-

Posts

4,986 -

Joined

-

Last visited

-

Days Won

43

Everything posted by Los_Control

-

Sitting here eating some left over pizza for lunch and saw this thread. By golly it is getting dark out there. I put on my welding helmet and went out and looked around. ..... Currently the sun only has 1/4 showing as the moon is covering it .... Radio says 10 more minute and will be totally covered. Make that Z fly!

-

Getting the truck ready to drag home

Los_Control replied to Bobacuda's topic in Mopar Flathead Truck Forum

Must be a Texas thing .... My truck had a female plug coming out by the rear bumper. Good heavy wiring going to it. The only scenario I can dream up, The owner was a night watchman at a construction company. I guess in his free time he would go night fishing. Sit on the tailgate and plug in a automobile head light and shine it over the water to attract fish .... I've heard light attracts fish ... I've never done it myself though. Same time I guess a guy could use a extension cord rigged to a head light and use it for a work light. ...... These were common articles a farmer might have laying around and easy to put together and make useful. ..... A good quality flashlight back then had big bulky batteries and were probably expensive while a old car headlight bulb was probably free in the back pasture. -

Getting the truck ready to drag home

Los_Control replied to Bobacuda's topic in Mopar Flathead Truck Forum

Here is the reply I got back from Erick Bannerman when I shared your casting # by the dipstick. that's a 1953 23" long 217.8ci (218) engine. Probably originally from a Plymouth car or maybe a factory replacement engine. Several are suggesting that it was A factory replacement engine that was shipped without a stamped number. Any used engine that was rebuilt was already stamped at one time or another. OTOH, I have heard of people grinding off the stamped # and re-stamping it for their own needs ...... not all of them went to jail for doing so I think there may be a really good chance when you get to the engine, it was a new replacement engine and not a rebuilt engine. Who knows how many miles were put on it after it was installed ...... It might be in pretty decent shape yet with original bores & crank ??? Is the motor stuck? Or does it spin like a pinwheel using your little pinky finger? -

Anyone come here from FaceBook recommendation?

Los_Control replied to Eneto-55's topic in Off Topic (OT)

Same. -

Getting the truck ready to drag home

Los_Control replied to Bobacuda's topic in Mopar Flathead Truck Forum

No Idea what you are using to take photos with ..... I use a android phone. The factory settings on the phone is always set to the highest resolution for the best results. I usually just go into my phone settings and reduce the resolution there .... usually is 3 or 4 different choices. ..... Your changes stay and now will not need to resize them on the computer. For me it is just simpler to change the settings on the camera then to have to resize each photo. Did you get it home? -

Getting the truck ready to drag home

Los_Control replied to Bobacuda's topic in Mopar Flathead Truck Forum

I just wish you good luck getting the brakes freed up .... I was lucky and mine was rolling and delivered to my driveway. I do have a old Flathead Ford motor here though, to get the clutch off of the flywheel/pressure plate I literally had use a thin drywall putty knife and a hammer to drive it and separate them. .... No big deal when the motor is sitting on the garage floor exposed. Just thinking about a brake shoe stuck to the drum of a tapered axle truck .... I hope it comes off easier then my clutch because you do not have the thin putty knife option available. -

Getting the truck ready to drag home

Los_Control replied to Bobacuda's topic in Mopar Flathead Truck Forum

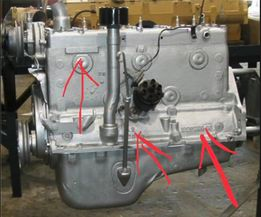

This is the reply I was waiting for, Erick Bannerman has been collecting this info for years .... If you can post these numbers, with his records he can probably tell you exactly what you have. it is clearly an added stamp. Two questions, one what country are you in? Two, can you share pictures of the casting numbers shown by the lower two arrows in the attached image. The very first post back, in under 2 minute. It is the invoice number from the shop that rebuilt the engine ..... With that number they can look up any needed information for warranty work .... Just a WAG, but makes sense to me. -

Getting the truck ready to drag home

Los_Control replied to Bobacuda's topic in Mopar Flathead Truck Forum

You are correct in how they stamped it ..... Hard to say what their intention was though. The way I understand it, you could buy rebuilt engines from many places .... JC Whitney, Western auto .... your local gas station, Sears .... They could come with the number removed and you stamped your own number on it. Very plausible thats what they did. All I can say, they stamped a number on it ..... It does not match any of the known numbers from the website posted above. I have been told that Dodge trucks were known known to install leftover engines at the end of the year to clear the shelf for current production. What I mean is, my Uncle had a truck with a engine number starting with a P .... most likely a used Plymouth engine swapped into it. He claims that it could have come from the factory like that, Dodge wanted to use all the old last year engines up to get ready for the next year models ..... No idea if that is true. So I went and looked at the other numbers from Plymouth, Chrysler, Trucks ..... That number is obviously a decent attempt at a amateur stamping job and the number matches nothing I've ever seen ..... I then went to Facebook and made a post if anyone else can figure it out .... There is a guy there that is pretty sharp and been collecting/cataloging these engine numbers for years .... be curious if he can make anything out of it ..... I kinda suspect someone was bored and stamped some gibberish on it and was thinking ..... This will make them work hard figuring this out ..... rolling over in his grave now laughing. If you follow FB, here is the post. https://www.facebook.com/groups/194200864347464 -

Hey look, I got drug into the thread just like you did ..... not sure who did it .... looks like the culprit edited and removed their post. ..... I'm just saying the old post got revived, I was a bit confused .... as I was tagged in it. I have 100% respect for everyone in the thread ..... and in 2024 my opinion has not changed. GO SOLAR ECLIPSE! It will be Monday.

-

Sometimes us old men sit around and gossip more then the old women .... 🤣🤣🤣

-

In my experience living vicariously through my Uncle that had 2 acres of cars .... broken windows can occur in Hot weather. In Eastern Washington where the summers often reach over 100 degrees in the summer ...... One day I told him that the passenger door window in a car had shattered. Forget the year but was the 64 Mercury? That had the rear window that rolls up and down. Anyways he explained that the electrical system was not working and he could not lower the windows to allow air to circulate. The heat builds up so high in the enclosed vehicle that it will crack the glass. He had saw it a few times over the years. Trust me, Uncle was a True grumpy man that did not want anyone on his property because they would steal or break windows etc ..... He never thought for a instant that the broken window was not simply heat generated in the car that broke the window. .... 85 years old he did the best he could, he was just glad it was a door window easily replaceable compared to a windshield. There is a reason why I suggested rolling down the windows .... A few inches to allow airflow will work ...... If you are in a cool climate it may not be needed.

-

I admit I may have been a little rude or direct there .... I mean no harm by it, just the way I am. It is the old 6V VRS 12V question and to each their own. Your hamburger, fix it the way you want it. Your gas tank analogy, I feel you improved your vehicle. My new tank the metal has been given some rust protection, it is setup for a electric fuel pump if I choose to add one inside the tank .... I should check to see if they have one for carburated vehicles? ..... I spent my money and I improved my vehicle. I got value for my money. I know of many reasons to stay 6V ..... Lets drag @keithb7 into it Keith Is a teacher or instructor, He is very good at it. His videos are top notch and I feel that he loves or enjoys what he is doing. He says he enjoys explaining how things work to the younger generation at local car shows. He drives his cars everywhere and he is going to stay 6V generator. I'm just not that guy, if I go to a car show will park in the parking lot and look at others work, and chat for a little while then head home. .... I went 12V alternator, My alternator on rockauto sells for $38 I can go to any auto parts store and and get a replacement. Again, I feel I spent my money, improved my electrical system and got value for my $$... So when it comes to 6V + ground alternators, It is just my personal opinion. It is a better way to deliver a inferior product ... Not good value for my $$. Honestly if I were a wise man, I would just keep my opinions too myself ..... sadly I'm not a wise man either

-

Getting the truck ready to drag home

Los_Control replied to Bobacuda's topic in Mopar Flathead Truck Forum

I think it is telling you it has been messed with or you read it wrong? ..... No idea Did you get a title with it?, what does that ID number say? In a normal world, if they stamped the rebuilt engine they would want to stamp it to match the title. I'm sure you are aware of this site here, https://www.t137.com/registry/help/otherengines/tengines.html The number you posted does not look correct to me. I suppose it would not be any issue here in TX if you have the title and put it in your name ..... but if were to sell it to someone out of state and has to go through a strict inspection ??? -

I feel more then I know .... The bad reputation that follows car covers, comes from past owners applying one on a vehicle stored outside then left to rot for 30 years. A lot of damage comes from sitting for 30 years ..... some you can tribute to the car cover ..... but without a cover it would have received different damage ..... Go figure which one is worse then the other. .... Too many variables IMHO to make a honest opinion. Being inside a metal building .... if there is a concrete floor and the current tires are junk .... let it sit. Always better to put it on blocks and get the tires, underside away from the floor allowing better airflow. I just can not think of one good reason why I would want to put a car cover on it .... paint is not worth saving, good airflow allows moisture to dry .... I would remove the plastic sheeting also ..... more harm then good. ..... I wonder what damage a nice thick layer of dust would cause? ...... I think as long as it is dry, it will protect the chrome more then hurt it. If it was me, I would set it up on blocks, roll down the windows ..... Possibly I might cover the seats if they are in good condition .... just cover with a blanket or such.

-

51 B3B build thread - after all these years

Los_Control replied to bkahler's topic in Mopar Flathead Truck Forum

Good luck getting it all sorted. I'm kinda sorta at the same point, getting everything lined up. Everything is all loose and can still be moved or adjusted. I was putting the bed together and realized I needed the running boards installed because they bolt to front & rear fenders. The bed I think is right because I centered it with the zirk fittings for the shackles .... But I can still wiggle it 1/2" in any direction ..... I'm just not going to tighten anything down until everything is installed and connected. I have not even started repairing or painting the rear fenders yet .... I put the truck on the back burner while I work on the wife car. ..... Maybe this summer will get to drive it. -

Maybe something like this will do all you want. This is Amazon,they sell from $30-$100 ..... I would think gravity fed would work pretty good. I see one model that offers choice of gravity or siphon for a few $$ more.Siphon you have a bigger container for media so not need to refill as often. Mine is really cheesy .... I picked it up at a local hardware store cheap ... wanted to play with it. It works ok just clumsy as I have it hooked up to a plastic 1 gallon jug ... need to hold the jug in one hand and spray with the other hand. ..... Now that I know it works, I would not mind spending a little more $$ and get a better one. I have to say that @Plymouthy Adams really did help and work with me on how to modify and control the air better with the big pot. No matter what I tried I could only walk away frustrated with it. ....little one is slower but it actually works with no frustration.

-

The problem with a sandblaster is to have enough air compressor to run it. If you are confident you have enough CFM to run a sandblaster ...... then make or model does not matter. You really need a commercial quality air compressor to run a sandblaster. It is straight air releasing sand to clean your project. There are several work around to make your sandblast pot usable .... IMHO all worthless ..... unless you have the big bad wammer jammer compressor to run it. I'm only suggesting that a sandblast pot is cheap, I have one in my back shed you can have. .... The issue is getting enough air to run it. I have tried several ways to tone down the air consumption .... some here have done a few things to actually make it workable .... I have a decent 2 stage compressor, just no way I can keep up and control sandblasting. ..... Just saying you need to look at the numbers on your air compressor and decide if it can run a sandblaster. I have 2 different versions of a hand held sandblaster my air compressor can run .... A actual sand pot takes more then I got.

-

WOW ..... Just WOW is all I got to say.

- 734 replies

-

Everybody has a opinion. ..... We are considered caretakers to these old cars. It is up to us on how good of a job we do. Some people are really good at keeping them exactly original and I love them for it. Some of us have connected a winch and drug them out of the grave. ..... This truck had a wrong used generator installed that does not work. The original wiring was non existent ..... This truck is a beater with a heater, A new 6V wiring harness requires heavy wire for more amps $$$ I would feel like a idiot to spend the money to put this back to original 6V .... When a 12V system is cheaper and superior. Same time if I owned a beautiful survivor, I would do everything I could to keep it original 6V ...... My truck is not that vehicle. Since I went with cheaper 12V, I'm going to get my CB radio, I want a decent stereo, I want to run the slant 6 electronic ignition. I want to try led lights .... I have a whole new world opened up to me. 12V is for me, it is not for everyone.

-

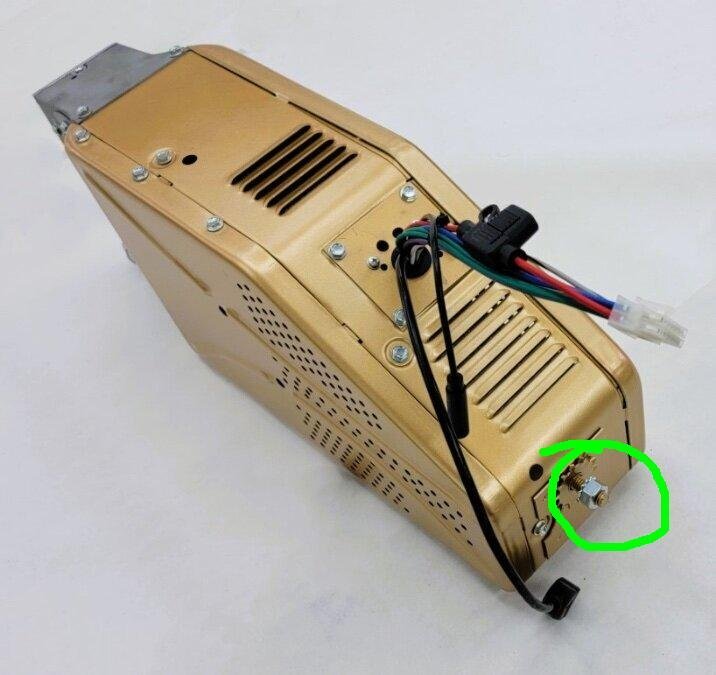

You are correct. The radio on these old trucks do need support. There is a short bracket that goes to the back of the radio and is hung on the cowl or body ...... Because the radio is so big, the support is really short. The radio is supported both front and rear. I had a radio and chose to pass it on to someone that would use it. I went 12 volt and will not pay to have the radio converted ..... It is too large and takes up valuable real estate under the dash ..... I'm only suggesting that the radio will fit, It is large and takes up more space then you think under the dash ..... I sold my radio as is because I did not want to install it. Same time I'm 12 volt and plan to install a radio in the center console .... just did not want the stock original radio hogging all the real estate under the dash.

-

I'm guessing it was around 1975 and living with my sister/BIL .... I was a bad kid and got kicked out of school, so went to live with them to continue school in a new district I was helping the brother inlaw convert some old hoopty over to 12 volt. I asked why? Car was not charging, A new generator was expensive the battery was weak and needed replaced .... It was a lot of $$ back then to maintain a 6V system. He could get a used 12V battery from the wrecking yard for $5, A used alternator, light bulbs .... everything needed for less then $50 at the wrecking yard. It literally was cheaper to convert the car rather then keep it 6V. Same thing today, it is cheaper .... Especially if I went to a wrecking yard and bought all common parts that are needed .... My price list is all new shipped to my door. I have far more advantages over a 6V system, it is cheaper to maintain, It just rocks my world to be 12V. If I wanted a 100 point show car trailer queen, 6V would be mandatory ..... A 49 Dodge truck that hauls dogs and firewood, 12V is perfect.

-

What charging system are you using? ..... In the past and even today it is cheaper and easier to just convert from 6V > 12V. I'm using a 12V 65 amp chebby alternator ... because I have reading comprehension issues .... cant read worth a crap! I wanted a single wire internally regulated but purchased a externally regulated .... so that added a extra item to wire in ... (regulator) All the light bulbs need to be changed, you will need a $12 voltage reducer for your fuel gauge, probably better off to buy a 12V heater blower motor. I would imagine the horn would work on 12 for awhile, unless it was worn out in the first place or they just layed on it and over heated it. You must live good to have electric wipers in a B1D .... My B1B has vacuum ..... again a $12 converter would fix that ...... I just do not understand the $75 buck converter or the Just kind of sounds like you got lost in the weeds on your conversion that you inherited when buying the truck. I figure I will have $300-$350 into a complete new 12V wiring system. I needed a new wiring harness. $75 for a basic 12 circuit from Amazon. $75 Alternator/regulator about $75 from rockauto. $75 I bought a 3 pack of the 12V > 6V converters from Amazon for $20 $20 All new bulbs including 2 new truck tail lights ... $50 $50 The different ends, extra wire, switches, flashers .... guessing $100 $100 So I already have $320 into it and just collecting parts ..... Someday I'm going to wire the truck! But I have everything for it .... And it is cheaper to go 12V then stay 6V ... IMHO

-

- 33 replies

-

- spitfire engine

- engine

-

(and 1 more)

Tagged with:

-

I have never used one before ...... They do appear to be New old stock by the faded colors and appearance of the package. There are many NOS packages on ebay so seems to be true. I have heard some have opinions of old condensers deteriorating from sitting on the shelf for decades. My opinion is that a used one that has been installed on a vehicle sitting in a field for decades, has a better chance of working then the off shore garbage sold today. Also the rub block on a NOS set of points would probably be better then the modern stuff sold today. For the $10 + shipping price I think they would be well worth trying. ...... Someone here mentioned Standard brand points, they are made in Mexico .... possibly better then China made ..... The rub block does look better. So thats what I'm running. I also bought the Standard condenser from the same seller ..... the condenser I got was from China and DOA. So I have a custom made condenser that a member on another forum makes and sells. They are maybe $65 .... I forget. Plus the price for the new set of points and rotor ..... $10 from ebay sounds pretty good to me.

-

That would be perfect if it was local ..... dealing with people on social media is a challenge. . There are a few local sellers advertising parts for these old rigs, they think they are worth a fortune and rely on them for proper retirement. Recently I was talking with a guy about buying a steel wheel off of a 1967 Dodge truck .... Ebay wants $80 + shipping for the wheel. So the guy tells me he will sell it for $75. .... I'm kinda ok with this, I want to set a time to pick it up .... then he tells me I have to go out to the field and remove it. So I spend $30 in gas to go pick it up, then remove it, it has a junk tire on it I will have to pay for removal & disposal .... Really is just cheaper if I went to Ebay and have one sent to me with no tire on it. People just do not understand, that there product sitting out in the field is not worth the same price as a Ebay seller that ships it to your door. Same seller that has the wheel also has some 40's-50's Dodges they are parting out ..... I feel like if I showed up and talked to them in person, possibly purchase a few other items at the same time ..... I could get a fair deal and make a friend. Today I talked to a guy, who has 12 wheels for sale. They are 15" 5 on 4.5" bolt pattern and asking $25 each .... only 2 of them are Dodge wheels with the 3 nubs for hub caps. He wants $25 each and his brother from 2 hours away is going my direction Sunday and will deliver them ..... I have offered to pay their gas for delivery Just saying I have dealt with some people on social media and they are just a joke. I agree to their price, I will come pick it up .... they wont share address will deliver .... then never hear from them again ..... Drugs are bad. ..... I'm not dealing with a stranger on craigslist 2000k miles away. $50 for a good wheel is awesome .... if they are willing to separate the wheel and ship it alone .... I have no desire to pay shipping for a column, steering box I have no use for.