge out. Not knowing what type of oil was in it before should have started and stuck with non detergent oil. Don't know what the 15W-40 is. That's how I started my engine to knocking in the mid 90s. Listening to "Flush it with kerosene then change the oil a few times". Sounded like yours. As LazyK said best thing to do is pull the oil pan and clean it thoroughly. I wouldn't keep running it until then. The smoking is probably from worn/rusted rings. Even if rebuilt, if it sat a long time it could have affected the rings. Do the easiest thing..CHECK THE SPARK PLUGS. If it's a head gasket, it will show up on one spark plug. If it's the rings generally all of the plugs will show deposits.