-

Posts

1,612 -

Joined

-

Last visited

-

Days Won

13

Everything posted by Bryan

-

Absolutely nothing out there. British (Lucas) has a set standard.

-

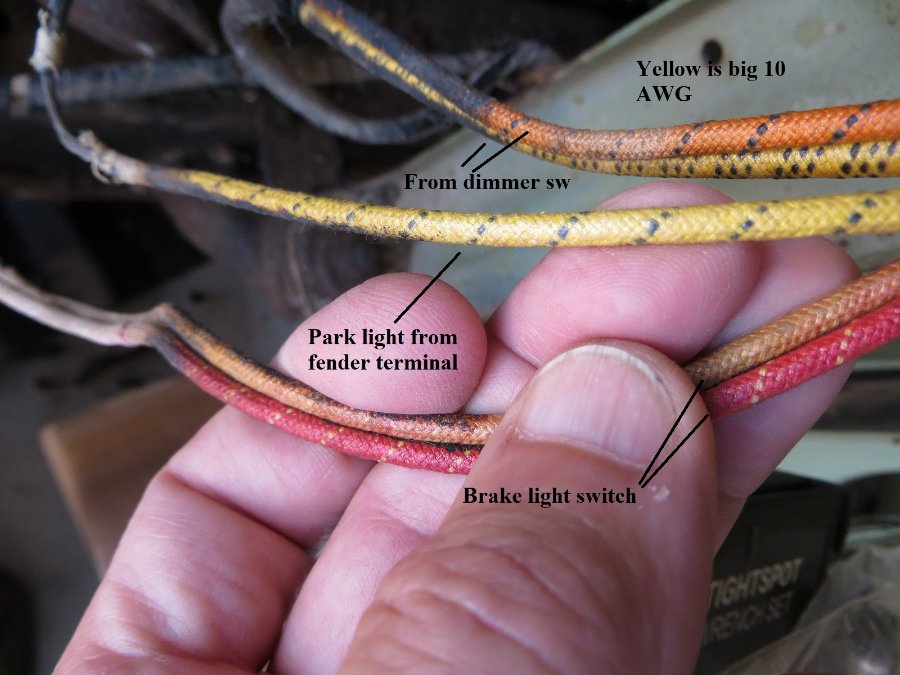

I'll try to look again. Did before and couldn't find a site that explained a standard. Looking at a P19 P20 schematic and my pictures of existing wires the horn wire is 10AWG green (has 3 tracers). Headlight red is 12 AWG (2 tracers), the yellow park light is 16AWG (1tracer). Black to headlight supposed to be 14AWG and has 1, black from terminal has 2 (might be 12AWG).

-

48 Chrysler axle shims and end play not making sense ???

Bryan replied to harmony's topic in P15-D24 Forum

-

Yep..

-

Eventually when I get this engine out, I'm planning to have it cleaned and magnafluxed, and broken bolts removed if block and head are okay. I'll probably do some quick inspection at the place, pick it up and take it back to my shop to inspect more thoroughly. Then have the machine work done. Questions: 1. What type of different block cleaning methods are out there, and what are the best? I know acid removes mineral deposits and rust. Bleach removes organic. Seen high temperature cooking. 2. How much would they cost? 3. I know to remove crank, pistons, valves, freeze plugs, oil galley plugs, distribution tube, etc. Anything else not so obvious that I should do for prep work?

-

Need some pics of original type interiors for 46-48 DeSoto

Bryan replied to MarcDeSoto's topic in P15-D24 Forum

The top sample.. -

Still not sure. The correct term is tracer. Have not seen a specific chart guide or industry standard. Might have just varied by manufacturers. All I'm trying to do is somewhat match what I have, but it won't be exact.

-

Not quite sure but I think the bigger the wire the more parallel dashes it has. Let me look.

-

From what I remember from my 71 Camaro it was a system like in the picture (but a V8). For our flat 6 engines you would think a good filter on the breather cap next to the dip stick would do the trick. We don't have overhead valve covers..

-

The little colored dashes on top of a different color of wire.

-

A engine rebuild theoretical discussion...Piston Sealing

Bryan replied to James_Douglas's topic in P15-D24 Forum

? ? You're going to have me do a Sanford "Elizabeth, this is the big one"... -

I measured the copper on my battery cable and it was .34-.36 inches diameter. A little squashed so not perfectly round. Think charts on internet showed this was 00 cable so that's what I ordered last week. Sam B - mine were $62 but I got the extreme insulation and ordered a 4AWG ground for near the front fender terminal to attach separate headlight ground.

-

I haven't done it for a while, but am I correct that a PCV valve should act almost like a check valve? Sucking on one end closes it tight, sucking on other end flows free? The one from VPW acts differently.

-

If Ton's on Ebay would reverse the direction of their tracers theirs would be more like the original. Dashes on the RIW are longer. Heck, if I was really trying to fool a judge..I'd take the unfaded good original wires that were well wrapped and splice them on the ends of modern PVC wiring with wraps covering the PVC wire..

-

Been on the road most of the day visiting step son. Came back and my wires from Rhode I wiring were in. Look good to me. Yellow for park light, got a brown and a green for turn signal wires. 12 AWG black for headlight, already had a 10 AWG red wire from Ton's on Ebay, going to use 12 AWG gray for separate ground. 10 AWG green horn wire. Only difference in the Ton's wire is that the tracers are in the wrong direction. Braided same quality. Last four pics are original wires. Still need to buy some 5ft lengths of solid colors from Ton's.

-

A engine rebuild theoretical discussion...Piston Sealing

Bryan replied to James_Douglas's topic in P15-D24 Forum

Bet these aren't any $200 a bore...? -

A engine rebuild theoretical discussion...Piston Sealing

Bryan replied to James_Douglas's topic in P15-D24 Forum

Automotive Engine Performance Coatings and Treatments • Muscle Car DIY end of article....2016 prices Nikasil, on the other hand, is very consistent for thickness and hardness uniformity. Because Nikasil allows tighter clearances and its oil retention is much higher, you can get away with creating a smoother finish. Typical Nikasil cylinder finishes are in the Ra range of6 to10. Rings It’s absolutely critical to use the correct type of rings in conjunction with Nikasil-coated cylinders. The top ring is typically moly or PVD; the second ring is ductile iron. Chrome rings cannot be used (including oil control rails) because chrome and Nikasil react to each other and result in scuffing. So just run plasmamoly top rings, ductile-iron second rings, and unplated oil rails. Ring seating occurs very quickly. Nikasil and other cylinder coatings are applied to aluminum or iron walls (on parent bores or on liners). Typically, the coating is about .008 inch and can be sprayed on between .012 and .015 inch thick. This type of coating visually appears to be chrome, very shiny and difficult to scratch. In order to touch up Nikasil in order to re-ring, a 150-grit aluminum-oxide stone usually suffices, just to clean and remove any high points. However, if you find excessive wear or if new sleeves are to be installed, finishing requires a 500-grit diamond stone. Cost For a four-cylinder block, cost could typically be around $750 for coating the metal bores, or $200 per liner if you need sleeves. Coated liners for an eight-cylinder block may run about $1,600. -

A engine rebuild theoretical discussion...Piston Sealing

Bryan replied to James_Douglas's topic in P15-D24 Forum

Nikasil? Cylinder Bore Surfaces- Kevin Cameron Insights | Cycle World "In two-stroke motorcycle racing, chrome-plated cylinder bores gave way in the 1980s to Mahle’s Nikasil, which is a layer of electroless nickel containing 5-percent super-hard silicon carbide particles. When diamond honed, this produced an oil-retaining textured surface that was extremely resistant to wear." "Guest 11 February, 2016 You don't hone or bore Nikasil. You send the cylinders to any number of companies here in the US, they remove the "old" Nikasil with an acid bath, then simply replate it with a fresh Nikasil coating. Cost is around $200." -

-

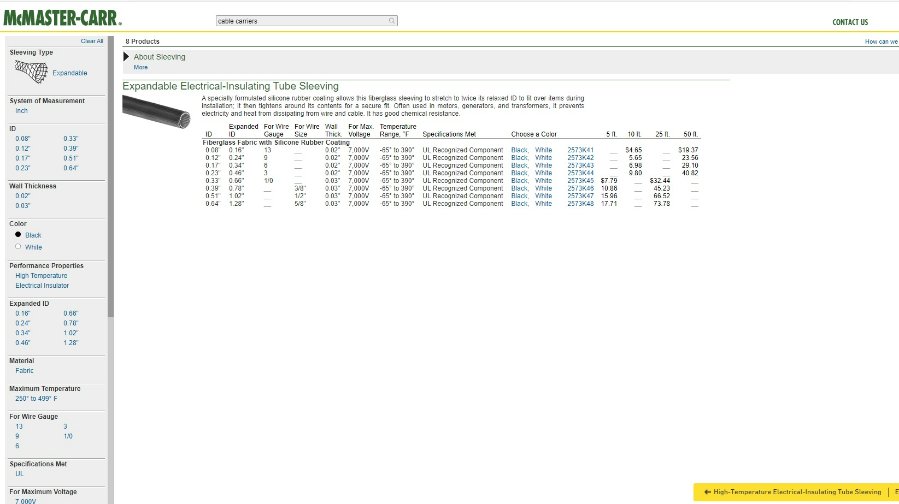

I found that McMaster-Carr has a lot of good cable sheaths, but you would never know it. They have even the smallest under "cable carriers". Go to the lower part of the page on this link. extension cords | McMaster-Carr This says extension cords but its the link for cable carriers & sheathing.

-

Bought cloth covered tracer marked wiring to redo my rotten wires. Still torn between trying to make it as original as possible and using better materials. One thing is the sheathing..each park light, head light and horn wire group had some kind of rubber tubing that was bound to the wires. Not shrink tubing..almost like rubber hose but tight. The run from the fender terminal towards the firewall had the horn, park and head lights combined in one bundle, then the park light split off to the firewall, the horn to the horn relay, and the headlights to the dimmer switch. This was only wrapped with electrical tape. I'm thinking about adding 2 more colored park wires for the turn signals, and making 3 separate runs (horn, park & headlights) each in its own rubber tubing/corrugated tubing/ shrink wrap (one of these). I like corrugated split tubing, but it also comes sealed without the split. Like it but it doesn't look original. Shrink tubing would look original, but isn't as thick and durable, and once it's on you can't get it off or get the wires out. Rubber tubes (like heater hose) - you'd have a time pushing the wire thru if it was not oversized..and I don't think rubber (new Chinese crap) would last very long. Does anyone know of different sheathings other than what I've mentioned?

-

A engine rebuild theoretical discussion...Piston Sealing

Bryan replied to James_Douglas's topic in P15-D24 Forum

A little over my head.. Piston Motion: The Obvious and not-so-Obvious, by EPI, Inc. (epi-eng.com) " From that it is clear that piston acceleration is important because many of the significant forces exerted on the pistons, wristpins, connecting rods, crankshaft, bearings, and block are directly related to piston acceleration. Piston acceleration is also the main source of external vibration produced by an engine. (Torsional vibration is discussed separately on another page.)" "Contemporary piston engines tend to have R / S ratios in an approximate range of 1.5 to 2.0. Note that a rod / stroke ratio less than 1.3 is, for practical applications, not possible due to physical constraints such as the need for piston rings and a wristpin, sufficient piston skirt length, and the inconvenience of having the piston contact the crankshaft counterweight, not to mention the excessive side load such a small ratio would produce." -

A engine rebuild theoretical discussion...Piston Sealing

Bryan replied to James_Douglas's topic in P15-D24 Forum

Page 2 was interesting. Stroker Motors Basics and Theory - FordMuscle -

A engine rebuild theoretical discussion...Piston Sealing

Bryan replied to James_Douglas's topic in P15-D24 Forum

Dang...y'all going to make me have to study. One would think at the top of the piston, rings would be the major point of contact. I'd have to check. I know the piston skirts and lower sides definitely contact the cylinders. With metals, the harder metal always wears the softer metal. A lower contact area rubbing on a surface with the same force behind it wears more than the same force spread over a larger area. Lubrication would be critical..I won't say the Synful oil word.