Alshere59

Moderators-

Posts

631 -

Joined

-

Last visited

-

Days Won

3

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Alshere59

-

-

When his time does come I hope he is carried in one of the trucks he contributed so much to. A very sad disease to take so much from you and your loved ones.

-

No special in washers in mine the gasket should seal the bolt holes. A thin sheetmetal plate souldn't cause any alignment issue. I have heard heat valves stuck open can burn a valve but can'y confirm.

-

I added a poll to a forum wide race to see if there is any interest. It is posted in Forum annoucements and feedback. http://mopar.pairserver.com/p15d24ph_forum/index.php?/topic/32785-any-interest-in-a-forum-wide-racing-competition/

-

That is what I did just fabed a plate and put the gasket on the exhaust side. Is the shaft still there or are you missing just the plate? I ask as the shaft may cause an exhaust leak and/or rattle depending how worn it is. That can be removed also and the holes sealed. So some background on the valve. It is there to keep the carb fom icing in spring and in fall. Open it heats the carb and it It closes as the engine gets warm to let the exhaust flow better. For those running headers you can get a plate that allows your coolant to flow under then intake where the exhaust would have bolted up to heat it as well. As to why some of the pics look different. Some split the exhaust (add another dump to make it have dual exhaust. That is why Dons is welded the way it is it directs the gas to his new dump. Although some chose to actually seperate the two halfs and add another dump. Just a cheaper way to get dual exhaust.

-

6th Annual Clements Tailgate BBQ......

Alshere59 replied to 48Dodger's topic in Mopar Flathead Truck Forum

That 46 dry box looks like a sweet project. You planning on a Build thread? Might make a nice camper for the BBQ next year. -

The link below will give you some times from members that have ran theres on the track. This could be fun if organized. Just have everyone take a run and post a pic of their car on the track and the time slip. Set up some classes and at the end of summer see who has bragging rights. Even some of our members across the ponds may be able to participate. Any thoughts? Good idea bad idea. For the members close to the same track they could meet and run the same day. http://mopar.pairserver.com/p15d24ph_forum/index.php?/topic/27088-quarter-mile-performance-numbers/?hl=%2Bracing+%2Btimes#entry270287

-

Tod the 33/34 engine won't bolt in. The changed the water jacket from 35 on so that will work. Look about halfway down. http://www.allpar.com/mopar/flat.html

-

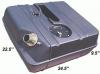

So I guess a quick update as to progress can be done. Tried to save the old tank even used a very gentle electrolytic rust removal. It worked well took a long time but worked well. So after doing the top I found about 13 total holes and stopped counting. The liner was still there like a balloon but the holes was the last straw. So the tank will be sent to scrap after I get another tank to help setup some angles. On a side note this may be the ticket to clean inside rust out. Fill it with water and washing powder power it up and let it go 14 or 15 hours. Not as abrasive as blasting. So I bit the bullet and ordered the 1949 Ford tank. It is the closest dimension wise but not the cheapest. The jeep tank was really calling at about 150 dollars cheaper. The deciding factor for me was the fill tubes. Just felt to do it right I would have to get it welded to make it work as adapters just didn't look easy. With my welding skills good for brackets only and not wanting to cut on a new tank anyway I went with the plastic tank pictured below and keep y 17 gallon capacity as well. Should allow for a new angled neck to bolt right on and then an angled hose and its done other than plumbing. So while waiting on that to arrive I have decided to put some new shackles on the leaf springs since the tank is out of the way and the bumpers are off for painting. Which is another story.

-

Gas milage of 20 mpg can be accomplished. Keep the speed down etc. As far as only taking 9 gallons to fill I have to agree with Dave. Pick up tube rusted is very likely. That and you may have some garbage in the tank taking up space but not 8 gallons worth. The oil may be going out the road draft tube so only when running. Have you had the valve covers off yet? If memory serves there is an oil return around that area if it is sludged up that may do it. Not sure my memory is right on that but others with good information can chime in. Other than that a good compression test and cylinder leak down test will help tell the story. Glad to here you got her home.

-

Georges info can be found here. http://mopar.pairserver.com/p15d24ph_forum/index.php?/links/link/78-george-asche-jr-overdrives/

-

File Name: Fenton Header installation instructions File Submitter: Alshere59 File Submitted: 08 Apr 2013 File Category: Instructions, Manuals & Templates Installation instructions for the original Fenton headers. May help others with headers for pipe layout but a cross over pipe would be required. Click here to download this file

-

6th Annual Clements Tailgate BBQ......

Alshere59 replied to 48Dodger's topic in Mopar Flathead Truck Forum

Marty Thanks for pointing them out. I see why you won that is a sweet set up. Don Thank you for your post as well. Al -

If using the search from a thread make sure you change to forum in the block to the right or you will not get any results. Here is one. http://mopar.pairserver.com/p15d24ph_forum/index.php?/topic/32499-vent-window-elimination/?hl=%2Bvent+%2Bwindows Full search results. http://mopar.pairserver.com/p15d24ph_forum/index.php?app=core&module=search&do=search&fromMainBar=1 Also on a side note posting this in the car forum may get you better visability and is more where it should be. Al

-

6th Annual Clements Tailgate BBQ......

Alshere59 replied to 48Dodger's topic in Mopar Flathead Truck Forum

Marty I went back to the picture site and couldn't find a single picture of your award winning Flathead. Your car but not the engine. Care to share one or two. Anyway congrats on the awards, sure looks like everyone had a good time. -

Keep posting I am looking forward to seeing your interior project. Always looking for ideas as that is on my list for later on. So you have kept the car from high school that is a long time I wish mine looked that good. My cars from those days went away a long time ago now I wish I had a few of them back. Looking at your pics will you be building your own wire harness or going with a kit? I would probably wire your dome like Joe did in his thread if building my own, fewer wires and less complicated. There is a wiring diagram for both your 48 and Joes 50 in the resource area if you want to compare they are different as mentioned. Al

-

1948 B1D Project Truck New Carb Purring Like A Kitten

Alshere59 replied to Dingo's 48's topic in Mopar Flathead Truck Forum

Nice truck. Just for general information if you do a search for truck you get a few links that may help. For those posting them you might add them to the link section for future use. I grabbed a few from this thread. http://mopar.pairserver.com/p15d24ph_forum/index.php?app=core&module=search&do=search&andor_type=&sid=33d8dfc1dc958b95a95e09ae1997720b&search_app_filters[forums][sortKey]=date&cType=topic&cId=32730&search_app_filters[forums][sortKey]=date&search_app_filters[forums][searchInKey]=&search_term=truck&search_app=links Sorry to hijack the thread partially anyway Al -

Villy I think you have one offered to you already. If that isn't the right one you might try here. http://mopar.pairserver.com/p15d24ph_forum/index.php?/links/goto/41-andy-bernbaum-auto-parts-inc/ Al

-

Since the battery is on the charger why not check your connections battery terminals, voltage regulator etc. Once you get the battery back in and started pull the battery cable does the engine die? Keep an eye on the amp gauge as well does it show a charge? A simple test for the regulator is once the engine is running ground the feild terminal on the voltage regulator, if it shows a charge then your regulator is bad or a connection is loose. Any pick in pulls near by?

-

No pic Rodney try again please.

-

My guess is that it is your brake shoe adjustment. I think what is happening is when you pump the brakes the shoes don't return all the way between pedal pushing and you finally get to a point where you have pressure. After it sits they return and your pressure is gone again. Look at this thread for brake info and notice the tool being used. http://mopar.pairserver.com/p15d24ph_forum/index.php?/page/p15d24/tech/brakes.html

-

My Salvation And Strengthening Of The Original Fuel Tank Straps

Alshere59 replied to 47heaven's topic in P15-D24 Forum

It can be tricky. The rubber grommet on mine only stays put when the end of the tube is parallel to the fender. With the new tank and looks like a new hose how much difference is there is the angles on those? You may have to move the tank a bit in the straps and adjust the length to get it aligned the way you need. Or as a last resort you could take your fill pipe to a muffler shop and have it bent to bring it back in alignment. -

-

Are the blue and green wire on your horn relay pic the ones you added for your OD? It looks like you crimped your connections are they soldered as well. May just be a bad connection not letting enough power flow. May want to take an ohms reading on the wire connections working your way to the bosch relay then going to number 4 terminal. You might look at this diagram as well as it feeds from the starter relay. The horn relay should work also though.