-

Posts

4,986 -

Joined

-

Last visited

-

Days Won

43

Everything posted by Los_Control

-

Back when these cars were in daily service, it was common to have a mechanic at the local gas station do rings and valves. Simply drop the pan and pull the head and then do what work was needed with the engine still in the vehicle. I understand that you are too busy yourself to do the work ..... Here on facebook we have a mobile mechanic that is local. .... just a idea. If this is true, and the engine sat for a long time not being used, it is common also for the cast iron rings to stick to the aluminum pistons. Two dissimilar metals causing corrosion. The rings are a spring that expand against the cylinder wall to seal. They also need to freely rotate in the ring landings of the piston. Obviously if they are stuck to the piston they wont seal and will smoke like a freight train ..... Is possible you have just one offending piston/cylinder causing your problem. A compression test would tell you .... also looking at the spark plugs to see which ones are oil fouled would tell you something. Personally I would drop the pan and pull head ... you need to know if the cylinders have been bored in the pass to find out what size rings to order .... top of the pistons would be stamped with size .... no stamp then stock pistons ... in theory. I would want to measure the bores looking for taper just to know what condition they are in .... Hone the cylinders and slap it back together with new rings. Rings are fairly cheap, and if the cylinders are worn and need bored .... you will now know and can make a game plan from there. If the Gods are smiling on you all will be fine .... if not, I bet it will at least be better and not smoke as much and you will be able to drive it again while making a game plan. As far as bearings go, if you have good oil pressure the bearings are probably fine .... but inspect them for wear and replace if needed. Again if it was rebuilt and the crank was turned, the crank will be stamped to indicate proper bearing size. These engines are very forgiving, they do not have tight exact tolerances like modern engines .... No rocket scientist needed to work on one. Seems you should be able to find someone that can help. Machine shops are crazy, seems like they might be getting forced out by rules and regulations ..... there are very few left out there. I talked to one last week about a short block for my wife car. Is a fair price, no core needed they have the block in stock. Pay 1/2 down and takes 3 months to build it. And it is a 3.5 hour drive one way to pick it up ... closest shop I could find. There is a shop closer, but they only do specialty work for off road construction vehicles. And thinking they may add automotive down the road.

-

Yup we all a bunch of slackers ...... except that @ggdad1951 ..... he has way too much time on their hands.

-

Question on installing fuel sending unit.

Los_Control replied to Los_Control's topic in Mopar Flathead Truck Forum

@Veemoney let me ask you this ..... does your gas gauge wander really badly with no basket? I also think you are correct in the basket is there to keep the the float from jumping around too much. I also wonder how effective it is .... Will it really be worthwhile difference if the float is outside the basket? You do not have a basket. I also think a true baffle should reach across the tank stopping fuel from sloshing ..... not just a basket in the middle of the tank. So while I'm looking at it .... I'm tempted to say "thats cute" I really do not think it is effective .... Think I will sleep on it and tomorrow just bend the rod to get past the basket. I simply can not see any reason to keep something that will not work in the first place. -

Question on installing fuel sending unit.

Los_Control replied to Los_Control's topic in Mopar Flathead Truck Forum

Thanks Bob that's good advice to add a ground strap .... I really was not thinking about it. The tank is a aftermarket direct fit for a earlier Dodge 47 and down truck .... For a 49 they actually need a modified rear mounting bracket. So I have modified the rear bracket and actually posted a how to thread for others that wanted to do the same. I suppose I could call Tank's and ask what they suggest. ..... I bought the tank and sending unit 7 or 8 years ago. Just never installed yet. I think I proposed 2 different installation methods .... I'm thinking they want the float in the basket. I'm thinking I would prefer to leave it long and outside the basket. Just wonder what others think ...... I'm often known to be wrong. -

I'm really mentally challenged on this stuff. Looking inside my tank's gas tank straight down is a basket/baffle .... Instructions say to leave the float 1/8" off the floor. I only assume they want the float installed inside the baffle. Here is the float for the sending unit bought from Tanks same time tank was purchased. If I'm to get the float inside that small basket directly below the mounting point ... I will need to cut over 3/4 of the rod off the tail end so it will actually go through the mounting hole & fit in the basket. The photo is still a few inches too long. ..... once you cut it off it would be difficult to put back on. ..... So I'm skeptical. Same time if I leave it long and let it hang over the basket, it sits about 2"-3" above the floor because it is sitting on the edge of the basket. Honestly I would prefer the float above the floor a few inches just so when the gauge reads empty I still have a couple gallons reserve before running out. Butttt, if the float arm was sitting on the edge of the basket, the gauge would never read empty. Too correct this I would need to bend the rod to clear the basket at least 2 bends so it clears and the sending unit still bottoms out and the float is a couple inches off the floor. Pretty sure I'm overthinking this .... Should I just cut it short and stick it in the basket? Or bend it so it operates outside of the basket ? What you all think about this?

-

Very cool you tried though. I'm still skeptical about this year .... it has been unusually warm down south in TX .... 84 degrees today, just 2 days ago it was 25 degree when we woke up and went up to 35 in the afternoon. ..... Just not a normal weather pattern this year anywhere.

-

Very cool indeed, and it is probably a very rare vehicle with not many made or left. Sure is scary though looking at the amount of rust in the body, makes me wonder what the frame/undercarriage looks like? It is just metal and anything can be repaired if you have the time and energy. I wonder how much body panels from a 4 door sedan would interchange? I'm guessing none buy I dunno. Looking on the bright side, just think about what a incredible welder/fabricator you will be upon completion Looking forward to seeing more of it as you go.

-

Mine did not look terrible, I honed it out good. When installed I bled them and felt fine ..... then I pretended to do a panic stop and stomped on the pedal. Went straight to the floor. .... Question is, how many times had it been rebuilt and honed before I rebuilt it? I am not completely stock, I felt it was a good time to just upgrade to a two stage master .... instead of having my original master re-sleeved. If you want to stay stock I would vote for having yours professionally re-sleeved, and avoid the painful curse of modern offshore parts quality.

-

I think I walk a lonely path .... it is every day accepted practice to use under coating. I guess if I lived in a snow belt area where road salt was a common practice I would think of undercoating as a lesser of two evils. I also will not use the dynamat floor insulation and sound deadener ... I'm concerned about trapped air, condensation and creating the perfect habitat to create rust. I suppose if there was 100% contact and no chance of trapped air ... it would be safe and not cause perfect conditions for rust. .... there is no guarantee though. Same with undercoating ..... A possibility to create trapped air. Then there is future considerations of having to remove it for some sort of future maintenance. ..... Paint did a fine job for 75 years and will continue to use it. While I really would like to do the cab of my truck, ceiling and floor for insulation against heat and sound ..... imho, it is not in the best interest of my truck and will not apply undercoating or stick on insulation. Just my personal opinion and shared by nobody I know of. ...... You asked

-

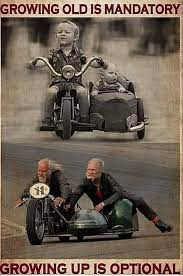

Observations upon reaching an advanced age

Los_Control replied to DonaldSmith's topic in Off Topic (OT)

I used to roller skate every weekend (almost) in the 70's .... I even belonged to speed skating team where other teams would race .... I can not imagine getting on skates today -

Observations upon reaching an advanced age

Los_Control replied to DonaldSmith's topic in Off Topic (OT)

-

I sure wish I never did that before I used free bed frames for the angle iron on the bedsides. They are attached and they are staying .... I just wish I knew how hard the steel was before I installed them. I burned through several drill bits, sharpen them many times and they are now 2" shorter .... I never did drill a hole in the metal. I figure I need at least 4 holes in each side to mount to the wood ... factory had 7 holes. The only way I was finally able to drill holes in them is using my mini die grinder with a pointed carbide bit. Good metal to weld with, terrible metal to work with .... They make great braces .... just as long as you do not need holes it is good metal.

-

Jeep XJ master cylinder pushrod?

Los_Control replied to gtech636p's topic in Mopar Flathead Truck Forum

I shortened mine .... at least 1" .... I did sneak up on it and cut 1/2" .... then a 1/4" until I got it to where I could insert it as needed. I also made sure the rod was adjusted as short as I could get it. Then on the bench grinder I rounded it down to a nice soft ball. Now with the end rounded, it fit into the MC and now was about 1/4" too short .... and could easily adjust that with the rod adjustment. It fit perfect Then I installed the toe boards for the first time, realized by asking here .... the toe board actually pushes the pedal down some more and the rod was too long .... so I got to do it all over again. Just make sure you have the toe boards in place when making the modifications. You do not want a sharp pointed edge on the rod, you need to round it off and soften it so you do not drill a hole in your MC. But it doe need to be ground down to fit into the pocket. -

Kinda sounds like a vacuum leak .... sucking in extra air, .... so closing the choke equals it out? Spraying some carb cleaner around the carburetor base, throttle shafts etc would give you a hint if you have a leak ..... Also do you have vacuum windshield wipers? A leaky hose from the manifold to the wiper motor could be a problem. I have the Carter carburetor .... It uses 2 ball bearings to control the idle circuit iirc .... they are different sizes and easy to mix up .... no idea what the stromberg uses, never worked on them. These motors when working properly are very quiet and boring .... air sucking sounds is a real clue and needs to be addressed. My bad for confusing the down draft terminology, just never thought of a standard carburetor as a down draft before. Was thinking of a updraft.

-

Looks at @Eneto-55 accusingly and wonders if they did the welding on my rear fenders ??? Years ago before mig welders came out to the average user, thats just the way it was done .... My truck rear fenders have a few repairs done that way in the past. I need to go over those past repairs before paint. Last I checked, ..... I paid $750 for my 190 MP welder .... was on sale from $1300 as it was a display model. ..... $500 more for the tig hoses & foot control pedal for the wire. It is more welder then I need, .... same time buying gas bottles and filling them I have around $500 into that over a couple years. ..... I'm pretty happy doing flux welding and not have to mess with gas If I can get away with it. Amazing how often a guy will use the welder if they have it available .... Once my truck is finished I wonder how often I will continue to use it.

-

I'm still a little dazed and confused ..... down draft stromberg carb on a 1951 pilothouse? As @Robert Harrison stated, when you richen the fuel by closing off the air .... you have a carb issue. ..... Typically I would direct you to the clogged idle circuit of your carburetor. I know nothing of down draft carburetors, and if your 1951 pilothouse has them ..... this is a self inflicted wound.

-

I gave the exact same advice a couple years ago. A: Tig is the cats meow especially with automotive sheet metal .... even more so with modern vehicles and the thinner metals used. Amazing to watch a youtube video of a dude tig welding aluminum beer cans together and end up with a beautiful weld. B: Dont mess with fluxcore welders for sheet metal ... get a mig welder. Then I spent a couple years with my 220/110 multi process welder. Is capable of tig, mig, fluxcore, stick welding. I have never bought the equipment to tig weld with it and never tried stick ..... I only have welded mig & fluxcore. Mig is a really nice clean weld, if I did a lot of welding I would only use mig. Fluxcore just leaves a brown soot over the weld & creates little tiny BB's and the weld looks disgusting. I use a 4" grinder with a wire brush cup wheel on it, ..... 2 seconds running it over your weld and it is clean and is a decent weld. Just saying, when I did fluxcore welding on my truck I could do the new floor because it would be all seam sealed & covered, nobody will see it. I also used fluxcore to do the body patch in the back of the cab, when finished and with the bed installed .... nobody will ever see it. I did have a 1/2 bottle of gas I saved to mig weld the patches on the front fenders, no way to hide them ..... IMHO it was just too much trouble to switch the welder over to gas and just did them with fluxcore and very pleased with the final product. I think the main point I wanted to make, I think fluxcore is fine for the home hobbyist that does not weld for a living. I think the quality of the welder giving you control for heat & wire speed is crucial. The cheap Harbor freight fluxcore gives you low/med/high settings ... you just work around those settings. While a better machine will have dials that you can dial it in and set it for exactly what you want. ..... Still a dirty weld and a extra step to clean it .... but a good weld. Dealing with gas bottles is a extra step and expense also .... I have $200 tied up in my used bottle, that now needs to be re-certified. Think it is just under $100 last time I filled it .... Is a week turn around for me to drop it off and send it out to be filled then pick it up the next week. I think if a guy spends a little bit more for a multi process welder, you will have all the options available and find you can dial in and fluxcore sheet metal fine and not mess with gas bottles. ...... My experience spending 3 years teaching myself to weld.

-

The only advantage of the Ford V8 is they sound awesome. ..... I had one when I was in school so brings back memories for me. What DJ stated is all true, plus they tend to run hot and many fight overheating issues ..... which can be solved. Seems they all have cracks from casting. Not uncommon to go through 10 blocks and only find 1 worth building. Some cracks can be repaired, many are fatal. There are many speed parts available for them all cost a arm and a leg. Also depends what year the engine is. I would only mess with the later 8BA (48-53) The older ones can have strange bell housing not sure which years ....8BA trucks had the most popular bell housing for transmission swaps. Also the 8BA has a normal distributor, early models had various distributors on the front of the timing cover .... real pita to work with. The only reason why I would consider putting mine into my truck Is it is a low mile engine. Farmer must have over revved it and spun a bearing, the crank has been turned 10 thousands and it has stock pistons with zero ridge in the cylinders. .... then the fuel pump went out and he parked the truck in the corner of the barn. It needs complete tear down and cleaning ... everything including rings & bearings are in excellent condition .... I may replace the cam and install adjustable lifters in it. I would only consider it because I already have it ....I paid scrap prices for it and was happily surprised when I tore it down. Unless you can hear it run, or you have documentation from a machine shop for work done .... they are basically worth scrap prices. I considered selling mine once to a Ford enthusiast .... He would only consider it if I took the block in and had it magnafluxed. Would not even talk to me without first a clean bill of health from a machine shop. I cant blame him, he already went through several blocks looking for a good one, put a few grand in machine work in his current block to find out it is junk .... He has about $25k in custom accessories Crank, Rods, Pistons, Cam, dual carbs, all the chrome .... probably make about 300 HP If lucky .... boy they sure look cool though I have since picked up a 318 and now wont even consider sticking the 8BA into the truck.

-

I just learned in the past month or so that in 1949-1950 the trucks had 2 different distributors available. I actually have to use the number off the tag in order to get correct parts for it. Not saying I have the wrong dizzy for my truck, just that they had different options and they used different sized caps, points, rotors. Just saying.

-

1948 Special Deluxe police buying advice

Los_Control replied to stukamensch's topic in P15-D24 Forum

Tough times to be a seller, with the current economic conditions the past few years .... really is a buyers market for these old Hot Rods. In top condition these old mopars are never worth as much as a popular Ford of the same year .... With exception of some really nice Chrysler's & Desoto that hold a higher value. A knock off police car really has a very narrow market to begin with ..... Not something I personally would want to daily drive ..... special occasions would be fun.- 42 replies

-

- special deluxe

- 1948

-

(and 1 more)

Tagged with:

-

You never know when you need a piece of wire for a roadside fix, just a handy place to store it.

-

I suppose someone needs to say it ..... absolutely be as careful as you can removing it. Even though you are as careful as can be, they were somewhat fragile when new, now they are ~75 years old. The one in my truck looks very good and seems to be in working condition ..... sometime in the past it leaked and no longer works. I have a later aftermarket I was using and planning to use as a donor to repair my original .... it started leaking when I went to remove it. I'm just saying you need to be as careful as you can, if you get it out and clean it up and it still works ..... go buy a lottery ticket.

-

NO NO NO!!! Thats cheating ? Thats what I did, I needed to clean out or go through my original carb ... same time I ordered a rebuilt from rockauto. So I went through the original and put it on the shelf for a spare, and was running the one I bought from rockauto. So it was really simple to swap out and try it last week. I now have a different problem with my accelerator pump not working. But the original problem I was trying to figure out went away ..... So I know it is a dirty carb in my case .... my spare needs a accelerator pump. Might get a bad rap for not going through proper troubleshooting procedures .... sure is nice having spare parts though ..... I also have known good working spares of my ignition system.

-

As a side note, sometimes it is difficult to distinguish between ignition and fuel problems. IIRC, If your points are wearing and no longer opening far enough, could cause your issue. Idles fine but stumbles picking up speed .... enough spark for idle but not for under load.

-

How about the gas tank? Last week I had to change the carb on my project truck, I had a spare. The carb had several hours of run time but not actually driving it yet. As a project I have been running on a temporary 2 gallon with no lid, just a hose stuck in the top. Dirt has got into the carb and will need to take it apart for a good cleaning. TBF I also need to make the permanent fuel line and has no fuel filter. I just think a dirty carb could be the sign of a deteriorating fuel tank .... or possibly dirty fuel from the last gas station you filled up at. Also what kind of fuel filter do you have? I currently have the glass bowl with no filter inside it, will add a modern filter under the vehicle near the tank when it is time. Various reasons why the carb can have dirt in it, I think pulling apart the carb to clean the passages was fairly common on these old cars. Not so much today. With better filters and tighter restrictions on gas stations .... unless the problem is on your end and in your tank. I would remove the carb from the car, then in a drain pan I would wash it down with carb cleaner so would not transfer any dirt from outside into it. Then disassemble the carb paying close attention to the idle circuit and using carb cleaner and compressed air blow out all the passages .... rinse and repeat and get it all as clean as you can and then reassemble it .... hopefully you should not need any new parts as new as it is. I then would change all filters in the car and throw in a can of seafoam in the tank ... A poor attempt at cleaning the fuel system while you are at it. Naturally if the tank is bad, it will happen all over again until that is remedied.