-

Posts

9,378 -

Joined

-

Last visited

-

Days Won

86

Content Type

Links Directory

Profiles

Articles

Forums

Downloads

Store

Gallery

Blogs

Events

Everything posted by Merle Coggins

-

Roxanne - She don't have to put on the red light.

Merle Coggins replied to FlashBuddy's topic in Mopar Flathead Truck Forum

That looks very similar to the yellow I ended up with, based on a number that was posted here many years ago. Can’t seem to find it now. The yellow that Mark used on FEF is different than what I used. His has a more orange, or brown hue to it. MIne is a brighter yellow. They both look good. Based on what paint was left on mine, I believe what I have is very close to the original color, and I believe Mark has claimed the same with his. Maybe the yellow color changed over the years? -

Have you tried giving it a little throttle while cranking? Works every time for me.

-

What else is stamped into the lid? It looks a lot like my Deluxe Filter, which uses the JC filter element. This is a sock type that crosses to Napa’s 1011. But it will be a very tight fit and you’ll be cussing it. If it indeed used a JC element, go find a Baldwin JC405. Much better fit.

-

The frames changed considerably between '53 and '54 with the conversion from B-series to C-series.

-

I'm guessing that your engine number "7317..." is actually T317... That would identify it as a Truck engine. I did some looking at www.t137.com but that engine number isn't listed in their guides. However, it may be because they don't have the Fargo engine number's guide listed. Maybe someone has a list of Fargo engine numbers that can assist. Typically the 1 ton trucks used the 230 CID engines. In your case, with a 25" engine, it would probably be the 228 CID version. Upon further inspection of the s/n guides I found that T339 is listed for the Canadian Fargo FC-1-D6, and it shows either 228 or 251 CID. So, unless someone can decipher the T317 we're not any further ahead.

-

Electronic ignition confusion

Merle Coggins replied to TylerB46's topic in Mopar Flathead Truck Forum

Did you order the Pertronix unit based on the Distributor ID number? If so, it should work. If you just guessed at it then you likely have a module for a different type of distributor. There are several variations in the distributors and the ID number is a Must Have when ordering any parts for them. I had to do a minor modification to my distributor plate, but the modification was explained in the Pertronix instructions. -

I'm Hearing Something New...A Bearing Howling?

Merle Coggins replied to keithb7's topic in P15-D24 Forum

You will have more end play with only 1 axle shaft installed. You need to have both installed before measuring, and adjusting the end play. -

There are a lot of damned (damed) rivers around here... I believe I was in high school when they drained the Flambeau Flowage to do work on the dam near my home town. I remember taking a drive up there with my Dad to have a look around. It was still too muddy to venture out very far, but you could see the remnants of barn and house foundations, and what was left of some roads. My Dad remembered riding the school bus down some of those roads, and could remember the names of the people that lived along it. Of course they were bought out and relocated when the dam was built.

-

I'm Hearing Something New...A Bearing Howling?

Merle Coggins replied to keithb7's topic in P15-D24 Forum

I’ve pulled some with a slide hammer. And when I’ve had a stubborn one that wouldn’t come with the slide hammer I’ve used the drum and some spacers to pull them. I would place deep sockets, or short pieces of pipe over 2 or 3 studs, long enough that when you slide the drum back onto the axle shaft that there will be 1 or 2 threads showing. Then tighten the nut to draw the axle out, into the drum. Be careful not to get it tight into the drum again or you’ll need your other puller to get the drum off again. If the taper gets close to seating again just take it apart again, add a few washers under your spacers, and do it again. It’ll come right out. The right size PVC pipe will work too, and you can cut a couple different lengths. -

Do you have room to add a jack shaft for a double reduction? Maybe just above the engine?

-

A 4 wheel alignment assures that the rear axle is squared up to the chassis. Have you ever seen a vehicle dog tracking while going down the road? This is because the rear axle is not aligned properly. Reseting the steering probably means that the steering box was centered up with the front wheels. Sometimes the linkage gets a little off and you will be slightly off center when driving straight.

-

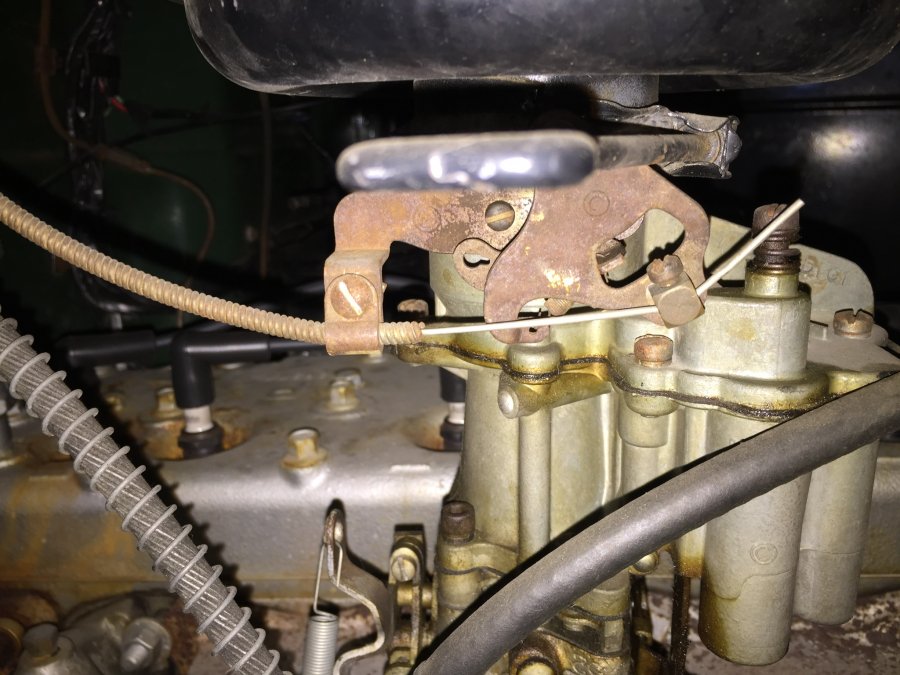

You haven’t said what year, make, model, car you are working on. I’m not sure when the cars started using the automatic chokes, but as was said, that one may be setup for that arrangement. Here’s the DTG1 in my truck. I know it’s a different carb, but it shows the choke cable clamps. Without a bracket to hold the cable housing it’s not going to work very well.

-

Pouting like a little kid... didn’t want to work... would rather play. ?

-

Again, for clarification, the small jumper wire is connected to the movable side of the points? If you have 6v there with the points closed, and 0 volts when touching the solid side of the points, that means that the points aren’t making a connection. You will need to clean the points contact surfaces so that they can complete the circuit to ground.

-

Another verification... Is your + terminal connected to the distributor? From the + terminal of the coil the circuit should ground out when the points are closed. Keep moving your test probe along the circuit. Test at the connection point of the distributor. Then under the cap, test the voltage where the small jumper wire connects to the points. And check again to the body of the distributor to be sure it’s grounding to the engine block.

-

When I disassembled my engine it was seized so tight I wasn’t able to access all of the Fluid Drive retaining nuts. So I laid the engine on its side and pulled the crankshaft out the bottom with the FD attached. I could then remove it from the crankshaft. Now I could focus on extracting the pistons, which was quite the task. Most of the valves were seized in place too, so that was the next struggle on disassembly. Once I got it all apart a trip to the machine shop got it back in good shape and it runs strong to this day.

-

New 1950 dodge Truck to me

Merle Coggins replied to 5027 steve's topic in Mopar Flathead Truck Forum

The tapered shaft/hub should be clean and dry. Don’t use anything abrasive to clean them. If you want to polish them just use a wire brush. Some use anti-seize or oil on the mating surfaces, but I don’t recommend it. The metal to metal connection when torqued up is key to the transfer of torque without putting extra load on the key. Get the nut TIGHT. As I recall, the torque spec is 160 ft/lbs minimum. So once you get to that toque, tighten enough more to line up the cotter pin. -

Are your posted readings Ohms? I’m having a hard time understanding how you were testing things, but it doesn’t sound right. Use a test light, or volt meter. (Assuming your car is Positive ground) With the key ON check the voltage at the Neg (-) terminal of the coil. You should see 6 volts. Now test the voltage on the Pos (+) terminal. With the points open you should also read 6 volts. With the points closed you should see 0 volts. 1. If you have 0 volts at the (+) terminal regardless of points open or closed you need to troubleshoot why the circuit is grounded out. 2. If you read 6 volts at the (+) terminal regardless of points open or closed you need to troubleshoot for an open circuit.

-

A question for you guys with 1 ton trucks. Yesterday when we were reassembling the rear brakes and hubs on Kris’s truck there was some confusion regarding how the bearings get lubricated. When we disassembled them there was no evidence of grease in the bearings, but had axle oil in there. I didn’t think anything about it at the time since every other full floating axle I’ve worked on lubricated the bearings with axle oil. However, upon reassembly I realized that the outer seal would keep the axle oil out of the bearings. I read through the shop manual and finally found reference to grease packing the rear bearings in the Lubrication section. So I packed them with grease. Were the bearings full of oil because the outer seals had failed, thus diluting any remaining grease to remove any evidence of it? I’m not used to seeing an outer seal to keep oil out of the bearings. Has anyone left the outer seal out and let the bearings get lubricated with axle oil, like a more modern axle? Merle

-

7th Annual "International Work On Your Truck Day"

Merle Coggins replied to 48Dodger's topic in Mopar Flathead Truck Forum

Just a smooth running flattie. See Kris’ post about Eddie’s Rehab -

All that time working with you on your truck and I had no idea you had named him Eddie. ?

-

Have you confirmed that you have spark at the spark plugs? How it works... When the points are closed they complete the electric circuit for the primary side of the ignition coil. This electrifies the coil and creates a magnetic field. When the points open the circuit is broken and the magnetic field collapses. This induces a secondary voltage that exits via the coil wire into the center of the distributor cap. It then transfers through the rotor to the associated spark plug wire, and up to the spark plug. The electric current then jumps the gap on the spark plug to find it’s path to ground. When all is right this will ignite the air/fuel mixture in the cylinder, things go BANG, and the engine runs... provided it all happens at the correct time, and there is adequate fuel in the cylinder.

-

7th Annual "International Work On Your Truck Day"

Merle Coggins replied to 48Dodger's topic in Mopar Flathead Truck Forum

Well, today we finished the brake job. Kris had the shoes relined locally, as well as cutting the drums. We get it all back together this morning, on hot and humid day. It was good to see the truck out of the garage again. Kris did quite a lot of work to it over the winter/spring. I helped him with some of the more technical things, but he did most of the work. Atta Boy, Kris. You done good... Our test run this morning... -

1953 pilothouse guage conversions

Merle Coggins replied to bergy's topic in Mopar Flathead Truck Forum

I suppose that makes sense, since it is an electro-magnet. -

If he assured you that it would be right, so you wouldn’t have to pay extra to Make it Right, I would be contacting him with pictures about how it’s NOT right. And give him a chance to Make It Right.