bkahler

Members-

Posts

1,951 -

Joined

-

Last visited

-

Days Won

39

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by bkahler

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Awesome! We will probably have the only two trucks with original floor mats installed. When/where did you get yours? Mine came from Franke Mitchell Motors back in 1998. The backing on yours looks to be the same stuff mine is made of. If you want to replace your backing I found the Jute backing used on my 72 TR6 is very similar in thickness and makeup and readily available. The only issue I have with mine is wrinkles in the rubber from having been rolled up for so long. Right now I have it laying on the floor with heavy weights over the wrinkles to see if that will take them out. Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

It's not a rumor, it's fact -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Steve, your panel is the first one I've seen using the square washers to hold the kick panel in place. I guess that might explain why I have so many of those square washers extra at the moment. I had round flat washers set aside but it looks like I should be using the square washers. Thanks for posting the picture. Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Finished making the cover plate. I still need to fasten the upper kick panel to the cab but the at least everything seems to fit. -

What you've described is pretty much what I've done.

-

I would think as long as the volume of air being sucked in by the carburetor exceeds that which can flow through the cap seal then all would be good. The rubber seal I used was large enough that it presses down on the top of the tube creating what I would consider a pretty decent seal. You can see in the picture below the rubber has indentations from the top of the tube. I believe that's a pretty good seal

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Digging through my old pictures last night I found one that shows the remains of my original upper panel. A PO torched off a section to the right of the steering column and apparently felt it was too difficult to remove the whole upper panel in one piece so he cut it in half. The clutch pedal opening looks to be very similar to Steve's. -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Steve, the top photo definitely shows the additional cover plate above the steering column as referenced in JB's links. That shouldn't be all that difficult to replicate. Thank you for posting the pictures. Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

JB, thanks for the links. The 2nd one was especially enlightening. It would appear I'm in need of a little patch panel that goes above the steering column. That makes me feel a whole lot better! -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Ok, I think I figured out how to fasten the upper floorboard. I believe it uses the same j-clips as the lower. I was expecting to see the little rectangular notches in the upper as is used on the lower. One less thing to worry about Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Thank you for the photos and dimensions. The 1-1/8" opening for the clutch won't work for mine. From other discussions I've had I believe Dodge moved the clutch pedal to the left for some unknown reason on the 51 and later trucks. Any idea what the small holes are around the steering column slot? I guess another question I have is how is the upper floorboard fastened in place? I have all the j-nuts and bolts for the lower floorboard but I'm not sure how to fasten the upper one. Thanks! Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

It would appear I have a problem with my upper floorboard. Looking at the pictures below it would seem that the slots in the floorboard for the pedals are way to wide. I have a hunch some PO has cut metal away to open them up. This particular floorboard is one I bought as a replacement because my original one had been cut and mangled horribly and was actually in two pieces when I took it out of the truck. Could someone post some pictures of their upper floorboard and possibly provide some dimensions of the slots? I have a feeling I've got some patching to do Two steps forward, one step back...... Thanks, Brad -

-

CHS Ricardo Cavallero S.R.L manual steering boxes

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I probably should post an update to this thread. The gearbox rebuild is complete and seems to be a quality kit. There is virtually no play in the steering box now and with the new parts in the rest of the steering system it should drive like a new truck. The only thing left is to actually do a test drive. Once that happens I'll post one last time with an update. Brad -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

Actually there are several reasons. The main reason was my differential ring gear was cracked in about 10 places (badly) and so I made the swap to a 98 Wrangler differential. The Wrangler diff yoke uses the more modern 1310 style of u-joint and the yoke on my driveshaft was for the earlier u-joints that used straps on the ends to hold them in place. In theory I could possibly have swapped yokes between the two differentials but then I would have had to set up the pinion lash and I would have still had a driveshaft with worn splines. When I took the driveshaft in originally I was going to just have them replace the rear yoke with one that would work with the wrangler diff. The splines really did have a lot of slop in them and in the end there wasn't a lot of difference in price having them build a new driveshaft compared to cutting the old yoke off and welding on a new on. Now originally my truck would have had the later 1310 style of u-joint but some time in the past some PO swapped out the diff for one with the earlier style of u-joints. I believe my truck originally was a 3-speed column shift that someone swapped over to the old crash box 4-speed and a different differential. Clear as mud? -

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

I got a call yesterday from the driveshaft shop, they said come pick it up After dropping off my old one I left thinking that the price would be in the $700 to $800 range. So when then bill came to $534.64 needless to say I left their shop happy. Brad -

Sorry. I had been watching several different pilothouse videos and wasn't thinking when I mentioned pilothouse. Videos of these old vehicles being built fascinate me

-

It would appear the Pilothouse trucks also came with cowl lights from the factory. I was watching an old dodge video on youtube and saw this. There are cowl lights on both sides of this truck. Here's a link to the video.

-

Interesting! I didn't know cowl lights existed. Thanks for clarifying. My spotlight looks just like the one in your picture. Brad

-

That looks more like a spotlight where the beam can be aimed forward and to the side by a handle on the inside. I have one on my truck on the drivers side.

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

-

-

Ok, you got me thinking now I had it in my brain that all of the holes on the outside would need to be covered for it to seal, however like you suggested, just plugging the two slits on the inside would solve the problem. Not sure why I didn't realize that earlier but I didn't. It would appear that a piece of rubber stuff up inside the cap would solve the problem. I wouldn't want to use cork for fear of cork pieces breaking off and falling into the oil pan. Time to find some rubber...... Thanks! Brad

-

Anyone know of a source for a non-vented oil filler cap. The tube diameter is 1.5" OD. I've been searching for a while but so far haven't had any luck. Thanks, Brad

-

51 B3B build thread - after all these years

bkahler replied to bkahler's topic in Mopar Flathead Truck Forum

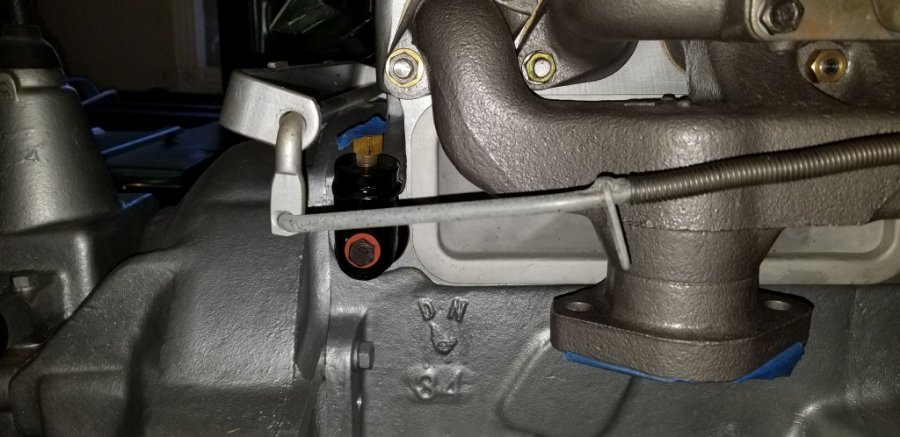

I'm finally making progress on the dual carb installation. Main thing left to do is fabricate the actuators between the shaft and the carburetors and between the shaft and the throttle cable pivot. I'm hoping that work will be done by next weekend. As part of the dual carburetor install I'm also installing a PCV system similar to those documented elsewhere on this site. I mounted the PCV valve on the center blanking plate where the original carburetor sat. I will be routing the hose and tube around the back side of the carburetor to the old road draft tube port. For the crankcase breather I silver soldered a fitting to the oil filler tube and another fitting to the bottom of the front air cleaner and I'll route a tube between those two fittings. The only thing I have to figure out is what to use as a non-vented cap for the oil filler tube. Brad